A car's tachometer is an important element for monitoring technical parameters. The article describes how to connect a tachometer to a VAZ-2109 with a carburetor engine.

Malfunctions of this device, methods for eliminating them, and a connection diagram to the electrical circuit of the car will also be considered.

To help the car enthusiast: tachometer connection diagram for VAZ 2109 carburetor

What is a tachometer? What is the connection diagram for the tachometer on a VAZ 2109 carburetor? A tachometer is a technical device that displays the number of revolutions of the engine crankshaft. The device shows not only engine speed. Modern developments inform the driver about fuel consumption and recommend a more optimal driving mode. There are devices with other functions. These are usually electronic models.

Purpose

The tachometer serves to visually monitor the number of revolutions of the power unit, both at idle and while driving at different speed ranges. It is convenient for the driver to control the number of revolutions when shifting a manual transmission if music is playing or the muffler is damaged. In addition to monitoring speed, using a tachometer it is very easy to adjust the carburetor of the car. A car enthusiast just needs to adjust the carburetor to a tachometer position within 800 rpm.

How to Connect a Tachometer to a VAZ 2108 Carburetor

Connect the tachometer to the VAZ 2109 (carburetor)

Tachometer. This device is used to display the number of revolutions the crankshaft makes. While conventional entry-level tachometers just reported this, modern models are equipped with additional features that are useful to the driver: fuel consumption, recommendations for optimal driving conditions, etc.

What can you get

The best solution for owners of nine top and bottom panels. This is to buy new modern computing equipment and install it as a freelance device on the VAZ 2109. This will provide additional information and a little more to decorate the interior of your car,

But before you go to the hardware store, you should learn about the types of tachometers.

Types

Features of work

For diesel engines

Diesel engines are not equipped with ignition coils, since the tachometer works based on the readings of the generator pulses.

For gasoline engines

There are gasoline power units ignition coils

, whose current pulses are read by the tachometer. Therefore, the panel provides relevant information. Gasoline tachometers differ from each other depending on the number of cylinders in the engine

When purchasing a tachometer for your vehicle, be sure to specify that it is a four-cylinder gasoline power unit. Or just say you need a device for nine.

Own device. nothing special

Price issue

Device cost. This is an always debated issue. Some people believe that it is useless to buy expensive equipment, because all spare parts for VAZ are available and cheap.

But buying a cheap tachometer involves obtaining inaccurate information. Available devices may have 20-30% errors. The idea is to install such equipment if the data is still not true and the real benefits of the device you are not getting?

On average, a good tachometer for a VAZ 2109 will cost 1000-2000 rubles. Not a lot of money to save. By installing it yourself, the entire setup will cost the largest number of readers. And we will tell you in detail how to install it.

installation

Installation of tachometer VAZ 2108

DIY customization of VAZ 2108 (tachometer from 06 to 2108)

This video describes how to install a tachometer

six to six

2108

, 2109, 2199.

Everyone has a tachometer in your hands, so you can safely take it to your garage and start connecting the device.

You don't have to be afraid of DIY. Although the tachometer is an electrical device, it has three wires. Therefore, even inexperienced drivers can easily cope with the task.

Connection agreement is not an issue

Determine in advance where your engine speed reader will be located. Here the choice is entirely yours. Some are mounted directly on the dashboard, while others. next to the ignition switch. Try to choose a site where the device does not interfere and will not spoil the appearance of the salon.

The location has been decided so you can start safely.

- Remove the tachometer from the cab from the passenger compartment to the engine compartment. Practice shows that it is most convenient to remove it from the hole intended for the speedometer cable.

- To make the task easier, take a heavy but fairly thin wire. It takes about a meter in length. Connect the tachometer to one end using an extension cord. Just do it carefully so it can fit through the speedometer hole.

- Insert the other end of the wire into the socket and begin to remove it. Therefore, without unnecessary hassle, you extend the wiring into the engine compartment.

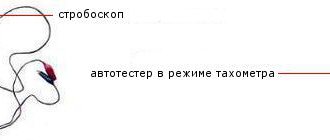

- Distribute the wires. 12. B ignition coil, signal. ignition coil but minus. the weight of your vehicle in any accessible or convenient location. For reliability, make sure that the weight can be increased with a nut.

- Even with high quality tachometers, the wires in the cable are thin and fragile. To prevent this from happening, solder full high quality wires to the device in 1 square wire. Try to find wires that match standard tachometer wiring colors. Then, on the other side of the wire, 1 square millimeter, install the lugs.

- Unscrew the mounting nuts on the ignition coil using a 10mm wrench, and then connect the wiring as shown in the figure.

- Tighten the nut, just pull it, showing that its strength is not worth it. Otherwise, you risk breaking the thread, and eliminating such a defect is problematic.

- Connect the ground. To do this, select a section where there is no wire that will interfere

, will not interact with other devices, will not overheat, etc. - Make sure your device is working. To do this, turn on the ignition. At the same time, the tachometer should show a proud 0. This means that the elevator is now zero and the crankshaft is not rotating.

- Start a car. At idle the normal speed for the VAZ 2109 is 750-850 rpm. The relevant information should appear on the device in the cockpit.

- If the tachometer has the additional function of a voltmeter (a very useful function for those who prefer to independently repair and diagnose their cars). When selecting a voltmeter, the mains voltage should be displayed. about 11-12 V when the battery is properly charged.

Everything on this tachometer setup can be considered complete. There is nothing complicated in this process, so even a beginner can do this job.

Installing a tachometer

You bought and brought home a new tachometer. Now you can go to your garage to install the device on a car that has a carburetor. Installing and connecting it is not that difficult. This is an electric device, but don't be afraid of it. How to connect it? The tachometer connection diagram is extremely simple. Even a less experienced person can easily connect the 3 wires coming from the device. So let's get started. You should:

- choose a location for the device in the car;

- lead the wires out of the passenger compartment into the space under the hood;

- distribute the wires on the ignition coil and on the ground of the car;

- check the operation of the device.

The choice of location is up to you. You can install a tachometer on the instrument panel or next to the ignition switch. As long as the device does not interfere with the driver and does not spoil the appearance of the interior. Then the wires are brought out. The best way to do this is through the hole through which the speedometer cable passes. To help, you can take a meter-long piece of rigid, but rather thin wire.

The cable coming from the tachometer is wound to the end of the wire with electrical tape so that it passes through the hole. In this way, you can run all the wires under the hood without any problems. Connect wire 12 to terminal B, the signal to terminal K. For the negative one, you need to find a suitable place on the ground of the car. It is better to tighten it with a nut.

Recommendations

- An electronic tachometer is recommended for use by inexperienced drivers

who do not know how to navigate by engine sounds; - When purchasing, pay attention to the back of the package, where it is written for which brands of cars it can be used. Otherwise, the readings will be false or prepare for problems in the electrical circuit (this applies more to injectors);

- Install the module itself somewhere in a visible place so that you can always see its readings without any problems. As practice shows, installation is carried out on the central panel of the torpedo. Some people manage to place an oblong module in the instrument panel in place of the “STOP” indicator; this is for models 2108, 2109, 21099

.

DIY installation instructions

Installing a tachometer on a VAZ is done as follows:

- First, a place is selected where the device will stand, after which the cable from it must be routed into the engine compartment.

- Before connecting the VAZ 2109 tachometer, it is necessary to distribute the wiring. The +12 volt terminal is connected to the coil (contact B, the signal is connected to contact K), and the “-” is connected to the ground of the car, and the ground must be securely fixed. If the wiring is very weak and fragile, then it is better to connect more reliable wires in advance.

- After the wires have been distributed, they need to be connected. To connect the ground wire, it is advisable to choose a place where the cable itself will not interfere with or interact with moving parts.

- To diagnose the functionality of the device, you need to turn on the ignition and start the car. During normal engine operation at idle speed, the needle on the instrument scale will remain in the region of 750-850 rpm. If the device is additionally equipped with a voltmeter function, you can check it - when you select this option, information about the voltage level in the on-board network should appear on the display. If the battery is operating normally, this parameter should be approximately 11-12 volts.

Device connection diagram

Principle of operation

The tachometer on the VAZ-2109 was installed only on versions with high and “euro” panels. On cars with a “Euro” panel, the tachometer is often of an electronic type, and works in conjunction with the control unit. Models with a low panel did not have such a device. The driver had to control the speed of the power unit by ear.

The system works according to the following principle:

- The ignition coil receives electrical voltage and equalizes it, converting voltage up to 35 thousand volts.

- The car distributor converts voltage into pulsed current due to the contact method of supplying voltage.

- These signals are sent to the tachometer pulse contact.

- At the back of the device there is an inductance coil, which, depending on the magnitude of the pulse current voltage, creates a magnetic field. The created magnetic field deflects the needle of the device due to the movement of the coil itself.

On carburetor cars, the distributor creates exactly 2 electrical impulses per full revolution of the crankshaft on power units with 4 pistons. This is worth taking into account, since installing the device from a 6-cylinder car will introduce a large percentage of error into the measurement of the number of revolutions.

The system is very simple and analog. Its operation is not affected by various sensors or third-party circuit components. But this system is not without its shortcomings. Next, the main malfunctions of the VAZ-2109 tachometer will be described.

Connection diagram for tachometer VAZ-2108 and 2109

Let us immediately note that the fuel supply system – injector or carburetor – does not play a special role here. As you know, currently the most common are cars with the following engine types: gasoline or diesel. Depending on this, the tachometer is selected, unless, of course, it comes in the stock version. The thing is that on gasoline engines the tachometer reads data from the ignition coil, or rather, the impulses that arise here. However, the design of diesel power plants does not provide for this unit. Accordingly, here the tachometer reads pulses not from the ignition coil (for lack of one), but from the generator.

The first two wires (12-volt and Signal) are to contacts “B” and “K” of the ignition coil, respectively. All that remains is to secure the mass in any convenient place.

Ignition system for gasoline engines

Control of engine ignition processes can be organized by several methods:

- Distributor with one ignition coil;

- Distributorless with a dual (triple, quadruple depending on the number of cylinders divided by 2) ignition coil;

- Individual (for each spark plug).

In all cases, the coil receives a powerful pulse with an amplitude of 12V from a breaker (for cars before the 90s), a transistor switch, or directly from the engine control unit. It is from this point that the signal to the tachometer should be taken.

Possible faults

It’s understandable why drivers decide to install the device on cars with low panels, but before you connect the tachometer, you need to understand its main faults.

Symptoms of device failure are:

- when starting the power unit or while driving, the instrument needle may begin to jump;

- When the engine is running, the needle on the scale points to zero.

To begin with, if malfunctions are detected, you should diagnose the wiring and condition of the contacts. If the circuit for connecting the tachometer to the ignition switch was made using silicone wires, this can also lead to incorrect operation of the device. Sometimes the reason for a non-working device lies in a breakdown of the motor speed controller. As for digital devices themselves, in this case the digital display most often breaks down, so in the event of such a breakdown, the display will have to be replaced.

Types of electrical circuits

There are several options for circuits for monitoring the condition of electrical equipment of the VAZ-2109:

- With a "high panel". This scheme is considered as the most interactive and relevant. It provides an additional circuit that is intended for an automotive mounting block.

- With a "low panel". This circuit is used to identify a malfunction in the automotive mounting block.

- With Europanel. This version of the diagrams provides complete information for both the internal diagram and the mounting block. It also includes a diagram that helps to connect a Europanel, that is, electrical devices and appliances created according to the “Euro” type.

Malfunctions of the carburetor version

An ignition coil is used as a source of information about the speed of rotation of the crankshaft in the VAZ 2109 carburetor. It is designed to generate a spark that ignites the fuel-air mixture in the combustion chambers. Essentially, it is a mini pulse transformer that converts 12V to 30KV. In a four-cylinder engine, a spark is generated twice per revolution of the crankshaft. Taking this circumstance into account, the tachometer determines the number of revolutions per minute and deflects the needle proportionally.

Normal operation of the engine while the tachometer needle of the VAZ 2109 is jumping indicates a failure of the device itself, a wiring fault or problems in the units associated with the ignition coil. Start by checking the wiring. The device removes the signal from the negative coil, switching occurs through the terminal system and the fuse block. If a visual inspection does not reveal a problem, you can connect the coil to the tachometer directly using a meter-long piece of wire. If the problem disappears, you can leave this temporary connection as a permanent one, attaching the wire to the standard harnesses.

Inspect the high-voltage wires, distributor and switch. A very likely cause of the needle jumping is a faulty switch. In the VAZ 2109 this device cannot be repaired and can only be replaced. Experienced motorists carry this inexpensive and easy-to-install spare part with them.

Connect the replacement switch without installing it, and if the arrow stops moving, replace the switch. If all this does not help and the tachometer still does not work, consider replacing the device.

Examination

The rotation counting system must be checked one at a time. It’s better to start by checking the ignition coil; it is the one responsible for the operation of this device in the first place.

Coil

This element is an inductor. Its task is to convert electrical voltage into a pulse of a certain magnitude and value. There are 2 contacts on the element.

- Contact "B" is the "+" input from the battery. This contact is the beginning of the primary winding of the inductor.

- Contact “K” is the outlet for the controller.

- The central contact is necessary to supply a spark to the spark plugs.

To check the coil you will need a multimeter. The check is carried out as follows:

- Switch the multimeter to the mode for measuring electrical resistance.

- The red test lead is connected to pin “B”.

- The black test lead is connected to pin "K".

- The resistance of the primary winding should vary between 3–3.5 Ohms.

If lower data is available, the device can be considered faulty. Next, the secondary winding is checked.

- The tester switches to resistance measurement mode.

- The red test probe is connected to contact “B” on the coil.

- The black test lead connects to the center output.

- Operating resistance should be in the range from 5.4 to 9.2 kOhm

Any deviations are considered a malfunction. Next, check for a short circuit:

- The multimeter must be switched to dialing mode.

- The red test lead is connected to pin “B”.

- The black test probe is connected to the device body.

The absence of a signal from the tester will indicate the integrity of the winding, and the absence of a short circuit between contact “B” and the housing. In a similar way, contact “K” and the central output are checked. The absence of a buzzer from the tester will indicate the integrity of all windings. It is also worth visually inspecting the reel for dents and cracks. Any damage may impair the operation of the device.

Voltage check

Voltage plays a big role in the ignition system. To check, start the engine. Next you need:

- Switch the tester to DC voltage measurement mode.

- Connect the red probe to the “+” terminal of the battery.

- Connect the black test probe to the minus terminal.

The generator charging voltage should be between 13 and 15 volts. Next, you need to connect the red tester probe to contact “B” on the ignition coil. The presence of voltage will indicate the integrity of the wiring.

Distributor

Also an important element. The tachometer receives electrical impulses from it. Contactors can be electronic or mechanical. Checking the mechanical device comes down to cleaning the contact itself and setting the gap between the breaker. When the starter is cranked, a spark should appear at the contacts.

The electronic contactor is a Hall sensor. During rotation of the shank, electrical impulses are generated. Checking your device is very simple:

- Connect the red measuring probe of the multimeter to contact “2” of the sensor.

- Connect the black probe of the tester to ground.

- Crank the engine with the starter.

The sensor should produce a voltage of 4 to 15 volts, depending on the crankshaft speed.

Capacitor

This element is responsible for equalizing the voltage in the circuit. It's easy to check. It is enough to turn on the control light in the circuit between the capacitor and the ignition coil.

When the ignition is on, the light should not light up. If this happens, the capacitor will have to be replaced.

Wires

The wires that distribute the spark to the spark plugs are also often the cause of short circuits. They can be checked with a tester. But the problem is that in this way only the integrity of the wire cores is checked.

For penetration with the body, the test can be carried out as follows:

- Start the power unit.

- Open the hood of the car slightly.

- In dim light, it is very easy to see the spark that breaks through the insulation of the wires onto the housing.

All faulty wires must be replaced.

Fuse

On vehicles with a high panel, the tachometer is protected by fuses “F16” and “F15”.

They must be checked for the integrity of the internal jumper. This can be done visually, or using the tester in dialing mode. The fuses are rated 10 amps. Replacement must be carried out strictly with an exact analogue.

Tachometer

To check the tachometer, you need to disconnect its pulse wire from terminal “K” of the ignition coil. Next, use this wire to touch the “+” terminal of the battery several times. The arrow should react with movement when voltage is applied. If this does not happen, then the tachometer receiver is faulty.

Next, we will describe the connection diagram for the tachometer on a VAZ-2109 with a carburetor fuel injection system.

What is a tachometer and why is it needed?

A tachometer is a device that, as I already said, shows the number of engine revolutions per minute (thousand rpm). The tachometer readings are necessary to make it easier for the driver (usually a beginner) to navigate and correctly select the desired gear (up or down). A tachometer is also necessary in order to monitor the correct operation of the engine by the number of revolutions. For example, when the speed fluctuates or is too high, a fault can be detected in time.

The first tachometers were analog (they are also called dial gauges). Analog tachometers have a dial with numbers and an arrow. One division of the analog tachometer is equal to 1 thousand revolutions. A little later, digital (electronic) tachometers began to appear on mostly Western-made cars. Data in electronic tachometers is displayed on a display (LCD or LCD display). In modern cars, digital tachometers look like analog ones because, like older tachometer models, they display information in the form of a dial and an arrow that indicates the number of revolutions.

October 2009

| Mon | W | Wed | Thu | Fri | Sat | Sun |

| « Sep | But I " | |||||

| 1 | 2 | 3 | 4 | |||

| 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| 19 | 20 | 21 | 22 | 23 | 24 | 25 |

| 26 | 27 | 28 | 29 | 30 | 31 | |

Recently, quite a lot of friends and acquaintances have been changing their carb systems to an injector. In principle, there is quite a lot of information on this matter... But people periodically have some questions... In this article I will tell you how to connect a tachometer and speedometer to an injection car with an old-style instrument panel (not VDO!)

I myself solved this problem simply - I installed a VDO panel. Everything there is simple and clear, and I have enough information on connection on my blog. But as practice shows, sometimes people do not have the opportunity to buy VDO, since the budget is limited... And sometimes, out of ignorance, they prefer not to worry at all and drive without a speedometer and tachometer.

Speedometer As we know, on old-style devices there is no speed sensor, but a speedometer cable. The dashboard also does not have a speedometer signal input, but there is a hole for the speed cable. The problem is easily solved, you just need to buy a suitable speed sensor. According to their design, there are two types. One without cable implementation

install such a sensor on the VDO dash

But such a sensor is installed on the devices with a cable

Those. it is connected to the COURT harness, and the cable is also inserted into its hole. those. the sensor takes data without disturbing the old design.

That's basically all about the speed sensor. The only thing worth considering is that there are different connectors, be guided by the one you need.

Tachometer

They told me that on the instrument panel of a tall torpedo there is a separate input for a low-voltage tachometer - pin 5 of the red block.

The following can only be considered as a theory of converting a high-voltage signal into a low-voltage one

The situation with this issue is even more complicated than with the speed sensor. To be honest, many friends asked “how do we connect the tachometer?” ... I kept silent and said, “I know it’s possible, but how? xs." Again, as for the VDO panel, everything is simple, there are initially two connectors on the white block for connecting the tachometer injection signal (pin 2) and for connecting a high-voltage signal (pin 3). A high-voltage signal is needed when the VDO tidy is installed on a carburetor car. But what if the tidy is old? I thought about this a lot, especially because I have an old instrument panel and tachometer on one injection machine. I was too lazy to look at how everything was implemented... Out of boredom today I started studying electrical circuit diagrams and came to an interesting observation. ’ll just make a reservation right away: I haven’t tested this in practice, so I can’t vouch for it. If someone checks it, please write about your success. While studying the circuit diagram of the VDO instrument panel, I noticed that the only difference in each signal input is that there is a resistor on the high-voltage track. that's all. everything is very simple. I dare to suggest that on the old tidy there is also a resistor on the tachometer track that converts the high-voltage signal into a low-voltage one. Therefore, to connect an injection tachometer to this tidy, you just need to disassemble the tidy, pay attention to the contact path that comes from pin 3 of the red block and find this resistor. Remove the resistor from the device or bypass it. those. solder the bypass wire. Again, I emphasize that these are all just theoretical thoughts, since I myself have not disassembled the device. If anyone does it, be sure to post the results. If someone sends photos of the disassembled device or a report on this operation, I will be grateful.

I checked it with the tachometer. I just connected the device with VP to January 7.2. Everything is a bundle, there are no problems, you don’t need to do anything with the resistor, just stretch the wire from the instrument panel (red connector, 3rd pin, red-brown wire) to the controller wiring (it’s also red-brown there). Everything works great. Thanks for the tip, I thought there was a completely different signal there.)

Resistors

Resistor R2 can be one at 50 Ohms, but there can be 3 in parallel at 150 Ohms or 2 in parallel at 100 Ohms. The purpose of using multiple resistors is to reduce the power dissipated by each resistor. It is reasonable to do this during maintenance or repair of the panel, and it is better to install 4 resistors of 200 Ohms with a power of 2-3 W. Probably, this resistor is needed in case of a break in the excitation winding or the wire going to it. In other cases it is not used. Usually gets very hot.

The panel has 3 connectors: white, red and BSK connector.

Idle speed adjustment

The second setting of the VAZ-2109 carburetor is idle speed, it can be partial or full. The first is for minor speed adjustments, the second is for adjusting the amount of air (setting CO emissions in the exhaust gases).

Partial adjustment is performed using the air-fuel mixture “amount” screw. This screw sets the opening angle of the throttle valves, which ensures that the air-fuel mixture enters the cylinders when the accelerator pedal is released. The “quantity” screw rests on the throttle valve control lever and when screwed in, it pushes the lever, causing the valves to open slightly.

Partial idle adjustment is performed with a warm engine and creating a load on the vehicle's on-board network by turning on the high beam headlights and the interior heater at full power. The adjustment is carried out with the engine running by screwing in/unscrewing the “quantity” screw until the optimal idle speed is established, which for the VAZ-2109 is 800-900 rpm (this can be tracked using a standard or plug-in tachometer).

If it is not possible to set the required speed or the motor operates unstably at it, a complete adjustment is made, which is made by two screws - “quantity” and “quality”.

The algorithm for this adjustment consists of the following stages:

- Warm up the engine and then turn it off;

- We find the quality screw (it may be closed with a plug that will have to be removed), screw it in until it stops, and then unscrew it 3-4 full turns;

- We start the engine, turn on electrical consumers (lighting and stove) to create a load in the on-board network;

- By rotating the “quantity” screw, we achieve 700-800 rpm on the tachometer;

- By turning the “quality” screw, we set the maximum possible speed (they will increase to a certain level, and then stop. The moment the speed increase stops is considered the maximum);

- We set the “quantity” screw to 900 rpm;

- Using the “quality” screw we lower them to 800 rpm;

- We slowly tighten the “quality” screw until interruptions appear in the operation of the power plant, after which we unscrew it back 1 turn;

- We adjust the speed with the “quantity” screw, bringing it to a normal value - 800-900 rpm;

After the adjustment operations, we check that they were carried out correctly. This is done by sharply pressing the gas pedal and then quickly releasing it. With a properly configured carburetor, the engine should respond quickly to pressure, without any failures or hesitations. And after releasing the pedal, the speed will drop to the idle level, without sags or instability of the engine.