Despite the fact that the VAZ 2107 has long been out of production, however, due to its ease of maintenance and unpretentiousness in repairs, it remains one of the popular cars among the population in its class. The fact that most cars are not new requires increased attention to their technical condition. When carrying out maintenance, it is also worth assessing the condition of the driveshaft.

In accordance with the instructions, lubrication of the splines of the driveshaft connection of the elastic coupling should be done every 10 thousand km.

The cardan shaft or cardan is one of the main parts of the VAZ 2107 car transmission, the main task of which is to transmit torque from the gearbox to the rear axle gearbox. Technically, the VAZ 2107 driveshaft consists of two components: a front driveshaft and an intermediate driveshaft, interconnected by a cross that allows them to rotate at a varying angle relative to each other.

Cardan VAZ-2107 - device, diagram, details

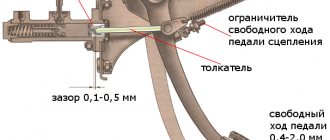

Description of design The cardan transmission consists of front and rear cardan shafts, an intermediate elastic support, an elastic coupling, a movable spline joint and two cardan joints. The presence of two universal joints and a spline connection makes it possible to transmit torque from the gearbox to the main gear at an angle that constantly changes during suspension operation.

Cardan shafts are made of thin-walled steel pipe. The front shaft has splined ends at both ends, and the rear shaft has universal joint forks. The elastic coupling is designed to absorb vibrations and jerks in the driveline. It connects the gearbox and the front driveshaft through two flanges. Their alignment is ensured by a centering ring on the gearbox shaft and a centering sleeve in the propeller shaft flange. The intermediate support consists of a radial ball bearing mounted in a bracket inside a rubber insulating pad. The bracket is secured to the body using a cross member through vibration-isolating bushings. The cardan joint consists of two forks mounted on shafts, which are connected to each other by a cross. The hollow spikes of the crosspiece are fitted with needle bearings with sealing collars. The bearings are secured in the forks with retaining rings. Currently (since 1988), cardan shafts are equipped with hinges of increased durability. They are equipped with crosspieces with spikes of increased diameter, stamped needle bearing housings, radial-end type seals without a metal clip and a fork of increased thickness. Modern and previously produced crosspieces are interchangeable, but installing “new” crosspieces into the forks of “old” driveshafts is not recommended, since this reduces the overall rigidity of the joints.

Description of design The cardan transmission consists of front and rear cardan shafts, an intermediate elastic support, an elastic coupling, a movable spline joint and two cardan joints. The presence of two universal joints and a spline connection makes it possible to transmit torque from the gearbox to the main gear at an angle that constantly changes during suspension operation. Cardan shafts are made of thin-walled steel pipe. The front shaft has splined ends at both ends, and the rear shaft has universal joint forks. The elastic coupling is designed to absorb vibrations and jerks in the driveline. It connects the gearbox and the front driveshaft through two flanges. Their alignment is ensured by a centering ring on the gearbox shaft and a centering sleeve in the propeller shaft flange. The intermediate support consists of a radial ball bearing mounted in a bracket inside a rubber insulating pad. The bracket is secured to the body using a cross member through vibration-isolating bushings. The cardan joint consists of two forks mounted on shafts, which are connected to each other by a cross. The hollow spikes of the crosspiece are fitted with needle bearings with sealing collars. The bearings are secured in the forks with retaining rings. Currently (since 1988), cardan shafts are equipped with hinges of increased durability. They are equipped with crosspieces with spikes of increased diameter, stamped needle bearing housings, radial-end type seals without a metal clip and a fork of increased thickness. Modern and previously produced crosspieces are interchangeable, but installing “new” crosspieces into the forks of “old” driveshafts is not recommended, since this reduces the overall rigidity of the joints.

Login to leave comments

Question

Over time, vibration appeared, it starts at a speed of 60 km/h and stops after 120. I replaced the outboard, replaced the gearbox. Doesn't stop. I climbed in myself. I removed the cardan and inspected it; the holes on the mounting of the pendant to the body were not fully bored out, because of this, the pendant is attached with tension and therefore with an inclination. Bore the holes. The hanging sat well. The vibration is gone. Traveled 20,000 km. Appeared again. It was not the wheels that sinned. It seems to have been balanced, the vibration has not disappeared. I changed from winter to summer tires, still the same. What you didn’t do doesn’t disappear. There is a slight play in the left rear axle shaft. Maybe because of this? Or maybe the spline joint of the cardan is not lubricated?

Login to leave comments

Your writing is interesting and lifelike.

Your writing is interesting and lifelike. Still, in order to make a truly interesting blog, you need to not only report something, but also do it in an interesting way.

see also

Lubricant for crosspieces

- 61 0 57k

How is the VAZ 2107 driveshaft balanced?

- 0 2 1k

Cross puller

- 10 0 19k

Balancing the driveshaft

- 28 0 36k

Knock in the rear axle of VAZ 2107

- 0 2 577

Despite the fact that the VAZ 2107 has long been out of production, however, due to its ease of maintenance and unpretentiousness in repairs, it remains one of the popular cars among the population in its class. The fact that most cars are not new requires increased attention to their technical condition. When carrying out maintenance, it is also worth assessing the condition of the driveshaft.

The cardan shaft or cardan is one of the main parts of the VAZ 2107 car transmission, the main task of which is to transmit torque from the gearbox to the rear axle gearbox. Technically, the VAZ 2107 driveshaft consists of two components: a front driveshaft and an intermediate driveshaft, interconnected by a cross that allows them to rotate at a varying angle relative to each other.

Features of the mechanism

The driveshaft transmits the torque generated by the car's engine to the rear axle, causing the wheels to rotate. It is located under the bottom of the VAZ-2107 car, which is why you can find a raised floor in the cabin.

The cardan on the VAZ 2107 consists of two main parts, which are connected to each other using a cross. This design of the device is necessary because the rear suspension constantly “plays” when driving due to shock absorption. The device is a hollow tube, which is the “arm” connecting the engine to the wheels. Despite the simplicity of the product, the shaft, like other car parts, fails and requires repair or replacement.

Main cardan malfunctions

The main malfunction of the driveshaft is that elements such as the spider and the outboard bearing fail. It is these parts that are the most loaded. The crosspiece and bearing fail for a simple reason - lack of lubrication. Over time, it is necessary to periodically diagnose these elements with the obligatory addition of lubricants. In rare cases, a cardan malfunction may be associated with a defective crosspiece, which requires its replacement.

The malfunctions of the mechanism in question are as follows:

- failure of crosspieces;

- destruction of the outboard bearing;

- violation of the configuration (imbalance) of the shaft;

- breakage of flanges, splines and couplings, which happens under heavy loads;

- excess moisture and dirt inside the crosspieces.

At the slightest sign of malfunction, it is necessary to diagnose the mechanism and eliminate all resulting damage. The malfunction can be identified by the following signs:

- the appearance of a knocking sound when the clutch is engaged, which may indicate wear of the splines or damage to the elastic coupling;

- the occurrence of a grinding noise when the car is moving indicates a lack of lubrication;

- the appearance of vibration when the car is moving, which indicates a violation of the alignment of the product;

- knocking noise during sudden acceleration or braking, which indicates wear of the crosspieces.

We will discuss how to replace the VAZ 2107 driveshaft in the next paragraph.

The process of removing and replacing the cardan

The mechanism is removed for the purpose of carrying out repair work or replacing it with a new product.

Often the driveshaft itself is an unpretentious device, but it is important to periodically check the condition of the bearing, splines and crosses. These are the weak points that need to be periodically looked at and monitored for their condition.

To avoid misalignment during disassembly, it is necessary to apply marks with chalk or a core, which will avoid incorrect assembly of the product.

Work on dismantling the cardan is carried out in the following order:

First, you need to secure the car by placing stops under the front wheels, and place the gearshift lever in the “neutral” position. Next, jack up the rear of the car, while suspending one of the drive wheels. We proceed to disconnect the device from the mount to the differential. To do this, you need to unscrew the 4 fastening nuts and then remove the bolts. After unscrewing the fastener, you can separate the product from the differential flange.

It remains to unscrew the two nuts securing the cross member on which the suspension bearing is mounted. After unscrewing, you can dismantle the cardan from the VAZ 2107. Using a wooden hammer, you need to knock out (if necessary) the shaft from the engagement of the splines with the elastic coupling. After the shaft is repaired or replaced, you can install it in place. The installation process is inversely proportional to removal

When installing the product, it is important to ensure that the shaft is positioned correctly.

WHAT ARE THE PROBLEMS IN THIS CONNECTION?

Of course, most often the most loaded elements fail: the universal joint and bearings. There are reasons for this: lack of necessary lubrication in the bearings and defects in the production of crosspieces. In the USSR, there was a terrible shortage of crosspieces: there is no crosspiece - the transmission is faulty - the car is stuck. Repairing the cardan shaft often cost a week's family budget, and replacing the crosspiece (or rather, the need for it) led many to despondency.

More rare transmission malfunctions of the VAZ 2107:

- Damage and misconfiguration (hitting rocks when driving in the mountains);

- Abundant amounts of dirt in parts and bearings;

- Failure of flanges, splines and couplings under load.

For lubrication, maintenance, if a part needs to be replaced, first of all, you need to properly remove it from the car and put it back. Repair of the driveshaft is also possible only after removal.

Popular and useful repair instructions for VAZ 2107

Those who are seriously interested in the repair and maintenance of the VAZ 2107 should familiarize themselves with the popular instructions that owners of this vehicle model most often refer to. These include replacing the VAZ 2107 clutch, replacing the VAZ 2107 master brake cylinder, replacing the VAZ 2107 generator and other procedures necessary during active vehicle operation in harsh road conditions.

In addition to them, drivers will find it useful to replace the VAZ 2107 pump, which will allow the cooling system to return to its former performance and eliminate the possibility of engine overheating. For those involved in an accident, replacing the wing of a VAZ 2107 will be useful - a procedure that even a novice driver who is aware of the algorithm of actions can cope with.

There are also a number of materials that site users found most useful. Thus, car owners believe that they will need information on why the VAZ 2107 heater does not heat well, how to adjust the ignition and how to repair a 5-speed gearbox.

In addition to video instructions, on the pages of the section you can also find a repair manual for the VAZ 2107, consisting of a photo and a text description. Photos of the process will be no less informative, which means that such a manual will be the best option for the car owner in comparison with factory information material.

Replacing the driveshaft crosspiece of a VAZ 2107

All repairs are carried out with your own hands quite simply; no pitfalls will be identified in the process. The first thing you need to do is get the rear of the car off the ground. Moreover, the larger your belly, the higher you need to raise it. Secondly, you will need some tool:

- A set of keys (in particular, for “12”, “13”, “14”).

- Screwdrivers.

- Hammer.

- Retaining ring remover.

- Wooden spacers.

That's all, now you climb under the car and unscrew everything you see. Namely:

- Suspension bearing with a key “13” from the body of a VAZ 2107.

- Four nuts from the flange, using wrenches “12” and “13”. Sometimes it is needed for “14”, it all depends on what spare parts were used during the previous repair.

Then the cardan falls to the ground and needs to be knocked out of the gearbox. To do this, you can use a hammer and a wooden spacer. Ideally, use a wooden mallet or a bronze hammer to avoid damaging the driveshaft.

Then arm yourself with a ring puller and pull them out one by one. What to do next? The instruction manual advises using a special puller, but practice shows that a few sharp blows with a mallet on the edge of the VAZ 2101-2107 driveshaft are enough for the glasses to fly out. Before installing a new cross, be sure to clean the seats to ensure there is no dust or dirt.

First put it on the flange, and then on the cardan - this is the most optimal sequence. And I would also like to note: when replacing the VAZ 2107 driveshaft crosspieces, there is no need to install the retaining rings that come with the kit. The fact is that they can be several microns wider, and this will lead to destruction of the mechanism. Therefore, it is better to leave the old rings.

The driveshaft is removed from a VAZ 2107 car if it is damaged, when the balancing is disturbed as a result of vibration during movement, as well as to perform other repairs, for example, to disassemble the universal joint or replace the elastic coupling.

Repair work to remove the cardan transmission must be carried out in a pit or overpass. To perform the work you will need a standard set of tools. The sequence of your actions should look like this:

- Having driven the car into the pit, engage neutral gear. Jack up the rear wheel so that it is suspended.

- If the seven is injection, then it is necessary to remove the heat shield located above the catalytic converter. Using a 13mm socket wrench, unscrew the four nuts securing it to the car body studs and remove it by pulling it towards you and up.

- Now you can start removing the driveshaft. Before removing the universal joint, it is necessary to apply marks using a file to the universal joint fork body and the rear axle gearbox flange. If you plan to replace the driveshaft with a new one, then the marks are not needed. We will need to take risks when installing it in place so as not to upset the balancing, since the driveshaft gradually becomes unbalanced during operation and if it is installed in a different position relative to its original place, then when driving at high speeds some vibration may appear in the lower part of the body car.

- Using a thirteen-size open-end wrench, unscrew the self-locking nuts of the bolts securing the cardan to the rear axle gearbox flange. Using a mounting bracket, we keep the cardan from rotating. After unscrewing the bolts, take them out and hang the rear part of the cardan on a wire to any rear suspension rod. The nuts must be replaced with new ones during installation.

- In the front part of the cardan, it is necessary to straighten the four tendrils of the oil seal race and move it inward along the shaft.

- Using a thirteen-size socket wrench, unscrew the two bolts securing the intermediate shaft support to the bracket and disengage the driveshaft from the elastic coupling and remove it from the car, pushing it towards the rear axle.

At this point, the repair work on removing the driveshaft of the VAZ 2107 is completed. Install in the reverse order of removal, aligning the marks on the hinge and the gearbox flange. Lubricate all spline joints.

Sources

- https://carnovato.ru/zamena-podvesnogo-podshipnika-kardannogo-vala-i-krestoviny-na-vaz-2101-2107-svoimi-rukami/

- https://vaz-remzona.ru/zamena-krestoviny-kardannogo-vala-vaz-2107/

- https://remont-vaz2106.ru/kardannyj-val-vaz-2107

Reasons for a loud sound or diagnostics of the exhaust system of a VAZ 2104

What problems can occur in the exhaust system and when does the muffler need to be replaced? Let's look at it in order:

- The first thing that can cause a loud exhaust is a malfunction of the muffler, or rather its burnout or rotting. This can be determined by external examination. Look for traces of rust - they often hide holes that are hardly noticeable.

- Let's go further - the middle resonator. Again, it could have rotted, or while driving you could have gotten caught in it and punched it. Also carefully inspected for cracks, holes and rust.

- The exhaust pipe or simply pants can also be a cause. They, as a rule, do not burn out. The same thing happens to them as to the resonator. After hitting the bottom of the pants, a dent appears, which then rots and a hole appears.

- If the entire exhaust system, after visual inspection and testing with your own hands, turns out to be safe and sound, then there is only one conclusion - the reason for the loud operation is definitely the gasket between the pants and the exhaust manifold.

Note! When inspecting areas with rust, be sure to test the strength of the surrounding metal. It is possible to repair the muffler.

Lada 2107 › Logbook › Classic driveshaft on CV joints

Hello everyone! This topic of CV joints from the Niva to the classics has haunted me for a long time. Now the moment has arisen not to miss this chance to install a cardan on the CV joints. Why a chance? Because my outboard bearing was humming, surprisingly the crosspieces were more than normal, the rear there was not much play (but not fatal). The last time I changed the crosspieces and the suspension was last year in November. And then how the change was driven into the service by a hand-assed master and he changed it in the end and then redid it after repairing it, here is a record of what he did www.drive2.ru/ l/488394819794632724/

What was purchased: Rear cardan 2123 Hammer and Sickle Reducer flange 2101 Suspension bearing Cardan nuts M8 with nylon Cardan flange nut

What has already happened: The total number of universal joints is 3 pieces))) Where do you ask for so many? One of the original ones was still on the car to this day, and was repaired more than once. The second corporate one was purchased (about three years ago) because it was necessary to change the crosspieces and suspension. I was too lazy, so I went and bought it for 2000 rubles. When I installed it, vibration appeared, the seller refused to take it back, allegedly there were traces of installation, in response, I sent it to hell. The original one was restored. But the third cardan was bought not long ago (a month ago) in a used .it is in disassembly condition, and I drove it for 5 days, the bearing began to hum even more. In the end, I installed my own one, there was less noise there)))

I started the process of disassembling the cardan. I started with the corporate cardan, pulled out the central crosspiece, removed the fork. And I noticed that the outboard bearing is facing the other way))), that is, the retaining ring is in the gearbox, but should be towards the bridge (I don’t know what the difference is, let me know who knows), there are no dust deflectors 2 pieces. But it’s half the trouble when I unscrewed the nut, the thread on the cardan was licked off by the nut, how do you like this corporate cardan? I throw it away and start working on the second cardan, everything was the same as with the first cardan, the bearing was not right , but the dust deflectors are in place and the threads are intact, this is what I need! Has the assembly of the cardan really begun? Having taken a new outboard bearing, I checked the grease and it can be said that there is almost none of it; everything is clearly filled with grease now! By the way, just for fun, I checked the lubrication of two disassembled cardan shafts in the outboard ones, they generally worked dry. Normally, I bought a corporate one and a used one in disassembly))) Most likely, the cardan I rode on also had a dry bearing. That’s why it hummed so quickly.

I read the installation and assembly process from many people. So I used the nut from the original cardan nut, I just put washers under the nut because the head didn’t fit (I didn’t sharpen it much) and there was no place to tighten it, the washer fixed this problem. I installed it on the ground , the studs did not interfere with the installation. Cut Drill Cook there was nothing like that, everything went perfectly, both assembly and installation! I didn’t touch the balancing weights in the small cardan, as they were, I left them like that. Someone removes them, someone leaves them. I decided not touch.

Now the most interesting thing begins, the time has come to go check it out))) I was satisfied with the work done, I won it))) When starting off, there are no clicking noises, etc. There are also no extraneous noises while driving. Usually when switching gears, and when starting off, you feel a slight blow to the bridge, regardless of whether the crosspieces are in good order or not. It rolls easier this way. Now it feels like I don’t have a universal joint, I can’t hear it! Today I installed it, and I drove 72 km, I like everything!

Why do breakdowns occur?

If you know what shortens the service life of a spare part, you can delay the breakdown as much as possible.

Main reasons

A part can fail due to something as trivial as insufficient lubrication. It is negatively affected by sub-zero winter temperatures, and in addition, the cardan is usually located above the exhaust system; when the engine is running, it heats up and thereby slowly dries out the lubricant. Metal shavings, sand or scale that gets into the lubricant are dangerous.

Two lead to corrosion

main factors:

- water, dirt or other substances that cause corrosion have gotten inside;

- incorrect fit, errors in the shape of the landing sites lead to fetting corrosion, that is, contact destruction.

A part deviates from the seating surface when the base on which it is installed is not flat.

Incorrect handling, disproportionately shared loads and excessive edge loads also take their toll. Problems will also arise if the materials used to make the shaft and bearings are not compatible.

Signs of malfunction of VAZ 2107 crosspieces

Malfunctions of crosspieces are usually associated with wear of the sealing collars and dirt getting inside the bearings, which, having abrasive properties, begins to destroy the metal. This manifests itself as follows.

- at a speed of about 90 km/h, characteristic impacts from below are felt;

- when the reverse gear is engaged, vibration appears;

- When the driveshaft swings from side to side, play is detected.

It is much easier to identify a faulty crosspiece on a removed cardan. If the bearings are damaged, the hinge will rotate poorly in one of the planes, and sounds resembling crunching or rustling will appear.

Clicking noise when starting

The first sign of a faulty universal joint is a loud clicking sound when turning on first gear at the start of movement. When such sounds, reminiscent of a clinking pan, appear, it is recommended to rotate the parts of the cardan in different directions with your hands, while holding the hinges. If large play is detected, the crosspieces must be replaced. It is noteworthy that sometimes clicks can appear only during a sharp start from a standstill, and when the movement begins smoothly, they may not appear.

Vibration

Often, if the crosspieces are faulty, vibration occurs when reversing. Sometimes it does not disappear even after replacing the crosspieces, but begins to appear at average speed. Moreover, the vibration may become even stronger than before replacing the CC. Such situations are a consequence of non-compliance with the alignment of the cardan elements during its assembly.

Sometimes vibration persists even after work has been done correctly. The reason for this is usually the use of low-quality products when replacing CC. Experts advise tapping the cups on all sides with a metal tube before installing new crosses. This will allow the stuck circlips to move and the vibration will go away.

Preparing for work

When buying a new crosspiece for a VAZ 2107, you don’t need to try to save money. Everyone knows that “the miser pays twice,” so it’s better to buy an original part right away than to change a couple of crosses in six months.

The body of the crosspiece is made of heat-treated steel. This is necessary to ensure the special hardness of the studs. Thus, the quality of the material plays a big role in the service life of the part. How long can a car run without replacing crosspieces? It is believed that approximately 500 thousand km!

The retaining rings and bearing also need replacement.

Please note that the rubber of the bearing itself must be sufficiently elastic

Installation of VAZ crosspiece

2101-2202110 Cuff 2101-2202115 Cuff holder 21211-2201015-01 Rear propeller shaft 21211-2201023 Flange fork for propeller shaft 21211-2201047 Sliding fork for propeller shaft 21211-2202025 Rolling bearing (designation GPZ - SN192819НРС10) without cross 21211-2202029 Grease nipple 21211-2202034 Grease nipple 21211-2202043 Retaining ring 1.45 mm 21211-2202044 Retaining ring 1.48 mm 21211-2202045 Retaining ring 1.52 mm 21211-2202046 Retaining ring 1.56 mm 21211-2202047 Retaining ring 1.60 mm 21211-2202048 Retaining ring 1.64 mm 21211-2202049 Retaining ring 1.67 mm 21211-2202050 Retaining ring 1.40 mm 21211-2203015-01 Front propeller shaft

Suspension bearing for propeller shaft VAZ 2107

The suspension bearing (or idler bearing) is designed to ensure uniform rotation of the driveshaft while driving. In addition, it is an additional point for attaching the cardan and is included in the design of the intermediate (suspended) support. In fact, it itself is a support, since it comes complete with a bracket, with which it is attached to the bottom of the car through a transverse bracket.

The bearing design is based on the outer and inner races and seven steel ballsOutboard bearing location

The bearing is installed in front of the spider at the end of the front of the driveshaft. It can be seen from the inspection hole in the axial recess of the bottom behind the exhaust pipe at its junction.

The VAZ 2107 suspension bearing is located in front of the crosspiece on the front of the driveshaft

Hanging bearing design

The hanger bearing is an ordinary closed type ball bearing. It consists of an inner and outer race and seven steel balls. For mounting on the bearing housing there is a steel bracket with holes for bolts.

The suspended bearing is equipped with a special bracket for ease of fastening

Diagnosis of outboard bearing faults

The causes of outboard bearing failure are usually wear or mechanical damage. The service life of the bearing is about 150 thousand km. However, exposure to moisture, dirt, as well as stress caused by poor road conditions can significantly reduce it.

Signs of bearing wear are:

- slight vibration;

- hum emanating from the place where the cardan is “suspension”;

- shaft play.

It is quite difficult to accurately diagnose bearing failure; this will require dismantling the driveshaft.

Outboard bearing selection criteria

Suspension bearings for the VAZ 2107 in Russia are produced under catalog numbers 2101–2202080 and 2105–2202078. The requirements of GOST 6–180605 apply to them. Imported analogues must comply with the requirements of ISO 62305.2RS. If there are no such markings on the packaging of a new part, it is most likely a fake, and it is better not to purchase it. The average retail price of a VAZ 2107 suspension bearing is 450–500 rubles. When choosing a manufacturer, it is better to give preference to the Vologda Bearing Plant. Bearings produced at VPP are considered to be of the highest quality and most durable.

Table: technical characteristics of the VAZ 2107 suspension bearing

| Characteristics | Indicators |

| steel grade | ШХ 15 |

| Outer diameter, mm | 62 |

| Internal diameter, mm | 25 |

| Height, mm | 24 |

| Rated rotation load, rpm | 7500 |

| Load capacity static/dynamic, kN | 11,4/22,5 |

| Ball diameter, mm | 11,5 |

| Weight, g | 325 |

Delivery by Russian Post (cash on delivery, no prepayment)

Advantages: the most widespread network in Russia, delivers to any corner of the country, including remote ones. Flaws:

- high cost of delivery of heavy or large parcels, as well as the weight of one parcel should not exceed 20 kg;

- long delivery times and queues in large cities for receipt.

To send your order by Russian Post:

Delivery time may vary depending on how far your locality is from Togliatti and usually ranges from 5 to 14 days.

The cost of delivery is calculated based on the volume, weight of the selected product and the distance to the recipient's settlement.

Required for sending:

- indicate full name recipient;

- Your mailing address;

- Your phone number (contact);

- Post office code.

Russian Post commission for cash on delivery service:

- purchase price up to 1,000 rubles. – 70 rubles + 5% of the amount;

- purchase price from 1,000 to 5,000 rubles. – 80 rubles + 4% of the amount;

- purchase price from 5,000 to 20,000 rubles. – 180 rubles + 2% of the amount;

- purchase price from 20,000 to 500,000 rubles. – 280 rubles + 1.5% of the amount.

Russian Post - Delivery of goods up to 20 kg throughout Russia. https://www.pochta.ru

Delivery time and cost Track the parcel Calculate delivery by mail

How to Correctly Install a Cardan on a VAZ 2107

Cardan transmission refers to the connection of 2 shafts through a spider, which is capable of transmitting torque from the 1st shaft to the 2nd. This transmission is necessary when the longitudinal axis of the two shafts does not lie on the same straight line, i.e. the angle differs from 180°.

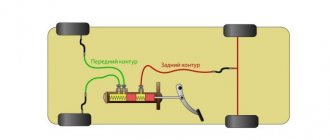

In rear-wheel drive vehicles, which includes the entire classic VAZ family, the PTO transmits all the torque turning the engine to the rear drive wheels. In particular, since the driveshaft is located under the bottom of the car, the floor in the cabin rises in the center. Front-wheel drive cars do not have this interior height.

Changing the angle didn't work at all because it's hard for the driveshaft to sit under the bottom without being overpowered. Somehow the engineers would manage. The fact is that the height of the rear suspension, and therefore the differential that receives the torque, is constantly “dancing” thanks to the elastic suspension.

It is clear that the gearbox is the “grasshopper” in the VAZ 2107, and the cross member connecting the shafts is the weak point. Now let's talk specifically about this simple but very important unit. Repairing a drive shaft is delicate, despite its apparent simplicity. Replacing parts requires delicate measurements.

- The parts capable of changing the angle and length of the transmission are the coupling (5), as well as the rigid connections (9.7) and elasticity (3). This is called clutch. The role of the coupling is that it reduces joint noise and transmits angle impulse. Repair of the screw shaft is required if the clutch material cracks and breaks. Simply put, a connection change is required.

- The universal joint consists of 6 rubber parts (30) with metal spacers (31) between them. These parts are tightly connected into a single unit, so in case of failure, the most correct solution is to replace the clutch.

- The coupling must be located between the flanges (4.2). They are screwed to this 35.

- Intermediate support (6), which is used to reduce vibrations and various impacts.

- The front shaft of the VAZ 2107 (5) is a pipe on which welding grooves are installed. In front of us is the tip (40). It is equipped with one of the clutch flanges, and the rear end is wound on the support bearing (6). The bearing itself is perfectly sealed with mud seals. Drive shaft repair is required if the studs are worn.

- The rubber pad (12) in which the bearing is located perfectly dampens vibration. This may move the windshield slightly.

- The intermediate screw support is mounted on a bracket (15).

- The safety bracket (27), which prevents the shaft from falling out if the clutch breaks, is fundamental. If this bracket was not available, cars would spill at full speed and incidents like this would have happened before. In such a case, repairing the drive shaft is impractical and needs to be replaced.

- The difference between the rear shaft (8) and the front “neighbor” is that there is a loop fork at its ends.

- In fact, the hinge is the main element of the transmission, it consists of a pair of forks (23), one spider (22) and a separate figure on top, needle bearings (20). of which 4, rings (19). ) and seals (21). The bearings are pressed with a fairly large force of about 800 kg into the holes for the fork. They are not detachable and require replacement if faulty.

- For the transverse part there is a corresponding gap of 0.1 to 0.4 mm. Only within such limits is the cross correctly centered. For proper alignment, there are rings in 5 sizes and 5 different colors. In most cases, repairing the drive shaft involves adjusting these gaps; the rings change.

Briefly about the purpose of elastic couplings

Before we begin to understand the design of couplings, we suggest that you familiarize yourself with the tasks that they undertake. As you can understand from the introduction to this material, they are needed to dampen loads. The same task is performed by many other car components , but elastic couplings differ from them, at least in shape. An elastic coupling can take on one or all of the following tasks:

- Absorb shocks and impacts caused by rotational moments;

- Connection of misaligned shafts;

- Protection of mechanisms and drives from so-called torsional vibrations.

The couplings themselves are a very inexpensive solution that allows you to reduce the harmful loads that arise during the operation of mechanisms. At the same time, they can compensate for both angular, axial and radial displacements of parts . They are especially effective in mechanisms in which frequent starts and stops alternate - the kinetic energy of impacts in them is accumulated by the clutch itself, which gradually wears out, but at the same time prevents wear of adjacent parts of the mechanisms.

Elastic couplings are used with great success in compressors, pumps, generators and many other drives in electric and diesel locomotives, ships, construction vehicles and, of course, cars. Since the elastic coupling allows you to create a soft but reliable connection, it is used to equip the driveshaft of cars. For this reason, an automobile flexible coupling is often called simply a cardan coupling, and occasionally called a jubo (from the English giubo).

VAZ transmission

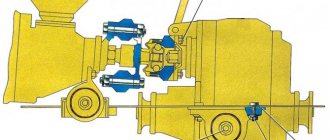

The transmission of torque from the gearbox to the final drive is carried out by a cardan drive, which makes it possible to transmit torque at a constantly changing angle (due to the elastic suspension of the rear axle).

The cardan transmission consists of front 14 and rear 21 cardan shafts, an intermediate support 17, an elastic coupling 23 and two cardan joints. The rear hinge is connected through fork 22 to the flange of the main gear drive gear.

Front driveshaft. Made from thin-walled steel pipe with splined ends welded to both ends. On the splines of the front tip there is a flange 7, which is connected through a rubber elastic coupling to the flange 2 of the secondary shaft 10 of the gearbox with bolts 6. The alignment of the connected shafts is ensured by the centering ring 15, pressed onto the end of the secondary shaft of the gearbox, and the centering sleeve 4, pressed into the flange 7 Ring 15 is fixed on the shaft with a retaining ring 16.

The spline joint is lubricated through a hole closed by plug 18. The lubricant is held by a rubber seal 9, which is placed in a steel cage 8, and on the other side by a seal 13, put on a nut 12. The rear splined tip of the shaft 14 rests on the ball bearing 33 of the intermediate support. The fork 28 of the intermediate cardan joint is secured to the splines of the tip with a nut 34.

Rear driveshaft. It is made of a thin-walled pipe, at the ends of which universal joint forks are welded.

Intermediate support. Absorbs vibrations from the driveshaft. It consists of a bracket secured to the crossbar with 26 bolts and nuts. The cross member, in turn, is secured with nuts on bolts welded to the body. Steel spacer bushings 20 and rubber insulating bushings 19, pressed with washers, are installed on the crossmember mounting bolts. The bracket contains a rubber cushion, which is vulcanized to the surfaces of the bracket and bearing housing.

The bearing housing contains a radial ball bearing 33 with seals, which is fixed in the housing with a retaining ring 27. Dust deflectors 32, installed on both sides of the bearing, protect the bearing from dirt.

Litol-24 lubricant is placed into the bearing during assembly and is not replenished during operation.

Elastic coupling. Absorbs noise and vibration of the driveline. It is made of six rubber elements 3, between which there are metal liners 5 with holes for bolts 1 and 6. The liners have six projections, three of which go into the grooves of the flange of the secondary shaft of the gearbox, and the rest into the grooves of the flange of the elastic coupling. This ensures that the flexible coupling is centered on the flanges.

Cardan joint. It consists of two forks 28 and 36 attached to the shafts and a cross 35, which connects the forks to each other. The hollow tires of the crosspiece are fitted with housings of needle bearings 30. The bearing of the crosspiece is sealed with an oil seal located in a metal cage 31. The assembled needle bearings are fixed in the holes of the forks with retaining rings 29, which are divided into five sizes according to thickness. Each ring size corresponds to a specific color: 1.62 - yellow; 1.59 - black; 1.56 - blue; 1.53 - dark brown; 1.50 - unpainted. By selecting a retaining ring of one thickness or another, the axial clearance of the crosspiece is ensured in the range of 0.01-0.04 mm.

Since 1988, a cardan transmission with joints of increased durability has been installed on parts of cars, and subsequently on all cars. It is externally distinguished by the increased thickness of the forks where the needle bearings are installed, the absence of metal clips for the crosspiece oil seals, and a sharper transition of the front driveshaft pipe into the splined tip (approximately at an angle of 90°). U-joints have improved needle bearing sealing. This is achieved by using oil seals 2 radial mechanical seals. The needle bearing housings are stamped from sheet steel, as opposed to turned from bar steel in the previously used cardan drive.

New and previously produced cardan joint crosspieces are interchangeable. But it is undesirable to install new crosspieces (VAZ-2105) in the forks of old driveshafts (VAZ 2103-06), since in these forks the rigidity of the stamped needle bearing housings decreases.

Due to changes in the size of the universal joint forks, the technology for disassembling and assembling new universal joints has been changed. Therefore, the text describes the technology for repairing both old and new hinges.

Source

Checking the condition of the cardan drive without disassembling

We clean the shafts, coupling and support from dirt.

We check the cardan joints for ease and smooth rotation of the forks and for the absence of radial and axial movements.

If damage to at least one of the shafts is detected, it is advisable to replace the cardan transmission assembly, since its balancing is carried out in the assembled state on a special stand.

The rubber parts of the elastic coupling and elastic support must not have cracks, tears or separation from the metal.

When operating a car, you should lubricate the splined joint of the propeller shaft near the elastic coupling within the prescribed period (10 thousand km).

Instead of a plug on the flange of the elastic coupling, we wrap the grease nipple and lubricate the spline joint with Fiol-1, Fiol-2U or CV joint grease.

Front suspension design of the VAZ 2107

The time-tested double wishbone suspension appeared much earlier than the McPherson swing plug. The double wishbone is objectively better than the racks in terms of geometry and controllability, stability and endurance. But it’s not for nothing that we started with the market. MacPherson is much cheaper. It is three times cheaper to produce the most profitable double wishbone suspension. That's why they put it on the front of very inexpensive cars. At the rear, MacPherson can be found in a Mercedes, Cadillac, or BMW - this is the number one suspension for expensive sevens. But it's not that.

Structurally, the double wishbone suspension holds the car much better when turning, has better control and is more stable in terms of directional stability. This happens due to a larger number of attachment points for the moving part of the suspension, if you don’t go into details. And the VAZ 2107 is an excellent example of how a strong and unpretentious design lasted on the assembly line for almost 50 years without any problems. This scheme is still used today and will continue to be used for a long time. Although the weak point in it is the ball joint.