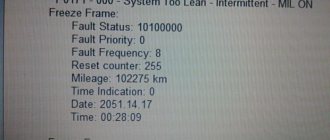

Description of the problem: At a speed of about 90 km/h, the “Check Engine” light comes on.

I should note that this is a fairly common situation among e-gas owners. We can say that this is most likely a manufacturing plant defect.

As for AvtoVAZ, it refused to recognize this problem as a “defect”, but published an information letter containing a description of this problem and ways to solve it.

This problem occurs in both Kalin, Prior, and Samar, equipped with 8-valve engines with an electronic gas pedal.

The “check” lights up due to error P1335 - “The damper position is in an unacceptable position.”

Reason for the error

- Faulty mass air flow sensor (on e-gas it is installed of the frequency type).

- The air-fuel mixture does not meet the standards (bad gasoline, injectors are overfilled/underfilled, high/low pressure, etc.).

- Faulty controller.

If you have checked these elements and the indicator does not go out, then all that remains is to reprogram the ECU using PB-6 (you will need an additional cable for the M74 controller) using the file “I414DE07.hex”.

This file can be found on the Internet.

A similar service should be provided by official AvtoVAZ dealers.

Auto electrician website. Repair practice, electrical circuits, etc.

Code P1335 Monitoring throttle actuator control, throttle position out of range

Code P1335 is entered if: - the ignition is on; — the throttle position exceeds the maximum permissible for 0.5 s; — the throttle valve is in the maximum permissible position for 3 s.

The malfunction indicator lights up 5 s after the fault code appears. Description of checks

1 Using a diagnostic tool, check for the presence of codes P0122, P0123, P0222, P0223, P2135, P1545, P1558, P1559, P1602, P1336, P1388, P1389, P0606. Troubleshooting must begin with these codes. 2 If the fault occurs periodically, the controller must be replaced. Diagnostic information From the moment the ignition is turned on until the main relay is turned off, the controller monitors the throttle position. The maximum permissible throttle position is calculated depending on engine speed, accelerator pedal position, engine temperature, etc. If a malfunction is detected, the engine management system will operate in emergency mode until the end of the current trip: de-energizing the electric throttle drive and limiting engine speed (2500 rpm). The reason for fixing code P1335 may be a malfunction of the processor hardware or software errors that lead to incorrect calculation of the specified throttle position.

Throttle valve wiring diagram for Lada Granta, Kalina 2

P0354 Ford error - Autognostics

Chevrolet Aveo 2012 DTC P0351-P0354 - LDE

Diagnostic guidelines

DTC IDs

Diagnostic fault information

Ignition voltage is supplied to the ignition coil. The Engine Control Module (ECM) connects the ignition coil control circuits to ground. When the ECM disconnects ground from the primary winding of the ignition coil, the magnetic field of the coil disappears. When the magnetic field disappears, voltage is induced in the secondary winding, which ignites sparks in the spark plugs. The ECM controls the order and timing of sparks.

Conditions for Diagnosing a DTC

Conditions for Setting the DTC

Action Taken When the DTC Sets

Conditions for clearing a fault code

Diagnostic guidelines

reference Information

Engine controls Layout: KL9 → Without KL9

Index of connector types

Description and operation

Reference information on electrical equipment

DTC Type Index

Diagnostic Tool, Link

Circuit/System Test

- Start the engine and set it to idle.

- Observe the scan tool Cylinder 1 Misfire Counter, Cylinder 2 Misfire Counter, Cylinder 3 Misfire Counter, and Cylinder 4 Misfire Counter parameters. Counters should not be incremental.

- Drive the vehicle according to the conditions of the existing DTC to verify that the DTC does not reset. The vehicle can also be driven according to the conditions of the frame/failure recording data.

- Ignition OFF, disconnect the harness connector at the K35 ignition coil module.

- Test for less than 5 Ω between ground circuit terminal B and ground.

Troubleshooting

If during diagnostics an error 0363 of a VAZ 2114 is noticed, then the reasons for this may be the following:

- Poor quality fuel.

- Air intake leaking.

- No spark.

- Damage or wear to the cylinders.

The first of these problems is quite simple to solve - you should try to refuel with gasoline from other manufacturers, and not the one that is currently used. Despite its apparent simplicity, this method very often helps - after all, as statistics show, more than half of the cases of error 0363 are associated with low-quality fuel.

If an error occurs very often and, as a result, leads to the shutdown of one of the cylinders (but the engine itself and related units are fully operational), you can reflash the engine control unit, removing information about this error from it.

If replacing the fuel does not help and the troubles continue, you should check the air intake system. It is necessary to tighten all fastening clamps, replace the air filter if it is worn out, and also measure the pressure in the ramp (normally it does not exceed 2.8 atmospheres).

The next step in troubleshooting will be diagnosing the ignition system.

So, you will need to check:

- the condition of the armored wire connecting to the faulty cylinder;

- condition of the spark plug of a faulty cylinder;

- presence of oxides at connection points.

In order to check the condition of high-voltage wires, you need to measure their resistance with a tester. Normally it should not be more than 10 kOhm. If the measurements show greater resistance, then the wires are faulty and should be replaced (this should be done even if a regular “continuity test” shows the presence of a working circuit).

If the wires are in good condition, then you should check the spark plugs, or better yet, replace them with new ones, especially if the ones already installed belong to the “budget” price segment (as you know, all four spark plugs should be replaced at once, and not just one faulty one).

If all the above steps did not help, all that remains is to check the condition of the cylinders themselves. To do this, you should measure their compression. Its difference among all four cylinders should not exceed 0.5 atmospheres. If in some cylinder it differs significantly (both up and down), the car should be taken to a car service center to diagnose the engine condition.

P2598 Ford error | Ford

How to read DTC Error codes — Ford Transit Connect without an OBDII device

VGT Turbo Position Sensor Test

Turbo Repeat Sensor HDI, TDCI

DTC P02A8 FORD TRANSIT DIESEL 2009. FALLA CIL #4

1.6 TDCI Ford Focus Turbo

Defeito Chicote Falha Sensor Map Ranger

2014 Ford Focus Frankfort IL P2598

Error P2562 Cause How To Fix Turbo Actuator Position Sensor Solenoid PART1

- Technorot spare parts Ford

- Ford explorer 2004 owner's manual

- Why are Fords bad?

- Wheel rim Ford a 150

- Sensors on Ford Focus

- Ford raptor 2015 dimensions

- Fuel system Ford Galaxy gasoline

- Ford parts

- Replacing rear wheel bearings for Ford Focus 1

- Ford Focus 2 frame size

- Ford Mondeo panther black

- Ford Transit 1994 2000 test drive

- Warranty period for Ford Focus 3

- Test drive Ford Transit video 2001

- Disease Ford Focus 2 hatchback

The speed check (e-gas) lights up, error P1335

Description of the problem: At a speed of about 90 km/h, the “Check Engine” light comes on.

I should note that this is a fairly common situation among e-gas owners. We can say that this is most likely a manufacturing plant defect.

As for AvtoVAZ, it refused to recognize this problem as a “defect”, but published an information letter containing a description of this problem and ways to solve it.

This problem occurs in both Kalin, Prior, and Samar, equipped with 8-valve engines with an electronic gas pedal.

Error p1335 ford connect

Crankshaft Position Sensor REF P1335 Testing and Replacement HD

6.0L Ford PowerStroke Egr Valve Removal P1335 P0401 P0402 P0404

How to check EGR Valve on a Euro 4 engine in a Ford Focus or Transit Connect

Crankshaft Position Sensor (POS) P0335 & P1336 Testing and Replacement

P0404, P0405 EGR Codes

DTC P244C: Catalyst Temperature Too Low During Regeneration. TEST AND EXPLAINATION

How To Clear A P0100 Engine Code On A 1998 Jeep Cherokee

FORD GALAXY HOW TO ERASE ENGINE MALFUNCTION FAULT ON DISPLAY (english)

Ford Focus 1.8 TDDI EGR Cleaning

P0340, P0335 Camshaft/Crankshaft Position Sensor Codes

- Ford Focus automatic transmission cooling pipe

- The whole range of Ford Sports

- Ford explorer 294 l with engine model

- Ford Focus vs Lada Priora

- Underskirt for ford c max

- Ford transit cargo 1994

Description of the problem

In general, there was a terrible downpour, puddles on the roads, and general floods in the yards.

But we had to go, my wife and daughter were in the shopping center, and the queue for the minibus, according to them, was huge. I am inclined to believe that the minibuses simply stalled (we have old, decrepit Gazelles in our city).

We have one place that is constantly flooded. I look, and there are new Kia Sid floating on the radiator grille in the water, well, I’m taller, I thought that nothing would happen. Here, as luck would have it, the traffic light is still red, and the intersection is straight, only a pedestrian crossing, on which there is no one at all, since it is knee-deep in water. Most people pass it, even on red lights, quietly. And I’ve only been driving for a month, I’m not used to breaking rules yet. Has stopped.

Belt whistled due to water ingress

My Granta is standing there, waiting for the green light, and then the alternator belt started whistling, as if it was slipping. I see the voltage on the on-board computer jumps, from 13 Volts to 11.8, and there is a whistle under the hood. The light turned green and I was off. I started, drove out of the puddle, accelerated a little and the whistle disappeared. The voltage on the on-board computer screen leveled out to 13.6.

Among the current consumers, my headlights were on, the rear window was heated, the tape recorder was working quietly, and the heater was turned on at second speed to blow the windshield.

I got to the shopping center, stopped, and waited for my wife and daughter. The engine begins to vibrate and bleed a little. I went home already on the detour, there are fewer puddles there. I dropped everyone off and decided to go to the garage.

I started the engine, the revolutions jumped to 6000, I was already scared. Then they dropped to 1000, the engine sneezed and died. The check engine light on the dashboard came on. It started again, it idles, but pressing the gas pedal does not respond. I try to start, it idles and doesn’t respond to the pedal at all when driving. So I drove to the garage in second gear, well the 21116 engine is torquey and drives like a tractor.

I repeated the experiment in the garage. I started it up, tried to press the gas pedal, nothing happened, the revs were like a glove, the engine icon was still on.

How I solved the problem of gas pedal failure

- I took a smoke break and decided to remove the terminal from the battery.

- I reset it and waited five minutes. He swore that he forgot the diagnostic adapter at home.

- Reconnected the terminal and started it.

- “Jackie Chan” stopped burning, the engine reacts to the gas pedal with a vigorous increase in speed. The engine really didn’t start at first, it started only the second time.

I left the garage, circled along the pit line, and came back. There were no signs of damage. Now I'm afraid to drive in the rain.

What could it be? Now I’m subconsciously afraid that if I start the engine, my Lada Granta won’t want to go anywhere in rainy weather. How likely is this situation to happen again?

On which cars is this problem most common?

The problem with code P0338 can occur on different machines, but there are always statistics on which brands this error occurs more often. Here is a list of some of them:

- BMW

- Chevrolet

- Citroen (Citroen C5)

- Dodge (Dodge Ram)

- Ford

- Hyundai

- Jeep

- Kia (Kia Optima, Sedona)

- Nissan

- Peugeot (Peugeot 307, 406)

- Subaru

- Toyota (Toyota Tundra)

- VAZ 2110, 2112, 2114, 2115

With fault code P0338, you can sometimes encounter other errors. The most common are the following: P0335, P0336, P0337, P0339.

How to Troubleshoot or Reset Trouble Code P0338

Some suggested steps to troubleshoot and fix error code P0338:

- Visually inspect the electrical wires and connectors of the crankshaft and camshaft position sensors.

- Check the level, condition and viscosity of the engine oil.

- Read all stored data and error codes using an OBD-II scanner. To determine when and under what circumstances the error occurred.

- Clear the error codes from the ECM and test drive the vehicle to see if the P0338 code appears again.

- Inspect drives, belts or timing chains for wear.

- If no problem is found, continue diagnosing by following the vehicle manufacturer's procedure.

When diagnosing and eliminating this error, you must follow the recommendations of the vehicle manufacturer. Failure to do so may result in severe engine damage and may result in hasty replacement of faulty components.

What are the symptoms of a P0103 code?

- When a P0103 , the Check Engine light will illuminate on your vehicle's dashboard. As a rule, the car continues to operate normally, which makes it possible to independently get to a service station to diagnose the error by a qualified specialist.

- However, there may be a slight drop in engine power, as well as unstable engine idling.

- In some cases, damage to internal engine components may occur.

VAZ (LADA) errors via OBDI protocol. Self-diagnosis.

1 — Malfunction of the engine control unit.

2 — The voltage in the on-board network is too high.

3 — Malfunction in the electrical circuit of the fuel level sensor.

4 — Malfunction in the electrical circuit of the antifreeze controller.

5 — Error in external temperature controller.

6 — Overheating of the engine (power unit)

7 — Emergency oil pressure in the engine.

8 — The voltage in the vehicle's electrical network is too low.

9 — Low battery level (battery is discharged)

12 — Malfunction in the electrical circuit of the malfunction indicator located on the instrument panel.

13 — No data (loss of communication) from the oxygen sensor (lambda probe)

14 — High signal level of the coolant temperature sensor (antifreeze).

15 — Malfunction in the electrical circuit of the coolant temperature controller.

16 — Increased voltage in the vehicle’s electrical network

17 — Low voltage in the on-board network

19 — Malfunction in the electrical circuit of the crankshaft position sensor.

21 — Malfunction in the throttle position regulator.

22 — Low signal level of the throttle position sensor

23 — High signal level of the intake air temperature sensor

24 — Malfunction in the electrical circuit of the vehicle speed sensor.

25 — Low signal level of the intake air temperature sensor

27 — Incorrect signal from the exhaust gas system sensor

28 — Incorrect signal from the exhaust gas system sensor

33 — Malfunction in the electrical circuit of the air flow meter

34 — Malfunction in the electrical circuit of the air flow meter

35 — The ECU has detected a deviation in idle speed

41 — Incorrect signal coming from the phase regulator

42 — Malfunction in the electrical circuit of the electronic ignition system

43 — Incorrect signal coming from the knock sensor

44 — The mixture in the engine cylinders is too lean or rich

45 — The mixture in the engine cylinders is too lean or rich

49 — Vacuum leak

51 — Malfunction of one of the memory modules of the control unit - RAM or PROM

52 — Malfunction of one of the memory modules of the control unit - RAM or PROM

53 — Incorrect signal coming from the exhaust gas sensor

54 — No signal from the octane corrector regulator

55 — Poor air-fuel mixture at low load on the car engine

61 — Malfunction in the electrical circuit of the oxygen sensor (lambda probe)

E - Determining an error in a data packet stored in EEPROM

Diagnosis and problem solving

Begin your diagnosis by visually inspecting all system-related wiring harnesses and connectors. Inspect electrical circuits, sensors, and connectors that are contaminated with engine oil, coolant, or power steering fluid.

Petroleum-based liquids are known to corrode the protective insulation of wires and cause short circuits or open circuits. This may cause the P0338 code to appear.

Multimeter test

Then connect the scanner to the vehicle's diagnostic port and get all the stored trouble codes. After this, continue testing the voltage and ground signals. Most models use five volt power. Also check the ground signal and the third wire, the control circuit, should be sending a signal to the PCM.

Disconnect the electrical connector from the CKP sensor and test it according to the manufacturer's recommendations using a multimeter. Replace the sensor if resistance values do not meet manufacturer specifications. If all CKP circuit resistance values are within specifications, proceed to the next step.

Checking with an oscilloscope

Connect the positive test lead of the oscilloscope to the signal lead of the CKP harness, and connect the negative lead to the CKP ground circuit. Select the appropriate voltage setting on the oscilloscope and turn it on.

With the transmission in park or neutral and the engine idling, observe the waveform on an oscilloscope. Focus on unexpected spikes or glitches in the waveform pattern.

If you notice any spikes or glitches, gently move the wiring harness and connector while looking at the waveform diagram. You are trying to determine whether the problem is a weak connection or a faulty CKP.

Notice the voltage blocks in the waveform pattern. If some of them are missing, this indicates a broken or worn toothed ring. Also check the CKP magnetic tip for excessive metal debris and clean if necessary. If the waveform is normal, proceed to the next step.

Now reconnect the oscilloscope test leads to the same circuits near the PCM connector and observe the waveform pattern. If an abnormality is detected, there is most likely an open or short circuit between the CKP connector and the PCM connector.

If no open or shorted circuits are found, the P0338 code may be due to a faulty PCM or its programming.