About the belt

Kalina uses a toothed belt that rotates not only the camshafts, but also the coolant pump. The belt length depends on the engine model. In 16-valve engines, due to the presence of two camshafts, the belt is significantly longer than in 8-valve models with one camshaft.

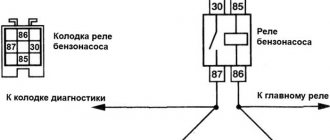

1 - Crankshaft gear; 2 - Water pump gear; 3 - Tension roller; 4 — Camshaft gear mark strip; 5 - Camshaft gear; 6 - Belt; A-B - Camshaft marks; C-D - Crankshaft marks;

The 16-valve engine belt has 136 teeth with a tooth width of 25.4 mm.

The 8-valve engine belt has 111 teeth with a tooth width of 19 mm.

Article numbers of original parts

Lada Granta, Kalina with 8-valve engines (VAZ 11183):

- Belt - 21080100604010 (“BalakovoRezinoTekhnika” PJSC Balakovo)

- Tension roller assembly - 21080100612000 (“VPK” JSC Vologda)

- Tension roller assembly - 21080100612001 (TD EPK LLC, Moscow)

Timing kit 2108 - 21080100604086 (Gates CIS LLC, Moscow). The kit includes a belt and a roller. This is the GATES K015521 kit, only in LADA branded packaging.

Lada Granta, Kalina, Priora with 8-valve engines (VAZ 11186, 11189)

:

- Toothed belt assembly - 21116100604000 (Gates CIS LLC, Moscow)

- Toothed belt assembly - 21116100604082 (Gates CIS LLC, Moscow)

- Tension roller - 21116100623800 (Gates CIS LLC, Moscow)

- Tension roller - 21116100623882 (Gates CIS LLC, Moscow)

Timing kit - 21116100604086 (Gates CIS LLC, Moscow). The kit includes a belt and a roller. This is the GATES K015670XS kit, only in LADA branded packaging.

Lada Granta, Kalina, Priora, Largus Vesta, XRAY with 16-valve engines (VAZ 21126, 21127, 21129 and 21179)

:

- Reinforced toothed belt - 21126100604000 (Gates CIS LLC, Moscow)

- Reinforced toothed belt - 21126100604082 (Gates CIS LLC, Moscow)

- Toothed belt - 21126100604001 (ContiTech Antriebssysteme GmbH)

- Support roller - 21126100613500 (“Lada Holding” GMBH Vienna)

- Support roller assembly - 21126100613501 (Schaeffler Technologies GmbH & Co. KG)

- Automatic toothed belt tensioner - 21126100623800 (“Lada Holding” GMBH Vienna)

Timing kit 21126 - 21126100604086 (Gates CIS LLC, Moscow). The kit includes a belt and 2 rollers. This is the GATES K015631XS kit in LADA branded packaging, which is installed on the AVTOVAZ conveyor.

Timing drive kit VAZ 21179 for Lada Vesta, XRAY - 21177-1006040-86 (Belt - ContiTech, rollers - Schaeffler):

- Belt Contitech 21126-1006040-01

- Automatic toothed belt tensioner 21176-1006238-00 (Slovakia)

- Support roller assembly 21126-1006135-01 (Germany)

Consequences of a broken belt

A design feature of the 16-valve engines on the Lada Kalina is that the valves bend when the belt breaks. This defect is caused by the absence of grooves in the pistons, but the absence of grooves is not due to a mistake by AvtoVAZ engineers, it is necessary to increase the compression ratio in the combustion chamber. Therefore, a broken belt in a 16-valve engine foreshadows a major and expensive repair in 99% of cases.

Bent valves due to broken timing belt

To prevent the belt from breaking, it is recommended to monitor it every 20,000 km and check it.

This problem is not observed on 8-valve engines.

Replacement procedure

The operation is not particularly difficult, does not require any special equipment, and can easily be done by the hands of the machine owner. In addition to a standard set of wrenches, you will need a good slotted and flat-head screwdriver. Car jack, car body stand, wheel chocks, key for turning the roller in the tensioner. When replacing, you can use any flat horizontal platform on which the machine is installed. The vehicle operating instructions recommend replacing the belt at 50 thousand km, but many owners perform it earlier, at approximately 30 thousand km.

Replacing the timing belt Kalina 8 valves will take place in the following order:

- With the vehicle installed, apply the hand brake and install wheel chocks under the rear wheels. Use a wheel wrench to remove the wheel bolts of the right front wheel.

- Using a car jack, lift the front side of the car on the right side, install a stand under the body sill, and remove the front wheel on this side.

- Open the hood of the engine compartment, since further work will be carried out there.

- To dismantle the timing belt in the timing drive, it is necessary to remove the plastic protective cover, which is secured with three 10mm socket bolts.

Timing cover

- The next step is to remove the belt in the generator drive. You will need a “13” wrench, which is used to unscrew the tensioner nut of the generator set and move the generator as close as possible to the cylinder block body. After such actions, the drive is easily removed from the pulleys.

- Now install the timing drive according to the marks. You will need a socket wrench or a “17” socket, which is used to rotate the pulley on the crankshaft until they match.

Camshaft mark

- To dismantle the belt in the timing drive, it is necessary to stop the crankshaft pulley from turning. You can ask an assistant to engage fifth gear and press the brake pedal.

If this does not help, open the plug on the gearbox housing.

Inspection window plug

Insert the blade of a flat-head screwdriver into the hole between the teeth of the flywheel and the gearbox housing, and unscrew the bolt securing the pulley to the crankshaft.

Crankshaft lock

- To remove the belt, release the tension roller. The bolt securing it is unscrewed, the roller rotates, the tension weakens, after which the old belt is easily removed. It is recommended to simultaneously change the tension roller, which is removed from the block, at the same time as the drive. There is an adjusting washer installed under it, which some “repairers” lose.

- Inspect the pulleys on the crankshaft and camshaft, paying attention to the wear of their teeth. If such wear is noticeable, the pulleys should be replaced, as the contact area with the belt teeth is reduced and they can be sheared.

They also check the technical condition of the coolant pump, which is also driven by a toothed belt. Basically, the belt shearing occurs after the coolant pump is jammed. If the pump is changed, you need to drain some antifreeze from the engine cooling system.

- Install the new tension roller in its place. Do not forget about the adjusting washer between the cylinder block and the roller, otherwise the belt will move to the side when rotating.

- Installation of a new belt is carried out in the reverse order, but before that, check again how the gas distribution marks match. You need to start the installation with the camshaft pulley, then put it on the crankshaft pulley and the pump pulley. This part of the belt should be tensioned without any possible sagging, and the opposite side should be tensioned with a tension roller.

- Installing the pulley on the crankshaft will again require securing it from possible rotation.

- Next, put the protective covers in place and adjust the generator drive.

After installing the timing drive, be sure to turn the engine crankshaft several revolutions, while checking that all installation marks match.

Setting marks

The efficiency of the motor depends on the correctness of this operation. There are three of them on the engine, which are located on the camshaft and rear protective shield housing, crankshaft pulley and cylinder block, gearbox housing and flywheel. There is a pin on the camshaft pulley that must be aligned with the bend on the rear timing cover housing. The crankshaft pulley also has a pin that is aligned with a mark on the cylinder block. The mark on the flywheel must coincide with the mark on the gearbox housing; these are the most important marks that show that the piston of the first cylinder is at the TDC point.

Mark on the flywheel

Correct belt tension

The tension roller is an important part of the gas distribution system on the Lada Kalina. If you tighten it, this will greatly accelerate the wear of the mechanism; if the tension is weak, ignition failure may occur due to the belt slipping. The amount of tension is adjusted by turning the tension roller on its axis. To do this, there are two holes on the roller into which a key is inserted to rotate the tensioner. It is also possible to rotate the roller using pliers to remove the retaining rings.

“Craftsmen” act differently; they use drills or nails with a suitable diameter, which are inserted into the holes. A screwdriver is placed between them, the handle of which is used as a lever to turn the tension roller to the left or right until the desired result is obtained. The correct tension will be when the body of the belt between the pulleys can be turned 90 degrees with your fingers, and after releasing the belt returns to its original state. If this condition is met, tighten the fasteners in the tensioning device.

The best timing belt for Lada Kalina

Choosing the best belt for Kalina is quite difficult, since when purchasing you can run into counterfeits of famous brands such as Gates and Dayco. It is these two brands that are most often counterfeited, since they are bought much more often than others. It is recommended to purchase products only from trusted stores.

From the factory, the standard belt on all Lada models is installed by Gates; AvtoVAZ gives its preference to it.

The table below shows timing belts for Lada Kalina with article numbers.

| Brand | vendor code |

| Gates | K015631XS |

| Gates | K015521XS |

| Dayco | KTB842 |

| Contitech | CT1137K1 |

Tests and tests

Experts from the Za Rulem magazine tested 36 drive belts - 6 copies of each from six different brands. The test results refer to specific product samples and do not allow us to judge the entire range of products of each item.

Recommended:

- Continental, Germany. Approximate price 850 ₽. There can be no complaints about a belt that has stood for 400 hours on the stand and could continue to work. In our tests, only two products were able to demonstrate this.

- Gates, UK. Approximate price 1150 ₽. 400 hours on the bench are sufficient grounds for unequivocal approval.

- Trialli, China. Approximate price 700 ₽. 286 hours is, let’s say, a strong middle peasant, which, unlike the leaders, nevertheless became toothless, although it lasted quite a long time, exceeding the requirements of the technical specifications. At the same time, strength tests have shown that some belt parameters are even better than those of the champions.

Not tested

:

- Gates (fake with reference to Germany). Approximate price 350 ₽. Which is what needed to be proven: “You, priest, should not chase after cheapness.” After just 3 hours of life tests, the belt lost its “teeth”: a complete failure. Checking individual parameters confidently placed the product in last place: such belts cannot be installed!

- Lynx, Japan. Approximate price 650 ₽. During endurance tests, the belt lasted 104 hours, after which some of the teeth were cut off. In general, not so little, but the leaders worked four times longer and were not injured! The remaining parameters are not failures, but overall we are looking at an mediocre product.

- Balakovorezinotekhnika (BRT), Russian Federation. Approximate price 750 ₽. Just 1 hour on the stand instead of the champion 400 - what can I say? Alas, the teeth came off the cord almost immediately. It feels like the belts are made of raw rubber. Note that after drying, the cutting force of the tooth more than doubled - and this turned out to be the best result. But the breaking forces are low, and according to the results of bench tests - the penultimate place.

Survey

Determine the best timing kit, belt or pulley

We will do it by voting. Leave feedback in the comments, in which you can indicate:

- Which timing belt and rollers did you choose and why?

- How often do you change the rollers and timing belt?

Where can I buy?

These and other original parts are presented at low prices in our online store:

We previously told you when to change the timing belt and rollers according to the manufacturer's regulations, as well as how to do it yourself.

Source

Video about setting marks on Kalina's 8-valve valve

When performing all work, do not close the hood and start the engine. If everything is installed correctly, then there should be no extraneous noise or creaks in the operation of the motor. With a well-tensioned drive, the engine should not move in “waves”, that is, regardless of the speed, the engine should not deviate from stable operation. If the belt is tensioned too much, a peculiar “hum” from the tension roller may be observed. If this happens, loosen the roller and fix everything again. Upon completion of all work, reinstall the belt and engine cover.