Knock sensor - purpose

Content

The controller responsible for regulating the ignition timing by reacting to fuel combustion is called a knock sensor. Its work is aimed at ensuring traffic safety and preventing emergency situations caused by unsystematic processes in the fuel tank. This is what the VAZ 2110 knock sensor does - it prevents troubles associated with the presence of a detonating air-fuel mixture in the engine. In a state of optimal performance, the device exists in a sleeping state. In a situation where detonation occurs, it determines its level and sends the value to the computer. There the advance angle decreases. Until the problem is resolved, correction continues.

Detonation is an out-of-system, uncontrolled processing of fuel and lubricants in the combustion chamber. The reasons for its occurrence: low-quality gasoline, incorrect advance angle, incorrect operation of spark plugs.

Optimal operation of the knock sensor protects the engine from overheating, promotes economical oil and gasoline consumption, and generates the necessary strength and power indicators.

If the knock sensor fails, the machine goes into safe mode, which reduces engine power and increases costs by increasing fuel consumption.

What is this?

To understand the essence of this device, let’s name its key features.

- DD, that is, the knock sensor, plays one of the main roles in the functioning of the engine. The device is responsible for controlling the degree of detonation and can determine the causes and nature of such a phenomenon. By supplying the appropriate information from the DD to the electronic control unit, characteristics that can lead to unwanted detonation are corrected.

- AvtoVAZ engineers could specifically place the DD in such a way that if problems arise with it, the driver could quickly and efficiently fix the problem. Alas, for some reason this was not done. Therefore, you will find this sensor on the engine block between its 2nd and 3rd cylinders. You need to look from the radiator side. Despite the inconvenient location, due to its reliable design, the developers still managed to minimize the likelihood of its failure. But this does not protect against breakdowns 100 percent. Therefore, sometimes the DD still needs to be replaced.

- For the VAZ 2114 model, several types of DD are used - broadband, with 1 and 2 working contacts, as well as resonant ones.

- The functioning of the DD is based on the reaction of the piezoelectric effect. Therefore, the main component of the element is a piezoelectric plate. They begin to generate energy as soon as detonation voltage vibrations occur. It increases depending on the frequency of oscillatory movements. The voltage from the sensor is transmitted to the control unit, which automatically adjusts the ignition timing, while debugging the ignition reaction of the fuel and air mixture.

DD location

Detonation phenomenon

First you need to understand the features of this phenomenon.

Externally, detonation manifests itself in the form of metallic sounds. With such noise, drivers usually say that their fingers are knocking.

But the occurrence of detonation is associated with an imbalance in the characteristics of the gasoline combustion process and a violation of the ignition timing. Because of this, the pressure and temperature inside the combustion chamber seriously increases, which leads to mini explosions of the air and fuel mixture. This manifests itself in the form of a sound similar to metal objects hitting each other.

Internal structure and specifics of DD

The sensor is reliable because it consists of a monolithic material of the same name, which forms a system of interaction between a specific plate and a piezoelectric element. This part resonates with mechanical vibrations of the required frequency. They are interconnected with the same frequency that occurs during fuel processing.

The resulting current with minivolts of voltage is tracked in metrics and sent to the computer. Based on this value, the electronics adjusts the ignition timing, increasing or decreasing it. This neutralizes the consequences of uncontrolled detonation of low-quality fuel and lubricants.

What are the symptoms of a broken knock sensor?

Separated from the entire system, the controller itself is reliable and rarely subject to mechanical damage. Its work is influenced by a number of indirect factors.

A decrease in its functionality may be suspected in the following cases:

- engine slowdown;

- increasing speed at minimum speeds;

- when the car has problems accelerating;

- if fuel consumption has increased compared to normal levels;

- with uncharacteristic engine knocking and spontaneous jerks (engine trouble).

Code indicator 34 is a signal of DD failure. The on-board computer sometimes makes mistakes; you can check the validity of its readings like this. To confirm, reset the self-diagnosis, drive several kilometers, and if the error readings disappear, it means the sensor terminals are loose or oxidized while driving.

Error 325 indicates a break in the knock sensor of the VAZ 2120, sometimes under this sensor fault code, the ECU stores the location of the throttle valve. To verify this, find in the menu the voltage value in the sensor of interest; if there is a problem with the damper sensor, the indicator in the menu will jump, but for the DD it will remain static.

Can the device fail?

Like any other part, this device may stop sending a signal to the ECU.

This may indicate a temporary failure or complete failure of the device. This can happen due to:

- the presence of large corrosive formations;

- wiring violations (this indicates an open circuit);

- serious malfunctions that occurred due to the device being broken;

- incorrect replacement of the device itself.

But are there any signs of trouble? Undoubtedly. A breakdown may be indicated by uncharacteristic engine behavior, which manifests itself in:

- a clear drop in engine power;

- a sharp increase in speed at low speeds;

- significant deterioration in car acceleration performance;

- increased consumption of fuel fluid.

Sources of DD failure

One of the main reasons is an open circuit, for this they check the terminals, then the wires ring, and when the engine operates more than 3000 rpm, self-diagnosis is activated.

If the electrical circuit is OK, you need to look for the problem in the controller itself. To dismantle the VAZ 2110 knock sensor (its location is problematic, between the cylinders) of the old model (resonant, single-contact), you need a socket wrench No. 13. For the new model of the sensor (broadband, two-contact), a key of 22 is required.

Testing with a Multimeter

A highly sensitive voltmeter is taken in the mode up to 200 MV; in the new sample, both connectors are connected to the meter.

In the old model, the first contact is attached to the probe of the device, the other is connected to the body. A massive object, a key or pliers is tapped without force on the body, changing the power, the voltmeter needle should react sensitively and deviate in proportion to the force of the impact. If this does not happen, the device has worn out and needs to be replaced. Move the multimeter controller to the resistance scale. The load in a working sensor will be from 1 to 10 MOhm. A broken controller will show an infinite value, and a broken one will show too small, less than 1, about a few tenths of an ohm.

Another diagnostic method is recommended to check for the presence of voltage on the DD. The multimeter is switched to the millivolt scale, the “+” probe is connected to the connector that supplies the signal, the negative probe is thrown to the ground of the sensor (the hole from the motor mounting bolt). DD, hold in your hand and tap on some hard metal surface, numbers from 30 to 40 mV should appear on the scale. If the display is empty (potential difference), this indicates a sensor malfunction.

Methods for self-diagnosis of DD in old and new samples are almost the same. The method of checking an existing sensor is also suitable when checking a new instance. It is better to do this directly at the time of purchase.

If, after replacing the sensor, the ECU still detects that it is faulty, then detonation occurs for indirect reasons: it depends on the quality of gasoline, there are problems with compression, the spark plugs are either burnt out or flooded.

How to check functionality?

If error code 34 appears on the display, this indicates a sensor malfunction. It is possible to check whether it is still operational or whether it needs immediate replacement. Having completely reset the self-diagnosis results, you need to drive a couple of kilometers and turn on the self-diagnosis system again.

If a new check shows an error again, then replacement is still necessary. If the error is not displayed, then you can still operate the old device. But since code 34 was still displayed earlier, it’s worth checking the connection for a break, that is, carefully inspect the wires, contacts, tighten them, clean them, and you’ll see that replacement won’t be needed.

Errors on the instrument panel display

Considering that the VAZ 2110 can drive for some time without a knock sensor, you can carry out a more thorough check of it, but for this you will have to remove the device.

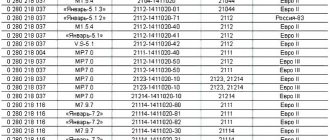

List of errors associated with DD from the on-board computer

The cause of the failure can be found out by analyzing the error signal on the console:

- 0325 indicates a break in the DD circuit, which can be eliminated by cleaning the sensor connectors from oxidation and ringing the wiring;

- 0325 may also indicate that the timing belt is shifted by one tooth; it is necessary to check that the belt is installed correctly;

- 0326, 0327 indicates a low controller signal, requires checking the connectors, securing the nut with a force of 10-23 Nm, the action is performed with a special torque wrench.

- 0328 - the control signal is higher than normal, may appear when the electrical circuit is broken, a piercing element, or a faulty DD.

Old and new sensors

Design of the knock sensor

The old-style resonant knock sensor of the VAZ 2110 monitors vibrations of a limited frequency spectrum, has the smallest indicator error, and high accuracy. It is equipped with VAZ 2110 cars from 2002-2003. This is a single contact controller.

The wideband controller reads the signal of all frequencies that arise during movement, its readings are approximate due to the wide range of received signals. From an electrical point of view, it is a two-pin device.

The sensors are not interchangeable, so purchase and installation must match the original part sample.

The controllers are screwed into the cylinder block on the left. Replacing it takes a few minutes.

Dismantling

First you need to find the sensor. It is located on the left side of the engine, where the line is half of the cylinder block. Next to it is the air filter.

To determine the malfunction or its absence, it is necessary to remove it in the following sequence:

- Disconnect the car from power by removing the negative terminal from the battery;

- Disconnect the block with wires from the contacts of the knock sensor. To do this, press the latch;

- Unscrew the nut securing the device and remove it from the mounting stud.

Please note that during further installation or replacement you will need a torque wrench (tightening force should be 20 Nm).

Replacing the knock sensor

Replacing a knock sensor

Replacing a resonant sensor with a broadband sensor is possible provided that certain operations are performed:

- production and purchase of additional parts (microphone cable (shielded), sensor mounting pin, sensor connector; new chip for the ECU.

- installation of the cable to the 1st contact of the connector, the screen to the 2nd contact;

- pulling the cable to the ECU to pin 11 (pin DD);

- pulling the screen to ECU pin 30 (sensor ground);

- removing the ECU, disassembling, removing the chip (the chip is not soldered);

- installation of a new w27c512-45 chip;

- Firmware download (m1d13a64) from an on-board computer repair company.

- installing the chip in the ECU, returning the ECU to its place.