Modern “tens” are equipped with many different electronic devices and components that perform various functions. One of the important elements is the crankshaft sensor on a VAZ 2110 car. In this article we will talk in detail about the purpose and symptoms of a malfunction of the regulator.

What does the crankshaft sensor do?

DPKV synchronizes the phases of fuel injection and pulse supply to ignite the combustible mixture in the combustion chamber. In other words, based on its readings, the controller determines when and into which cylinder the fuel mixture should be supplied.

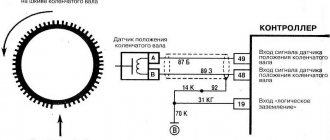

The sensor is of the inductive type and reacts to the passage of the teeth of the drive disk on the generator drive pulley near its core. The teeth are located on the disk at 6° intervals. To synchronize with TDC, two teeth out of 60 are cut off, forming a cavity. When a depression passes by the sensor, a so-called “reference” synchronization pulse is generated in it.

Crankshaft position sensor on a VAZ 2110: how to check?

It is no secret that the engine control of the “tenth” model of the domestic automaker AvtoVAZ is carried out through the operation of a computer. Various sensors take data and send it to the main computer, which distributes the operation of the systems.

It is noteworthy that only this element is capable of keeping the engine running if the regulator fails. The task of this sensor is to synchronize the ignition system and the fuel supply system.

If the device breaks down, synchronization is disrupted. Consequently, the entire system malfunctions. There is no spark, no fuel is supplied. The engine may behave strangely for a while, but then it will still stall.

A little history

The VAZ 2110 was produced from the end of the 20th century until the middle of the first decade of the 21st century. During its existence, the top ten managed to gain a huge number of fans and underwent a large number of changes.

The tenth VAZ family was initially equipped with 8-valve carburetor engines that had common roots from the G8 engines. Time moved forward and AvtoVAZ needed to develop further, and at the end of the 90s, an injection engine was installed on the top ten for the first time, which was distinguished not only by a new injection system, but also by the number of valves; some new engines received a doubled number of valves from 8- mi to 16.

To operate an engine with an injection system, you need a huge number of different sensors responsible for the operation of the internal combustion engine, and the VAZ 2110 is no exception; the dozens of injection engines have many different sensors installed that ensure correct and smooth operation of the engine.

In this article we will talk about VAZ 2110-12 sensors, their symptoms of malfunction and installation locations.

How does he work

Let's figure out how this element works. The regulator reads data on the crankshaft speed and also reports its current position using magnetic pulses.

Location

Since the engines installed on the VAZ 2110 differ from each other, different PCV sensors are used. Therefore, when replacing, be sure to choose a similar device, since a regulator with other characteristics simply will not work, so the system will still not work even if you have a high-quality, serviceable sensor.

Device and classification

Despite the fact that the VAZ crankshaft sensor may have a different design, its operating principle is based on a single electromagnetic effect. That is, the signal is generated without direct contact with the crankshaft.

The most common type of DPKV is induction. Such a part consists of two main elements - a magnetized rod and a special winding. Induction sensors read information from the crankshaft toothed pulley. When a metal tooth passes near the DPKV, an EMF is formed in the latter, which is captured by the electronics. On the VAZ-2110, the crankshaft sensor is installed of the induction type.

DPKV can also be based on the Hall effect. Such a sensor is constructed in approximately the same way as an induction sensor, however, when a metal shaft passes near it in the winding of the device, the resistance changes. Structurally, it consists of a permanent magnet.

It should be noted that both the first and second types of sensors are used to read data from the crankshaft pulley. It can be toothed or all-metal. In the latter version, there is a special recess that passes by the sensor and generates a signal that is sent to the vehicle’s electronic engine control unit.

Symptoms of a problem

If you have a multimeter and a regular screwdriver at your disposal, you can independently check the operation of the device without any problems.

Unscrew the nut

Signs of a faulty crankshaft sensor include:

- A warning light comes on on the dashboard, recommending that you check the engine;

- When idling, the engine behaves unstable;

- Thrust drops;

- Engine speed drops and rises;

- Detonation occurs, that is, shots from the intake or exhaust manifold;

- The engine cannot be started.

Main symptoms of breakdowns

But if the device has not completely failed, but is only showing signs of breakdown, you will see it immediately. A light will light up on the instrument panel to indicate engine errors.

This will be accompanied by the following signs:

- Unstable idle.

- Reduced traction characteristics of the vehicle.

- Spontaneous change in engine speed.

- Difficulty starting the engine.

- The presence of pops in the intake manifold.

If such symptoms are present, you need to replace the VAZ-2110 crankshaft position sensor. It is located near the oil pump cover, next to the generator drive pulley.

Examination

Before you can check it, you first need to get to it. And the device is located in a not very convenient place on the engine. So be prepared to spend some time on this.

In general, the sensor we are looking for is located on the oil pump cover. You need to look for it directly near the generator pulley.

Now to the question of how to check it. Let's look at the two most common situations, but first, let's remove the element.

- The sensor is removed with a 10 mm wrench;

- Be sure to make special marks on the crankcase and sensor before removing. This will allow you to return it to its original place, or install a new regulator in the correct position;

- If there is no external, visible damage to the crankshaft sensor, then you need to use a multimeter;

- Don't forget to measure the distance between the sensor and the timing disk. In the normal position, the gap ranges from 0.6 to 1.5 millimeters.

First way to check

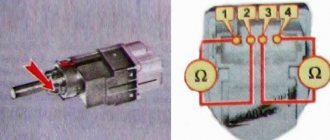

In this case, you will need an ohmmeter , which you will use to replace the resistance on the winding. According to the manufacturer's standards, the indicator ranges from 550 to 750 Ohms.

It's okay if your numbers are slightly different from the norm. If the deviations are serious, you will definitely have to replace the sensor.

It should be noted in fairness that the crankshaft position sensor on VAZ 2110 models rarely breaks down. Among the main reasons for its failure to function normally is the accumulation of dirt, mechanical damage, as well as banal factory defects.

Second method

Here you will need a voltmeter, a transformer and an inductance meter. It is advisable to measure resistance under compact temperature conditions.

Once the ohmmeter readings are obtained, arm yourself with an inductance measuring device. Normally, the device should show from 200 to 4000 units (millihenry).

A megger measures the resistance when the crankshaft position sensor winding is powered at 500 volts. Under normal conditions, the readings will be no more than 20 MΩ.

Device diagnostics

The performance of the crankshaft position sensor is checked using a special tester. All diagnostics involve measuring the resistance of the DPKV winding with an ohmmeter. Normal values should be between 800 and 900 ohms. If the received data does not meet the standard, you need to check the quality of the contact connections. If this does not help, a new part is purchased. Replacing the crankshaft sensor itself is so simple that even a novice motorist can handle it.

Sometimes it happens that the malfunction of this device is caused by mechanical damage to the winding. This often happens when performing any repair work in the engine compartment of the car or some foreign object forms between the pulley teeth and the DPKV. In this regard, many motorists recommend carrying a spare crankshaft position sensor in the trunk. The cost of it is very small, but it is of colossal importance for the operation of the engine.

Replacement nuances

Replacing the sensor is quite simple. It is removed from its habitat, and a new device is installed in its place.

Installation location and fasteners

However, it is important to take into account some nuances.

- Choose high-quality auto parts, which should be purchased in specialized stores. It is advisable to check their performance on site.

- When installing a new regulator, maintain the original position. To remember it, mark it with a marker or chalk.

- Be sure to maintain the required distance between the sensor and the timing dial. We have already told you the normal clearance indicator.

- The bolts must be tightened with a torque not exceeding 8-12 nm.

- Test the new sensor before it is used in the fuel system. An incorrectly selected device can lead to a number of other malfunctions and failure of the power unit.

It’s not difficult to independently check and change the crankshaft position sensor on a domestic “ten”. The most problematic stage of the work is gaining access to the device, since it is hidden quite far away. However, if you cope with this, all subsequent events will seem like a mere trifle to you.

Just don’t relax under any circumstances, act carefully, consistently, follow all the labels and rules for replacing the device.

What does DPKV do in a car?

As the name implies, the crankshaft position sensor reads and transmits to the on-board computer information about the state of the crankshaft at a particular moment. The control system then gives a signal about the correct distribution of the fuel mixture between the cylinders.

DPKV in the vehicle system

That is why, if there are malfunctions associated with this device, then the computer “freezes in bewilderment” and cannot supply the fuel mixture, since it has no information about what it should be, and also cannot ensure synchronization of the operation of the injectors and the ignition system.

This is how a small device can block the operation of an entire car. Therefore, if it fails, there can only be one solution - immediate replacement. Moreover, repair is impossible, and in general, it makes no sense, if only because of the cheap cost of the product.

see also

Comments 52

Please tell me. I wanted to change the crankshaft sensor on a VAZ 2110, I bought a new one, the car won’t start. I bought another one and the car won't start. I bought a third one, everything seems to be fine, but when you sharply press the gas at speed to accelerate, at a certain moment you feel a failure. As a result, I bought five crankshaft sensors, three of them won’t start at all, and with two of them such nonsense is happening. What could it be. I install the old one, no problems at all.

Please tell me. There is a problem, the car jerked and stalled at a traffic light. And the crankshaft sensor gave an error. I replaced the sensor, the problem remained. What could it be?

Hello everyone The problem is this: there was a non-standard immobilizer and decided to turn it off and as a result the spark disappeared. What could be the reason ?

And I’ll address my problem) error 0335 popped up - DPKV malfunction, followed immediately by 0328 - knock sensor - high signal level. The on-board vehicle does not reset, the car does not pull. The question is this: can a faulty DPKV cause detonation?

Good evening! Please tell me, my 10 on my way to work suddenly stalled. I pulled it home and found that there was no spark. I thought that the ignition module was screwed up, I changed it and nothing changed, I don’t know what to do anymore. Tell me please

look at me here: I made a recording a long time ago: www.drive2.ru/l/10392503/

Good afternoon! Tell me if you can, I have a VAZ 21102, back in the summer I started having problems with the engine. When I was driving along the highway, the car just started losing speed to idle and stopped driving, after standing for a while with the engine turned off, it drove normally again for 5-10 km and according to the new one, but when I was driving, it pulled in the entire range, then there were cases that the car would not start, and after a while the filled spark plugs had dried, it would start as if nothing had happened, in winter there are no such problems, there is another problem - the engine accelerates poorly and revs poorly speed, you have to press the gas to the floor after changing gears, and then reduce it as you accelerate, the check light does not light up and did not light up, the diagnostics show nothing, the module, wires, spark plugs are new, many sensors have similar signs of malfunctions, I don’t know what to do, in advance thanks for the help!

Symptoms of problems

The very first and surest manifestation of a malfunction of the DPKV is that the engine shows absolutely no “signs of life”. In addition, the fact that perhaps the device has not yet completely failed, but is already experiencing interruptions, can be judged if:

- The engine runs unstably at idle;

- The car's power is felt to decrease;

- The number of crankshaft revolutions spontaneously increases or decreases;

- As the load increases, engine detonation is clearly felt;

- The machine starts intermittently.

Engine VAZ 2110

Of course, having only these signs, we can also assume other malfunctions, so you need to check not only the sensor, but also everything that has to do with starting the engine - from the wiring to the fuel pump.

Algorithm of operation of the injection system

The microprocessor has several inputs and outputs. The inputs receive signals from all sensors. But first, these signals are converted and, if necessary, amplified. The microcontroller is programmed to work with sensors and actuators. Programs (firmware) can provide various engine characteristics.

You can achieve an increase in power (gasoline consumption will increase) or a decrease in consumption (power will suffer). But most motorists prefer programs that provide work with average parameters. In this case, the signal from the VAZ-2110 crankshaft position sensor does not change; only the reaction of the actuators to changes in input data is adjusted.

To change or not to change?

Let’s make a reservation right away: before deciding that the DPKV needs replacement, you need to check:

- Condition of the wiring going to the DPKV;

- Availability of high-quality contacts in the circuit;

- No damage to wire insulation;

- No oil on the crankshaft position sensor. Since the oil pump is located next to the DPKV, oil leakage can also cause its malfunction.

Functional crankshaft position sensor

If you have already examined everything, you need to check the sensor itself. But to do this you need to remove it.

Removal

Removing the crankshaft position sensor is very simple, and you already know where it is located - in the same place as the oil pump. So, let's do the following:

- Turn off the ignition;

- Remove the negative terminal from the battery;

- Remove the connector with the wire from the sensor body;

Disconnect the wiring harness from the crankshaft position sensor - Using a 10mm wrench, unscrew the screw holding the DPKV to the oil pump cover;

Unscrew the bolt (1) and remove the DPKV (2) - We remove the device.

Functionality check

To check whether the crankshaft position sensor is working, you need to measure the resistance of its windings using an ohmmeter or multimeter. Normal readings are 550 – 570 Ohms.

If they differ from these numbers, then a replacement with a new one is needed. The old one cannot be repaired, but it is inexpensive, and replacing it is as easy as shelling pears, following the reverse removal algorithm.

Sources

- vazweb.ru/desyatka/dvigatel/datchik-kolenvala.html

- luxvaz.ru/vaz-2110/90-datchik-polozheniya-kolenchatogo-vala.html

- osensorax.ru/posiciya/datchik-kolenvala-vaz-2110

- drive2.ru/l/6251079/