Types of gearbox cushions

The existing gearbox on the VAZ 2110 is equipped with reliable spare parts, the interaction of which ensures smooth operation of the vehicle. It should be noted that it is maintainable. One of the elements of the transmission is gearbox cushions. These components can be of the following types:

In terms of price, the rubber-metal option is cheaper. As a rule, it is most often found on the 2110 model. The rubber can be made of polyurethane. This material is characterized by increased wear resistance and has good shock-absorbing properties.

Hydraulic options cope well with the loads placed on them and are able to effectively dampen vibrations that occur when movement occurs. The design of the present support is a housing that has two chambers with a special filler, between which there is a membrane.

Problems with box supports are rare. Long-term operation of the vehicle over rough terrain and temperature changes help reduce its service life. Because of this, the rubber of the cushions loses its elasticity and breaks down. As a result, there is a need for repair and restoration work.

Troubleshooting airbags

The metal base of the cushion provides good mechanical support for the gearbox. Thanks to her, this unit is securely fixed in its normal place. The gearbox support 2110 has good resistance to external loads, as well as temperature changes. The service life of this component depends on the operating conditions of the vehicle. The ingress of dirt, sand, etc. flying from the roadway helps to reduce their service life.

You need to pay attention to the condition of the pillows if the following manifestations are noted:

- vibrations at the beginning of the trip;

- extraneous knocking noises when braking;

- hum

In addition to this, it can knock out speed. Among the reasons for these manifestations may be deformation of the pillow as a result of strong temperature exposure. Also, the life of the gearbox cushion is negatively affected if oil or antifreeze gets on it.

Important! The presence of knocks and extraneous noise from the VAZ 2110 high-speed gearbox is not always due to the fact that the airbags have become unusable. These manifestations may be the result of broken gear teeth or loose threaded connections. Taking this into account, vehicles are subject to full professional diagnostics.

Thus, if the faulty consumables on the VAZ 2110 are not replaced in time, then the motorist may soon experience engine and gearbox breakdowns. As a result, vehicle control will deteriorate and there will be a need for serious repairs.

Alternative supports

Considering the long-standing problem of Samara and a dozen, the manufacturer immediately released a whole series of alternative pillows:

- OJSC-BRT;

- SS-20;

- "Assomi".

Let's now consider their features:

- The support of JSC-BRT and the peculiarity of its structure is contained in a hinged product, which replaced the bearing in this place. At first glance, it looks like a panacea, since the general principle of operation seems to be clear: the creators of this technical innovation used an element that has increased rigidity in the radial direction. At first glance, the sounds should disappear and the car should become silent on uneven roads, however, conflicting reviews from the motorists themselves do not allow us to completely agree with this fact.

- An alternative to OAO-BRT is SS-20, where a steel bushing was installed in place of the standard bearing, which was completely welded into a rubber damper. The manufacturer of this new product claims that the SS-20 will completely eliminate the appearance of elevators and extraneous sounds. Moreover, the manufacturer directly promises that the SS-20 will be able to guarantee the classic behavior of the rocker (see Replacing the rocker on a VAZ 2110 on your own): regardless of the topography of the road surface, the lever will be stable and without extraneous sounds.

- The developers of "Assomi" boldly claim that the use of a special prescription rubber mixture will completely smooth out all impacts and sound noise, thereby significantly increasing the overall level of comfort of the car.

So, you need to choose who to trust, because there are a huge number of manufacturers to choose from, who all guarantee the high quality of their products. And most importantly, they guarantee that they managed to create a universal high-tech product that is most effective from a practical point of view.

Note. But it’s not entirely clear why some manufacturers of backstage cushions use rubber ears that quickly break?

Practical Feature of Alternative Choice

Unfortunately, “Assomi” and SS-20 are quite difficult to find in local stores; in the future they will go on wide sale, however, it is impossible to answer exactly when this will happen. It all depends on the store owners. The motorist is mainly offered imported products, as well as from national manufacturers, but only standard ones. It should be objectively understood that the quality of imported products varies significantly in comparison with national standard factory models, as does the price. Therefore, if you are pressed for time, it is best to order your own national alternative via the Internet, which is much lower in price than its foreign counterpart, and the quality is almost identical.

When to change your pillow

Factors that indicate the need to replace the wing cushions:

- extraneous sound during movement, the irradiation of which can even spread to the body of the vases;

- traces of hardening or cracking of the rubber cushion are visible, as well as if it is separated from its metal base;

- there is a pronounced increasing vibration that has not previously been observed;

- in case of unsatisfactory backlash length, etc.

Features of replacing the VAZ 2110 box cushion

It is possible to carry out repairs yourself. Initially, it is worth purchasing suitable cushions for the gearbox for a VAZ 2110 car (produced by the Volzhsky Rubber Plant). Also, you need bolts, nuts, washers, and a casing bushing.

The main stages of replacing the VAZ 2110 gearbox cushion:

- The car starts up in the inspection hole.

- A beam is placed across the pit, on which the jack is installed (closer to the support).

- Visually you can determine the condition of the support. If it is deformed, the spare part needs to be replaced.

- To remove the pillow, you need to unscrew the nuts that secure it to the box.

- The through fastening bolt is unscrewed.

- The pillow is removed.

Installation of a new spare part occurs in the reverse order. Replacing a pillow on a box does not require any specific skills; this procedure does not require much time.

Thus, replacing the VAZ 2110 gearbox cushion can be done independently. When carrying out this procedure, you need a set of keys and a jack. In normal condition, the products should be solid; components should be periodically checked for integrity. There are many signs that the gearbox cushions have become unusable, for example, vibrations of the gearbox lever, knocking noises when switching from 1st to 2nd gear. The car must be equipped with original spare parts only.

Engine mount replacement process

We remove the protection from the engine to make it easier to reach the necessary parts. First of all, you need to fix the engine with a jack; this can be easily done in the inspection hole by placing a crossbar from a large board so that it supports part of the weight of the engine. This is done so that when you unscrew the support, the engine will sag and there will be nothing to support it.

Raising the engine as much as possible so that it is convenient to unscrew the mounting bolts, remove the mount. In the reverse order, we install the new pillow, tighten the bolts well and move on to the rear pillow, this is where the dance with the tambourine begins, since as the car moves, it bears the heaviest load. As a result, not only the fastener itself, which is not the same in shape as the previous ones, bends, but also the fastening bolts are deformed.

It will no longer be possible to lift the engine; it is better to tie it to a beam from above or put a crossbar on the glasses and tie the engine to it, having previously lifted it with a jack. Some vehicles will require you to remove pants or other parts that may interfere with replacement. If the fastening bolt is severely deformed, you will have to cut it off with a grinder, otherwise there is no way to unscrew it, some drivers straighten the bolt, but this does not last long, after a while you will have to align it again or replace it with a new one.

In order to remove the cushion from its seat, lubricate it with oil or WD-40; often, due to dirt, the cushion can simply rust to the frame. An important point is the installation; on the rear cushion there is a guide, or in other words, an arrow that indicates the direction of movement of the car; it should not be confused, as after a while it may break again. Having assembled everything in reverse order, we move on to the right engine mount. This support also has a problem with deformed bolts, but the main problem is the generator or air conditioning compressor. As we remember, it is not recommended to remove the air conditioning compressor, since as a result of depressurization all the freon will come out, and refilling will cost even more than the airbags and replacement.

For most foreign cars, the right airbag is located closer to the right front, so the right headlight and radiator grill are often removed, thus simplifying the replacement procedure.

Having made room for removing the cushion, we are faced with the problem of deformation of the bolts; there is no way to cut it with an angle grinder, as it can damage adjacent parts or you simply won’t be able to reach the bolts. I would advise you to take a hacksaw and slowly cut off the bolt; although the procedure is long, it will still not damage the adjacent parts. Having removed the pillow, install a new one in the reverse order; be careful with the radiator, as you can cut your hands on its honeycomb.

VAZ 2110: replacing the gearbox cushion on your own

Replacing the box cushion

If the car has been in use for more than three years, it starts to knock somewhere and a squeak comes out somewhere. When accelerating or driving on broken roads, a knocking sound begins under the bottom of the car. A knock can also be heard at the location of the gearbox. For a VAZ 2110, replacing the gearbox cushion, which will be discussed in the article, can completely solve the problem. Replacing the VAZ 2110 gearbox cushions is a simple matter that anyone can handle.

Replacing the wing cushion with your own hands

Begin:

- we place the car on the overpass;

- we go into the salon;

- remove the cover and the plastic handle on top;

- Use special pliers (platypus) to remove the retaining ring;

- we climb under the car;

- The rocker pad is held in place by four nuts that need to be unscrewed.

Note. It is worth noting that the standard ring can be removed very easily, because it has special lugs. If you bought a new imported set of backstage cushions, then there is another locking ring without ears, but it is better not to install it, but to use the old one.

After replacement, defects in the backstage support are not detected in most cases. Assembly is carried out strictly in the reverse order: a support is installed, which is secured with nuts. It is necessary to consolidate the above listed theoretical aspects of replacing the backstage cushion with the help of photo and video materials. Instructions on how to do the replacement yourself will be most effective if you have some visual reinforcement. In most cases, the price of the issue is small, but everything depends directly on the quality of the part itself. You can also find out about replacing the short-stroke rocker on our website.

avtoexperts.ru

In today's article we will talk about such important elements of the transmission as gearbox mounts. Many car enthusiasts do not even know what they look like or where they are until these products make themselves felt with various types of malfunctions.

In order to understand and promptly respond to emerging problems with gearbox mounts and resolve the issue with minimal means, we will try to talk about their purpose and malfunctions in more detail.

Purpose

The gearbox supports are designed to secure it to body elements, as well as to suppress vibration and noise when driving.

Device and types

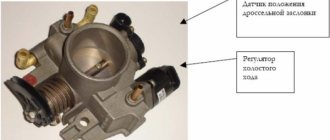

Depending on the design of the vehicle, gearbox supports can be made in different designs. Depending on the type of cushion, the boxes can be rubber-metal or hydraulic.

Rubber-metal

This type of product is a simple design consisting of two metal plates between which there is wear-resistant rubber.

This is the cheapest and most popular type of pillow. Recently, some manufacturers have begun to replace rubber with polyurethane due to its increased wear resistance. This type of support is available in both collapsible and non-dismountable versions.

Hydraulic

These cushions are a more modern design and are able to effectively smooth out any vibrations, adjusting to the operation of the power plant.

The support itself is a housing with two chambers located in it, with a membrane between them. Both chambers contain a hydraulic filler. The purpose of the membrane is to eliminate slight vibration when the car is not moving quickly on a flat highway and the engine is idling.

The liquid in the chambers is responsible for the vibrations that appear at speed. The changing pressure forces it to move between the chambers of the support, increasing the stiffness of the cushion, while dampening almost any strong vibrations.

Basic faults

On average, the service life of gearbox supports is about 100 thousand kilometers or more. However, during long-term operation of the vehicle, the power unit supports experience various loads, plus temperature changes, which negatively affects their condition. The rubber of the cushions loses its elasticity, delaminates, or cracks, and eventually completely collapses.

Large loads on the gearbox supports occur when starting and braking the vehicle. At the same time, if the driver prefers an aggressive driving style, that is, he starts abruptly and brakes sharply, then the airbags simply will not be able to last their service life and will fail ahead of time.

Malfunctions also include collisions with various obstacles, when the support bracket itself may be damaged. In addition to this, oil or antifreeze leakage that gets onto the rubber base of the cushion can also reduce the service life of the support. Plus, there is a high thermal load in the engine compartment with simultaneous splashes of cold water.

Signs of a faulty support

A failed gearbox cushion will make itself felt with characteristic signs. So, when driving or braking the car, unpleasant clicks, jolts, knocks, squeaks and noise will appear in the area of the front of the car.

When driving over various uneven surfaces, shocks will again appear in the front of the car, as well as vibration and feedback to the gear shift lever. Plus, when the support wears out, a characteristic squeaking and clanging sound often appears and can interfere with speed.

On rear-wheel drive car models, if the gearbox mounts are worn out, shifting gears will be difficult, plus the car will vibrate while in motion.

A support malfunction can also be determined by structure-borne noise, for example, when starting and stopping the engine, as well as when the load changes.

Checking status

The condition of the supports can be checked visually. Upon inspection, the product should not show cracks (most often appear along the edges), tears, delaminations, or hardening of the rubber. Sometimes, when hardening, the rubber part peels off from the body of the pillow, which will be visible upon inspection.

When the silent blocks of the gearbox supports wear out, the gearbox linkage fastenings may break, the cushions may become deformed with the appearance of cracks, and eventually the support may burst.

For the presence of backlashes

The malfunction of the gearbox cushion can be determined in the inspection hole or overpass during its inspection. You need to apply force to the box, moving it sideways or up and down, while looking at the condition of the support. You can also apply force to the support using a pry bar. A worn part will “move” with its internal part. The working support in this case will look like a single whole, elastically resisting the applied load.

In addition to the supports themselves, their mounting bolts may fail, which will be visible from the sagging box.

General replacement scheme

Dismantling and installing a new gearbox cushion on most car models can be done with your own hands, without turning to car service professionals. It is enough to have an inspection hole in the garage, not be afraid of dirty work and purchase a minimum list of tools.

To work you must have:

• the necessary set of tools (the list is indicated in the repair manual for this vehicle);

• Safety stands for the engine;

Operating procedure

• The car is placed on the inspection hole, the handbrake is raised and supports are installed under the wheels;

• The battery and battery stand are removed (depending on the design of the car model);

• The body is lifted with a jack, and a reliable piece of board is placed under the power unit across the inspection hole. If the garage has a manual hoist, then only the engine itself is raised;

• Stops are placed on the board and the body is lowered onto them from a jack, thereby unloading the supports;

• The gearbox support fasteners are released and removed;

• Before installing a new cushion, you need to place it on the future location and check the alignment of the holes in the support and the holes in the body. If necessary, you can lower or raise the body a little with a jack;

• A new product is installed, the fasteners are made using the torque prescribed by the manufacturer, and everything is assembled in the reverse order.

Finally

To extend the service life of the supports, we recommend choosing a gentle driving mode, avoiding sudden acceleration and braking. Also, periodically pay attention to the condition of the power unit cushions in order to replace them in a timely manner. It is recommended to check them at every scheduled maintenance or when signs of malfunction appear.

If oil or coolant gets on the supports, clean and wipe them dry, keeping the rubber from corroding.

Replacement

engine mounts on VAZ-

2110

, 2111, 2112

A cushion is an element of a motor support that serves to secure the motor to the car body. Do-it-yourself oil change in a VAZ 2110 engine: which one. Replacing the crankshaft oil seal VAZ 2110 8 valves: video. The support is a rubber-metal structure consisting of an iron body and a thick rubber pad .

The main role of the pillow is to dampen vibration coming from the motor.

On VAZ 2110 , eight-valve engines are attached to the body with 3 supports (two side and rear), and sixteen-valve engines are attached to 4 (two side, lower front and upper front).

Signs and causes of malfunction of VAZ 2110 engine mounts

- A strong hum in the cabin while the engine is running often indicates hard contact of the power unit with body elements. This phenomenon usually indicates the destruction of one of the supports on which the motor and gearbox connected together should rest. If their rubber cracks or even breaks away from the metal base, then the power unit receives an additional unwanted degree of freedom, creating noise.

- A dull knock can also be heard when driving away sharply, due to the engine being misaligned on torn mounts.

- In turn, the torn support is “given away” by a dull knock. every time you press the accelerator and every time you release the gas and switch to engine braking mode.

Sometimes the problem of extraneous sounds lies in the pressed, deformed crankcase protection. After going outdoors, dirt may accumulate in the gap between the adjacent protective sheet and the pan, which also leads to the appearance of an extraneous hum.

The appearance of so-called fatigue cracks in the engine support, which form over time, is also considered critical. They are usually identified by careful inspection of the pillows.

You need to visit a car store, buy the necessary spare parts: 2 assembled pillows (choose from the Volzhsky Rubber Plant or Balakovo);

2 bolts M12x75; 4 washers dia. 12 mm; 2 nuts - 12 mm with nylon insert; 2 bolts M10x25; 6 wide washers - 10 mm; 2 engraving washers - 10 mm; 1 VAZ-2108 timing case bushing. Many owners have dozens of 16kW cars.

engine encounter a knocking noise in the gearbox area, which appears when accelerating the car or when driving on a rough road. Let's talk about the causes of knocking and methods of dealing with it. A strange rattling noise comes from underneath the car and sounds like a knocking noise in the gearbox. There is a knocking sound in the gearbox during vibration (acceleration, driving over bumps). In 2nd and 4th gear the knock is stronger, in 1st, 3rd and 5th it is less. At the service station they shrug their shoulders or point out that the gearbox is broken, as if something has broken inside it. I didn’t want to disassemble the VAZ 2110-2112 gearbox to eliminate this knocking noise. At one service station, I finally came across a knowledgeable person who pointed out the cause of the rattling, it turns out that it was the rocker hitting the transverse rod. And all because the gearbox sagged, because... the distance between the gearbox rocker and the transverse rod should be greater than it was when knocking.

The easiest way to eliminate gearbox rattling, or rather the knocking of rods, is to put a rubber hose on the gearbox rocker. This way the impacts will be softened and there will be no knocking noise during acceleration. It’s cheap and cheerful, but it’s better to eliminate the cause than to deal with its consequences.

So, since the VAZ 2110-2112 gearbox is sagging, then you need to find the cause of the sagging. The first thing you need to check is the nut on the left gearbox mount; often this nut gets unscrewed and the engine sags, and with it the gearbox.

If the nut is tightened, then you need to replace the engine and gearbox mounts. New mounts will raise the gearbox by about 5mm. (depending on the wear of the old engine and gearbox cushions).

Airbag malfunctions

Understand that pillows

They have become unusable based on the amount of engine vibration. If it operates in normal mode, and the body begins to rattle, transmitting vibration to the steering rack, pedal block, and instrument panel, you can be sure that the reason for this is the wear of the pillows.

The greatest vibration is usually observed when the engine starts, as well as when it is turned off. When the rubber cushions are completely worn out, a knocking noise may appear caused by the contact of the engine elements and its supports.

To be more convincing, start the engine, open the hood and visually inspect the engine mounts and the cushions . Replacing the VAZ 2110 clutch without removing the box and draining the oil. Place your palm on the motor and feel how much it vibrates.

The causes of failure of engine mounts can be:

- deformation due to spent life, mechanical or temperature effects;

- loss of elasticity due to “aging” of rubber and temperature changes;

- delamination or cracking caused by exposure to chemically active liquids.

Malfunctions and solutions

Some defects can be eliminated with your own hands, but to do this you need to learn to determine which defect is interfering with the normal operation of the gearbox. The main faults are listed below:

- The lever is loose. The cause may be worn-out gearbox and motor cushions. Also, other parts may be the “culprits”. Below are instructions for replacing the cushions and lever.

- Noise in the VAZ 2110 gearbox when switching. There may be several reasons: parts are worn out, poor lubricant is used or its level has dropped below the minimum, or water may have gotten into the working fluid. In the case of worn parts, only replacement will help. As for the lubricant, its quality and the presence of water in it can be checked with a dipstick.

- The gears are switched off randomly. This defect appears when parts wear out - an inspection is necessary to determine the cause of the spontaneous shutdown. The malfunction also appears due to incorrect operation of the drives that need to be adjusted.

Advice! In order not to waste a lot of time searching for faults, it is recommended to take the car to a service station, where professionals perform diagnostics. Subsequent repairs and replacements can be done by yourself.

Do I need to change

There are no recommendations for replacing pillows depending on their service life, but once you determine that they are faulty, you should not delay replacing them. Replacing the rear window of VAZ 2109 2110 2114 21099 2106, Matiz. Replacing the crankshaft oil seal VAZ 2110 16 valves. Vibration processes can not only worsen the comfort of the driver and passengers, but also lead to destructive processes in the engine or gearbox itself.

Having decided to repair the engine mounting elements, you need to decide whether you will change the pillows

, or support assemblies. In principle, if the metal support itself is not damaged, it can be left, replacing only the pillow.

Replacement

The replacement procedure should not cause much difficulty for those who have independently repaired their car more than once, especially the suspension and chassis.

If you have no experience, then we recommend contacting a service station. Only proven and reliable.

Dismantling works

Replacement has its own nuances depending on the pillows for each engine in question. We will separately talk about the repair of 8 and 16 valve engines.

For eight-valve engines

- Prepare the car for repair: place it on a flat surface, place stops under the rear wheels, remove the engine protection.

- Unscrew the generator belt tensioner bolt and remove the belt (key 13).

- Place the jack under the engine, place a thick wooden beam or board under its upper part. Raise the engine to remove the load on its mounts.

- Unscrew the nut of the central fastening of the right pillow

(15 wrench). - Unscrew the bolts securing the pillow

to the bracket (key 13). - From the bottom side of the right arch, unscrew the 3 bolts securing the bracket to the spar (17 key).

- Remove the bracket and replace the old cushion with a new one.

- Carry out installation in reverse order .

- Move the jack under the gearbox and lift it up.

- Unscrew the nut of the central fastening of the left pillow

(15 wrench). - Unscrew the two bolts securing the support and remove it (key 13).

- Replace it and reassemble the structure in reverse order .

- Unscrew the two 17 nuts securing the cushion to the body, and then two more nuts securing it to the gearbox (removal and replacement of the rear support is carried out from the bottom of the car).

- Remove the rear support.

- Unscrew the nut securing the pillow to the bracket (19mm wrench). Replacing the front crankshaft oil seal VAZ piston replacement VAZ 2110 8 VAZ 2110 8 valves. Remove the old pillow and install a new one.

- Install the rear support in reverse order .

For sixteen-valve engines

Removing and replacing side airbags is done in the same way as for 8-valve engines.

Work to replace the front lower airbag is carried out from underneath the machine.

- Unscrew the bolt securing the front lower support rod to the front suspension cross member (15 wrench).

- Unscrew the nut of the bolt fixing the support to the engine bracket (2 wrenches x 15). Remove the bolt

. - Remove the support, replace the pillow or the entire structure.

- Carry out installation in reverse order .

- In the engine compartment, unscrew the bolt securing the upper front support to the body, holding its nut with your hand (17 wrench).

- Remove the bolt

and nut. - Unscrew the bolt securing the front upper support to the engine bracket (15mm wrench). Remove the bolt

and nut. - Remove the support, replace the pillow or the entire structure.

- Install it in reverse order .

Left support - removal and replacement

- We drive the car into a pit or onto an overpass;

- Remove the engine splash guard (protection);

- We install a jack under the gearbox (it is better to place a small wooden block between the jack and the gearbox) and lift the box slightly, thereby freeing the left support;

Take a 15mm socket wrench with an extension and unscrew the support stud nut;

Remove the upper support stop;

We release the jack a little so that the box drops slightly and remove the support pin;

After this, using a 13mm socket wrench, you need to unscrew the 2 bolts that secure the support cushion to the body bracket;

Slightly move the cushion towards the engine and remove it;

Remove the lower support stop.

Installation of the new left support (cushion) must be done in the reverse order. To prevent the pin from turning, you need to make sure that its protrusions fit into the oval hole in the gearbox housing bracket.

Installation of an additional lower gearbox (engine) support for Lada Priora

Lada Priora is a modernized version of the VAZ 2110; the design of these cars has many of the same parts, for example, doors or body parts. This allows you to adopt some improvements from the “ten”, one of which is the installation of an additional gearbox cushion.

On 8 valve engines the factory installed a rear gearbox mount, but on 16 valve engines they have already abandoned it. As practice and reviews from VAZ 2110 owners show, installing an additional gearbox support is a useful modification that can make the operation of the car more comfortable.

On Priors with 16 valve engines, the rear gearbox mount is also missing, but the attachment points to the body remain.

Gearbox - device and location

The VAZ 2110 has a five-speed manual transmission with two shafts. There are two main tasks of the checkpoint:

- Speed change - due to a change in torque, speed modes are switched.

- Direction of movement - shifting to reverse gear causes the crankshaft to spin in the opposite direction, as a result, the car goes backwards.

The box in the VAZ 2110 car consists of two shafts - the drive and driven, which are also called the primary and secondary. Each ox has a block of gears, due to which the torque is adjusted. Also in the gearbox housing there is a main gear (using a clutch it is connected to the crankshaft) and a differential. The mechanism for changing speeds is a lever that goes into the car interior. To get to the box, you need to remove the fasteners both in the hood and under the car. Together with the engine, the transmission forms the power plant.

Installing an additional gearbox cushion

- Rear cushion of the VAZ 2110 gearbox (8 cells), catalog number 2110-1001286/50;

- 2x Bolt M12*80 or M12*75;

- 2x Nut M12 with plastic;

- 4x Washer baud bolt M12;

- 2x Bolt M10*35 or M10*25;

- 2x Grover for M10;

- 4x Silent block washer;

- 2 keys “19”;

- key "17".

- We fasten the additional support to the gearbox with two M12 bolts, using two “19” keys;

- We fasten the pillow to the body with M10 bolts using a “17” wrench;

- Make sure that the support is not stressed and there is a gap in the indicated place (if necessary, place washers under the bolts).

The lever is loose: do-it-yourself repair

To determine why the handle is loose, it must be removed. The work is carried out according to the following scheme:

- The lever holds the housing, so it must be removed, but the lever must remain in place. This operation is performed using the key at “13”;

Reviews after installing the rear gearbox support

The purpose of the rear mount of the power unit with the engine is to reduce the load on the front and rear engine mounts and reduce the rolling of the gearbox. In other words, after installing the additional gearbox support:

- The engine jerks less when starting to move, when changing gears or when you sharply press/release the gas pedal;

- The rattling of the gearshift knob has decreased;

- Shifting into gears has become clearer, especially 2nd.

Many Lada Priora car owners notice that after installing an additional airbag, vibration appears at idle, the reasons may be the following:

- the engine mount is made of low-quality rubber, it is better to choose another manufacturer, for example, BRT;

- The gearbox cushion is not installed correctly (in tension), as a result of which it does not dampen vibration from the power unit;

- other engine mounts are worn.

Have you installed an additional gearbox cushion on your Priora? Share your feelings after revision. Let us remind you that body reinforcements/struts are also very popular among car enthusiasts?

Design and purpose of tens engine mounts

Over the years, vast practical experience has been accumulated on the topic of how to change engine mounts on a VAZ 2110, and videos of repair processes can also be found in abundance. However, few people pay attention to the features of the part. And, it must be said, it is in vain, because such knowledge will help to accurately determine the source of vibration and purchase the necessary spare part for repair.

The main purpose of the engine support is to reduce the level of vibration transmitted from the power unit to the car body. The rubber-metal structure consists of a steel base with a thick rubber cushion. The device has proven itself well, since it is quite reliable and is worth the money.

The eight-valve Lada 2110 engines are attached to the body at three points: right, left and rear. The side supports connect the body to the engine block through through holes. The rear support is attached with two bolts to the gearbox, and two nuts to the body. The importance of this damper part is very significant - it prevents longitudinal vibrations of the internal combustion engine during braking and acceleration.