Print this article Font size 16

The motor control system includes a wide range of different elements, each of which plays its own important role.

In some situations, high voltage disappears on several or even one cylinder. The reason for this may be the ignition module on the VAZ 2110, or rather its malfunction.

It should be noted that replacing the ignition module of the VAZ 2110 may not be necessary. First try to repair it, diagnose and fix the problem.

Design

Disassembled module

Structurally, the ignition module includes two main elements:

- 2 ignition coils that generate high-voltage pulses directed to the spark plugs;

- Dual channel switch.

The reasons for failure can be different, ranging from interruptions in the operation of the engine, ending with an unexpected stop of the power unit. Please note that the "Check Engine" light does not turn on.

Checking the coil for VAZ 2101-2110

First, let's look at the sequence of checks on VAZ cars. Moreover, checking the carburetor for VAZ-2101 and VAZ-2110 is no different, the only difference is in the readings.

Next is the verification process itself:

- It is better to test the coil when it is removed from the car. Before starting removal, disconnect the negative terminal from the battery. From the coil we disconnect the wires from the side terminals, as well as the central wire. It is better to mark the wires from the side terminals so that they are not confused during installation.

- Loosen the coil fastening and remove it. Before checking with a multimeter, we clean it from dust and dirt, especially paying attention to the terminals. Then we inspect it for external damage. If there are any, further checking is pointless; it is better to replace it immediately;

- Checking the primary winding. To do this, switch the multimeter to ohmmeter mode and connect its probes to the side terminals. Different types of coils were used on different VAZ models, so you need to know which resistance readings are correct for them. So, for the B-117A model, used on classical models (VAZ-2101-2107), the resistance of the primary winding is 3.07-3.5

Ohms.

And on classic models with a contactless system, coils marked 27.3705

; this parameter is

0.4-0.5

Ohm.

On VAZ-2108-21099 cars, as well as VAZ-2110 carburetor, models with numbers are used - 3122.3705

and 8352.12.

For the first of them, the resistance of the primary winding is considered normal in the range of 0.39-0.47

Ohms, and for the second -

0.37-047

Ohms; - Next, the secondary winding is checked. To do this, switch the multimeter to the kOhm measurement mode, leave one of its probes on the side terminal, and connect the second to the central terminal. For a working B-117A coil, the resistance of the secondary winding should be 7.4-9.2

kOhm.

For model 27.3705 this parameter should be around 5.0

kOhm, for 3122.3705 -

0.4

kOhm, and for 8352.12 -

1.0

kOhm; - The last thing to check is the insulation resistance. To measure this parameter, switch the multimeter to measurement mode in MOhm. To measure, we connect one probe to the coil body, and connect the second to each terminal in turn. When measuring this parameter on all specified models, the multimeter should show at least 50

MOhm; - If any of the parameters does not match the specified values, then the coil is faulty and must be replaced.

Malfunctions

Diagnosing the problem will not be a problem for you if you understand a little electrical engineering and know how to work with a device such as a multimeter. If not, we recommend that you contact a specialist. A professional check of the ignition module of a VAZ 2110 using a multimeter will give you the result you need and will allow you to answer important questions.

Do not rush into repairs, since the problem may not lie in this element at all. Before checking the ignition module on a VAZ 2110, consult with professionals and arrange a check of your car. You will have to spend time and money on this, but it is better to be prepared for troubles.

Before checking the VAZ 2110 ignition unit, make sure that all other engine systems are working properly.

Quite often, short-term breakdowns occur in the system, which soon disappear. The check engine light does not detect them, but they remain in the controller and are entered into its memory. If you try to read errors on the controller with a tester, it will not show anything, since there were problems, but now they are gone.

We have already become familiar with the signs of a malfunction in the VAZ 2110 ignition module, and the reasons for such situations may be dirty contacts, poor ground connection, electrical interference, and so on.

Possible causes of failure

The weak point of the ignition coils and modules is the secondary winding, which generates a high voltage pulse. A coil break or breakdown may occur in it. The following factors lead to this phenomenon:

- use of low-quality or unsuitable candles;

- operation with non-functioning high voltage wires;

- frequent attempts to check the spark.

The high-voltage pulse arising in the secondary winding must be realized (spent). If this does not happen (if the integrity of a high voltage wire is broken, for example), a high-energy electrical pulse seeks an outlet. He will find it, with a high degree of probability, in the thin secondary winding.

Often, a module malfunction occurs when the integrity of poor-quality factory soldering of wires going to the switch elements is violated. This happens from vibration. Also, the cause of non-working coils can be a banal contact failure in the incoming connector. Another factor leading to a malfunction of the ignition unit is often moisture that gets on the device during washing or driving in unusual conditions.

Repair

So, for the VAZ 2110 the most common problem is the disappearance of voltage on cylinders 2 and 3. After some time, the engine starts working normally again if you press the rear plate of the module.

You should not put up with such a situation; it is better to immediately check the functionality of the unit, restore or replace it completely.

Removing the module

The procedure is quite simple.

- Disconnect the negative cable from the battery.

- Remove the plastic cover that covers the motor.

- Remove the wires from the spark plugs.

- Disconnect the wires from the ignition module. Their numbering is indicated on special white rings. And the cylinder number is indicated on the ignition module housing.

- Disconnect the connector from the ignition module.

- Using a 10mm socket, unscrew the three nuts that hold the block we are looking for.

- Carefully remove it, after which you can begin further work.

Now let's move directly to working with the module:

- Open the aluminum plate on the ignition module. A flathead screwdriver is useful for this.

- Inside you will find a small printed circuit board with electronic components. It is covered with a transparent layer of silicone, which will have to be removed.

- There are also wires that connect the board to the connector contacts. They are made of aluminum, so they can tear quickly.

- Tear off all the wires from the contacts, don’t be afraid. Others will be installed in their place. By the way, experts recommend using stranded wires used in computer mice.

- The ignition module circuit includes two switches and two powerful transresistors. If you decide to change these elements, you need to know that the switches are manufactured by SGS-THOMSON (model L497D1), and the transistors are of the BU931 type.

- The contacts are made of aluminum, so you will need a special flux to work with this metal.

- We solder the wiring to the board. It is more difficult to solder to the transistor collectors, since they are covered with a special material, the soldering of which is problematic. Therefore, try to hide the top coating from the element as carefully as possible. To prevent the soldering iron from transferring all the heat to the plate, place it on the stove and heat it to 180 degrees Celsius.

- Solder the wires to the contacts on the module so that they are as short as possible.

- Cover the areas where you soldered with varnish. Regular nail polish borrowed from your wife will do.

- Check if the ignition module is working.

- If everything is fine, coat the inner surface with a special autosealant, then reassemble in the reverse order.

- Upon completion of assembly, the wiring should be positioned fairly freely. Make sure that they are not compressed inside the box and that the integrity of the connections is not broken.

Carrying out such a repair of the ignition module on a VAZ 2110 with your own hands will not be difficult. But be careful, act carefully and consistently. Pay special attention to the soldering process.

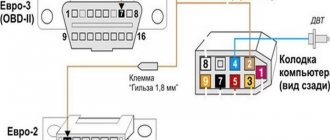

But keep in mind that we have addressed the problem of bad contacts. She is not the only one for the “ten”. You may need to pinout the ignition module on the VAZ 2110. For this, it is better to contact specialists.

If the cause of the malfunction lies elsewhere, then there is a high probability that it is better to simply replace the VAZ 2110 8-valve ignition module with a new one. The search may drag on without yielding results. Replacing the element will completely solve the current problem.

Methods for diagnosing device performance

The simplest method that will help determine the performance of the coil is to replace it with a similar working device. This is possible if there is somewhere to get it. Please note that the module must match the parameters of the device under test . If the engine with a working coil works as before the breakdown, the ignition module is definitely faulty.

The main testing method involves using a multimeter. It consists in determining the resistance of the secondary windings of the coils built into the ignition module. The method is simple and does not require additional skills. The device does not need to be removed for testing. The check is done with the engine turned off.

This is how you check the resistance of the secondary winding with a multimeter

- High-voltage wires are removed from the module sockets.

- The tester switch is set to the 20 kOhm position.

- The multimeter rods are placed in turn in the recesses of the corresponding contact pairs (1 and 4, 2 and 3).

- With an intact secondary winding, the performance in both cases is the same. Normally, the resistance should be about 5.4 kOhm (in some models the indicators differ, which needs to be clarified). If the resistance is much greater, then there is a winding break. The resistance is much lower - a breakdown. The coil is faulty and cannot be repaired.

Fines for crossing the stop line and speeding will no longer bother you!

Video: How to check the secondary winding with a multimeter

A little about prices

We have already noted which switch and transistor are used when repairing the ignition module of a dozen. The first costs about 3 dollars, and for the second you will have to pay about 6 dollars.

Some craftsmen use a domestic analogue of the transistor - model KT848A . Of course, it costs less. But its problem is its lower quality and larger size, which somewhat complicates the repair process.

Ignition module

As mentioned above, the “ten” has 4 engine types: 16 and 8 valve internal combustion engines, as well as with a volume of 1.5 and 1.6 liters. This will lead to differences in the ignition modules. Depending on the installed engine with a certain volume, its own ignition module will be installed.

Differences

The main differences between the modules will be the size and mounting holes. In a 1.5 liter internal combustion engine, the ignition module is larger in size in contrast to the 1.6 liter engine. The cost of the modules depends on the manufacturers, but it should be noted that the MZ from a 1.5 liter engine is always more expensive than a 1.6 liter one.

16 valve MZ

In a 16-valve internal combustion engine, the ignition module is installed on the valve cover near the oil filler neck.

8 valve MZ

The MZ on an 8-valve engine is installed on the front of the cylinder block between the dipstick and the breather.

Advantages of a sixteen-valve engine

We have already said that the internal combustion engines of the VAZ-2110 (2112) family discussed in the article are distinguished by greater power, lower fuel consumption, and also high technical characteristics, unlike the V8s. It's time to find out what design features make the VAZ 2112 16 valve engine such an attractive choice for motorists.

- fuel economy;

- higher power;

- detonation resistance;

- advanced cooling system;

- simple tuning due to the separation of the intake and exhaust tracts.

It is the separation between the intake and exhaust tracts in the design of the VAZ-21120 and 21124 engines that makes it possible to achieve quite noticeable fuel savings. Thus, the supply of fuel and the intake of exhaust gases is carried out by a separate spaced valve system, due to which there is no unwanted mixing of fuel and combustion products. It is also obvious that this increases the efficiency of the engine and its power.

Sixteen-valve VAZ 2110 engine

The innovations did not ignore the combustion chamber, as well as the structure of the cylinder block. Their design is slightly modified in such a way that the risk of detonation of the fuel mixture is minimized. This is truly a significant advantage, because the quality of gasoline in our gas stations leaves much to be desired. Accordingly, this kind of internal combustion engine design remains a guarantee of its long service life.

The operation of the cooling system of such devices is also pleasing with high stability. This is the most important factor ensuring long engine operation and reliability during its operation. Effective heat removal allows the internal combustion engine to operate at a given temperature, preventing premature wear. Are the benefits of 16 valves significant enough for you? But that is not all.

Let's sum it up

As you can see, the VAZ 2110 ignition module is a fairly simple device consisting of contacts, coils, boards and wires. However, only contact connections can be repaired. Other elements are beyond repair and need to be replaced.

At the same time, before starting repair work, it is necessary to properly test the module. To do this, you should adhere to the general rules, and also take into account the subtleties and nuances discussed above. As a result, diagnostics of the VAZ 2110 ignition module allows you to quickly identify certain problems and eliminate problems.

Signs

- If one of the module coils completely fails, then two cylinders do not work. This is clearly visible even to the naked eye - the engine is feverish at idle, starting is difficult, fuel consumption is sky-high, loss of dynamics.

- To eliminate all other components of the ignition system, make sure that the spark plugs are in working order. To do this, unscrew them and check the spark on each of the spark plugs by cranking the engine with the starter and placing the spark plug with the high-voltage wire on the head so that the body (threaded part) of the spark plug touches the engine mass. If there is no spark or it is weak, replace the spark plug with one that is known to work.

- If this does not lead to anything, check the high-voltage wires. Thus, we will exclude spark plugs, caps and high-voltage wires from the list of non-working elements. Next we will check the ignition module.

Breakdown of the spark plug insulator.

Dirty spark plug electrodes.

Filled candles.