Installing a car alarm on a Lada Granta - Connection points, location and colors of wires

Ignition switch: +12 – brown ign1 – blue/black starter – red

Instrument panel: turns – blue and blue/black handbrake – brown/blue (diode breaks)

Driver's threshold: driver's limit switch - red/green, we connect the rest of the doors to it

Under the hood: Tahoe - white/black on the ignition module, the hood tip is in its normal place

Trunk limit switch – we install the connector on the trunk (the limit switch is already in the lock).

central locking .

Car alarm connection points for Lada Granta 2012

Ignition switch: + 12V - pink IGN_1 - blue Start - red

Left threshold: Turns - blue and blue/black Fuel pump - gray Driver's limit switch - red/green Handbrake - brown/blue

Tidy: Driver's limit switch - red/green Handbrake - brown/blue

Central locking - install an electric drive in the driver's door, if there is no electric drive in the door Trunk - white/black; harness in the trunk (install a diode) Tachometer - brown/red; In the configuration, the standard can be taken on the electric power steering unit

If the car has painted bumpers (standard equipment), then there is no need to install an additional activator; we connect pins 2 and 7 on the door lock using a power circuit. The locks on the doors are Kalinovsky, the activator is built inside, but the wires are not routed.

There is only a driver's door switch. The rest need to be installed and connected to the driver's limit switch, i.e. to red/green in the threshold. The limit switches are the same as the engine compartment on the Priora. The limit switches will have to be taken with a connector and wiring.

Car alarm connection points for Lada Granta 2022, equipped with one driver's limit switch

Ignition switch: +12 – brown ignition – blue/black starter – red

Central locking (power control) - insert the wires into pin 2 and pin 7 into the driver's door power connector.

Pandora DX50 alarm via can - immobilizer bypass , engine running , handbrake , brake .

Alarm Starline A93 2Can by can - the same as Pandora DH50 plus engine blocking.

The driver's door switch (-) is green/red at the driver's threshold. We connect all installed door limit switches to it. We put a diode in the green/red gap. We connect the signal to the gap on the end switch side.

The trunk limit (-) is white/black on the trunk lighting. We put the diode in the gap and connect the alarm towards the limit switch.

Opening the trunk (+) - close the contacts on the trunk release button using normally open relay contacts.

Hood end cap - install your own.

Instrument panel: CAN - pink/green and yellow/blue turns - blue and blue/black

Fuel pump (+) - gray in the driver's threshold

Car alarm connection points for Lada Granta Liftback 2019, manual transmission with a new face, simple equipment

Ignition switch: +12 – black ign 1 – blue/black starter – red

Instrument panel: turns - blue and blue/black handbrake - brown/blue (diode broken)

Tachometer - gray on the power steering unit to the right of the steering wheel in the small connector, pin 2

Driver's threshold: doors - brown/red (diode in the gap) trunk limit switch - on the trunk light white/black (diode is already in the light)

limit switches on the remaining doors and hood .

Passage under the hood is through the rubber of the hydraulic corrector.

Central locking - install pins 2 and 7 in the driver's door connector, control by “strength”. Since the door lock does not close when the ignition is on, we program the alarm “completion of program neutral upon closing of the last door.” Then everything works correctly.

Immo bypass is standard. I made a ring for the lock.

Car alarm connection points for Lada Granta 2022, automatic transmission, Starline A93 2can2lin

Ignition switch: +12 – brown ign 1 – blue/black acc – pink starter – connect to the gray connector at the bottom of the fuse box, the outermost red

From the can doors , brake pedal , engine running . When activating the comfort function, be sure to allow control of the standard security system.

Instrument panel: turns – blue and blue/black c an h – pink/green c an l – yellow/blue

LIN bus - red/green to the gap (white/green towards the connector, white towards the car) in the harness from the driver's door

trunk - black/blue from the trunk, diode in the gap hood - standard limit switch white/black, diode in the gap

The keyless bypass was trained not when the ignition was turned on, but rather when it was attempted to start (before starting, both learning methods gave an error). The engine had a mass air flow sensor.

Passage under the hood through the plastic plug of the clutch pedal.

Exterior

The exterior appearance of the five-door is dominated by elements of the original West design, complemented by elements of a dynamic sporty style. Traditionally, the most striking details of body design are concentrated on the front side of the front end.

In numerous advertising photos and posters, the new station wagon model confidently demonstrates:

- dynamic slope of the windshield and short hood;

- a modern layout of xenon head optics units and an X-shaped radiator lining covered with a fine mesh.

Decorative chrome plating is present in small quantities on the brand logo, as well as on the perimeters of the fog lighting equipped with lampshades and the side aerodynamic cutouts.

The design of the front end is complemented by the ventilation air intake of the engine compartment and the ribbed relief of the compact body kit. In the top-end configuration, the new station wagon body is equipped with plastic protective linings.

Less aggression in the profile projection of the body. When viewed from the side, attention is drawn to the roofline sloping towards the rear window, the glossy black frame of the three-section windows and the oval reverse mirrors.

The design of the sidewalls uses the functional and decorative properties of the sporty stepped relief. Branded wheels look great in the overall ensemble.

The design of the rear side of the body is designed with elements of crossover style. This is an enlarged format of the spoiler visor, a combination of an inclined window and a vertical edge of the compact trunk lid.

The Lada Vesta SW 2022 station wagon has:

- modern layout of multifunctional stops and registration plate;

- transverse bumper relief and a small-sized plastic body kit complemented by a horizontal reflector;

- A characteristic feature of many budget models is the placement of the exhaust pipe under the bottom of the trunk.

How to determine the CAN bus in a car yourself

On-board electronics systems in modern cars and trucks have a huge number of additional devices and actuators. In order for the exchange of information between all devices to be as efficient as possible, the car must have a reliable communication network. In the early 80s of the 20th century, Bosch and developer Intel proposed a new network interface - Controller Area Network, which is popularly called Can-bus.

About the operating principle of the CAN bus network interface

The can-bus in a car is designed to provide connection to any electronic devices that are capable of transmitting and receiving certain information. Thus, data on the technical condition of systems and control signals pass over twisted pair cable in digital format. This scheme made it possible to reduce the negative influence of external electromagnetic fields and significantly increase the speed of data transfer via the protocol (the rules by which control units of various systems are able to exchange information).

In addition, diagnosing the ECUs of various car systems with your own hands has become easier. Due to the use of such a system as part of the vehicle’s on-board network, a certain number of conductors have been freed up, which are capable of providing communication via various protocols, for example, between the engine control unit and diagnostic equipment, alarm system. It is the presence of the Kan-bus in the car that allows the owner to identify controller malfunctions and errors with his own hands using special diagnostic equipment.

A CAN bus is a special network through which data is transferred and exchanged between various control nodes. Each node consists of a microprocessor (CPU) and a CAN controller, with the help of which the executable protocol is implemented and interaction with the vehicle network is ensured. The Kan bus has at least two pairs of wires - CAN_L and CAN_H, through which signals are transmitted via transceivers - transceivers capable of amplifying the signal from network control devices. In addition, transceivers perform such functions as:

- adjusting the data transfer rate by increasing or decreasing the current supply;

- current limiting to prevent damage to the sensor or shorting of transmission lines;

- thermal protection.

Today, two types of transceivers are recognized - High Speed and Fault Tolerant. The first type is the most common and complies with the standard (ISO 11898-2), it allows you to transfer data at speeds of up to 1MB per second. The second type of transceivers allows you to create an energy-saving network with a transmission speed of up to 120 Kb/sec, while such transmitters are not sensitive to any damage on the bus itself.

Features of the network

It should be understood that data is transmitted over the CAN network in the form of frames. The most important of them are the identifier field (Identifire) and the data system (Data). The most commonly used message type on Kanbus is Data Frame. This type of data transfer consists of a so-called arbitration field and determines priority data transfer in the event that several system nodes simultaneously transmit data to the CAN bus.

Each of the control devices connected to the bus has its own input resistance, and the total load is calculated from the sum of all executable blocks connected to the bus. On average, the input resistance of engine control systems that are connected to the CAN bus is 68-70 Ohms, and the resistance of the information and command system can be up to 3-4 Ohms.

CAN - interface and system diagnostics

CAN control systems not only have different load resistances, but also different message transmission rates. This fact complicates the processing of similar messages within the on-board network. To simplify diagnostics, modern cars use a gateway interface (resistance converter), which is either designed as a separate control unit or built into the car’s engine ECU.

Such a converter is also designed to input or output certain diagnostic information via the “K”-line wire, which is connected during diagnostics or changing network operating parameters either to the diagnostic connector or directly to the converter.

It is important to note that there are currently no specific standards for Can network connectors. Therefore, each protocol determines its own type of connectors on the CAN bus, depending on the load and other parameters.

Thus, when carrying out diagnostic work with your own hands, a unified OBD1 or OBD2 type connector is used, which can be found on most modern foreign and domestic cars. However, some car models, for example Volkswagen Golf 5V, Audi S4, do not have a gateway. In addition, the layout of control units and CAN bus is individual for each make and model of car. In order to diagnose a CAN system with your own hands, you use special equipment, which consists of an oscilloscope, a CAN analyzer and a digital multimeter.

Troubleshooting work begins with removing the mains voltage (removing the negative terminal of the battery). Next, the change in resistance between the bus wires is determined. The most common types of CAN bus malfunction in a car are a short circuit or line break, failure of load resistors and a decrease in the level of message transmission between network elements. In some cases, it is not possible to identify a malfunction without using a Can analyzer.

Main operating modes of the CAN bus: active (ignition on); sleeping (with the ignition off); waking up and falling asleep (when turning the ignition on and off). During sleep mode, the bus current consumption is minimal. However, at the same time, signals about the state of opening doors and windows, and other systems related to the security functions of the car are transmitted via the bus (at a lower frequency).

Most modern diagnostic devices provide a mode for diagnosing errors via the CAN bus. Technically, this is organized by directly connecting the conductors to the diagnostic connector.

Advantages and disadvantages of using a CAN bus in a car To begin with, if the CAN standard had not been proposed in the 80s of the last century, another type of interaction between car systems would have taken its place. It is possible, of course, to place all vehicle system control units in a single superblock, in which the interaction of different systems can be ensured by software. French manufacturers have made similar attempts. However, as functionality and performance increase, the likelihood of failures increases significantly. Failures, for example, of wipers, can lead to failure to start the engine.

The main advantages of using a CAN bus: the ability to carry out operational monitoring and diagnostics of all vehicle systems; combining information flows in a single noise-proof channel; universality, promoting the unification of diagnostic processes; ability to connect security systems via CAN bus (no need to run wiring to each control element). Disadvantages of the CAN bus: low reliability; Damage to one of the control units can lead to complete inoperability of the CAN connection. Troubleshooting There is no CAN fault indicator light on the vehicle dashboard.

You can judge that the functionality of the CAN bus is being disrupted by indirect indicators: several fault indicator lamps on the dashboard light up at the same time; coolant temperature and fuel levels disappeared; "CHECK ENGINE" light came on. First of all, you should perform a diagnosis. If it indicates a CAN bus malfunction, you should begin to fix the problem. Sequence of work: Find the conductors of the twisted pair bus. They are often black (high) and orange-brown (low). Check the voltage on the conductors with the ignition on using a multimeter.

Levels should not be 0 or more than 11 Volts (usually about 4.5 Volts). Turn off the ignition and disconnect the battery terminal. Measure the resistance between the conductors. If it tends to zero, it means there is a short circuit in the bus, if it approaches infinity, there is a break. Start looking for an open circuit or short circuit. If there is a suspicion that the bus is closed due to the failure of any control unit, you can sequentially turn off the control units and monitor the resistance and performance of the bus. A CAN bus malfunction is a complex malfunction of the vehicle's electrical equipment.

If the car owner does not have the necessary electrical repair skills, then it is better to use the services of a specialist.

A CAN bus is an electronic device built into a vehicle's electronic system to monitor performance and driving performance. It is a mandatory element for equipping a car with an anti-theft system, but this is only a small part of its capabilities.

Source: lubimauto.ru, voditeliauto.ru.

And finally: if you have any doubts, or do not have the proper experience or capabilities in diagnosing and determining the CAN line, it is better to use the services of certified service stations (car service stations), contact a dealership or an experienced diagnostician. Turning to fly-by-night specialists with pirated copies of diagnostic equipment can only aggravate the problem in cars and add new ones,

Interior

The budget status of the car is reminiscent of its presence in the interior with fabric and plastic trim and a standard list of functional and comfort-creating options for its price category. The embossed front panel will delight future owners:

- design and soft, white illumination of the instrument panel;

- expanded, due to the placement of command button blocks on the front plane, the functionality of the steering wheel;

- volume of the glove box.

The typical layout of the upper tier of the center console offers a block of two vertical deflectors and a small-format multimedia monitor.

In the middle of the dashboard there is a panel for setting the interior microclimate; the lower part includes a cigarette lighter and ports for charging smartphones, as well as connecting digital external gadgets.

In addition to the technical platform with power transmission control levers and parking brake, the tunnel design offers a set of cup holders and a spacious refrigerator compartment located under the folding armrest.

Unfortunately, the renovation of the interior had a lesser impact on the comfort of the seats. The filling is not the softest; the design of the front seats does not provide for lateral support. The shortcomings are partially compensated by the range of electrified adjustments and the heating system, including the rear sofa seats.

The test drive confirmed that by folding the back of the sofa, the 480-liter volume of the luggage compartment can be almost doubled.

Grant FL winding with ABS

Do you drive a company car and need to periodically increase the odometer reading? – winding the Lada Granta FL speedometer will help you. The device has a simple connection to the standard OBD2 diagnostic connector, does not require intervention in the wiring and will allow winding in such a way that it will not be detected later during diagnostics at the OD.

Using the Granta FL spinner is extremely simple, see for yourself by watching the video:

What is it for

This device is designed specifically for winding the odometer up, which helps solve the problem of low fuel standards. The fact is that the consumption rate for departmental transport is most often simply taken from the factory characteristics. In fact, the car consumes fuel 15%-20% more than in the passport. And this doesn’t even take into account warming up, easy traffic jams and the cold season. As a result, it becomes common for a driver to cover the excess fuel from his own pocket.

You can get out of this situation on a more budgetary basis - every day after the shift, using the Lada Granta FL, add a little mileage. For a longer mileage, more fuel will be allocated according to the norm - the problem is solved.

Please note that we do not encourage using a winder to pour gasoline “into your pocket.” This is just a way not to waste your salary on work trips.

Unlimited mileage rewinders for other models: Lada Granta, Lada Vesta

How the device works

The operating principle of the Grant FL speedometer CAN is that after connecting such a device, it begins to transmit data packets to the car’s digital bus, similar to those sent to the CAN by the ABS unit while driving.

Of course, there is no traditional speed sensor on a gearbox equipped with an ABS system. Therefore, for her, the Lada Granta FL spinner is not a simple pulse generator, but a digital device, the circuitry of which is based on a 32-bit microcontroller, the “firmware” of which was developed by specialists from our company.

Also, do not forget that in almost all new cars, and, oddly enough, in domestic ones, the mileage traveled by the car is recorded, in addition to the speedometer, in the engine control unit. Official dealers can easily deduct this parameter when undergoing maintenance.

Therefore, our developers paid special attention to ensuring that the Lada Granta FL winder adds mileage to both the speedometer and the “brains”. This is achieved through a special algorithm, read from a real car and rolled on it. Learn more about this in the video above. There we connect the diagnostics, look at the mileage, then rewind and subtract the mileage again in the “brains”.

Also, a prerequisite for recording a new value in the Electronic Engine Control Unit is compliance with the connection algorithm. Namely, before winding, we will need to disable the ABS. To do this, simply pull out the corresponding fuse (F03) in the interior unit.

After the fuse is turned off, the ABS system indicator will light up on the dashboard.

Now turn on the ignition

We take the winding of the Lada Granta FL

We connect it to the OBD2 diagnostic connector

Pay attention to the instrument panel - the speedometer needle “lays down” to 200 and remains at this value, without “jumps” or jerks. It is in this mode that the mileage is recorded evenly and synchronously on the instrument panel and in the computer.

After reaching the required odometer value, turn off the Grant FL winder, turn off the ignition and return the fuse to its place.

Let's go through frequently asked questions

- I have a new Granta, it has ABS, but I didn’t find a speed sensor on the box. Can I be sure that your device will work?

Yes, sure. In principle, since 2016, these ATO models with a speed sensor are no longer produced; on the contrary, even the simplest equipment is equipped with ABS, which is responsible for reading the speed and mileage of the car. It is in such cases that it is advisable to use the CAN winding of the Grant FL speedometer, while there is simply nowhere to connect the pulse twister.

- Is it possible to adjust the winding speed? In the video the needle is at 200, is the speedometer stuck? At the MOT they won’t ask later where you got it so fast?

The problem of the speedometer needle jamming occurred on domestic cars produced 15-20 years ago. Modern devices do not suffer from such “sores”. And if you look carefully at the recorder table in the ECU, read by the diagnostics, you will not find a single line that is responsible for the maximum speed developed by the car. Those. making it smaller simply doesn't make sense.

- The car is equipped with the ERA GLONASS system, will it not be used to calculate the winding?

The ERA GLONASS system, which is equipped with all new cars in Russia, is designed to call emergency services in the event of an accident or other emergency. Vehicle movement, driving speed, etc. it does not measure, much less transmit anywhere.

- Is it necessary to remove the ABS fuse every time before winding? Why is this necessary? Is it possible to remove it and then not install it at all?

Yes, this fuse will have to be removed each time before winding. It is necessary to disable ABS so that with its messages to the CAN bus it does not interrupt messages from the winder and the winding process occurs synchronously in both the speedometer and the ECU. There is no other way to achieve this. It is also impossible not to install this fuse at all, because When the ABS is disabled, the speedometer simply will not work while driving.

Let's summarize. Our Lada Granta FL speedometer winding

- Unlimited, i.e. has no restrictions on the number of kilometers it adds. You can cover at least a hundred or two hundred thousand kilometers with this device, and after that it will not be blocked and will not require firmware.

- Precisely registers the mileage in the “brains”. This will allow you to avoid unnecessary questions and problems when undergoing diagnostics from an OD.

- It is delivered completely ready for work - our specialists will make all the necessary settings and check the device on a canbus analyzer before shipping.

- Will work on two, three or more identical cars. There is no connection to the vehicle's VIN code.

- Inexpensive. As manufacturers of our devices, we can offer you the most favorable price, because you buy directly, without intermediary markups.

- Has a 5 year warranty. Strict control over production quality, checking each device before shipping - all this allows us to provide such an impressive warranty period with free replacement in case of winder failure.

our company

- Has been developing, producing, selling and installing speedometer winders for more than 10 years. During this time, a significant amount of knowledge, experience and decisions on this issue have been accumulated.

- Offers you to purchase a Lada Granta FL winder at the best possible price and without prepayment! Payment occurs upon receipt by mail. Delivery at our expense! Upon receipt, you pay only the amount indicated on the website.

- You can always get advice from us on the installation and further operation of our devices. Please contact the contacts listed on the website.

Specifications

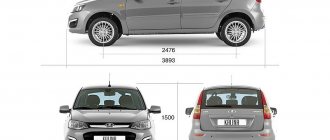

The body of the new product has been edited in the ratios of length, width and height - 4,410 x 1,764 and 1,512 mm. The advantages of the chassis: independent suspension, center wheelbase extended to 2635 and crossover-type 178 mm ground clearance.

In terms of technical equipment, the Lada Vesta SV 2019 station wagon is identical to the equipment of the predecessor of the same name in the sedan version. In the basic configuration of the new station wagon, AvtoVAZ offers naturally aspirated petrol engines with basic parameters of 1.6 l/106 hp. and 1.8 l/122 hp, working in tandem with a five-speed manual or robotic transmission of the AMT series.

The dynamics of reaching the first hundred are 12.4 and 10.9 seconds, respectively, the maximum speed is 174-180 km/h, the average fuel consumption is 7.4-7.8 liters.