In modern cars with injection engines, electronics are responsible for preparing the working mixture. The quality of the working mixture depends on the ratio in which fuel is mixed with air. Depending on the amount of air passing through the throttle valve, the electronic engine control unit determines how much fuel needs to be supplied to the cylinders. To determine the amount of air entering the engine, a mass air flow sensor or mass air flow sensor is used ; in some sources the name “volumeter” is found.

“Where is the air flow sensor?” - inexperienced car owners are interested. This sensor is installed in the intake air tract immediately behind the air filter; it is connected to the control unit using a six-pin block.

In theory, the process of measuring the amount of air passing through the throttle valve is not particularly difficult. If you press the gas pedal, the damper opens, and it will be easier for air to get in; when you release it, on the contrary, much less air is sucked in. However, the engine constantly operates in different modes, the driver either presses or releases the gas pedal, and constantly in different ways; in addition, turbulence occurs in the intake tract, so in reality the task will be much more difficult.

Design and principle of operation of the mass air flow sensor

There are no moving parts in the mass air flow sensor. Thanks to this, its service life increases. The principle of its operation is as follows. The sensing element of the first sensors developed by Bosch is a platinum wire or nickel mesh. Electric current is supplied to the element, which heats it. If the system is wire, then the thermoelement will heat up to a temperature 100 degrees higher than the temperature of the incoming air, the temperature of the nickel mesh is 75 degrees higher than the temperature of the incoming air.

The incoming air flow cools the sensing element, therefore, more current is required to maintain its temperature. Based on how much the current has increased, the engine control unit determines how much air enters the engine. Some mass air flow sensors produced frequency output signals, i.e. their variable variable was the frequency of the output pulses. Such mass air flow sensors were used in VAZ car engines equipped with a “January-4.1” controller.

Modern mass air flow sensors, installed, including on VAZ cars, have a more complex design. Instead of wire or mesh, they have a thin film as a sensing element on which temperature sensors and a heating element are placed. The principle of operation of the mass air flow sensor of VAZ cars is slightly different. In the center of the film there is a heating zone; the degree of heating is controlled by thermal sensors. On both sides of the film there are two additional thermal sensors, i.e. one is directly in the path of the air flow, and the second is hidden behind the film. When the car is stationary, the temperature of both sensors is the same; when driving, the first sensor is cooled by the incoming air flow, and the second has an almost constant temperature. The temperature difference between the temperature sensors is directly proportional to the mass of intake air.

How to check the mass air flow sensor

This device is quite complex and expensive, which will require care when rejecting it. It is better to use instrumental methods, although situations may be different.

Method 1 - external inspection

The location of the MAF along the air flow path already behind the filter should protect the sensor elements from mechanical damage from flying solid particles or dirt.

But the filter is not perfect, it can be torn or installed incorrectly, so the condition of the sensor can first be assessed visually.

There should be no mechanical damage or visible contamination on its sensitive surfaces. In such cases, the device will no longer be able to give correct readings and intervention will be required for repair.

Method 2 - Power off

In unclear cases, when the ECM cannot clearly reject the sensor and switch to bypass mode, this action can be performed independently by simply turning off the engine and removing the electrical connector from the mass air flow sensor.

If the engine operation becomes more stable, and all its changes remain only typical for software bypass of the sensor, for example, an increase in idle speed, then the suspicions can be considered confirmed.

Method 3 - test with a multimeter

All cars are different, so there is no single way to check the MAF with a multimeter voltmeter, but using the example of the most common VAZ sensors, you can show how this is done.

The voltmeter must have suitable accuracy, that is, be digital and have at least 4 digits. It must be connected between the instrument ground, which is on the mass flow sensor connector, and the signal wire using needle probes.

The voltage of the new sensor after turning on the ignition is quite a bit short of 1 Volt, for a working mass air flow sensor (Bosch system, Siemens is found, there are other indicators and methods) it is approximately in the range of up to 1.04 volts and should increase sharply when blowing, that is, starting and set of revolutions.

Theoretically, it is possible to test the sensor elements with an ohmmeter, but this is already an activity for professionals who know the material well.

Method 4 - scanning with Vasya Diagnostic scanner

If there are no prerequisites for displaying an error code yet, but suspicions about the sensor have formed, then you can view its readings through a computer-based diagnostic scanner, for example VCDS, which in Russian adaptation is called Vasya Diagnost.

The channels associated with the current air flow (211, 212, 213) are displayed on the screen. By switching the engine to different modes, you can see how much the MAF readings correspond to the required ones.

It happens that deviations occur only during a certain airflow, and the error does not have time to appear in the form of a code. The scanner will allow you to look at this in much more detail.

Method 5 - replacement with a working one

The mass air flow sensor is one of those sensors whose replacement is not difficult; it is always visible. Therefore, it is often easiest to use a replacement sensor, and if the engine operation returns to normal according to objective indicators or scanner data, then all that remains is to purchase a new sensor.

Diagnosticians usually have replacements for all such devices available. You just need to make sure that the replacement device is exactly the same as required for this engine according to the specification, appearance alone is not enough, you need to check the catalog numbers.

Which mass air flow sensor is better

Each sensor has its own advantages and disadvantages, so this question cannot be answered unambiguously. The wire mass air flow sensor is highly reliable. This is its main advantage, which can cover all the disadvantages, including lower measurement accuracy compared to film mass air flow sensors and the inability to register reverse air flow.

The film sensor, which is installed on modern VAZ engines, due to the presence of two temperature sensors, is capable of registering reverse air flow (if the temperature of the second sensor is lower than the first), in addition, the accuracy of its measurements is very high. The main disadvantage of the sensor is that it is afraid of dirt and moisture, so if the car owner wants uninterrupted operation of the sensor, he needs to carefully monitor the condition of the air filter.

Checking the mass air flow sensor using an experimental method

If the car owner suspects a malfunction of the sensor in question, but does not have a multimeter on the farm and cannot borrow one, then it is quite possible to carry out the check without a tester.

To do this, you will have to deactivate the mass air flow sensor and drive the car, monitoring its condition. You can remove it completely if you are inclined to think that it is not working, or simply turn off the power when doubts are still present.

Next you need:

start the engine; increase the speed to 1,500; move away carefully.

In the absence of communication with the sensor, the VAZ on-board computer turns on an emergency mode, in which the volume of supplied fuel is calculated based on the opening angle of an element such as the throttle valve.

When it turns out that without a mass air flow sensor the car begins to move more vigorously, accelerates more easily, the speed does not fluctuate at idle, etc., then this means one thing - the mentioned sensor will have to be changed.

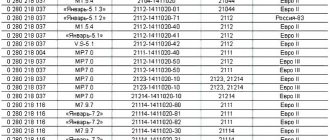

Interchangeability of mass air flow sensor for VAZ cars

Some owners of VAZ cars are interested in what will happen if they install another mass air flow sensor instead of the standard one, and how safe such an improvement is.

Still, if absolutely necessary, if the standard sensor cannot be found anywhere, you can “reflash” it to the parameters of the mass air flow sensor intended for another VAZ engine. However, this should be done extremely carefully, since there is a high probability of completely destroying the ECU. » alt=»»>

All modern engines are equipped with a mass air flow sensor (mass air flow sensor). This sensor is necessary for the normal operation of the car. Signs of a malfunction of the mass air flow sensor appear in unstable engine operation , as the fuel mixture is not formed correctly. You cannot drive a car with a non-working sensor; this can lead to other, more serious damage.

TEST SEQUENCE

HINT: Use a handheld diagnostic tool to read the fixed parameters. These parameters reflect the state of the engine at the time the malfunction was detected. When troubleshooting, fixed parameters allow you to determine whether the car was moving at the time of the malfunction or not, whether the engine was warmed up, what the air-fuel mixture was (lean or rich), etc.

| 1.TAKE HAND-HELD TEST READINGS (MASS AIRFLOW) |

Connect the handheld diagnostic tool to the DLC3.

Start the engine and turn on the handheld scan tool.

Select the following menu items: Powertrain / Engine and ECT / Data List / MAF.

Read the values displayed on the scan tool.

Result:

| Air mass flow (g/s) | Next step |

| 0,0 | A |

| Not less than 271.0 | B |

| Between 1.0 and 270.0 (*1) | C |

*1: The value should change when the throttle valve is opened or closed while the engine is running.

| B |

Go to step 6 C

CHECK FOR INTERMITTENT PROBLEMS

| A |

| 2.CHECK MASS AIRFLOW SENSOR (SUPPLY VOLTAGE) |

Disconnect the mass air flow (MAF) sensor connector B1.

Turn on the ignition (IG).

Measure the voltage between the harness-side connector pin and ground.

Rated voltage:

| Contacts for connecting a diagnostic tool | Specified conditions |

| +B (B1-3) - mass | 9-14 V |

Reconnect the mass air flow sensor connector.

| NG |

Go to step 5

| OK |

| 3.CHECK MASS AIRFLOW SENSOR (VG TERMINAL VOLTAGE) |

Check the output voltage.

Disconnect connector B1 of the MAF sensor.

Apply battery voltage to terminals +B and E2G.

Connect the scan tool positive (+) probe to terminal VG and the scan tool negative (-) probe to terminal E2G.

Rated voltage:

| Contacts for connecting a diagnostic tool | Specified conditions |

| VG (5) - E2G (4) | 0.2-4.9 V |

Reconnect the mass air flow sensor connector.

| NG |

REPLACE MASS AIRFLOW SENSOR

| OK |

| 4.CHECK HARNESS AND CONNECTOR (MASS AIRFLOW SENSOR - ECM) |

Disconnect connector B1 of the MAF sensor.

Disconnect ECM connector B32.

Nominal resistance (check for open):

| Contacts for connecting a diagnostic tool | Specified conditions |

| VG (B1-5) - VG (B32-118) | Less than 1 ohm |

| E2G (B1-4) - E2G (B32-116) |

Nominal resistance (check for short circuit):

| Contacts for connecting a diagnostic tool | Specified conditions |

| VG (B1-5) or VG (B32-118) – weight | 10 kOhm or more |

Reconnect the mass air flow sensor connector.

Connect the ECM connector.

| NG |

REPAIR OR REPLACE HARNESS OR CONNECTOR

| OK |

| REPLACE ECM |

| 5.CHECK HARNESS AND CONNECTOR (MASS AIRFLOW SENSOR - INTEGRATED RELAY) |

Disconnect connector B1 of the MAF sensor.

Remove the integrated relay from the No. 1 relay block in the engine compartment.

Nominal resistance (check for open):

| Contacts for connecting a diagnostic tool | Specified conditions |

| +B (B1-3) - 1A-4 | Less than 1 ohm |

Nominal resistance (check for short circuit):

| Contacts for connecting a diagnostic tool | Specified conditions |

| +B (B1-3) or 1A-4 - mass | 10 kOhm or more |

Reconnect the mass air flow sensor connector.

Reinstall the integrated relay.

| NG |

REPAIR OR REPLACE HARNESS OR CONNECTOR

| OK |

| CHECK ECM POWER CIRCUIT |

| 6.CHECK HARNESS AND CONNECTOR (SENSOR GROUND) |

Disconnect connector B1 of the MAF sensor.

Nominal resistance:

| Contacts for connecting a diagnostic tool | Specified conditions |

| E2G (B1-4) - mass | Less than 1 ohm |

Reconnect the mass air flow sensor connector.

| OK |

REPLACE MASS AIRFLOW SENSOR

| NG |

| 7.CHECK HARNESS AND CONNECTOR (MASS AIRFLOW SENSOR - ECM) |

Disconnect connector B1 of the MAF sensor.

Disconnect ECM connector B32.

Nominal resistance (check for open):

| Contacts for connecting a diagnostic tool | Specified conditions |

| VG (B1-5) - VG (B32-118) | Less than 1 ohm |

| E2G (B1-4) - E2G (B32-116) |

Nominal resistance (check for short circuit):

| Contacts for connecting a diagnostic tool | Specified conditions |

| VG (B1-5) or VG (B32-118) – weight | 10 kOhm or more |

Reconnect the mass air flow sensor connector.

The principle of operation of the mass air flow sensor

Mass air flow sensor design

The mass air flow sensor is responsible for ensuring that the fuel mixture is correctly formed based on the amount of air consumed.

The mass air flow sensor is responsible for ensuring that the fuel mixture is correctly formed based on the amount of air consumed. It determines how much gasoline should enter the cylinders of the block through the injectors, sending appropriate signals to the electronic control unit . In order to determine the amount of air that passes to the throttle valve, highly sensitive threads are built into the sensor. The mass air flow sensor is located immediately behind the air filter, and determines the amount of air already purified. Mass air flow sensor is installed on all modern gasoline and diesel engines. In older engines without a mass air flow sensor, the fuel mixture is formed based only on the throttle position . That is, the harder the driver presses the accelerator pedal, the richer the mixture. This does not take into account air quality and density, and the engine does not always operate optimally when temperature or other environmental factors change.

How to comply with consumption standards

The dosage of the liquid component is easy to ensure. The pressure, the diameter of the gas line, and the throughput of the fuel injectors are known. By opening the injector valve for a certain time, the ECU controller can fill the combustion chamber of the cylinder with exactly as much gasoline as is required to form the mixture. How to measure the mass of incoming air?

To generate data on the amount of air, injection cars are equipped with a mass flow sensor. It converts information from physical (kg/hour) to electronic, in the form of varying voltage at the sensor output. There are even special calibration schedules for the engine ECU.

A certain mass of air passing through the mass air flow sensor corresponds to a clearly established voltage value, accurate to 1/1000 volts.

Having received additional information:

- air temperature;

- the presence of oxygen in it;

- engine temperature;

- data from lambda probes;

- speed from crankshaft sensor;

The electronic control unit mixes the optimal proportion of the fuel mixture in the combustion chambers of the cylinders.

Since the air sensor generates a continuous stream of data, the mixture composition is adjusted in real time, ensuring acceptable fuel consumption for the vehicle. In addition, based on this data, the ECU complies with exhaust gas toxicity standards in accordance with the Euro environmental standard for a particular vehicle.

Many fans of power plant tuning are wondering: is it possible to drive without a mass air flow sensor? There is a misconception that this device is intended solely for the environment, and turning it off will increase the power of the car. To get the correct answer to this question, let’s look at the mass air flow sensor device.

Causes of DMRV malfunction

MAF sensor location

Most often, the mass air flow sensor does not work correctly due to clogging.

- Clogging. Most often, the mass air flow sensor does not work correctly due to clogging. Crankcase gases from the throttle valve, or propane gas when connected to the throttle valve block (Euro-2), can get here along with the air. As a result, a layer of deposits forms on the threads that sense the amount of air.

- Broken threads. Sensor threads can fail due to wear or misuse. Like any other device, the mass air flow sensor has a limited service life, and, as a rule, it lasts for 100-150 thousand mileage. In addition, the sensor may break due to gas detonation in the throttle assembly.

MAF sensor on a diesel engine, signs of malfunction

DMVR began to be installed on diesel engines recently. This is due to the improvement of the latter and the introduction of more complex but effective monitoring systems into their work.

The air meter performs several important functions:

- Limits smoke on turbocharged engines.

- It monitors not only the amount of air in the intake pipe, but also the volume of crankcase gases.

In the first case, when the gas pedal is sharply depressed, a certain volume of diesel fuel is formed, for which a corresponding volume of air must be formed.

But since the turbine spins up late (a turbo lag forms), the required amount of air does not have time to form. The mixture is over-enriched, fuel is not completely burned, soot is released into the exhaust system, and short-term smoke is observed from the exhaust pipe. The DPF filter partially solves the problem, but if it exists.

To solve this problem and limit excess fuel during sharp acceleration, the mass air flow sensor is activated. It transmits information to the controller about the actual amount of air pumped by the turbine.

The electronic control unit, having received this data, limits the cyclic supply of fuel, adjusting its amount to the volume of air.

This solution made it possible to reduce diesel fuel consumption while maintaining the power characteristics of the engine, but provided that the MAF sensor works correctly.

Secondly, the mass air flow sensor on a diesel engine works in conjunction with the crankcase ventilation system. It monitors how much exhaust gas enters the intake system through the EGR valve when it opens and transmits this data to the ECU. The latter, based on the information received, controls the opening and closing of the EGR valve.

This solution reduces both fuel consumption and the amount of harmful emissions into the atmosphere.

Based on this, the main signs of a breakdown of the flow meter on a diesel engine may be:

- Brief appearance of smoke (soot) from the exhaust pipe during acceleration.

- Unstable operation of the motor in transient modes, reduction in power.

- Increased consumption of diesel fuel.

Diagnostics of mass air flow sensor on a diesel engine is no different from the methods described above.

The main symptoms of a malfunction of the mass air flow sensor

- The engine runs rough at idle. If the sensor is faulty, the idle speed of the car will be unstable. Especially when starting the engine before warming up, there will be strong fluctuations in speed. Sometimes the engine simply stalls if you increase the speed with the accelerator pedal.

- RPM freezes. Also, the revolutions can hang at around 2-3 thousand when the gas is completely released and stay there for several seconds.

- Lost engine thrust. If a faulty sensor leans the mixture, the engine power will decrease. The car will accelerate poorly and go downhill.

- Increased fuel consumption. A low signal from the mass air flow sensor can cause the mixture to be too rich, resulting in a 20-30% increase in flow.

Messages 12

1 Topic from Vital 2111 2016-02-12 19:18:47

- Vitalya 2111

- New member

- Inactive

- Registration: 2016-02-08

- Messages: 6 Thanks : 1

- Auto: 2111

Topic: problems with engine speed and starting, Is it possible to drive without a mass air flow sensor?

Hi all . I encountered this problem: the engine starts, then the speed drops and the engine stalls; when you press the gas, it stalls immediately. Replacing the IAC and TPS, cleaning the DZ did not give any results, all the symptoms are the same. I decided to turn off the mass air flow sensor, it started from half a turn, the speed floats, drops to 500, but it doesn’t stall and responds normally to the gas. Is it possible to drive without a mass air flow sensor?

2 Reply from sergo9531 2016-02-12 19:25:57

- sergo9531

- Local

- Inactive

- From: Domodedovo

- Registration: 2014-01-12

- Messages: 578 Thanks : 208

- Auto: 21114

Re: problems with engine speed and starting, Is it possible to drive without a mass air flow sensor?

Vitalya 2111 , it’s possible, but the consumption will increase. This infection is expensive, try to clean it. If there are traces of oil in the air duct to the engine, you need to repair the crankcase ventilation, and only then install a mass air flow sensor. otherwise it will fail quickly.

3 Reply from Alevtina.Trofimova 2016-02-12 19:26:02

- Alevtina.Trofimova

- Experienced

- Inactive

- From: Selty, UR

- Registration: 2014-08-04

- Messages: 181 Thanks : 65

- Car: VAZ 21103

Re: problems with engine speed and starting, Is it possible to drive without a mass air flow sensor?

Consumption will increase significantly, and when switching to neutral it will stall.

Diagnostics of mass air flow sensor

When you turn off the mass air flow sensor, you can deceive the ECU - it switches to emergency mode using a simplified algorithm.

Before you begin repair work, you need to find out whether the problem is really in the mass flow sensor. You can check the mass air flow sensor yourself even without instruments. To do this, you simply need to turn off this sensor with the engine off. Then the operation of the car without the sensor is checked. If the problems disappear, then in this case the sensor is faulty. When the mass air flow sensor is turned off, the control unit can be deceived, and it switches to emergency mode and operates according to a simplified algorithm. But it is not recommended to constantly use a car with the mass air flow sensor turned off. In this case, fuel consumption increases and the engine does not work quite correctly. You can also check the mass air flow sensor with a multimeter. In order to ring the air flow sensor, you need to connect the probes to the sensor while the engine is running. The device should show 1-1.02 volts. If the voltage on the sensor is more than 1.05 volts, then the sensor is faulty and does not work correctly. It is advisable to clean it or replace it. The pinout of the mass air flow sensor is described in the instructions for the car, since different cars have different connectors for connection. You can also check the performance of the mass air flow sensor by reading errors from the on-board computer. A faulty sensor necessarily transmits an error message to the control unit. Before checking the mass air flow sensor, it is advisable to rule out other potential problems. Similar problems with lean or over-rich mixtures can be caused by the throttle position sensor, idle air control valve and lambda probe.

Video “Checking the mass air flow sensor using a multimeter”

This video from the “Simple Opinion” channel demonstrates how to check the mass air flow sensor with a multimeter.

Help me figure out if the DMRV malfunctions, immediately change the DMRV or clean it. And how to check the DMRV. and how did your car behave with a faulty air sensor and after replacing it?

Comments 11

But when I turn off the mass air flow sensor, the car stalls, is that how it should be?

Soak it in gasoline overnight. It helped me when carb cleaner didn’t help!

I turned off the DMRV today, nothing has changed

That means it’s not a matter of the mass air flow sensor!

It’s just that the diagnostics already show that the DMRV has been screwed up and the control unit is blocked; it’s already in emergency mode. I don’t have a check on my car. I have an EPS (control of engine electronics). I think I’ll probably buy a new one.

YOU CAN check! turn it off and that's it! The car will start working in an “emergency” state, the “check” will light up! and try to ride! Good luck!

The spark plugs are blown, when you give it gas, there is black smoke at rpm. As they say, the consumption increases

first, of course, try to clean it, it’s cheaper than changing it right away, if that doesn’t help, then of course replace it. Symptoms of a dead sensor can be either separately, but more often all together - it becomes dull when accelerating, eats gasoline in buckets (for 1.6 liters 12-13 probably), the smell of gasoline from the exhaust pipe when the engine is running, black carbon deposits on the spark plugs. In general, if the computer says that there is a weak signal from the DMRV, then it is half-dead, but it can be brought back to life) regarding cleaning - I would not recommend cleaning it with carbkiner, it is a very active mixture. although people cleaned it, it seemed without consequences, at least at first)) (certain types of air flow sensors, tape ones definitely cannot be cleaned) I cleaned mine like this - I warmed up a glass of alcohol in the microwave, lowered the sensor there to let it dry (this three or four times), then I very carefully cleaned those very sensitive elements with a pen and alcohol. I took photos before and after the event - the difference is noticeable, and this difference was visible only during macro photography and when viewing the photo on a 16x zoom)) after cleaning, the smallest wire on the sensitive elements became visible.

Replacing the air flow sensor

If the mass air flow sensor is faulty and cannot be cleaned, it must be replaced with a new one. Depending on the car model, the price of a mass air flow sensor is 3-5 thousand rubles.

- Disconnect battery. In order not to damage the power supply circuit, it is advisable to carry out all procedures with the battery disconnected.

- Remove the old sensor. First, the plug with the wiring is disconnected, then the fastener is unscrewed and the sensor is removed from the air duct.

- Install a new sensor. The new sensor must be installed carefully, without touching the threads inside the sensor. Then the plug with wires is connected. The sensors have a standard connector for each car brand.

- Connect the battery.

The main causes of failure of the mass air flow sensor

The most common causes of sensor failure are:

- dust ingress;

- oil contamination;

- short circuit of the wiring due to damage to the insulation or plug;

- mechanical damage to active elements.

A common cause of incorrect operation of the mass air flow sensor is the failure of electronic components, which increases the sensor’s response time to changes in air flow. A working sensor monitors changes at a speed of 0.5 ms, and if it breaks down, the response time increases by 20-30 times. The defect is detected only by recording the operation graph with an oscilloscope. Such a sensor cannot be repaired; it must be replaced with a new one.

What factors disable the mass air flow sensor?

Factors causing failure of the air flow sensor:

- Dust may be caused by improper installation of the sensor on the filter, which causes the sealing ring to become distorted. With this defect, a thin coating of contamination will be present on the sensor input grid. Another cause of dust is a clogged air filter, so regular maintenance will prolong the life of the air flow sensor.

- Oil is thrown onto the sensor if the level in the crankcase is high or if the oil separator in the ventilation system is clogged. An additional negative factor is engine wear, which causes lubricant to actively enter the crankcase ventilation.

- Contact with sharp objects on the insulation, oiling. Such impacts are the result of careless repairs.

- Damage to the sensor is possible during vehicle maintenance (impacts to the body) or during improper cleaning of the active part.

How to clean the mass air flow sensor

It is not possible to repair the mass air flow sensor with your own hands, since the threads inside the sensor cannot be replaced.

It is not possible to repair the mass air flow sensor with your own hands, since the threads inside the sensor cannot be replaced. Therefore, you can only replace it with a new one or try to clean it. The air flow sensor is quite expensive, so it is advisable to try washing the threads. In half of the cases, this helps and after using the mass air flow sensor cleaner, the engine starts working normally. Under no circumstances should you use aggressive solutions to clean the sensor. If you apply acetone or carbocleaner, the threads will most likely be damaged and the sensor cannot be restored. It is advisable to use Liqui Moly air flow sensor cleaner. Also a fairly high-quality product is the Luftmassensensor Reiniger air flow sensor cleaner. Among folk remedies, formic alcohol is often used. To clean, the sensor must be carefully removed without touching the threads. Then a cleaner is applied to the threads inside. The liquid is applied several times at intervals of half an hour so that all deposits can dissolve. After washing, the sensor dries and is installed in the car. Do not use a hair dryer or other devices for drying. DMRV is one of the most important sensors in a car, as it is responsible for the formation of the fuel mixture and normal engine operation. If it breaks down, engine performance deteriorates and consumption increases greatly. Therefore, it is advisable not to delay repairs and replace or clean the sensor as quickly as possible.

With the advent of electronic processor devices and injection systems for forming an air-fuel mixture into the internal combustion engine control system, it was necessary to use special sensors that determine the parameters of the mass flow in the intake manifold. The first was the mass air flow sensor.

We clean the DMRV ourselves

After we have discussed methods for diagnosing the sensor, as well as means for cleaning it, let’s move on to the most important question - how to clean the air flow sensor on a VAZ 2114 yourself?

First, you need to disconnect the block that supplies the power wires - to do this, you just need to press the button on its lower part, and then pull it towards you. You also need to unscrew the two fastening screws connecting the air flow sensor to the air filter (for this you will need a 10mm wrench).

After this, you should use a Phillips screwdriver to unscrew the screws located on the sensor casing in the area where the block with wires is attached - having done this, you will be able to disassemble the casing itself and remove the sensor out.

Flushing the air flow sensor

We wash all elements of the sensor responsible for its sensitivity - the contacts and wire of the temperature sensor - with a spray from a can (if it is a carburetor cleaner or VeDe-shka). At the same time, you should strictly monitor the jet pressure - to do this, you need to keep the sprayer at a distance of at least 15 cm from the sensor.

After half a minute, this operation can be repeated, after which wash all areas where the first composition was applied using a syringe with a solution of ethyl alcohol. After this, all that remains is to assemble the sensor in the reverse order and mount it in place.

What is a mass air flow sensor in a car?

The controller that controls the amount of fuel injected by the injector must receive information about the mass flow moving through the intake manifold. For this purpose, the readings of the mass air flow sensor are used - a device for fixing the mass air flow. The more accurate the information, the better the mixture.

The reason to get acquainted with the “hardware” of the mass air flow sensor and its location in the engine appears at the first symptoms of a malfunction of the mass air flow sensor. The reasons may be:

- unstable engine operation, both at idle speed and when driving on the highway;

- the engine starts with great difficulty, especially if it was previously running under load;

- the appearance of an indication on the dashboard indicating problems with the engine, and fuel consumption increased noticeably.

Symptoms and troubleshooting

Since the mass air flow sensor is electronic equipment, and a very complicated one at that, most car owners do not dare diagnose it themselves and take it to a car service center the old fashioned way. But quite often, having just connected the diagnostic device to the sensor, the auto repairman declares that the device is completely faulty, it cannot be repaired, and its place is only in a landfill. Rest assured, if you bring in a completely new sensor, the technician will tell you the same thing.

But any disinterested expert will say that the mass air flow sensor is an almost indestructible device. It may malfunction, sometimes seriously, but this is a completely fixable problem, something that will take no more than an hour. But how to check the mass air flow sensor for performance? Very simple. If, after installing a new sensor on your car, you notice that it works perfectly, then that is where the problem lies. If the situation has not improved at all, then there is no point in wasting your energy, time and money on the empty hassle of replacing a completely “healthy” sensor.

Just above we mentioned such a device as a multimeter. You can understand whether the sensor is working or not by finding out the voltage of the device. If everything is normal, then the multimeter produces 1-1.2 W. If there are any problems, then the scale goes down, the critical mark starts at 0.99 W. If, on the contrary, the voltage is higher than normal, for example 1.037, then this indicates one thing: the sensor is very clogged, and therefore makes errors in the readings. If you clean it, it will work again at the same rate.

If there is neither a new sensor nor a multimeter, then you can check the condition of the part in the old-fashioned way. At engine idle speed (870-910 rpm), the sensor in good condition produces 9.6-10 kg of air per hour. If the revolutions reach two thousand per minute, then this figure increases to 20 kg/h. We looked at ideal indicators. When they become higher or lower, the need for repair is obvious. What are the well-known symptoms of a sensor failure?

First of all, this is a sharp increase in fuel consumption. Here you should not blame the car for its large “appetites”: it is not to blame, and the manufacturer is not to blame, here you just need to “treat” your “iron horse”. Of course, this can happen not only in the case of a sensor failure, but from this fact alone you can come to the right idea: most likely the problem lies in the tiny device.

Also, when the engine loses power, a hot engine will stop starting. The car, previously dynamic and controllable, turns into some kind of monster on wheels, which is constantly lost in control and “freezes”. And finally, if you see a simple Check Engine sign on the instrument panel, then there can be no doubt: this sensor is asking you for an ambulance.

Design and operation of the air flow sensor (AFS)

Considering the fact that AvtoVAZ generously stuck mass air flow sensors on all more or less hard-working cars, from the tenth to the fourteenth model, it is worth knowing how this miracle works and works.

The principle of operation of the mass air flow sensor uses a change in the temperature of a 0.07 mm metal layer welded onto the ceramic layer of the sensor, or a thin platinum wire under the influence of an air flow. The mass air flow sensor is installed on a special holder and placed in the central part of the air manifold section in front of the throttle valve to reduce the influence of local turbulence.

In addition to the platinum layer, two thermistors are glued to the surface of the silicon element to record the temperatures of the air and the sensitive element. A small electrical circuit controls the measurement process, and under certain conditions it also starts a self-cleaning mode of the sensor from varnish and oil films of dirt. At the same time, on the surface of platinum the temperature soars to 1000 o C, and oxygen in the air converts organic substances into combustion products.

How to restore the mass air flow sensor?

The optimal solution for problems with the mass air flow sensor is to replace the faulty sensor with a new one. But since the cost of the device is about 2500-3900 rubles, many owners are trying to “revive” the old part.

There are four recovery methods:

- installation of additional resistance;

- blocking part of the air supply channel to the thermistor with aluminum tape;

- updating the engine control unit firmware;

- washing the sensor body and housing from dirt.

Installing additional resistance

Additional resistances are installed in the circuit connecting the sensor to the control unit. When an electric current passes, the voltage decreases, which can be brought to the required limits. The resistance value is selected experimentally. Most often, a 1 kOhm resistor is soldered to the yellow wire and a 15 kOhm element to the green wire.

Blocking part of the air supply channel

The repair principle is based on partially cutting off the air supply to the thermistor. Due to this, less intensive cooling is ensured and it is possible to bring the voltage value to the state of a working device. The cross section is selected experimentally with voltage monitoring using a multimeter. In some cases, owners block the supply channel by 70-80%. Aluminum tape is used for gluing.

Correcting the firmware of the engine control unit

An adjustment means a change in the calibration or operating schedule of the mass air flow sensor stored in the unit’s memory. The dependence graph is constructed in such a way that at a sensor voltage of 0.996 volts, the flow rate is considered equal to zero. But if the sensor fails and the starting voltage is 1.055 volts, then the control unit considers the air supply to be 1.8 kg when the engine is not running. Changing the graph using the MAF Corrector utility will allow you to set the flow rate to 0, which will improve engine performance. This method can be recommended to owners who are well versed in the control unit software.

Do-it-yourself cleaning of the air flow sensor

The air volume sensor is cleaned after it is detected that it is not working correctly. The procedure is performed by partially disassembling and removing the device body with active elements. At the same time, the body is washed and cleaned from remaining leaves and dirt deposits. In many cases, washing the air flow sensor on a VAZ 2114 does not help restore the device’s parameters.

Mechanical methods of cleaning the mass air flow sensor on the VAZ 2114 are prohibited, as is blowing dust with compressed air.

What products should be used to clean the sensor?

To clean sensors, there are special liquids supplied in pressurized aerosol cans. An example of such a product is a special air flow sensor cleaner Luftmassensor-Reiniger from Liqui Moly. There are similar liquids from other manufacturers. You can wash the sensor with a mixture of 70% isopropyl alcohol and 30% distilled water, after warming the device to 60-70 ºС with a hair dryer.

When washing the mass flow sensor it is prohibited:

- try to clean the sensor with cotton balls, hard objects and brushes;

- use household cleaning products;

- Use carburetor cleaners based on acetone or ether.

Cleaners based on heavy petroleum products, for example, WD40, will remove plaque from working parts, but will leave a greasy film that must be washed off with isopropyl alcohol. The use of ether-containing substances is not recommended due to the destruction of the compound filling and electronic components.

Algorithm of actions

Sequence of steps when washing the mass air flow sensor:

- Remove the sensor together with the housing from the engine air duct. The device is attached with a clamp to the channel and two bolts to the air filter housing.

- Unscrew the two screws securing the sensor to the housing. The bolts have a star head, but many owners unscrew them with pliers.

- Wash the measuring thermistors and the air passage channels with a cleaning agent. If the cleaning method with alcohol is used, the removed sensor is heated with a stream of warm air and placed in a container. The alcohol-water mixture is also heated to 60-70 degrees.

- Dry the sensor.

- Wash the sensor housing with warm soapy water. Rinse under running water and dry.

- Assemble the sensor and install it in place.

We check and evaluate the symptoms of a DMRV malfunction

It is clear that signs of a malfunction are conditional, problems may not be limited to the performance of the mass flow measurement device, so before deciding on further procedures it is worth conducting a couple of additional tests to diagnose the mass air flow sensor.

To do this you can do:

- driving with the mass flow sensor disabled;

- measuring the potential of the mass air flow sensor;

- An old military trick is to temporarily replace the problematic sensor with a known-good mass air flow sensor, rented from a gullible neighbor.

If you are not the proud owner of an ECU controller Ya7.2.M7.9.7., simply disconnect the connector block on the air flow sensor. With another type of engine, fault testing will not work. What happens if you disconnect the mass air flow sensor (MAF)? The engine will start and run. In this case, the logic of the controller, which has detected a complete malfunction of the air flow sensor due to a removed contact, will switch it to emergency mode based on information about air flow and will use its average values and information about the throttle position.

In practice, this will mean increasing the idle speed to 1400 rpm, depending on the deadness of the throttle position sensor. Most importantly, in the sensations during control acceleration, you will feel that the agility and throttle response of the car has noticeably increased. Conclusion: most likely the mass air flow sensor is bad, but the question is - how bad? The main idea of the check is not to rush to buy and replace an expensive mass air flow sensor, but to try to find a compromise. It is possible that by washing or other manipulations the operation of the mass air flow sensor can be restored.

Is it allowed to travel?

You can drive without a mass air flow sensor - yes, but you should carefully assess the situation. When devices fail, the driver does not always have a spare one with him in his emergency kit. Also, sensors for some types of cars are extremely difficult to find, especially when it comes to brands of foreign cars.

In the event of a planned or emergency shutdown of the device, the vehicle operates in emergency mode. Only the throttle valve is responsible for preparing the air-fuel mixture. The state of affairs cannot be called correct, since it provides ideal performance indicators, quickly breaks down and leads to breakdown of the constitutive parts of the mechanism. What will happen if you drive without a mass air flow sensor for a long time, it is clear that the car will become unusable.

When operating in emergency mode, only the damper determines fuel consumption. There is high fuel consumption. There will be no fuel savings, which is extremely unprofitable in Russian realities. The crankshaft rotation speed will be at least half a thousand revolutions per minute. There are no gradations.

You can determine whether the sensor needs to be replaced yourself. To do this, the device is turned off and only the throttle valve reads the readings. If, in the absence of equipment, the vehicle moves quickly, then it is faulty and requires replacement.

Measuring the potential on the mass air flow sensor

If your car has a Bosch version of the flow sensor with catalog designations 0280218004, -037, -116, it is easier and more reliable to directly measure the potential generated by the mass air flow sensor DMRV. We measure using any device that allows you to work with a range of 0-2 V and an accuracy of at least a hundredth of a volt. Try to use a proven device for measurements, without additional extension cords, wires and needles.

Finding the mass air flow sensor housing in the air manifold is quite simple. A wire harness of different colors fits into the connector chip, tightly closed with a rubber cap. The MAF pinouts include the following:

- The 1st wire provides the sensor input signal, usually a yellow wire;

- The 2nd and 3rd wires are responsible for the power supply, “+” and “-”, respectively;

- The 4th wire is connected to the main relay.

To measure the potential, we use the first and third wires of the harness. There are several options for connecting the probes of a measuring device, but you should definitely not use paper clips or thin sharp wires. They can significantly affect the accuracy of the measurement. You can finely sharpen the copper tips of the probes and pierce the insulation of the wires with them, as close to the contacts as possible.

The measurement is performed with the ignition switch on but the engine turned off. If the connection is made correctly, the device will show a value from 0.996 - for a new sensor, to 1.05 - for one that is practically “dead” and requires replacement.

Checking and repairing at home

There are eight ways to independently check amplitude and frequency mass flow sensors.

Method No. 1 - disabling the air flow meter

The method consists of disconnecting the sensor from the fuel system of the car and checking the functionality of the system without it. To do this, you need to disconnect the device from the connector and start the engine. Without a mass air flow sensor, the controller receives a signal to switch to emergency operation mode. It prepares the air-fuel mixture only based on the throttle position. If the car moves faster and does not stall, it means that the device is faulty and requires repair or replacement.

Method No. 2 - flashing the electronic control unit

If the standard firmware has been changed, then it is unknown what reaction of the controller is programmed in it in case of an emergency. In this case, you should try to insert a 1mm thick plate under the throttle stop. The turnover should increase. Now you need to pull out the chip from the air flow meter. If the power unit continues to work, then the cause of the malfunction is the firmware.

Method No. 3 - installing a working sensor

Install a known good part and start the engine. If after replacement it begins to work better, the motor does not stall, then replacement or repair of the device is required.

Method No. 4 - visual inspection

To do this, use a Phillips screwdriver to unscrew the clamp holding the air collector corrugation. Then you need to disconnect the corrugation and inspect the internal surfaces of the air collector corrugation and the sensor.

Inspection of duct corrugation

There should be no traces of oil or condensation on them, the surfaces should be dry and clean. If you do not take care of the air filter and change it rarely, then dirt can get on the sensitive element of the sensor and cause it to break. This is the most common malfunction. Traces of oil may appear in the flow meter if the oil level in the crankcase is high, or if the oil sump of the crankcase ventilation system is clogged. If necessary, you need to clean the surfaces using special cleaning products.

Method No. 5 - checking the mass air flow sensor with a multimeter

To do this, you need to turn on the tester in a mode in which constant voltage is checked. The limit value for measurements should be set to 2V.

DMRV operation diagram

- The yellow wire is located closer to the windshield. It serves as an input for a signal from the flow meter.

- The white-gray wire is the sensor voltage output.

- The black and pink wire leads to the main relay.

- The green wire is used to ground the sensors, that is, it goes to ground.

The wires may have different colors, but their location is unchanged. To check, you need to turn on the ignition, but do not start the car. The red probe from the multimeter must be connected to the yellow wire, and the black one must be connected to ground, that is, to the green wire. We measure the voltage between these two outputs. Multimeter probes make it possible to connect without disturbing the insulation of the wires.

On the new device, the output voltage ranges from 0.996 to 1.01 V.

During operation, this voltage gradually increases and by its value one can judge the wear of the flow meter:

ADC flow meter readings

Diagnostics of the mass air flow sensor "Tseshkoy" is not difficult and can be done with your own hands.

If there is dirt on the removed sensor, you can clean it yourself. You can use WD-40 to wash it. To clean the mass air flow sensor, you must first remove the pipe from it, and then dismantle the device itself. Inside the device there is a mesh and several wires - sensors.

Assessment of the condition of the air flow sensor by external inspection

To remove the sensor, you need to unscrew its mount on the air duct, loosen the clamp and disconnect the corrugated piece of pipe. The sensor itself is fastened with a pair of screws that can be unscrewed with a ten key, after removing the chip with wires, you can carefully remove the housing from the socket. Inspecting the surface, you can see traces of dust and oil. The presence of stains and dirt suggests that the self-cleaning mode will no longer help it. But we need to find the cause of the pollution.

Pay attention to the rubber ring sealing the connector. It performs the function of blocking possible suction from the engine compartment into the sensor cavity of dirty air clogged with fumes. In the normal position of the suction ring, most likely there was no suction.

Most often, dirt settles on the surface of the sensor due to poor condition of the air filter. Sometimes, on the recommendation of numerous experts, car enthusiasts treat the filter cartridge with a special oil aerosol. Typically, this preparation is used on full-flow air filters of zero resistance. But the effect is achieved for a new filter within the same 5-10 thousand km. The aerosol will not provide special protection for the mass air flow sensor from microdust particles.

The video shows a little more about the mass fuel flow sensor:

Removal and replacement

If the VAZ 2114 air sensor was checked, and the check confirmed incorrect operation, then you should think about replacing it. Experts do not advise rushing to throw away a part, even if it is not working correctly. Sometimes it happens that after cleaning the contacts it starts working again

It’s worth paying attention to this possibility if you don’t want to replace the part.

When it is not possible to revive an existing part, you should go shopping. A new part will not be cheap, it is an expensive pleasure. That is why experienced technicians advise initially checking the functionality of the old sensor before spending your savings. To replace the product, you will need to prepare a flat-head screwdriver, as well as a 10mm wrench.

The sequence of actions should be as follows:

- Initially, the ignition is turned off, the hood is opened, and the negative terminal is removed from the battery.

- Now you have to determine where exactly the sensor is located. Usually there are no difficulties with its location. In the engine compartment you can see the air filter unit; it is made of plastic. This sensor is located on its rear part; it is usually mounted on the air filter pipe.

- Next, the clamp made of metal is removed and the product is connected to a corrugated hose through which air is supplied.

- You will need to pull off the corrugated hose.

- Next, the contact block is removed, and it should be taken into account that there is a button on the bottom of the plug. When pressed, the spring wedge is released. This is necessary to freely pull out the block.

- A pre-prepared 10mm wrench is needed to unscrew the bolts one by one; they are used for fixing. By the way, the second of them is located on the lower part of the case.

- All that remains is to remove the sensor.

Characteristic

On VAZ cars, the mass air flow sensor is mounted between the air filter element and the throttle hose. Today, products from the manufacturer Bosch are very popular among compatriots. Regardless of whether it is a universal Bosch sensor or, for example, spark plugs, quality from a German manufacturer can always give a head start to domestic products. Let's look at the main characteristics of regulators models 116 and 037.

116

DMRV 116 is designed to control and convert the air flow that enters the motor into voltage. The data transmitted by the regulator makes it possible to determine the operating mode of the power unit and calculate the cyclic filling of the cylinders with air flow. This filling is carried out in steady-state operating modes of the motor, which last no more than 0.1 seconds.

Let's look at the technical features that Bosch 0 280 218 116 has:

- the regulator operates on the principle of measuring air flow;

- the device provides accurate data, which ensures optimal fuel consumption;

- operating range varies from 8 to 550 kg/h;

- the output pulse level when measuring the range from 0 to 100% will be about 0.05-5 volts;

- As for power supply, the controller is powered from the vehicle’s electrical network, that is, 12 volts is enough for it;

- current consumption is about 0.5 ampere;

- the regulator can function normally in the operating range from 45 degrees below zero to 120 degrees;

- The service life of the Bosch 116 mass air flow sensor is about 3 thousand hours.

Bosch 116 device

037

As for the mass air flow sensor 037 from Bosch, the technical features will be similar. The controller consists of two main elements - working and control, as well as a heating resistor device. The air that enters the engine cools one of the controllers, while the electronic module converts the temperature differences between the controllers. In the event that sensor 280 218 037 fails, its options will be performed by TPS.

As mentioned above, the technical features of the models are the same:

- the operating range for normal operation varies in the region of 8-550 kg/h;

- when operating correctly, the controller will provide accurate data, making it possible to achieve optimal gas mileage (of course, if the engine is running in normal mode);

- since the element is used in a car, it is logical that it should be powered by 12 volts;

- the controller consumes about 0.5 ampere of current;

- the part can operate normally both at 45 degrees below zero and at 120 degrees of heat, this is its operating range;

- service life is at least 3 thousand hours;

- Unlike model 116, the new one in calculations can produce an error of 2.5 percent (both down and up).

Regulator model 0280218037

What happens if you turn off the air sensor of the VAZ 2110

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

It is worth killing the one who invented the mass air flow sensor. Kill. Resurrect. Kill again. Then torture.

PS. I don't think anyone turned it off. Either exchange it for Siemens or all sorts of dadas, or buy a new one and pray that it will last for more than 10 thousand

You can still wash it when you have nothing to lose.

there are 2 rows of numbers stamped on it, and you need to take t

where did you see two rows of numbers? what's on the box?

Prevention of breakdowns and cleaning of the air flow sensor of the VAZ 2114

The flow meter sensor is located in a vulnerable place: exposure to temperature changes, moisture, dust.

Precision electronics located in the measuring channel fail when foreign objects enter.

- untimely replacement of the air filter;

- the use of so-called “zero” filters;

- loose connection of the mass air flow sensor with the air duct flanges;

- moisture entering the air intake;

- Debris left in the ductwork or filter housing after repairs and maintenance.

How to clean the mass air flow sensor if contamination does not render it inoperable

The sensor must be removed, the protective nets removed, and blown with clean compressed air. If there is dried dirt or oil stains, washing with special means for mass air flow sensor is required. Of course, it is necessary to clean the air duct itself with the filter housing.

In most cases, such prevention brings the flow meter back to life.

What happens if you turn off the air sensor of the VAZ 2110

There will be: 1. Higher consumption. 2.Higher revs XX. 3.Accordingly accelerated engine wear. 4. The engine will not produce the required horses and torque.

and with DMRV? . it seems like XX with air flow sensor should be like this, but without it = about 2000

Quote: There will be: 1. Higher consumption. 2.Higher revs XX. 3.Accordingly accelerated engine wear. 4. The engine will not produce the required horses and torque.

patap48

If you carefully read my topic, then I myself challenged it there))))))))) because it became better. but I did not receive a clear answer.

PySy since the mass air flow sensor had to be changed, I washed it. The month is already plowing. ugh ugh ugh

I didn’t get a clear answer

and with DMRV? . it seems like XX with air flow sensor should be like this, but without it = about 2000

Quote: There will be: 1. Higher consumption. 2.Higher revs XX. 3.Accordingly accelerated engine wear. 4. The engine will not produce the required horses and torque.

Is there any marking there? Which one should I buy?

For fuck's sake, did you speed up the car? However, it is fraught.

037 is easily placed instead of 004. But for 116th you need to change the calibration in the firmware.

It’s like this: if I’m wrong, people will correct me.

patap, since the DMRV is to be thrown away, for the sake of science, wash it))))) we are just interested in whether it makes sense or not. but few people wash it, everyone buys a new one

037 is easily placed instead of 004.

What happens if you turn off the mass air flow sensor on your car?

On auto forums there are a lot of posts from keyboard “experts” on the topic: “I drive without a mass air flow sensor, the power has doubled, I can kill everyone at a traffic light.”

Of course, these statements have nothing to do with reality. It is impossible to increase power with a disabled mass air flow sensor.

- Firstly, without information from the sensor, the ECU will not be able to form the correct proportion of the fuel mixture, and combustion efficiency will decrease. The driver, compensating for the lack of power, will press on the accelerator, increasing gasoline consumption. As a result, the fuel will simply fly out into the pipe, without giving the car the required dynamics.

- Secondly, when we disconnect any important sensor (and the mass air flow sensor is one of these), the ECU switches the engine control to emergency mode. That is, in principle, you can drive a car, but only slowly and to the nearest service station.

Information: It is not the mass air flow sensor that is directly related to the environment, but the lambda probes. It is the disabling of these sensors that, in principle, will lead to an increase in engine output with a deterioration in exhaust toxicity. Only then will you need to reflash the ECU controller.

What factors cause the mass air flow sensor to fail?

Most often, the device fails for reasons such as:

- Internal defects of the part;

- Oxidation of contacts;

- Poor wiring connection;

- Short circuit;

- Dust ingress;

- Filling with oil;

- Mechanical damage to the element.

Often, a malfunction of the mass air flow sensor occurs due to careless actions of the owner. For example, after careless washing of the power unit or during maintenance or repair. Failures associated with broken contacts or wiring can be corrected by cleaning the connections or repairing the break. Other problems usually require replacing the sensor. But if it becomes dirty with dust or oil, it can sometimes be cleaned. Most faults can be diagnosed by yourself. Some of them are visible during inspection, the rest are determined when checked by a tester. If self-diagnosis does not help you find the cause of the breakdown, it is recommended to contact a car service center.