Ignition of gasoline in the cylinders of an internal combustion engine occurs using a spark generated by the ignition system. The ignition module is the main element of the system, creating a spark on the spark plugs using high voltage. Each car manufacturer develops and produces its own original module, but the principle of its operation is the same for all devices. During operation, deviation from the specified parameters or breakdown of the ignition module negatively affects engine operation until the power unit fails.

How module malfunctions are shown by diagnostics

By visiting a service station or using amateur diagnostic equipment (error scanner, a special application and an adapter for computer diagnostics via Bluetooth), you can also find out that the “root of evil” is in the ignition module.

In this case, the following error codes should be displayed:

- P3000 (P3001, P3002, P3003, P3004) - ignition in the cylinders does not work;

- P0351 - break in the winding of a pair of cylinders 1-4;

- P0352 - break in the winding of a pair of 2-3 cylinders.

However, it is not at all necessary that the results of engine diagnostics indicate the “death” of the module. High-voltage wires (for example, breakdown) and spark plugs can also create problems. Therefore, it is recommended to first go from small to serious. And only if other elements of the ignition system are fully operational does it make sense to start checking the module.

Methods for diagnosing device performance

The simplest method that will help determine the performance of the coil is to replace it with a similar working device. This is possible if there is somewhere to get it. Please note that the module must match the parameters of the device under test . If the engine with a working coil works as before the breakdown, the ignition module is definitely faulty.

The main testing method involves using a multimeter. It consists in determining the resistance of the secondary windings of the coils built into the ignition module. The method is simple and does not require additional skills. The device does not need to be removed for testing. The check is done with the engine turned off.

This is how you check the resistance of the secondary winding with a multimeter

Video: How to check the secondary winding with a multimeter

Ignition module

Causes and Symptoms of faulty spark plugs and ignition coils. Signs of faulty ignition coils

The ignition module is designed to generate the high voltage necessary to form a spark discharge between the electrodes of the spark plug.

Ignition module design.

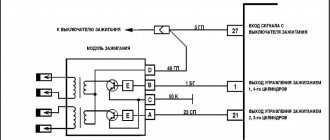

The ignition module consists of two ignition coils with a closed magnetic circuit and a two-channel switch. But a twin ignition coil without a built-in switch is also called a module. In this case, the switch is displayed separately, but most often it is combined with the electronic engine control unit. Such modules can be distinguished by the number of wires on the connection connector. The ignition module with switch has four wires in this connector, but the twin coils have only three. This is due to the need to connect the negative wire to the switch, while the coils receive negative through a switch in the ECU or installed separately

This difference is very important when troubleshooting

Ignition module malfunction.

A malfunction of the ignition module is characterized by the absence of a spark discharge or a weak discharge on a spark plug, a pair of spark plugs, or all spark plugs.

It is important to use a spark gap when checking the spark discharge. Checking the spark discharge for a break or by connecting a spark plug placed on the housing to the wire can lead to failure of the ignition module or electronic engine control unit

The easiest way to check a module is to replace it with a known good one. But if this is not possible, then you will need to check the serviceability of the secondary coil by measuring the resistance between the terminals on spark plugs 1-4 and 2-3. The resistance value in this case is about 4 - 5 kOhm, the exact value depends on the manufacturer. But if the value is less than 4 kOhm, then most likely there is a turn short in the secondary coil, and if the module is new, then the manufacturer is saving money, which affects quality. Very high resistance indicates a break in the coil

When measuring resistance, you need to pay attention to the difference in resistance of the coils of one module. This difference should not exceed the instrument error value

The primary coil and switch can only be checked on a bench.

In addition to a malfunction of the coil windings in the module, the built-in switch may be faulty. The switch is made on a printed circuit board consisting of several microcircuits and filled with heat-dissipating gel. It is located on a metal plate at the back of the module, which serves as a heat exchanger. The specific switch design depends on the manufacturer. A common cause of commutator malfunction is poor contact between the commutator and coil connections. If you have the desire and experience in repairing electronic boards, you can try to disassemble and repair, but it’s easier to change the module.

Malfunction of the ignition module without a built-in switch (dual ignition coil)

In contrast to the module, the absence of a spark on the spark plugs with a dual ignition coil may indicate a malfunction of not only these coils, but also a malfunction of the electronic engine control unit. The thing is that the switch in this case is built into the ECU. On some foreign cars the switch can be made separately. In this case, you can check the coils by measuring the resistance of the windings. The actual resistance value varies by brand and manufacturer. For the primary winding, the resistance should not be less than 3 ohms, and for the secondary winding less than 4 kohms. But the difference between the coils of different pairs of terminals should not exceed the error value of the device used to make the measurement. A breakdown of the secondary winding to ground is also possible, although this happens extremely rarely. Finding such a malfunction is quite difficult, but the breakdown mainly occurs along microcracks on the body and breaks through only one terminal, and the spark disappears only on one spark plug of the pair.

Troubleshooting the ignition module.

The easiest way to find a faulty ignition module is to replace it with a known good one or replace the module being tested in a working car. The second way to determine serviceability with a degree of probability is to measure the resistance of the coil windings. Since the original value is almost never known, it is better to simply compare the value between the coils. The third, most accurate, but also the most difficult method is to check the module on a stand. In this case, the stand can be either factory-made or home-made. The latter can be made using a carburetor nine distributor driven by a drill. To check the double coil in this case, you can use a commutator from the same nine.

“If you notice an error in the text, please highlight this place with the mouse and press CTRL+ENTER”

Is the renovation still relevant?

When the symptoms have been identified and the ignition module has been diagnosed, it’s time to decide: try to “save” the old device, or replace it with a new one. The choice is not an easy one, especially considering the fact that repair of the ignition module is possible only on contact connections; in rare cases, it is possible to replace the coil or transistor. For a complete repair we will need:

- Screwdriver;

- Hexagon 5;

- Soldering iron;

- Multicore cable;

- Socket wrenches for 13 and 17;

- Nail polish;

- Flux for aluminum.

We repair the ignition module in the following order:

- We dismantle the device;

- Use a screwdriver to open the case;

- Carefully get rid of the silicone film, which probably covered the entire board;

- All aluminum in the area of explosive contacts is cleaned.

- We remove absolutely all the wires from the board and solder new ones. To do this, clean the surface of the board from plaque and heat it to a temperature of 180 degrees.

- After finishing the work, all contacts, the board and the module itself are varnished.

- The device is mounted in its original seat, and if the final diagnostic results are positive, the ignition module is firmly seated on the sealant.

If you were unable to restore your device, don’t be upset; not everyone can do this task! But now you know exactly how the ignition system works and what it actually is. Moreover, you can easily tell us how to ring the chain, and if necessary, you will take on the repairs yourself. Well, isn't this enough? Looking forward to the next post, but I’m done here! See you later!

Ignition of gasoline in the cylinders of an internal combustion engine occurs using a spark generated by the ignition system. The ignition module is the main element of the system, creating a spark on the spark plugs using high voltage. Each car manufacturer develops and produces its own original module, but the principle of its operation is the same for all devices. During operation, deviation from the specified parameters or breakdown of the ignition module negatively affects engine operation until the power unit fails.

Checking for errors

VAZ 2114 engine mounts signs of malfunction

Checking the ignition device for malfunctions always concerns the location of the wires on the ignition module of the VAZ 2114. For simple diagnostics, we simply measure the resistance between the wires of the first and fourth cylinders and the second and third cylinders with a multimeter. If the indicator is 5.5 kOhm (switch the multimeter to ohmmeter mode!), then everything is in order. There are also other checks:

- The first thing to check is the wiring block; it is better to disconnect it and check it with a multimeter in voltmeter mode: we attach the multimeter probe to pin A, and throw the other one onto the ground of the sliders. We start and look at the voltmeter values: excellent. If the voltage fluctuates around 12 V. If there is no voltage, check the ignition coil fuse, it may blow, as well as the correct connection of all contacts. By the way, about that. Another way of checking can indicate that the circuit of contacts is closed incorrectly: by connecting a tester to both contacts - A and B - connect a multimeter to it; if it blinks, then the circuit is in perfect order.

- It’s worth checking all the high-voltage elements (with the same multimeter in ohmmeter mode); if they are installed incorrectly, the ignition coil will burn out.

- To understand whether the ignition module behaves correctly, move the wire block, you can knock on it. The contact should not disappear, if the engine responds to your movements, the contact is unclear. It can break at any moment.

Symptoms of an ignition coil malfunction are often displayed by the system during basic diagnostics in a service center (or in a garage environment via a connected laptop with a special program) in the form of errors:

- P0351 – break in the winding of wires of cylinders 1-4

- P0352 – break in the wire winding of cylinders 2-3

- P3000 (P3001 P3002 P3003 P3004) – the ignition does not work.

All these errors are motivation for a deeper diagnosis of the situation, on which the decision will depend: replace the module with a new one, or repair it. Also, these errors may indicate a possible malfunction of one of the spark plugs or an explosive contact.

Should high-voltage wires be replaced and when?

No matter how well the armored wires are made, they also have a limited service life. According to current regulations, they must be replaced after every 30,000 km traveled. In practice, many motorists ignore this rule, continuing to travel with wires that have already outlived their useful life.

Such inattention can cause a whole host of problems, including:

- poor ignition;

- overclocking problems;

- engine tripping;

- inability to start the car.

All these troubles are caused by one single factor - an increase in the electrical resistance of the core of high-voltage wires, as a result of which it becomes “more difficult” for the impulse from the coil to reach its destination.

You can check whether you can still drive with the old wires or not - at home.

- Turn off the ignition.

- Remove one of the armored wires.

- Measure its resistance using a megohmmeter or multimeter in the appropriate mode.

- If the resistance turns out to be equal to or close to the figure indicated on the wire insulation, then it is in good condition, but if it turns out to be greater, then the wire should be replaced.

- Repeat this operation on the remaining three wires.

It should be remembered that if only one of the wires is faulty, then all four should still be replaced.

Also, do not forget about the cleanliness of the contacts of high-voltage wires - they can also cause ignition problems. If oxides are noticeable on the metal tip, they should be cleaned with fine sandpaper or a cloth moistened with kerosene. By following these simple rules for caring for armored wires and replacing them, you can almost completely avoid troubles associated with the ignition system.

How to check the ignition coil with a tester on a VAZ 2106, as well as a VAZ 2109 and VAZ 2110 carburetor

Crankshaft position sensor, testing methods, symptoms of malfunction, location

On old VAZs it is not difficult to find a coil. It is located in a freely accessible area, under the hood. To check, you will need a regular multitester, which can be purchased for a small amount in many stores.

Video tutorial on measuring ignition coil resistance

The procedure is as follows:

- Disconnect the negative voltage on the battery. Disconnect the ignition coil wires, loosen the brackets. Clean the reel body. If obvious damage, cracks, etc. were discovered, it is better to immediately replace the device with a new one, since such a coil cannot be used.

- On the tester, turn on the ohmmeter mode. To check the “primary”, install probes or clamps on the side terminals located on the coil body. The tester display will show about 3.07-3.5 Ohm (original coil 2106 for a contact ignition system) or 0.45 ± 0.05 Ohm (coil 27.3705 for a contactless ignition system). For VAZ 2108, 2109 and 2110 - 0.43±0.04 (coil 3122.3705) and 0.42±0.05 Ohm (coil 8352.12). If the “primary” is broken or burned out, the resistance indicators will most likely tend to infinity.

- "Secondary" requires a similar check. But now the first probe goes to the side terminal, and the second to the central terminal. In addition, the indicators will be calculated in thousands of ohms. So, in accordance with the factory figures for the VAZ 2106 it should be 5400-9200 Ohms, for 2109 and 2110 - 0.40 kOhm (coil 3122.3705) or 1.00 kOhm (coil 8352.12).

- Also check the insulation resistance to ground. To do this, install one probe on the coil body, the second on each of the terminals in turn. The tester should show at least 50 mOhm.

The ignition coil cannot be repaired

Strong deviations from the normal range are a reason to replace the coil with a new one. It should be noted that this element of the ignition system cannot be repaired.

Primary winding diagnostics

In the process of diagnosing an ignition coil, a technician cannot do without a multi-measuring tool . Experts recommend using a car tester. But an ordinary laboratory meter will do.

During diagnostics, it is necessary to establish the exact level of resistance between the contacts of the connector into which the wire block is inserted. There are 3 contacts at the input: A, B and C. You need to check the resistance between contacts A-B and B-C. In each of the two chains, the resistance should fit into the range of 4.5-5.5 (kOhm).

How to check the ignition module on a VAZ 2114

An ignition module is needed in a car to produce high voltage current, which then ignites the spark plugs. On different VAZ vehicles, a separate or block ignition module can be installed. In separate type modules, there is a separate coil for each cylinder. In block modules, one coil is used for two or all cylinders at once. It should be noted that the block ignition module is much easier to remove, check and install back, compared to a separate one.

The VAZ 2114 is now available with a block ignition module; its coil design includes: a core, a winding, high voltage wires and low voltage terminals.

How does a malfunction of the ignition module manifest itself:

– idle speed floats; – engine tripping; – loss of traction with increasing speed; – the message “Check engine” error is displayed.

Note. Some drivers believe that high-voltage wires and the ignition module are completely different things, and if the wires become faulty, the module will not be affected. This is mistake. If the wires are damaged, the spark may not fire accurately, which can result in the ignition module burning out altogether.

The easiest way to check the ignition module is to install a similar, working ignition module instead of your own. If this is not possible, then you can get by with a multitester or a regular 12-volt light bulb (“control”).

Checking the serviceability of the ignition module using a multitester

Checking the health of the winding

Set the multitester to ohmmeter mode to measure the resistance between the terminals of the secondary winding. Install the probes on the leads to the first and fourth cylinders, then to the second and third (see video below). Usually the tester shows a result close to 5.4 kOhm (plus or minus 0.1 kOhm). The main thing is that the resistance between paired terminals is approximately the same. If the difference exceeds 100 Ohms, then this is evidence of failure of the secondary winding.

Solution to the problem: replacing the ignition module.

Checking the serviceability of high-voltage wires

You need to “ring” the wire block. Set the multitester to voltmeter mode, disconnect the wire block from the ignition module. Place one probe on contact A, the second on engine ground. Have someone start the engine (or turn the starter), and you note the display readings for yourself. Normally, the voltage should be around 12 Volts. Do the same manipulation with the other contact.

If there is no voltage at all, then you need to check the fuse: it may have blown. There are three fuses on the VAZ 2114 electronic control unit. The third one from the top, rated 7.5 A, is the fuse for the ignition module.

There may be no electric current not only due to a blown fuse, but also due to oxidation or broken wires or loose contacts.

Checking the serviceability of the ignition module using a “control”

If you don’t have a multitester at hand, a 12 V test light will help you check the ignition module. Connect one wire of the light bulb to the contact of block A, the other should be shorted to the engine body. Now let someone start the engine (or turn the starter), and you look at the light bulb - it should flicker. Do the same manipulation with the other contact.

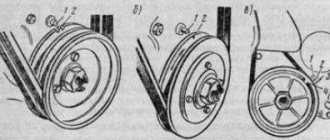

How to remove the ignition coil of a VAZ 2114

1. Disconnect the negative terminal from the battery.

2. Remove the tips from the spark plugs.

3. Release the latch and disconnect the low-voltage wire block from the coil.

4. Unscrew the bracket mounting bolts from the gearbox and the lower mounting bolt from the cylinder block.

5. Remove the coil together with the bracket.

6. Disconnect the high-voltage wires from the coil.

7. Unscrew the bolts securing the coil to the bracket.

8. Remove the coil. How to check the ignition coil

On the coil, on each terminal there is a mark indicating which wire goes to which cylinder. There are also marks on the high-voltage wires. When installing the ignition module back, you need to take these marks into account. When changing a coil, the new coil must have the same markings.

Video: How to check the ignition module

Video: How to remove the ignition coil of a VAZ 21114

Cost and alternatives

In the vast majority of cases, it is poor contacts, as well as the transistor and switch, that cause the failure of the ignition module in a VAZ-2110 car.

If a problem is detected, you can perform soldering yourself. In this case, you will need to purchase a switch, which costs about 6 US dollars. In turn, purchasing a transistor will cost approximately $3.

There are alternative options, for example, the KT848A transistor. But this semiconductor device is large. Therefore, additional difficulties may arise when performing repairs. Experts also note that the analogue is of low quality. Therefore, saving is not recommended. Finally, we note that you need to buy any spare parts, consumables and accessories only in trusted online stores.

How to check the ignition module yourself

Let's say you have clearly determined that the engine is malfunctioning (maybe another malfunction) due to the ignition module. You know where it is located, the pinout of the input block is known. To decide whether to repair the module or replace it with a new one (this is your cost), we will test it at least with a multimeter.

The easiest way is to replace the unit with a known good one. This is only possible if you have a good friend with a similar car. With such a check, the so-called “support group” - cables, electronic switch. Performance of the contact group

While the motor is running, press on the plugs of the high-voltage wires (Caution!) and the control block. If the nature of the motor’s operation has changed (it does not oscillate, the speed has become stable), check the condition of the contacts. We measure the resistance at the coil contacts

Secondary windings are guaranteed to be tested. Between the output contacts of 1.4 and 2.3 candles, the resistance should be the same and within 5 Ohms. We examine the disassembled module. Of course, you need to have basic skills in electrical engineering (the level is somewhat higher than “screwing in a light bulb in a hallway”). Broken wires or burnt contacts are immediately visible, and the serviceability of transistors can be checked with a multimeter. The primary winding of the coils becomes accessible.

If the parts are replaceable, we carry out repairs. Wiring and contacts are restored simply.

How to choose high-voltage wires

When choosing new high-voltage wires for your car, you should be guided by their two most important parameters - resistance and breakdown voltage. So, the less resistance the armor wire core has, the better it will transmit the impulse from the module to the spark plugs, and the easier it will be to ignite.

As for the second factor, this is the maximum voltage value, above which there is a risk of insulation breakdown, which can result in a number of unpleasant consequences. In addition, when choosing wires, you should pay attention to secondary indicators, for example, insulation resistance to cold, etc.

According to survey results, most car enthusiasts prefer high-voltage wires from Tesla - they have good performance, reliability, and are also resistant to cold and caustic substances.

How to improve the spark or modify the circuit of individual VAZ ignition coils

| The problem of floating engine speeds, sluggish acceleration with jerks and increased fuel consumption are familiar to almost every owner of a VAZ car. One of the reasons for these ailments lies in the ignition system. Let's consider the modification of individual ignition coils (ICC), which will help cope with unstable sparking. |

What is the reason

- dips need to be smoothed out by installing capacitors, as close as possible to the load itself;

- simplify the power supply chain of the IKZ.

Installation of capacitors

- it is possible for a higher voltage 35/50/63V, but not 16V;

- capacitance range 3000 - 4700 µF, the upper limit does not need to be exceeded;

- recommended manufacturers: Jamicon (TX, TL, TZ, WG, TK, TM), Samwha (WB, WF, WL, RD), CapXon (KF, LZ, KM, GL);

- 105 degree, low impedance (LowESR).

- We cut the insulating tape of the IKZ harness under the corrugation between 2-3 cylinders, we find 5 blue wires. We connect the plus of twisted capacitors to twist S1.

- In order not to touch the twist, you can solder the positive wire of the capacitors to the lead (thick) blue wire that comes from the ECM connector (stripe 5-8mm in a circle).

Result

- ─ the car accelerates better;

- ─ failures disappeared;

- ─ response to the gas pedal has become clearer;

- ─ idle speed became stable;

- ─ gasoline consumption decreased by 0.7-0.9 liters to 7.8 l/100 km in the city.

- ─ the engine starts faster, the starter does not turn for more than 2 seconds.

xn--2111-43da1a8c.xn--p1ai

Ignition module diagram 2115

The ignition module installed on the Lada Samara is extremely resistant to both low and high temperatures. Operating temperature range: -400/+1300C.

The only negative point in the operation of this electronic device is its complete inability to repair. However, even a novice car enthusiast can replace it on his own.

Experts consider the most common malfunctions of the Samara ignition module to be:

- Unstable operation of the power plant when accelerating the vehicle.

- Decrease in engine power.

- “Intermittent” idle speed.

- Malfunction of paired (1/4 – 2/3) engine cylinders.

The main symptoms of a malfunction and the reasons for their occurrence

In good condition, any equipment performs its duties exclusively, but at the slightest breakdown it begins to feel feverish, and when the entire engine compartment is filled with a mass of other irritants, go figure out where the source of your troubles is. And here, experienced drivers come to the rescue, highlighting a number of reasons to look for the problem here! In turn, experts are in absolute solidarity with experienced ones. The main symptoms of a faulty ignition module are as follows:

- Problems with starting the engine when cold - this is caused by the absence of a spark from several or even one spark plug.

- Reduced power of the power unit.

- Dips in power are noticeable during acceleration or long ascents.

- Unstable idle.

- Lighting “Check Engine” peephole.

Let me tell you this, friends, in fact, the ignition module has proven itself to be a durable and reliable device, but it does not last forever. Sooner or later, problems with it will arise; the main thing here is to understand what caused such troubles. Most often, the driver, by mistake or for the sake of saving money, uses inappropriate components, as well as damaged or completely defective parts. As a result, it is precisely this component that fails. To prevent this, take purchasing a spare part more seriously.

The principle of operation of the ignition coil.

The module is a kind of connecting link: from the electronic control unit, which controls its working process, a certain signal is sent to the winding (in the form of charged pulses); then, the module produces high voltage, which is transmitted to the spark plugs through high voltages. This action allows the candles to produce the necessary spark to start the internal combustion of the air-fuel mixture in the chamber space.

The new generation VAZs, including the fourteenth, are equipped with an ignition system coil; it is not included in the general module, since its other important part - the switch - is located in the electronic unit. If you take the old-style VAZs, including the fourteenth with a 1.5-liter engine, then they have an ignition system module: two coils and two switches in a single housing. Two coils are connected to the cylinders by high-voltage wires (each for two cylinders: one for the 1st and 4th, the second for the 2nd and 3rd). The most experienced ladies get high only if the dick penetrates deep into their anal, the rest is all kindergarten. Watch deep anal porn, here the girls bring their partners to extreme bliss, squeezing their dicks with a tight asshole until the sperm flows like a river.

Signs of a faulty ignition coil:

- When accelerating you feel a failure,

- Power drops

- At idle the engine behaves unstable,

- The engine has problems (cylinders fail).

Before deciding what to do with a failed ignition coil, you need to check it. No special skill is required, just know what a multimeter is and how to hold it in your hands. Depending on the test result, you should make a decision: replace or repair.

In principle, the fundamental malfunction of the ignition coil is always the lack of normal contact. Maybe the mass has broken, maybe the contacts are stuck or oxidized. A small deposit of dust can put an entire cylinder out of working order, not to mention a modest module.

Along with possible module malfunctions, it is recommended to check all sensors - from mass air flow to DS - there is a serious possibility of failure of one of them.

Possible causes of failure

The weak point of the ignition coils and modules is the secondary winding, which generates a high voltage pulse. A coil break or breakdown may occur in it. The following factors lead to this phenomenon:

The high-voltage pulse arising in the secondary winding must be realized (spent). If this does not happen (if the integrity of a high voltage wire is broken, for example), a high-energy electrical pulse seeks an outlet. He will find it, with a high degree of probability, in the thin secondary winding.

Often, a module malfunction occurs when the integrity of poor-quality factory soldering of wires going to the switch elements is violated. This happens from vibration. Also, the cause of non-working coils can be a banal contact failure in the incoming connector. Another factor leading to a malfunction of the ignition unit is often moisture that gets on the device during washing or driving in unusual conditions.

VAZ 2114 ignition module replacement, malfunctions, repair

The ignition module in a VAZ 2114 car is an improved starting system. The device produces cycles that produce a spark - the engine starts. The ignition module creates high voltage current and then transmits it to the spark plugs through four high voltage wires. Among motorists, the device is called an “ignition system coil.” The electrical network of the VAZ 2114 powers the module, its “minus” is attached to the car body. It consists of:

- Ignition coils;

- Small plastic case;

- Electronic units;

- High voltage transformers;

- Outputs for connection.

The signal is transmitted to the electronics by the controller, which processes data on the functioning of the VAZ 2114 systems. The controller reads data from the sensors and then sets a certain sequence. The ignition coil is highly resistant to temperatures; withstands from -40 to +130 degrees Celsius.

Malfunctions of the VAZ 2114 ignition module

Determining that a module has malfunctions is not so difficult. One of the signs is a decrease in engine power of the VAZ 2114 or acceleration in jerks. If the unit malfunctions, the engine begins to operate intermittently when idling. If such “symptoms” are present, then it is necessary to check the serviceability of the spark plugs and the fastening of high-voltage wires, as malfunctions may appear due to these elements.

Checking the VAZ 2114 for malfunctions must be carried out in compliance with safety precautions: hands must be wearing rubber gloves, and tools must be isolated. If the spark plugs and wires are in perfect order, the module needs to be replaced. You can find it under the hood; the device will reveal itself as large high-voltage circuits, from which replacement begins.

In order not to make a mistake with connecting the wires when replacing, it is advisable to plug the high-voltage wires into their sockets and then label each of them. Then the new ignition coil can be connected, following the wires from the old one. Modern units have numbering that will help you figure out the connection. Marking will be useful if you buy an old-style module without numbering on the outputs.

Module replacement

Replacement is carried out using a hexagon, a 10' head and 13' and 17' keys.

- You need to disconnect the negative terminal from the battery.

- Then remove the wiring harness.

- Pull out the signed high voltages.

- Remove all fastenings to the motor.

- After these steps, the faulty element will be exposed to the motorist. You can get it out using a hexagon.

Replacing with a new unit begins with connecting high-voltage wires. There should be hints on the case, but you can use your own. The wires should also be carefully examined - they should have marks that indicate the cylinder number. For example, if the number “2” is on the wire, then it is intended for the second cylinder. Replacement is complete. Now you need to start the VAZ 2114 engine and check whether the module is secured correctly. If necessary, tighten the fasteners.

Repair

Before going to a car dealership to buy a new module, it is recommended to check the device contacts. If they fail, you can do the repairs yourself and not spend money on a new module. To check, you need to start the engine at idle and try to press the module cover with an insulated tool. If the engine starts working normally, then the problem is in the contacts. The work is not difficult, but quite painstaking, and you will need skill in handling a soldering iron. For repairs, you need to stock up on small and thin wires, varnish, a soldering iron, a screwdriver and flux for soldering aluminum.

Process:

- You need to dismantle the device according to the instructions described above.

- Next, you need to remove the housing cover; to do this, press down with a screwdriver. If the device is not standard, there may be bolts there.

- On the board you can see whether the guesses are correct or not.

- If the contacts have come loose, then you need to strip the board of small wires and replace them with new ones.

- A problem may arise with transistor controllers - they are covered with a protective layer that the soldering iron does not take. It can be cleaned with improvised materials or a burr machine.

- Small wires need to be replaced.

- The final step is to cover the soldering areas with varnish or silicone. Even nail polish will do. That's all.

note

Repair

Ignition module VAZ 2107

The design of the ignition module is quite complex: it includes one or more coils, a board, contacts and wires. Of all the above elements, only contact connections can be repaired; in some cases, replacement of parts (transistors, coils) is possible.

The module is dismantled and opened for repair purposes. For this you will need:

- Socket wrenches with heads 1, 13 and 17.

- Hexagon 5.

- Screwdriver.

- Soldering iron.

- Flux for aluminum.

- Stranded wire.

- Nail polish.

Opening the ignition module

Repair of the ignition module is carried out in the following order:

- On the removed device, open the case by prying it off with a screwdriver.

- Remove the silicone film covering the board.

- All aluminum is removed from the explosive contacts.

- On the board, new wires are soldered in place of all the dismantled old ones. To do this, the surface of the collector is cleaned of deposits, after which the board is heated to 180 o C (a characteristic smell will indicate when the desired temperature has been reached). During the soldering process, the ends of the wires are connected to the module.

- At the end of the operation, all contacts, the board and the module are covered with nail polish.

- The device is assembled in the reverse order, installed on the car and the engine is started. In case of normal operation, the ignition module is sealed tightly with sealant, while the wires are tucked inside the cavity so that they are not pinched at the edges by the plate.

If the device does not work, then a breakdown inside the module should be looked for more carefully. The transistor, electronic component may have failed, or there may be a break in the coil. Such a repair makes sense only if its price is significantly lower than the cost of a new part.

The operation of the engine of the VAZ 2110 model is ensured through the use of various elements, including the ignition module. The task of the device is to determine the optimal interval for the appearance of a spark.

As a result of the failure of the device, misfires occur and interruptions in engine operation are observed. Therefore, if such “symptoms” occur, first of all it is necessary to check the ignition module. Voltage loss can occur on one or more cylinders.

You need to know that replacing the device is not always necessary. First you need to diagnose the module. The device is also repairable.

What determines the performance of the coil?

The classic ignition coil or “bobbin”, as it is also popularly called, is essentially a low-voltage voltage converter from the battery and generator to high-voltage, which is then supplied to the spark plugs. That is, this is a miniature electrical transformer.

The ignition coil is a kind of mini electric transformer

The traditional coil, used on carburetor models of vehicles, consists of two windings. The primary winding receives low voltage pulses, for example 12 Volts. As a rule, this is a small number of turns (up to 150) of thick insulated copper wire. The “primary” has 2 terminals on the coil cover. There are much more turns in the secondary winding - up to 30 thousand, but the wire used is much thinner. One end of the “secondary” goes to the “minus” of the primary winding, the other to the central terminal of the coil. In the center of the windings there is a core that enhances the magnetic field. The coil body is insulated, and its cavities are filled with special oil for transformers.

The fundamental characteristic that indicates the serviceability of almost any coil is the resistance of the windings.

Operating principle and location

The ignition module is controlled by a controller, which in turn receives information about the state of the vehicle from various sensors (IAC, DMRV and others). The controller also sets the sequence of operation of the ignition coils or, in other words, regulates the supply of current to the spark plugs. The ignition module operates at temperatures from -40° to +130°.

Finding its location is not difficult; high-voltage wires (HV) go from the module to the spark plugs; along them you can find the module.

Troubleshooting the ignition module.

The easiest way to find a faulty ignition module is to replace it with a known good one or replace the module being tested in a working car. The second way to determine serviceability with a degree of probability is to measure the resistance of the coil windings. Since the original value is almost never known, it is better to simply compare the value between the coils. The third, most accurate, but also the most difficult method is to check the module on a stand. In this case, the stand can be either factory-made or home-made. The latter can be made using a carburetor nine distributor driven by a drill. To check the double coil in this case, you can use a commutator from the same nine.

admin03/07/2016

Ignition, Devices

A comment

Name *

Website

This site uses Akismet to reduce spam. Find out how your comment data is processed.

« Kan-shina

Immobilizer flashing »

Tags

VAZ, VAZ malfunctions Sensors Ignition Injector Devices Starter Circuits Electric cars Power supply VAZ 2110 gazelle gazelle business recorders car repair

Recent Entries

- Design and principle of operation of parking sensors

- Multifunctional device Roadgid X7 Hybrid GT

- Malfunction of the GAS ignition system

- Electric Xiaomi Mi Mijia M365

- Additional vehicle equipment (installation)

Archives

Archives Select month August 2022 July 2022 December 2022 August 2017 July 2022 June 2022 May 2022 April 2022 March 2022 December 2016 November 2016 October 2016 September 2016 August 2016 July 2016 June 2016 May 2016 April 2016 March 2016 February 2016 November 2015 October 2015 August 2015 July 2015 June 2015 May 2015 April 2015 March 2015 February 2015 January 2015 December 2014 November 2014 October 2014 September 2014 August 2014 July 2014 June 2014 May 2014 April 2014 February 20 14 January 2014 December 2013 November 2013 October 2013 August 2013 June 2013 May 2013 March 2013 February 2013 January 2013 November 2012 October 2012 September 2012 August 2012 July 2012 June 2012 May 2012 April 2012 March 2012 February 2012 January 2012 December 2011 November 2011 October 2011 November 2011 August 2011 July 2011 June 2011 May 2011 April 2011

Categories

- Accumulator battery

- Video

- Generator

- Sensors

- Diagnostics

- Ignition

- News

- Equipment

- Devices

- Repair

- Spark plug

- Starter

- Scheme

- Devices

- Electric cars

- Electricity supply

We are in social networks

Autoelectrics@ All rights reserved. When copying site materials, you must provide a link to the site.

When is there an option to repair?

If during testing both secondary windings show integrity and serviceability, the reason for the inoperability of the coils may be a break in the soldering of the switch wires. Such damage is detected when the rear cover of the module is removed. If you have a soldering iron and know how to use it, you can restore the integrity of damaged contacts, while at the same time strengthening the rest. This, unfortunately, is the only failure of the ignition module that can be repaired.

Testing the ignition module can be done using simple do-it-yourself instruments. Based on our advice, you will be able to fully check both the module itself and other elements of the mechanism that may be the cause of the breakdown. We wish you success in this matter!

Source

How to check

Checking the VAZ 2114 ignition module begins with preparing the equipment. And the best diagnostician in this case would be a device for checking the ignition module such as an oscilloscope. Unfortunately, not every Russian driver has an idea of what it is, not to mention the ability to use it. Therefore, we focus on the end consumer and use available means:

- 12-volt light bulb or control in common parlance

- Tester, it can be purchased for pennies at any spare parts store

Before touching the module itself, pay attention to its accompanying parts. We start with the wire block, it’s worth disconnecting it and checking the voltage

To do this, we fix the tester terminal on contact A, and throw the other one onto the ground of the sliders. Normal voltage is 12 V. If it is not there, then the problem is clearly in the fuse. It's a different story with him. Next, along the wires: we throw the tester terminal onto contacts both A and B. We start, the starter starts, the control indicator should ideally blink. If this does not happen, then the problem is a break in the contact circuit A.

Now directly to the ignition module. There are several options for diagnosis:

- One of the simplest types of diagnostics is to replace a non-working unit with a working one. Of course, for this you need a “donor”. We replaced it, looked at it, and drew conclusions. The only thing that can be an obstacle is that you need an identical unit, that is, a friend with the same car of the same year as yours. Because for 1.5 engines it is the module that is used, and for 1.6 engines only a coil is used. And remember about the working explosive wires, if they fly, then the module is bent because of them. Again, checking BB contacts is a different story.

- You can do it differently - move the ignition unit. What does this mean: you need to shake the block with contacts, then hit the module and shake it. At this time, the engine itself must be running, because all these actions are necessary in order to see whether its operation will remain flawless when staggering. If not, then again take a closer look at the wiring.

- Another way: put the tester in the operating state of the ohmmeter. We measure the resistance on the explosive wires that go to cylinders 1 and 4. And then - to 2 and 3. The normal resistance is considered to be from 5.2 to 5.5 Ohms.

Important: the ignition module most often cannot be repaired. Or is the repair not worth it?

It's easier to buy a new one and install it.

You can buy an ignition module for a VAZ 2114 anywhere and anytime, the price is not that steep - from 2,000 to 4,000 thousand rubles, depending on the region and the quality of the unit (manufacturer, new or used). But, if you decide to get confused, then be sure to look at the information on how to check the serviceability of the ignition module.

If you still doubt your own abilities, the doors of the service are always open for you. Moreover, the ignition module itself can be of both domestic and foreign production. But, no matter how strange it may sound, a qualified mechanic will most likely use all of the above techniques for the process, because he knows how to check the ignition module on a VAZ 2114. With rare exceptions, you can find someone in the service who will use an oscilloscope. Therefore, ride it once and see how and what is being done. At least some benefit from the time and money spent is a clear example for independent garage diagnostics.

We recommend

- Phase sensor errors on VAZ 2114

- Replacing the voltage regulator on a VAZ 2114

- How to replace the license plate light bulb on a VAZ 2114?

- Replacing the phase sensor on a VAZ 2114

https://nadomkrat.ru

Connection features

The order of connecting high-voltage wires must be strictly sequential, since each cylinder of the engine corresponds to a specific socket on the ignition module. Considering that there is a numbering of the sockets on the ignition module body, the risk of confusing anything is minimal.

The procedure for connecting high-voltage wires of the VAZ 2114 injection type depends on the year of manufacture of your car. Fourteen cars before 2004 had 4-pin ignition modules installed, and cars after 2004 had 3-pin coils.

The connection diagram for VAZ 2114 high-voltage wires to the ignition module (until 2004) is as follows:

Connection diagram for VAZ-2114 with ignition coils (after 2004):

In the pictures you can see the numbers of the landing slots. Each number must have a corresponding cylinder connected to it (cylinder numbering is counted from left to right).

To correctly install high-voltage wires on the VAZ 2114, follow the following algorithm of actions:

- Turn off the ignition. Open the hood and remove the power terminals from the battery;

- We remove the old GDPs from the mounting sockets on the module and cylinders;

- We remember the location of the high-voltage wires of the VAZ 2114 and connect new GDPs according to the diagram. Before replacing, it would not be amiss to draw this very diagram by hand on paper so as not to confuse anything;

- We connect power to the battery and, to check whether we did everything correctly, start the engine.

When installing the wiring, do not try to connect individual air intakes to each other with plastic clamps; to do this, you must use the comb holder that comes with them. A thin clamp can easily wear through the insulating coating. Also make sure that the GDP does not bend.

Connecting armored wires on VAZ 2115 and 2113 is carried out in a similar way.

Signs of a malfunctioning ignition module

The list is relevant only if the other systems (spark plugs, injectors, crankshaft position sensor, cylinder compression, fuel system) are in good working order and operate according to the established parameters. The symptom of a faulty spark plug may not differ from a banal loss of contact between the ignition module and the high-voltage cable.

- Troubles the engine. In fact, there are many reasons, but the main culprit is our module. Moreover, this could be a contact phenomenon, or a breakdown of the radio element. A clear sign of coil failure is that failures occur in two cylinders simultaneously. That is, candles either Nos. 1 and 4 or Nos. 2 and 3 “do not burn.”

- The engine thrust has noticeably decreased. The car does not hesitate, it runs smoothly, but acceleration uphill or under load occurs lazily.

- During sharp acceleration, a kind of failure of thrust occurs in the engine. It's as if the fuel pump is not performing enough. If the gas tank is in order, look for the cause in the ignition module.

- At idle the speed fluctuates (of course, with the IAC running).

And of course, the “check engine” alarm. If the fault is detected by the ECU module, this is good for diagnosis. You can read OBD errors in any available way:

- using electronic odometer codes (if such an option is available);

- using the on-board computer, if it has a decoding function;

- any diagnostic scanner, for example, ELM327 paired with a smartphone.

If you recognize error codes associated with misfires specifically in a pair of spark plugs, the most likely cause is a faulty ignition module.

High-voltage wires VAZ 2115

Automotive high-voltage (HV) wires play an important role for internal combustion engines, since they help transmit high current from the ignition coil to the spark plugs. The serviceability and efficiency of the wires determines the timeliness and intensity of ignition of the fuel-air mixture, and therefore the correct and uninterrupted operation of the engine. Despite their simplicity, wires have many different “sores” and can cause a lot of troubles to their owner, which in one way or another will affect his nerves and pocket.

Connection

The order of connecting high-voltage wires must be strictly sequential, since each cylinder of the engine corresponds to a specific socket on the ignition module. Considering that there is a numbering of the sockets on the ignition module body, the risk of confusing anything is minimal.

The procedure for connecting high-voltage wires of the VAZ 2114 injection type depends on the year of manufacture of your car. Fourteen cars before 2004 had 4-pin ignition modules installed, and cars after 2004 had 3-pin coils.

The connection diagram for VAZ 2114 high-voltage wires to the ignition module (until 2004) is as follows:

Connection diagram for VAZ-2114 with ignition coils (after 2004):

In the pictures you can see the numbers of the landing slots. Each number must have a corresponding cylinder connected to it (cylinder numbering is counted from left to right).

To correctly install high-voltage wires on the VAZ 2114, follow the following algorithm of actions:

— Turn off the ignition. Open the hood and remove the power terminals from the battery;

— We remove the old GDPs from the mounting sockets on the module and cylinders;

— We remember the location of the high-voltage wires of the VAZ 2114 and connect new GDPs according to the diagram. Before replacing, it would not be amiss to draw this very diagram by hand on paper so as not to confuse anything;

— We connect power to the battery and, to check whether we did everything correctly, start the engine.

When installing the wiring, do not try to connect individual air intakes to each other with plastic clamps; to do this, you must use the comb holder that comes with them. A thin clamp can easily wear through the insulating coating. Also make sure that the GDP does not bend.

Connecting armored wires on VAZ 2115 and 2113 is carried out in a similar way.

How to remove high-voltage wires?

Turn off the ignition. Open the hood. Pull out the wires from the ignition module and from the engine.

How to connect high voltage wires?

The BB wires must be connected in a certain order. Each wire goes to a specific cylinder and to a specific connector in the ignition module (ignition coil). There are markings both on the wires and on the ignition module. But without removing the module, the markings cannot be seen, so see the photo below.

Connection diagram for high-voltage wires:

Cylinder numbering from left to right. Ignition module numbering: first cylinder - lower left compartment of the ignition module

Second cylinder - upper left compartment

The third cylinder is the upper right,

The fourth cylinder is the lower right compartment of the ignition module.