Good afternoon. I decided to install a turbine on my VAZ 2107 with an injection engine. I have already purchased all the components necessary for this: a small air filter, a turbine, a bypass valve, a low-pressure fuel pump and everything else. Of course, an intercooler is also needed to cool the air flow, otherwise the 7’s engine simply won’t hold up. So I understand that an additional radiator is needed, so the question is: where is the best place to install a radiator for maximum cooling of the system? I hope there will be craftsmen who will share their own experience of installing a turbine on a domestic car.

You've got something wrong with the pump. A low pressure pump is installed on carburetor engines. You probably need a Velbro pump or whatever it is. it has more productivity. plus at least Volga injectors

Turbine for VAZ 2107

According to tuning specialists, a turbine on a VAZ 2107 is not a rewarding task, one of those things about which they say “it’s not worth the candle.”

The idea with a turbine in itself is not bad, and when implemented, you can significantly increase engine power (with a 2-liter engine capacity up to 700 hp, for example) and torque on almost any model. But it’s problematic to do this on VAZ vehicles.

The features of a classic carburetor engine are such that installing a turbine is quite difficult, troublesome and expensive.

. When installing a turbine on VAZ models, an intercooler will be required (to cool the air heated by the turbine), which will still not give the expected effect. Then - a turbine on a VAZ 2107, as well as on all other classics, is unsafe to install, unlike a compressor. There is a great danger that the exhaust manifold may not withstand the high pressure created by the turbine. There is no need to explain what this entails. Having decided to install a turbine on your well-worn (or never seen) VAZ 2107, sooner or later you will be faced with the need to convert (or change) the engine to an injection one.

All this will take hundreds of hours and tens of thousands of money. The question is - in the name of what? It’s understandable if you are an avid tuner and decide to end up with something like this:

Tuning: VAZ 2107 (turbo) 250 hp

Other videos from TheWikiHow channel

We install a cheap TURBINE on a VAZ. part 1

VAZ 2107

volume 1.6 l carburetor

turbine

from Skyline!! he's totally freaking out.

(1.7 liter engine from Niva, turbine, 5-speed manual transmission, front brake discs with perforation, rear brake discs, R15 wheels, Goodyear Tire F1 195x50 tires, body kit, neon underbody lighting, JOM leather sports seats, equipment salon)

And if you want, like any driver, to improve engine performance, and even accelerate at a traffic light not in 20 seconds, but at least in 8-10, take an interest in the “Kit kits” (0.5 bar compressor, increases power to 45-50 %)

. Kits for installing drive superchargers are designed for all domestically produced models. They are distinguished by their small size, low noise level in operation, and high reliability.

Structurally, the supercharger consists of two parts: a centrifugal compressor and a high-speed multiplier.

The drive is carried out by a poly V-belt from the engine crankshaft pulley. The compressor is not maintained during operation

When installed on foreign-made cars, it is possible to orient the direction of the pressure part of the volute relative to the position of the air line.

What you need to know about supercharging

Turbocharging is the forced injection of air into the combustion chambers by creating a high-pressure zone at the inlet of the intake tract. When the driver of the car presses the pedal and the throttle valve opens, significantly more air will enter the intake manifold than if it were supplied at atmospheric pressure. As the amount of oxygen increases, the carburetor or injector also increases the amount of fuel. Due to this, the engine power increases.

The combustion chamber has a fixed size, and its volume is a constant value. On a standard engine, only a limited amount of the fuel mixture fits into it. To increase power, it is necessary to place a larger volume of fuel in the cylinder. This is achieved by creating high pressure, which will compress the mixture. Then it will take up less space. This is why turbocharging is needed.

Features of turbocharging

The most important thing to understand is that although turbocharged engines are similar to naturally aspirated internal combustion engines, they are built on the basis of completely different principles. This is due to the specific features of combustion of a mixture of fuel and air under conditions of excess pressure and loads. The more air, the more fuel needed. Accordingly, the car's dynamics will be more acceptable.

In practice, on the one hand, the planned increase in capacity is 20-30 percent, while the volume of work and the injection of funds are significant. Therefore, it turns out that it is best to raise the result to an average level so that the costs pay for themselves and meet the desired requirements.

Where to begin?

Not every car is suitable for tuning. It is important to pay attention to the condition of the car. It is better to disassemble the car to the ground. The main problem is corrosion. You need to understand that the metal on AvtoVAZ cars is quite thin, and high loads are contraindicated for it. If you apply a serious load, the rusty metal will literally tear.

You should start by replacing the metal in the engine compartment with a more powerful one. When all body faults have been repaired, you can continue tuning further. If the car was purchased specifically for tuning, then the first thing you need to do is get it moving in stock condition. Next, they change the electrical wiring, bring the engine into good condition, or change it to a sixteen-valve one. The brake system and transmission are also inspected.

This is the first point from which the instructions for turbocharging begin. When the iron has returned to an ideal, close to factory condition, you can continue further. Moreover, we already know enough about turbocharging equipment.

How to do cooling

When upgrading a car, it is imperative to install new elements in the cooling system. You will need a double-row copper radiator. It is used on VAZ-2110 cars. It works much better than other radiators.

Try to use a normal sized intercooler. If it is very large, then the problem of turbo lag will arise. This is the case when a long time passes between opening the throttle and building up boost pressure. But a very small intercooler will not be able to cool the air properly.

Turbocharger

This supercharger is made as a separate unit, which is driven by a drive belt.

The latter will take torque from the crankshaft. The compressor is in no way connected to the lubrication or cooling system of the engine. To relieve excess pressure, which sometimes occurs in the intake tract in some operating modes, an additional valve is connected to the air valves. Often, two types of compressors are used for tuning cars - centrifugal and screw. The first is made in the shape of a snail, inside of which there is an impeller. In a screw compressor, pressure is obtained through the simultaneous rotation of two shafts equipped with blades.

Centrifugal compressors are used for self-tuning of cars. They are more affordable, have small overall dimensions, and are easy to install. Due to the fact that the performance characteristics are limited by the engine speed, it can produce no more than 0.7 Bar of pressure. The compressor can increase engine power from 15% to 30% at maximum speeds of up to 40 thousand per minute. This is a pretty serious indicator.

Among the advantages of compressors are high durability and reliability, low requirements for the condition of the motor, ease of installation, and accessibility. During operation of the turbocharger, pickup occurs at speeds of three or more. The engine immediately responds to pedal pressure - in this case there is no so-called “turbo lag”, which happens when installing other superchargers. However, at high engine speeds (more than five thousand), the increase in power is almost unnoticeable.

Visual installation

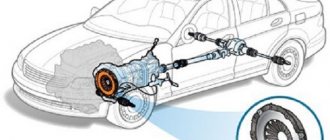

A sample with a low-pressure turbine and a VAZ 2107 engine with distributed injection involves the use of the following factory parts: cylinder block, crankshaft, connecting rods, camshaft and valves. The difference in additional components is associated only with the pistons and cylinder head due to the need to reduce the compression ratio during installation. This functional feature is achieved by enlarging the combustion chamber or special pistons. However, there is a theory that the pistons can be factory pistons and you can limit yourself to replacing the head.

The injector output also differs. The turbine fills the space between the exhaust pipe and the exhaust manifold. The factory model remains the resonator and muffler. If you need to obtain more power, still use the recommendations for installing a direct-flow exhaust. Injection requires an enlarged receiver and a non-standard control program. The lubrication system also undergoes minor changes. Summarizing the above, we can conclude that the turbine itself will be the most expensive and scarce part.

Gas turbine

Among the features of the turbine, one can highlight its rotation speed. It can reach 200 thousand rpm, and the pressure can reach up to 2 bar. This turbine can increase engine power by up to 50 percent. Turbine bearings rotate at enormous speeds and require lubrication. The system is connected to the lubrication system of the internal combustion engine. The turbine needs a certain time to gain the required speed. Therefore, it will start working only after three thousand revolutions. If you try to press the accelerator pedal sharply at low crankshaft speeds, the exhaust gas pressure will be too low for the unit to operate. You can feel the failures. This phenomenon is called nothing less than “turbo lag”.

Final result

During the research, the turbine installed on the VAZ 2107 engine injector showed the following results: provided that the clutch and tires are of high quality, the acceleration time to 100 km/h is reduced by 5 seconds (compared to the base engine). The same principle applies to elasticity: acceleration time in 4th gear from 60 to 100 km/h is also reduced by 5 seconds.

Practical implementation

The idea itself is simple. However, it is difficult to implement it on the VAZ 2107. Representatives of companies that will undertake the production of turbochargers are counted on the fingers of one hand. But turbine kits for installation on a conventional injector began to appear on the market. The kit includes all the pipes, a new block cover, the turbine itself and the intercooler.

The difficulties of installation and further adaptation to the injector are as follows:

- The exhaust gas temperature level that the turbine must withstand is theoretically between 900˚C and 950˚C.

- The working speed of the rotor injector with the impeller is numerically represented not only in tens, but in hundreds of thousands of revolutions per minute.

- The functional resources of the volume of engine compartments of passenger cars are limited, and therefore require the manufacturer to place the unit within a specific framework.

Based on the above, a turbocharger must have high heat resistance, be compact, well-balanced, and at the same time inexpensive.

8-valve engine kit

The turbo kit for the 8-valve engine has the following characteristics. It is capable of generating pressure up to 0.5 Bar. With this kit you can increase power to 120 horsepower and torque to 190 Nm. Installing this kit does not affect the life of the power unit in any way. Installation is quite simple, and all parts from the kit are hinged. There is no need to modify the engine in any way for installation.

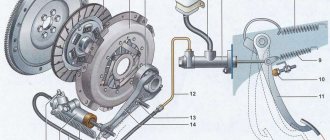

The turbo kit includes:

- Steel manifold.

- Turbocharger.

- Gaskets.

- Oil supply hose.

- Coolant supply system.

- Valve for releasing excess pressure.

- Connecting elements.

- Fasteners and other parts.

The set for 16-valve units is completely similar. Its technical characteristics are also similar. On sale you can find a turbo kit for an 8-valve engine with a power of up to 250 horsepower. A turbocharger with a pressure of 1 bar is used here.

Advantages and disadvantages

Electric turbine: characteristics, operating principle, pros and cons of operation, do-it-yourself installation tips and owner reviews

The turbine drive of the electric motor eliminates the main disadvantages of mechanical turbochargers.

- There is no lag, since the electric motor can provide a very high speed of rotation of the rotor.

- There is no turbo lag caused by a lack of exhaust gases, since in this case the lack of energy is compensated by the electric motor.

- The electric motor allows you to maintain boost during transient processes like anti-lag without the negative effects of the latter.

- This ensures a wide operating range and uniform torque.

- Some types of these mechanisms are capable of generating electricity, reducing the load on the generator and reducing fuel consumption.

- It is possible to recover lost energy, as Ferrari did in its Formula 1 engine.

- Electric turbines operate in more gentle conditions and at lower speeds (100 thousand instead of 200-300 thousand).

However, this technology has a number of disadvantages.

- Great complexity of the design, including an electric motor and controllers.

- This results in a high cost.

- In addition, the complexity of the design affects reliability.

- Due to the large number of structural elements (in addition to the turbine, this includes an electric motor, controllers, and battery), such turbochargers are much larger and heavier than conventional ones.

In addition, each type of electric turbine is characterized by specific features.

| Type | E.C. | EAT | EST | TEDC upstream | TEDC downstream |

| Advantages |

|

|

|

|

|

| Flaws |

|

|

|

|

|

In terms of durability, according to IHI, electric turbines will be equivalent to mechanical ones due to operation under the same conditions in a more gentle mode with greater design complexity.

Installation

It must be remembered that equipping an engine with a turbocharging system is a rather lengthy process. Although kit manufacturers say that you can do without upgrading the engine, this is not entirely true. Where to begin? Of course, with the purchase of the necessary spare parts and preparation of the engine. It is necessary to replace the pistons, rings, cylinder head gasket, fuel regulator, throttle, as well as pipes and other parts. All these mechanisms must be as reliable as possible.

You also need to remember that building a powerful car can vary significantly depending on the turbine model. The instructions will be quite average. For example, in order to build a turbo VAZ-2106, you first need to replace the engine.

It is necessary to install a 16-valve injection unit. The first step is to prepare the engine. The engine is disassembled, the cylinders, crankshaft, connecting rods, and oil pump are checked. If necessary, grind the block. Pistons should be purchased after the cylinders have been prepared.

Next, the attachments are assembled. At this stage, the injectors are installed and the fuel pump is changed. Then a receiver and exhaust manifold are installed and a turbine is used. All steel elements are also installed. And finally, the last stage is setup. The maximum power, torque and other characteristics of the motor will depend on how professionally and correctly the adjustment is performed. If all the operations for preparing and assembling the system can be done with your own hands, then for setup it is better to turn to professionals (especially if the VAZ is a turbo on gas). By the way, there is now a lot of controversy about whether it is possible to install an LPG on a “turbo”. Experts say that the octane number of such a mixture is more than 102. Therefore, gas will not harm the operation of such a power unit.

Preparatory work

The installation operation requires certain preparatory measures.

It is worth thinking through every minor detail in advance. Technically, the installation is simple, but beginners may have some difficulties. The first step is to select a turbocharger. It must be suitable for a specific engine. The scheme of work performed depends on the type of supercharger, the size of the turbine, as well as its characteristics. It is necessary to find a compromise unit where the combination of power and heat dissipation is as optimal as possible. If a catalyst is installed, you should check whether it works or not. Excess exhaust gases will interfere with the operation of the turbocharger. The air filter is also checked. It must be airtight and solid. And it’s best to install a zero switch, say the reviews of the owners. The next step is to flush the crankcase ventilation system.

Technical characteristics of the car

The car demonstrated excellent maneuverability

The main mystery of Lada Kalina fans was the origin of the 4x4 formula. After all, initially this classic car is front-wheel drive, and the platform on which it is produced does not allow the production of all-wheel drive cars. Many believe that engineers have created a hybrid of Kalina and the legendary Niva. However, all these are just rumors, and Niva has nothing to do with it.

The Lada Kalina TMS Turbo transmission is a new development by AvtoVAZ engineers, close to the Toyota RAV4 transmission. It is designed so that the power unit is located transversely with the center differential. Lada Kalina Turbo is equipped with forced locking of the viscous coupling and an increased friction differential of the rear axle. The rear diagonal independent suspension was designed specifically for Kalina, and it was developed at the Tolyatti plant.

https://www.youtube.com/watch?v=SwEK6uaMkOE

The engine inspires confidence with its significant volumes. The 1.6-liter power unit with a fairly large air filter and the Garett GT25 turbine installed with it make a strong impression even on seasoned car enthusiasts. It has already been said above about the horses under the hood; all that remains is to add that not only the turbine is involved in generating such power. Modifications to the engine add strength to it. For example, different connecting rods and pistons have been installed, the engine cooling system has been equipped with a new system, etc.

197 horses under the hood behave boldly on the road. A quick start, an instant increase in speed, a truly racing growl - this is what the happy owner of a Kalina Turbo can talk about. Even at a speed of 120 km/h, the car holds the road perfectly and behaves confidently on it.

However, there are also minor issues related to the clutch pedal. It remained slightly harsh and insufficiently adjusted.

Instant steering response, excellent start and acceleration with minimal slippage. Newly modified brakes with discs instead of drums improve the braking process and make sporty driving safer.