The VAZ 2114 car was produced by the Volzhsky Automobile Plant in the period 2001-2013. The bottom of the VAZ 2114, unlike the sills, was not a common consumable. If immediately after the purchase the driver carried out routine inspections and fully protected the body from the aggressive effects of salt reagents and moisture, parking and overnight stays of the car in the open air were limited.

An exception is an accident or collision with an obstacle, as a result of which the bottom is deformed from mechanical damage.

Design Features

Model 2114 was built on the basis of the VAZ 2109, it is a restyled version. The hatchback received a new steering column, a modernized dashboard, an updated one and a half liter engine, redesigned for Euro 2 protocol. The VAZ 2114 shares the same wheelbase with the Nine, 2460 mm. The configuration of the bottom panel is the same for the models.

Are there any differences between 2114 and 2115

The VAZ 2115 model is considered a related model. The hatchback is built on the basis of the VAZ 21099 with various transport sizes and shares one wheelbase with the entire Lada Samara family. The standard dimensions of the bottom and sills for VAZ 2108, 2109, 21099, 2113, 2114, 2115 models are the same and interchangeable.

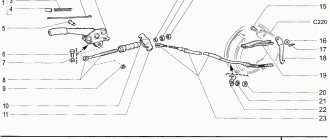

The bottom of the VAZ 2114 structurally consists of the following parts:

- central reinforced panel;

- driver's side panel;

- side passenger;

The factory stock bottom is a one-piece stamped part, primed and painted black. The polyethylene coating acts as protection.

Threshold selection

The threshold consists of three parts:

- External shield.

- Amplifier inside.

- Connector

Thresholds can corrode in a variety of ways, but generally, if you have through holes, you will need to purchase a complete three-piece sill kit.

The threshold code for the right side is 21100-5401060-00, the left side is 21100-5401061-00. Please ask for connectors and amplifiers in stores; according to factory codes they are not available.

When repairs are required

For all VAZ models, the body was made of black or low-carbon steel of class 08Yu, 08KP. The parts were not galvanized, but were coated with a polymer anti-corrosion composition; the film protected the bottom from moisture for up to 6 months, then natural oxidation processes began. After the purchase, drivers had to carry out thorough anti-corrosion treatment of the metal.

Repair or complete over-welding of the bottom of the VAZ 2114 will be required in the following cases:

- It is impossible to jack up the car; the jacks fall through.

- The floor in the car became uneven, the metal sagged from corrosion.

- The driver's seat cannot be adjusted; when the doors are closed, increased gaps appear.

- Noticeable areas of corrosion on the sills and wheel arches. If you lift the car onto an overpass and check it with an awl, the anti-corrosion layer from the bottom will fall off, and traces of rust will be clearly visible.

Deformations and damage to body iron 2114

VAZ 2114 body color

As mentioned above, certain areas of the 2114 body are most often subject to deformation. In addition to the wings and bumpers, this is also the hood. These body elements were originally made in order to protect certain components of the car and people from the shock wave that they take on and absorb.

Based on the above, the car owner must draw a conclusion. If these body parts on the VAZ 2114, so to speak, take the heat upon themselves, their condition must be periodically monitored.

Here are the situations in which the owner is obliged to take action:

- If corrosion spots appear on the elements;

- If there are dents, even minor ones, on metal and plastic parts;

- If an accident occurs and the body is distorted, not necessarily immediately visible.

Corrosion is the main enemy of all metal parts of a car. It appears not only as a result of damage to the part, but more often, during long-term operation, over time, when the negative impact of an aggressive environment can no longer be restrained by paintwork, and the metal is left face to face with rust, which eats it away completely.

Attention. Rust is dangerous not only for one specific part. It will continue to develop, moving to other body elements.

VAZ 2114 body parts and rust

Some 2114 owners install a plastic hood instead of a metal one. This is good in terms of resistance to corrosion, but the plastic element is less durable, and during an accident there may be practically nothing left of it if the impact falls directly on it.

On the other hand, the plastic element is not subject to corrosion, as was said, but it can also be quickly repaired in case of moderate deformations, and painting it is generally very pleasant and does not take much time.

VAZ 2114 body and its parts

| 1 – front bumper | 11 – hood | 21 – rear floor |

| 2 – radiator frame | 12 – front suspension spring support | 22 – rear bumper |

| 3 – front right wing | 13 – air supply box | 23 – back door |

| 4 – radiator frame panel | 14 – windshield frame | 24 – spoiler |

| 5 – radiator frame support | 15 – front door | 25 – front seat bracket |

| 6 – upper cross member of the radiator frame | 16 – roof beams | 26 – front floor |

| 7 – right front fender mudguard | 17 – roof panel | 27 – front floor cross member |

| 8 – right front spar | 18 – trunk lid | 28 – floor amplifier |

| 9 – hood hinge | 19 – rear window frame | 29 – front left fender |

| 10 – front panel | 20 – left outer side panel | 30, 31 – left front fender mudguard and towing eye bracket |

Repairing certain body parts usually involves the following steps:

- The surfaces are first prepared, special liquids and degreasers are applied to them to remove external contaminants and fatty substances;

- Damaged elements are straightened, straightened, then polished and traces of corrosion are removed;

- The third stage of work involves selecting paint colors;

- Surfaces are puttied and primed, body elements are given smoothness;

- The parts are painted to match the color of the car.

If the body is seriously deformed, it is not necessary to buy a new one. You can only buy body hardware, replace damaged areas and that’s it. This way, there won't be any legal issues like there would be with a unibody replacement.

Note. The most important step is to check the compliance of the new body elements with the original ones, the geometric dimensions of which can be viewed in special reference books and tables posted on our website.

If you decide to replace the VAZ 2114 body parts with your own hands, then you must adhere to the following steps:

- Cut off the part if it is welded to the body or remove it if it is bolted;

- Check the geometric compliance of the new element with the factory specifications.

Advice. If there is a noticeable discrepancy in size, then you can adjust and adjust the part and the elements in contact with it.

- The prepared body elements must be sanded and primed if they do not match the color of the car, and then painted.

Preparation for repair

Repairing the underbody of a VAZ involves a set of measures:

- preparation of the necessary material and tools;

- interior dismantling;

- installing the car on a lift or repair plane;

- cutting out rotten elements of the bottom during partial or complete replacement of a part, if it is necessary to completely digest the body;

- patch welding or bottom welding;

- anti-corrosion treatment;

- installation of interior, replacement of sound insulation, additional work.

To repair the body yourself, you will need to prepare the following materials and tools:

- A new bottom or part of it for a complete replacement, metal patches for a partial repair. It is recommended to take industrial steel with a thickness of up to 1-1.2 mm. The standard metal on the body of the VAZ 2114 has a thickness of 0.9 mm for the bottom, 0.8 for the sills.

- Angle grinder, grinder with a set of replaceable discs from metal, for processing a weld seam, stripping metal from corrosion, to a soft attachment for grinding soil.

- Welding machine. For self-repair, it is recommended to use a semi-automatic machine using wire in a carbon dioxide environment.

- Electric drill, set of drills.

- Sound insulation sheets.

- Metal brushes, coarse and fine sandpaper, chisel, set of screwdrivers.

- Zinc-based primer, putty, set of spatulas, anti-corrosive agent for final processing.

The first stage of work is dismantling the interior and lifting the car onto the overpass.

Craftsmen do not recommend carrying out repairs in a pit; it will be inconvenient for the driver to weld the body and treat the surface. The most convenient option is to lift the car on hangers or turn it on its side.

Dismantling the interior

The bottom 2114 is a stamped part that is welded to the reinforcements of the side members and hinged panels along factory lines. Original replicas require no trimming and are ready for installation. Description of replacement in stages:

- The fuel is drained from the car and the battery is removed.

- The electrics are turned off, the front and rear doors are dismantled.

- The chairs and flooring are pulled out, and the sound insulation is removed.

- All plastic lining of the pillars is dismantled, the dashboard must be covered with a thick piece of rags.

- The glass is sealed on both sides with thick paper.

- An inspection is carried out from the inside, rusty areas are tapped with a hammer, and the scale of work is determined.

Welding speed will be provided by an inverter

For many years, the UAZ 469 car has been very popular among Russians. Having rolled off the assembly line back in the Soviet Union, it is still in demand among extreme sports enthusiasts. It should be noted that the body of this car was very reliable. But it doesn’t last forever, so today the UAZ 469 can increasingly be found in workshops where its body part is being strengthened.

To complete welding work as quickly as possible, an inverter is most often used.

This welding machine uses high frequency currents in its work. Its main advantages are its compactness and excellent speed of operations. In addition, various operating modes allow even a novice master to master the unit in a matter of hours. However, the device also has disadvantages:

- high price;

- impossibility of welding iron thicker than 3 mm;

- frequent breakdowns due to dust.

Carrying out repair and welding work

Repairing the underbody of a VAZ 2115 is quite difficult. Under the bottom of the car there is a fuel system, brake system and muffler pipes. When replacing an entire part, these systems must be completely removed and reinstalled after welding. Experienced tinsmiths recommend not dismantling the muffler elements, but cutting them out, after repairing the bottom, boiling the part and installing it in place.

If the underbody is partially repaired, there will be no need to remove the fuel and brake system pipes. When cutting out entirely, it is recommended to cut out the bottom not along the factory welding line, but leaving an allowance of 1-2 cm. The new element is welded with an overlapping seam, which increases the rigidity of the body and the durability of the weld seam.

What is the best way to cook?

Typically, welding work is carried out using electrodes. This welding method is quick and simple. But it is not recommended to use it when repairing the body, since the seam is quite rough, so the car with it will not look very aesthetically pleasing.

The equipment for welding with electrodes is quite cumbersome, which will not allow you to reach the most difficult areas of the body. But this work must also meet safety requirements. Therefore, electrode welding is used only in special cases, for example, if it is necessary to strengthen a broken frame.

Currently, when carrying out welding work, an inverter or semi-automatic machine is most often used.

Each of these methods has its own advantages and disadvantages. To use such welding, you must have special skills, as well as know and follow safety precautions. The critical point is the equipment of the workplace. If welding work is planned to be carried out in a garage, it is important to properly organize the space and purchase the necessary tools in advance. The lighting of the room is also of great importance. It is quite difficult to do welding work alone. It is good if the welder has an assistant.

Replacing parts or the entire bottom

Repairs begin with inspection and repair of thresholds. Rotting of the central part of the body begins with corrosion of the sills and wheel arches, so if rust has destroyed parts of the bottom by 30%, then we can confidently say that the sill is rotten by 60% and requires complete replacement. The bottom of the VAZ 2114 consists of the following elements:

- underbody panels under the seats;

- threshold extension;

- crossbars;

- side member amplifier;

- space for a jack or jacks;

- central support platform;

After cleaning the underbody from anticorrosion, the jacks, side members and panels under the feet of the driver and passenger are inspected. These are the most vulnerable parts. If the general condition is satisfactory, then it is recommended to cut out the problem areas and install the original floor parts from the repair kit. The process of partial overcooking of the bottom in steps:

- Drill out the spot welding points and cut out the rusted metal with a chisel.

- Clean the edge of the future weld with a grinder and treat with a degreaser.

- Attach the original part or the cut out patch. The metal patch should protrude 1 cm beyond the edges of the trim; welding will be carried out overlapping.

- Spot weld the edge of the metal. Weld the patch in increments of 2 cm welding, 4 cm skip.

It is not recommended to weld a one-piece sealed seam; when the engine vibrates, the body experiences torsional loads, and the solid seam may crack.

- Clean the weld seam.

- Treat with primer, apply a layer of oil anticorrosive or bitumen mastic under the sound insulation layer.

- After complete cleaning, treat the outer part of the bottom with bitumen mastic.

conclusions

The design of the 8-valve injection engine VAZ-2114 is quite similar to the first generations of this engine - “Samara”. Of course, the designers made many changes to the features of the power unit, but in many ways they remained similar. Repair and maintenance of this engine must be carried out regularly, which will not only extend its life, but also reduce wear on the parts located inside.

The current condition of the car can largely be assessed by analyzing the body. If all kinds of consumables need to be replaced, you can even rebuild the suspension yourself and even install a new engine, then restoring a completely rusted body is expensive and pointless.

No one will tune, modify, or invest a lot of money in a car if its body is already in its last years. This significantly reduces the cost of the car, even if the engine is in perfect condition.

Therefore, if you want to maintain the attractive appearance of your VAZ 2110, extend its service life, and, if necessary, sell it for good money, keep an eye on the body and periodically carry out repair or preventative body work aimed at combating corrosion.

Final processing

Primer, anti-corrosion treatment, installation of new sound insulation and installation of the interior with electrical connections are the final stage of work on the bottom. For external treatment, you will need bitumen mastic or anticorrosive Body 930. The product has a budget cost and is highly resistant. The mastic forms a dense but elastic protective layer that does not allow moisture to pass through and protects the iron. Final work step by step:

- Clean weld seams.

- Treat welding areas with a primer containing zinc.

- Cover the inner surface with mastic and install new sound insulation.

Rotten metal destroys the skimmer sheets in 3-5 months, so if the car needs the bottom to be overcooked, the sound insulation definitely needs to be changed.

- Treat the outer part of the bottom with bitumen anticorrosive. You can use paraffin aerosols; it is convenient to reach the hidden cavities of the bottom with an anticorrosive agent.

During operation, during routine inspection, it is recommended to periodically remove the plugs in the parts and pour the oil composition into the internal pockets.

- Install interior, doors. Connect the electrical.

Is it worth soldering

You can also seal holes in the bottom using soldering. However, ordinary household soldering irons are not suitable for heating metal with a thickness of 0.5 mm or more. Most likely, a hair dryer will not help you with this. You need to use a portable gas burner, for example, Super-Ego R355, which fits into a small - volume from 400 to 700 ml - cylinder for camping stoves.

Solder and flux are required for soldering. The solder used is low-melting, with a predominant content of tin or lead. Flux can be replaced with electrolytic acid. The connection is strong and can withstand high vibration loads.

Soldering has two disadvantages.

- It involves hot work, which increases the overall complexity of the repair. This can be neglected if your hands grow from the right place;

- The main material of solder - lead or tin - is a substance that has a lower electronegative potential than iron. Therefore, upon their contact, electrochemical corrosion occurs, in which iron will play the role of a “sacrificial anode” and be destroyed.

Now you have an idea of how to seal the underbody of a car without welding. If you are careful and persistent in cleaning the surfaces, then treating them and protecting them, then the installed patch can outlive the car itself.

Cost of the kit and work with it in the service

The service station carries out the full range of work to restore the body. You can weld the bottom of a VAZ 2115, the price of work without the cost of dismantling, materials and components starts from 15,000 rubles. It is also permissible to change rotten jacks, sills and replace part of the bottom, the cost of work is up to 10,000 rubles.

Repairing the underbody, like any other part of the body, is classified as labor-intensive and complex. The cost of the repair kit must be added to the cost of the work.

- original floor from AvtoVAZ - from 3,000 rubles;

- bottom with thresholds ─ from 5,000 rubles;

- sound insulation ─ from 500 rubles per 1 sq. meter;

- anticorrosive ─ from 600 rubles per 1 kg.

Simple calculations show that self-repair will cost three to four times less, but only if the driver understands the complexity of the work and has minimal skills in using electric welding and working with metal.

Spare parts catalog VAZ Samara 2115, 2114, 2113 - Body floor

1.

AVTOVAZ — 21080-5101372-00 — VAZ-2108 rear right floor spar

2002 r.

1.

AVTOVAZ — 21085101372 — LADA 21085101372 Rear right floor spar

check price

1.

EKRIS — 2108-5101372 — Rear floor spar of VAZ 2108 right

check price

1.

AVTOVAZ — 21099-5101372-00 — Floor spar VAZ-21099 rear right

2125 rub.

3.

AVTOVAZ — 21080 8404416 00 — Bracket for mudguard VAZ 21080 left (flag)

check price

4.

AVTOVAZ — 21080-5101376-00 — Spar reinforcement for lever mounting

check price

6.

AVTOVAZ - 21080-5101084-00 - Front floor cross member VAZ 2108 average,

check price

7.

AVTOVAZ — 21080-6810030-00 — Right side front seat bracket assembly

210 rub.

7.

AVTOVAZ — 21086810030 — Seat bracket

check price

7.

EKRIS — 2108-6810030 — Seat bracket for VAZ 2108

check price

8.

AVTOVAZ - 21080-5101083-00 - front left floor cross member

124 rub.

8.

AVTOVAZ - 21080-5101082-00 - front right floor cross member

124 rub.

8.

EKRIS — 21080510108200 — right cross member for VAZ 2108 seats (crown strength)

check price

9.

AVTOVAZ - 21080-5101066-00 - Middle floor threshold connector

146 rub.

9.

ChKPZ - 2108-5101066 - Threshold connector VAZ 2108-09-099

check price

10.

AVTOVAZ - 21080-5101024-00 - VAZ 2108-21099 body floor assembly

7535 rub.

11.

AVTOVAZ — 21080-5101302-00 — Front floor spar

check price

11.

AVTOVAZ — 21085101302 — LADA 21085101302 Front right floor spar

check price

12.

AVTOVAZ - 21080-5101064-00 - floor reinforcement assembly

check price

13.

AVTOVAZ — 21080-5101303-00 — Front left floor spar

128 rub.

13.

AVTOVAZ — 21085101303 — LADA 21085101303 Front left floor spar

check price

14.

Noname - 21085101067 - Threshold connector

check price

14.

AVTOVAZ — 21080-5101067-00 — Left threshold connector assembly

146 rub.

17.

AVTOVAZ - 21099-5101042-00 - Trunk floor VAZ 21099,

2547 rub.

17.

AVTOVAZ — 210995101042 — Part

check price

18.

AVTOVAZ — 21099-5101275-00 — Floor cross member 21099 rear

check price

19.

AVTOVAZ - 21099-2804180-00 - rear towing eye assembly

check price

20.

AVTOVAZ - 21099-5101276-00 - Rear trunk floor cross member VAZ-21099,

check price

21.

AVTOVAZ - 21099-5101047-00 - Rear floor extension 21099 (JSC AVTOVAZ)

check price

22.

AVTOVAZ - 21080-5101276-00 - rear floor cross member

328 rub.

23.

AVTOVAZ - 21080-5101042-00 - Trunk floor VAZ 2108-2109, 2113-14,

2650 rub.

23.

AVTOVAZ — 21085101042 — VAZ-2108 TRUNK FLOOR AVTOVAZ

check price

23.

BEGINNING — 2108-5101042 — Spare wheel floor (OAOAVTOVAZ) VAZ 21080

check price

23.

START — 21080 5101042 00 — Spare wheel floor (OAOAVTOVAZ) VAZ 21080

check price

24.

AVTOVAZ - 21080-5101272-00 - Floor cross member 2108 average (JSC AVTOVAZ)

check price

25.

AVTOVAZ - 21080-5101373-00 - Floor spar VAZ-2108, 21099 rear left

RUR 1,771

25.

AVTOVAZ — 21085101373 — SAR VAZ 210821099 REAR LEFT WITHOUT HOOK

check price

25.

AVTOVAZ — 21099-5101373-00 — Floor spar VAZ-21099 rear. left

check price

26.

AVTOVAZ - 21080 8404417 00 - Mudguard bracket VAZ 21080 right (flag) rear

check price

27.

AVTOVAZ — 21080-5101377-00 — Spar amplifier

check price

29.

AVTOVAZ - 21080-5101076-00 - floor reinforcement for installation of a jack Polad CJSC Tolyatti

check price

30.

AVTOVAZ - 21080-5101034-00 - Floor panel VAZ-2108-09, 2113-14 middle

check price

30.

AVTOVAZ — 21085101034 — FLOOR PANEL MEDIUM VAZ 2108

check price

31.

AVTOVAZ — 21080-5101286-00 — Connector for rear side member and front floor

130 rub.

31.

AVTOVAZ — 21080-5101287-00 — Connector for rear side member and front floor

127 rub.

32.

AVTOVAZ - 00001-0076711-01 - Screw 4.9x12.7

check price

32.

BelZAN - 1/76711/01 - Self-tapping screw 4.9*12.7 with cylinder head.

check price

33.

AVTOVAZ - 00001-0005193-01 - Washer 5

5 rub.

33.

BelZAN - 00001-0005193-01 - WASHER 5

check price

33.

BelZAN - 00001000519301 - WASHER 5

check price

34.

AVTOVAZ — 00001-0041897-71 — Flange nut 10

check price

34.

BelZAN - 1/41897/71 - Medium metal mounting piston for self-tapping screws

check price

How to save money?

If a car owner wants to save money, he needs to do a preliminary inspection of the bottom himself. For this you will need:

- Lift, inspection hole, overpass.

- Good lighting: a flashlight or a carrier with a powerful lamp.

- Hammer.

Using a hammer, it is necessary to tap all suspicious areas of the bottom and determine the extent of their damage in order to approximately know the volume of materials needed.

If all of the above is not at hand or there is simply not enough time for a thorough inspection, then a special mirror for inspecting the underbody of the car will come to the rescue. It will allow you to generally assess the condition of the metal and get an approximate idea of the amount of work. But the situation will become completely clear only after a thorough examination.

The welding process itself is simple; anyone can master it in the shortest possible time. Sometimes it takes longer to connect and set up equipment. The easiest way to overweld the underbody of a car is to use a semi-automatic welding machine. But often such repairs are simply impossible without the use of gas welding. Best of all, when both of these devices are used, they complement each other and improve the quality of underbody repairs.

What is this?

Features of repairing and over-welding the underbody of a car with your own hands

Under over-welding the underbody is understood as updating the floor of the car using welding equipment and a number of tools. The bottom of the car is the most vulnerable place. It takes on mechanical damage, the negative effects of active chemicals, and dirt. Most often you have to deal with the corrosion process.

Overcooking the bottom of a VAZ-2112 may be required in the following cases:

- The bottom is covered with rust.

- There are holes.

- There are big cracks.

- The bottom has become thinner.

In these cases, auto technicians recommend overcooking. This work is labor-intensive and expensive. To repair a car, you need to do a number of these steps:

- Find a service station that restores VAZ-2112 cars.

- Contact the administrator and ask him about the terms of cooperation and approximate prices for services.

- Agree on a time to come to the master or call a specialist.

- Provide your vehicle to the mechanic.

- After a professional inspection, negotiate the exact cost of the work and the time frame for its completion.

- Give consent for repairs.

- Accept the job.

- Pay the specialist the previously agreed amount of money.

- Receive a warranty card for the work done.

The wizard performs a number of such actions:

- Inspects the bottom of the car.

- Makes a decision about the need to digest it.

- Cuts out the damaged part.

- A patch is welded to this place.

- Treats the area with an anti-corrosion compound, sealant and mastic to increase resistance to external negative influences.

- Provides the restored car to its owner.

For work, the specialist uses a semi-automatic welding machine, gas welding.

Device for applying liquid anticorrosive

The problem faced by car enthusiasts who decide to process hidden cavities on their own is the lack of necessary equipment. They can use a relatively simple device that operates on the principle of air spraying of drugs under a pressure of 4-6 kg/cm2.

The simplest design of such a device is as follows: a nozzle for it can be made from a cologne spray bottle by drilling out the nozzle in its tip to a diameter of 1.2 mm. A brass tube must be soldered to the inner wall, through which the anti-corrosion agent will be supplied.

The pump is connected with a hose to the spray tube going to the container with Movil. To supply the drug to the tube, you can use a polyvinyl chloride tube lowered into the vessel. For greater clarity, a diagram of such a device is shown below.

With the constant creation of air pressure by the pump, the torch emerging from the Movil nozzle is ensured within 14-20 cm, which is enough to apply it inside hidden cavities.

Before applying Movil to hidden surfaces of cavities, it is necessary to ensure that the sprayer has access to the required areas. For this:

- remove the seals of the front wings, headlights and their rims (VAZ - 03, -02);

- remove the spare tire, tools and floor covering (VAZ - 013), upholstery (VAZ - 03, -07 and -06) from the trunk;

- open the rear door (VAZ - 02) and remove the carpet, trim, spare tire and its cover;

- remove the door signal lamps (VAZ - 03, -06) and the reverse signal lamp (VAZ - 03).

Then you should perform a somewhat unpleasant, but technically necessary operation - drilling holes (9 mm) in the sills, and for VAZ-013, -21 and -05 - also in the end surfaces of the rear doors.

If possible, accessible treatment areas should be washed with water, blown with air and dried. In garage conditions, where it is impossible to carry out effective drying, it is enough to limit yourself to wiping them with a damp cloth, followed by natural drying. Considering that the largest number of points requiring treatment are located in the bottom area, it is advisable to carry out all work on a lift or overpass.

To process the sills, the place of the spare tire and the cross member of the front part, you need to pull out the plugs. Two plugs are installed on both sides under the front fenders, a plug on both sides in the rear arches, in the center in the spare tire niche, and one on both sides in the cross member under the front seats. The drainage holes also need to be cleaned.

Before anti-corrosion treatment of thresholds, arches, and bottoms is carried out, they should first be washed with ordinary water and blown with a compressor (this will dry them out faster). It is advisable to dismantle the wheels so as not to complicate the process, and place the car on reliable supports. Cover wheel rims, brake mechanisms, and transmission elements with something to prevent anticorrosion. After this, open all doors, lids and begin application.

Where and from whom can I order the service?

If it is necessary to digest the thresholds in the car, the motorist has three options:

- Contact the service center.

- Find a competent private auto mechanic.

- Do the work yourself.

The first option is the best, but expensive. You should only contact a private owner if he has been recommended by a good friend. You can digest the rapids yourself. But for this you need to have knowledge, skills, a welding tool, follow the algorithm of actions and be extremely careful.

Metal thickness

To repair the underbody of a car with your own hands without any problems, you need to choose metal of optimal thickness. Its recommended thickness varies from 1 to 2 mm. But here you should take into account the qualifications of the person who will carry out the welding work. When working with thinner metal, you must strictly observe the temperature requirements during welding. Which, in turn, depends on the debugging of equipment and the quality of consumables.

Thicker metal is more difficult to process, but it is also more difficult to damage or spoil. Therefore, before purchasing consumables, you need to realistically assess your qualifications as a welder.

List of VAZ colors

| The floor panel is an integral component of the car, its location at the bottom of the car makes the floor the most susceptible to corrosion. This page of the site presents floor panels for many VAZ models, as well as repair inserts that are ideal for local body repairs. | rear left trunk floor panel VAZ 2110 | Rostov | RUB 840.00 | RUB 780.00 |

| 2112-5101041 | rear left trunk floor panel VAZ 2112 | Rostov | RUB 700.00 | RUB 650.00 |

| 2110-5101040 | rear right trunk floor panel VAZ 2110 | Rostov | RUB 1,260.00 | RUB 1,170.00 |

| 2112-5101040 | rear right trunk floor panel VAZ 2112 | Rostov | RUB 980.00 | RUB 910.00 |

| 2108-5101024 | floor panel assembly VAZ 2108 | AvtoVAZ | RUB 6,300.00 | RUB 5,850.00 |

| 2110-5101024 | floor panel assembly VAZ 2110 | AvtoVAZ | RUB 5,040.00 | RUB 4,680.00 |

| 2121-5101024 | assembled floor panel VAZ 2121 | AvtoVAZ | RUB 7,560.00 | RUB 7,020.00 |

| 1111-5101024 | Floor panel VAZ 1111 OKA | KamPRZ | RUB 3,500.00 | RUB 3,250.00 |

| 2105-5101030 | floor panel VAZ 2101 | AvtoVAZ | RUB 8,400.00 | RUB 7,800.00 |

| 2108-5101034 | middle floor panel VAZ 2108 | AvtoVAZ | RUB 2,100.00 | RUB 1,950.00 |

| 2101-5101040 | trunk floor of VAZ 2101 | Rostov | RUB 840.00 | RUB 780.00 |

| 2103-5101040 | trunk floor of VAZ 2106 | Tolyatti | RUB 840.00 | RUB 780.00 |

| 2108-5101042 | trunk floor of VAZ 2108 | AvtoVAZ | RUB 2,940.00 | RUB 2,730.00 |

| 21099-5101042 | trunk floor VAZ 21099 | AvtoVAZ | RUB 2,450.00 | RUB 2,275.00 |

| 2110-5107120-50 | trunk floor of VAZ 2110 | AvtoVAZ | RUB 1,540.00 | RUB 1,430.00 |

| 2112-5107112 | trunk floor of VAZ 2112 | AvtoVAZ | RUB 1,680.00 | RUB 1,560.00 |

| 21213-5101034 | trunk floor VAZ 21213 | AvtoVAZ | RUB 1,600.00 | RUB 1,450.00 |

| 1118-5101040 | trunk floor LADA 1118 Kalina | AvtoVAZ | RUB 3,920.00 | RUB 3,640.00 |

| 1119-5101040 | trunk floor LADA 1119 Kalina hatchback | AvtoVAZ | RUB 3,640.00 | RUB 3,380.00 |

| 2190-5101040 | trunk floor of LADA 2190 Granta | AvtoVAZ | RUB 4,200.00 | RUB 3,900.00 |

| 2101-5101176 | VAZ 2101 gas tank floor | Tolyatti | RUB 200.00 | RUB 160.00 |

| 2102-5101091 | VAZ 2104 gas tank floor | Izhavto | RUB 700.00 | RUB 650.00 |

| 2103-5101176 | VAZ 2106 gas tank floor | Rostov | RUB 200.00 | RUB 170.00 |

| 2101-5101043 | rear left floor VAZ 2101 | Lipetsk | RUB 840.00 | RUB 780.00 |

| 2108-5101031 | rear left floor VAZ 2108 | Rostov | RUB 490.00 | RUB 455.00 |

| 2101-5101042 | rear right floor VAZ 2101 | Lipetsk | RUB 840.00 | RUB 780.00 |

| 2108-5101032 | rear right floor VAZ 2108 | Rostov | RUB 490.00 | RUB 455.00 |

| 2101-5101180 | VAZ 2101 spare tire floor | Rostov | RUB 200.00 | RUB 160.00 |

| 2102-5101082 | VAZ 2104 spare tire floor | Izhavto | RUB 700.00 | RUB 650.00 |

| 2103-5101180 | VAZ 2106 spare tire floor | Start | RUB 200.00 | RUB 170.00 |

| 2108-5101031 | floor left side 12 VAZ 2108 | Tolyatti | RUB 1,885.00 | RUB 1,755.00 |

| 2101-5101035 | front left floor assembly VAZ 2101 | Tolyatti | RUB 1,540.00 | RUB 1,430.00 |

| 2101-5101025 | front left floor VAZ 2101 | Lipetsk | RUB 840.00 | RUB 780.00 |

| 2108-5101031 | front left floor extended VAZ 2108 | Tolyatti | RUB 700.00 | RUB 650.00 |

| 2101-5101034 | front right floor assembly VAZ 2101 | Tolyatti | RUB 1,540.00 | RUB 1,430.00 |

| 2101-5101024 | front right floor VAZ 2101 | Lipetsk | RUB 840.00 | RUB 780.00 |

| 2108-5101030 | front right floor extended VAZ 2108 | Tolyatti | RUB 700.00 | RUB 650.00 |

| 2110-5101031 | front floor repair left VAZ 2110 | Rostov | RUB 1,400.00 | RUB 1,300.00 |

| 2110-5101030 | front floor repair right VAZ 2110 | Rostov | RUB 1,400.00 | RUB 1,300.00 |

| 2108-5101030 | floor right side 12 VAZ 2108 | Tolyatti | RUB 1,885.00 | RUB 1,755.00 |

| 2110-510103100 | Repair floor left 12 VAZ 2110 | Rostov | RUB 2,310.00 | RUB 2,145.00 |

| 2110-510103000 | repair floor right 12 VAZ 2110 | Rostov | RUB 2,310.00 | RUB 2,145.00 |

| 2121-5101031 | Front floor repair insert left VAZ 2121 | Rostov | RUB 1,260.00 | RUB 1,170.00 |

| 2121-5101030 | Repair insert for front floor right VAZ 2121 | Rostov | RUB 1,260.00 | RUB 1,170.00 |

Price*

price for registered users

How to repair a hole in a car body without welding: the best ways

It often happens that before painting a used car, we discover a through hole formed due to corrosion.

What can be done in this case, if we leave the topic of professional body repair and high costs. Is it possible to fix the hole yourself, and if so, how to do it? All this will be discussed below. If you decide to start painting your vehicle, it is likely that you will be faced with through holes in the body that have arisen as a result of exposure to rust. It is worth noting that body repairs are quite expensive, so not every car enthusiast wants to turn to professionals. As a result, many are interested in how to repair holes in a car body without welding with their own hands. This is exactly what we will talk about now.

Apply putty

First of all, if you don’t know how to repair a hole in a car sill without welding, you should take a closer look at the putty method. This solution is distinguished by its simplicity, so you can resort to it even if you do not have special knowledge of body straightening.

Before repairing a hole in the car body, you should prepare:

- fiberglass and automotive putty;

- aluminum mesh;

- putty knife;

- sandpaper (if possible, it’s also worth looking for a sanding machine);

- primer, paint, varnish.

Fixing holes in a car body itself is distinguished by its simplicity. First of all, you should remove the rust using an angle grinder or any other suitable equipment. Next, we cut out the patch from aluminum, and then attach it to the body using masking tape. We apply a thin layer of fiberglass putty (here it is important not to touch the tape, because then you will have to remove it). When the putty sticks, peel off the tape and putty the remaining areas.

It is important that the layer is as thin as possible, without tubercles or other irregularities.

When everything is dry, sand everything using coarse sandpaper or a sander.

Having achieved a flat and smooth surface, apply a second ball of putty - automotive putty. We wait until it dries and level it again. Then the surface is primed (do not forget to cover the areas that do not require painting with film). When the primer is finished, you can paint the body.

It is worth noting that the patch will be more stable if you apply a couple of layers of putty on the back side. In addition, it is also possible to seal holes in the car body without welding using putty and without using a patch. In this case, it is necessary to apply a lining on the back side so that the composition is well fixed. On the other hand, this solution is only suitable for very small through holes.

There is another way to repair a hole in a car body without welding. A soldering iron is required here. First of all, we clean the area from rust. We make the patch from a sheet of metal (you don’t need to worry too much about this; an ordinary can of auto chemicals will do).

It is important that the patch is slightly larger than the holes and also completely covers them.

Additionally, you can coat the metal surface with anti-corrosion compounds - this will increase the quality of our repairs. Then we service the edges of the patch, after which, using a fairly powerful soldering iron, we solder it with a continuous seam.

In order for the putty to adhere well, it is important that abrasive marks (small scratches) appear on the patch.

The next step is primer. Here it is necessary to complete everything as quickly as possible to avoid the possibility of rust occurring in the future. It is best to first apply a thin layer of phosphate primer, and when it dries, another two or three layers of acrylic two-component composition (the interval between applications should be about 5-10 minutes). Everything dries in about 3-4 hours; if there is infrared heating, you can reduce the procedure to 20 minutes.

It is worth noting that this solution is more durable than in the case of aluminum mesh, and it can be used to eliminate holes of almost any size.

So, in the article we discussed how to repair holes in a car body without welding. It is worth noting that these options are not the most optimal. Naturally, it is better to turn to professional vehicle repair specialists. At the same time, self-repair will help give the body an aesthetically attractive appearance and also prevent further development of corrosion. Both options are distinguished by their simplicity, so repairs can be performed even without special knowledge and skills.

Recently, it has been possible to close the holes in other ways. One of them involves working with fiberglass.

Fiberglass patch

Instructions:

- The surface of the body is also cleaned and degreased, as in the two cases described above.

- Overlays are cut out of fiberglass, the size of which should be 2 cm larger than the hole size.

- The area is pre-primed and the composition is given time to harden.

- The pad is applied to a completely dry surface.

- Fiberglass linings are fixed using an adhesive-resin composition.

First, one overlay is glued, then the second, third, and so on. Again, it is recommended to put a lining on the reverse side.

After the glue has dried, the body surface is treated and painted.

Read more: How to quickly sell a car, sell your used car at a profit

As you can see, holes on the car body caused by corrosion can be easily eliminated with your own hands. Visual examples can be seen in the video and photo.

Tired of paying fines? There is an exit!

Forget about fines from cameras! An absolutely legal new product - Traffic Police Camera Jammer, hides your license plates from the cameras that are installed in all cities. More details at the link.

- Absolutely legal (Article 12.2);

- Hides from photo and video recording;

- Suitable for all cars;

- Works through the cigarette lighter connector;

- Does not cause interference to radios and cell phones.