Replacing the outer CV joint on a VAZ 2112

On cars with front-wheel drive, instead of a driveshaft with crosspieces, constant velocity joints (CV joints) with axle shafts are used. Both crosspieces and CV joints tend to fail. This article discusses in detail: replacing the external grenade of a VAZ 2112, visual photos for a better understanding of the process and practical advice from an auto repair specialist.

- Why does the CV joint fail? Principle and working conditions

- How to determine if a hinge is faulty? Diagnostics

- What will you need?

- Replacement

- Removing the axle shaft

- Grenade replacement

- Installing the axle shaft on the car

Why does the CV joint fail? Principle and working conditions

A torn boot is the cause of all troubles with grenades

So:

- A car's wheel is its dirtiest part. The wheel is constantly in contact with the road, and the road is not always asphalt, but often dirt or sand.

- The outer grenade usually wears out much faster than the inner one, since it is closer to the wheel and is more subject to overload when driving on uneven surfaces.

- Anther breakage. One of the reasons for grenade failure is a violation of the integrity of the boot. This usually happens due to a torn boot clamp, a cut of its fastening, or a cut in the boot itself.

- It also happens that the boot loses its rubber properties over time and stretches. Then it does not fit tightly to the axle shaft.

- For all these reasons, dust gets inside the outer CV joint, and even worse, sand and dirt.

- If harmful substances get inside the grenade, the bearing fails - it collapses or jams.

If you notice a torn grenade boot, this means that on a VAZ 2112, replacing the CV joint is simply necessary for its further safe operation.

This is interesting: How to reset the counter on a Skoda Fabia 2

Drive shaft installation

So:

- The shaft is finally fixed in the side gear.

- The drive shaft is installed in the wheel hub.

- Further assembly is carried out reversely to removal.

How to correctly replace the internal grenade on a VAZ 2112 can be clearly seen in the video. Timely replacement of CV joint elements increases the service life of the vehicle in good condition.

Rear-wheel drive cars are being replaced by cars with front-wheel drive. In this regard, the crosspieces are replaced by hinges of equal angular velocities, which are called grenades. This article is instructions for replacing the internal grenade on a VAZ 2112 car and other cars from this family. Here you will find a video describing the process, as well as photos of some of the process steps. So, let's begin:

- Causes of constant velocity joint failure

- Determining the need to replace the internal grenade

- Replacing a grenade Tool for work

- Removing the axle shaft (wheel drive)

- Removing and installing a new CV joint

- Installing the drive on the car

Causes of constant velocity joint failure

What can cause the failure of this element of the car:

- Poor quality boot is the first reason and the most important. If the boot on a grenade is made of low-quality material, it will quickly wear out, and all sorts of debris will begin to get inside the grenade.

- Loosening the boot clamp also allows sand and dust to get inside the CV joint.

- Other defects of the boot (see), such as a cut of the clamp, rupture of the boot or its stretching also lead to bad consequences.

- An insufficient amount of lubricant, or, even worse, its absence in the constant velocity joint housing, leads to rapid wear of the bearing and, as a result, wear of the entire part.

Advice! When repairing your car, especially if you have to crawl under the car, do not be lazy and pay attention to the condition of the axle shaft boots. If you notice at least one of the defects listed above, replacing the CV joint on a VAZ 2112 is simply necessary!

Determining the need to replace the internal grenade

Before any repair, it is important to make sure that there is a fault. And now we’ll do this with the CV joint:

- Often, a malfunction can be determined by the sound emanating from the suspected component of the car.

- A joint malfunction is detected while driving or starting the car.

- Of course, sounds can come from a faulty shock absorber strut, or from the engine. Let's learn how to determine what kind of sound should come from the CV joint and when it appears.

- The sound of a faulty grenade is the grinding of metal on metal, similar to a crunch, breaking of metal, or a stone hitting a bearing or other drive mechanism.

- When can this sound be heard? If such a sound appears when turning, it means that you need to change the outer grenade, not the inner one.

Advice! Although external grenades fail much more often than internal ones, when repairing external ones, be sure to check the others for functionality. Lubricants should also be added if necessary.

- On a VAZ 2112, the internal CV joints make a sound when driving straight, and especially when the car starts to move.

To more accurately determine the malfunction of the unit, diagnostics should be carried out in the inspection pit. The following explains how to do it yourself:

- The car is driven into a viewing hole. Wheel chocks must be placed under the rear wheels, and the car must be set to the parking brake.

- Next, you should raise the car with a jack so much that one of the front wheels is lifted off the ground.

- Then you should turn the wheel by hand. When the wheel rotates, a sound appears - there is a malfunction in the internal grenade. If you turn the wheel at the same time, then rotate it, and only then does the sound appear - there is a malfunction in.

- After carrying out such an operation, it should be done on the second side (with the opposite wheel).

Now that the breakdown has been identified, you can begin repairs. Replacement of the internal grenade on the VAZ 2112 begins!

General recommendations

Obviously, the inner joint cannot be removed without lifting the vehicle structure, since the wheel must be removed. This can only be done when the car is suspended. Some technicians recommend draining the oil before such repairs, but you should not do this. Carrying out the replacement according to the instructions will allow you to do without draining. It is also recommended to replace the CV joint seal together with the hinge. The CV joint is changed separately without replacing the boot and oil seal only in cases where there is a functional reserve, and the wear of the CV joint is more pronounced than other structural elements. Typically, repairs are divided into two stages if it is not possible to complete a replacement in full. Don’t forget to replace the oil seal and boot afterward in order to maintain all variations to maintain the level of vehicle safety.

Watch the video instructions for performing the work. For example, the grenade and hub are changed until the mechanism completely fails.

Sources

- ladaautos.ru/vaz-2110/kak-delaetsya-zamena-vnutrennego-shrusa-vaz-2110.html

- drive2.ru/l/7210376/

- vazweb.ru/desyatka/hodovaya/zamena-vnutrennego-shrusa.html

List of tools that may be needed when replacing CV joints

To carry out repair and replacement of CV joints, you will need the following tools and materials:

- hammer,

- punch,

- mount,

- screwdrivers,

- powerful car lock,

- vice,

- wooden spacer,

- gasoline for washing removed components, CV joint-4 lubricant.

Replacing a CV joint on a VAZ 2109 - operating procedure

First, you should remove the handbrake handle and secure the front wheels with a stop. Then you need to unscrew the hub nut while the car is on the ground. Next, you should raise the car and support its front part. The next step is to remove the wheel and wheel hub thrust nut. Next, the tie rod end must be disassembled. Using a special puller, press the finger out of this assembly. Subsequently, you need to unscrew the ball joint mounting bolts. After the steering knuckle with the stand is moved to the side, it is necessary to remove the splined end of the outer CV joint from the wheel hub. Then, in order to squeeze out the CV joint, you need to use a pry bar.

It should be noted that if the repair work affects all CV joints on both sides of the car, then the old part should be installed instead of the removed part, otherwise during assembly you will encounter the fact that the CV joints will not be installed in their designated place.

It should also be noted that if during the operation of your vehicle you could observe oil leaks near the gearbox, then most likely you will have to replace the CV joint seal. The old part should be pulled out with a screwdriver, and the new one should be pressed into this place until it stops.

It should be understood that the entire repair process in this case is not very labor-intensive, just like repairing a steering rack, however, in this case it is necessary to take into account the recommendations of experienced motorists, which state that replacing the inner CV joint, as well as replacing the outer CV joint, should only be done with similar spare parts assembled. In this case, replacing individual elements is not recommended, unless it is possible to replace the inner CV joint boot or other similar components.

After the shaft with CV joints is removed, the following manipulations must be done: the shaft is installed in a vice, after which the cover clamps are removed. Using a drift, the inner CV joint is knocked out. A similar sequence of actions applies to the outer CV joint. But installation on the shaft is done in reverse order.

Here it should be taken into account that the right shaft is longer than the left one

Before final installation, it is necessary to check the presence of the proper amount of lubricant in the CV joints. During assembly, new clamps must be installed, and during the installation process, care should be taken to ensure that no contamination gets inside the CV joint.

Installation of the CV joint in its designated place is carried out using a hammer and a wooden spacer, and the movements should not be sharp or strong. After the CV joint is placed, the CV joint boot should be installed

During the installation process, it is very important to bend the edge of the boot with a screwdriver, thereby equalizing the pressure inside and outside this element

It should also be noted that if the described process seems too labor-intensive to you, you can always contact a car service. Since such a replacement is quite common, it will take very little time for a professional. Another operation that you can do yourself is pressing in the silent block.

Replacement of internal and external CV joints - affordable price, impeccable quality

In a car service, replacement of CV joints, internal and external, is carried out with a minimum of discomfort for the car owner: quickly and at an affordable price. Carrying out such a responsible operation as replacing the outer or inner CV joint on a car, our craftsmen guarantee the exceptional quality of the work performed and the spare parts used.

Replacing a CV joint (replacing a grenade) - the design and principle of operation of this unit

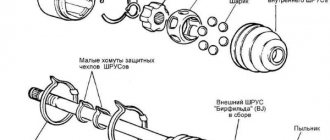

CV joint - or constant velocity joint - is a device that transmits torque from the differential to the wheels. The CV joint consists of the following parts:

The spherical body has grooves for the balls, just like the CV joint cage. The cage is designed to hold the balls in position (just like any regular bearing). Thanks to its design, this joint can transmit rotation at almost any angle of deflection of the shafts (up to 350 degrees), and transmit it evenly. The boot also protects the internal surfaces of the hinge from moisture, dust and dirt, which increase friction and prematurely wear out this unit.

Prices for replacing the CV joint boot

| Name of works | Domestic cars | Foreign cars: | SUVs, minibuses |

| Replacing the drive assembly | from 1,000 rub. | from 1,500 rub. | from 1,500 rub. |

| Replacing the CV joint | from 1,000 rub. | from 1,500 rub. | from 1,700 rub. |

| Replacing the CV joint boot | from 1,200 rub. | from 1,500 rub. | from 1,600 rub. |

Replacing a grenade (CV joint) - signs of a malfunction of this unit

A malfunction of the outer CV joint and the inexorably approaching replacement of the outer CV joint will show the following symptoms:

- Distinct clicks from under the wheels when turning;

- Barely perceptible jerks at the moment when the car starts moving.

These signs intensify on potholes, when moving over snowdrifts and holes. And replacing the outer CV joint (outer grenade) becomes obvious. Moreover, replacing the outer grenade is required somewhat more often, because it is these CV joints that are subject to increased loads, since the rotation angles at the hub of this joint are much greater.

There is another surefire way to make sure that the outer grenade needs to be replaced:

- Turn the steering wheel as far as possible;

- Start moving (slowly);

- If a crunching sound appears from below, you should carefully check the outer CV joint - it may have failed and needs to be replaced.

The inner CV joint is checked in a slightly different way:

- Grab the drive shaft with your hand.

- They shake it and try to rotate it around its axis.

- If the backlash is increased, then replacing the inner CV joint (grenade) is not far off.

Replacing the internal grenade (internal CV joint) - algorithm

- The car is raised (you can lift only the front or rear of it using a jack).

- Unscrew the hub nut.

- Remove the desired wheel.

- Unscrew the ball.

- Unscrew the 6 fasteners of the internal grenade to the gearbox flange and remove the axle shaft.

- Remove the stop ring.

- Remove the inner CV joint from the axle shaft.

- Change the boot.

- Mount a new grenade on the axle shaft and perform reverse assembly in a mirror order.

Replacing the outer CV joint (outer grenade) is an important nuance

A number of motorists believe that replacing a grenade is a simple operation, feasible even for an inexperienced driver. However, incorrect replacement of the outer grenade can lead to an unpleasant phenomenon when the car begins to noticeably move to the side where the new CV joint was installed. As a rule, a more correct, or even better, professional replacement of the outer CV joint eliminates this symptom.

There is another fairly simple but important operation with CV joints - replacing the grenade boot in the event of its depressurization. If carried out in a timely manner, it can protect against complete replacement of a CV joint that has become worn out due to dirt and moisture getting into the joint.

Replacing a grenade - price and other advantages of contacting Maximum Security

In addition to competitive prices, our company is ready to offer high speed and quality of service. We carry out grenade replacement, that is, replacement of the internal and external CV joints, for cars of any makes and models, including VAZ 2109, VAZ 2110, VAZ 2114, VAZ 2115, Toyota and many others.

How to determine if a hinge is faulty? Diagnostics

CV joint diagnostics

At any service station, before repairs, they carry out diagnostics of the unit that is going to be repaired. Let's do it ourselves:

- Are there any strange sounds while driving your favorite car? One possibility could be a faulty CV joint.

- Most often, a CV joint in need of repair manifests itself during turns (not necessarily sharp ones). When turning the car, a sound comes from the hood, similar to metal jamming, the sound of metal breaking, metal grinding on metal.

- If such sounds appear even when driving straight, then the CV joint definitely needs to be changed!

Advice! Do not ignore sounds that occur when operating the vehicle. In some cases, this can cost the lives of the driver and passengers.

- After sounds similar to a malfunctioning grenade appear, it is necessary to diagnose the front chassis of the car in a pit or overpass, or, as a last resort, just in the garage.

- To do this, you need to lift the car using a jack. Raise the side from which the sound was heard. Don't forget to put wheel chocks under the rear wheels of the car.

- When the wheel can rotate freely, you should rotate it around its axis and listen for sound. If the sound does not appear, then you should turn the wheel in the direction of the turn at which it occurred.

- When a sound appears, it will become clear that the VAZ 2112 CV joint is faulty and requires replacement as soon as possible.

- If the sound still does not appear, then check the other side (the other wheel) in the same way. By the way, if the sound appears, check it anyway - you may have to change both grenades.

After diagnosing the constant velocity joints, you can begin replacing them.

What will you need?

Here is a short list of what is needed to replace a grenade on a VAZ 2112:

- Partner

- A set of sockets or spanners (you will still have to find a 30 socket)

- Rust remover (WD-40 or equivalent)

WD-40 - no repair can be done without it

- Long collar

- Pre-purchased CV joint (average price) and lubricant for it (usually included)

- Hammer

- Pliers

- Flat screwdriver

- Vise

- Petrol

- Brush (a regular paint brush will do)

- Rags

- Copper or bronze tip

- Metal brush

In some cases, you may additionally need the following:

- Oil container

- Plug in the gearbox

- Watering can

This is interesting: How to reset it on a Peugeot 406

Useful tips for replacing CV joints

Use additional recommendations when replacing a grenade on a car:

- When assembling the shaft and grenade, you can use the old boot if it is not worn out and there are no defects on it, but be sure to clean it before installation.

- For better installation of the grant on the shaft, it is recommended to use a special hammer, which is equipped with a hammer made of soft material.

- Be sure to use all the parts included in the CV joint kit.

- Do not use other lubricants to fill the hinges and boot; you should only use the one that came with the grenade.

How to avoid CV joint failure?

A grenade flew out, movement is not possible.

Advice! To avoid early failure of the part, it is not recommended to start abruptly with the steering wheel turned in any direction.

Those parts that are installed on new cars can easily serve for 100-150 thousand kilometers. This cannot be said about those spare parts that are sold separately in car shops or markets.

Removing the drive, boot and CV joint

To replace the outer CV joint, follow the following procedure:

- We place the car on the inspection hole and support it with wheel chocks.

- Using a 30mm socket, loosen the hub nut. If the nut does not break off, then you can extend the key with a pipe.

- Raise the car with a jack in the right place and remove the wheel.

- We unscrew the bolts securing the ball joint of the lower arm to the hub.

- We squeeze out the tie rod end with a puller.

- Unscrew the drive shaft nut completely.

- We pull out the hub by grasping the brake disc and pulling the shock absorber strut towards us.

To change the boot and hinge, you will have to climb into the inspection hole. To remove the CV joint, remove the clamps that hold the boot. Next, we get rid of the old boot, which is easier to do with a knife. Use a rag to remove grease from the hinge. Then you need to knock down the inner race, for which we lightly hit the attachment with a hammer, which must be rested against the end of the hinge. Next, we thoroughly clean the CV joint from dirt, sand, dust and grease.

Build process

When assembling the outer CV joint, you must perform the following steps:

- We put a rubber part on the shaft.

- We stuff the CV joint (new or cleaned) onto the shaft until the part is secured with a retaining ring.

- We place fresh lubricant in the hinge and boot.

- We put the boot on the outer race.

- We remove excess air from the boot by pressing it with your hand.

- We secure the boot with clamps.

Then the drive is put in place, the hub is clamped with a nut. It is also necessary to put back the tie rod end, support and wheel. Next, you can lower the jack and tighten the nut securing the drive. To prevent it from unscrewing on its own, the nut should be capped.

Features of repairing the internal CV joint

To replace the inner CV joint, it is necessary to completely remove the drive, for which the outer joint is first disconnected without subsequent dismantling. Next, using a pry bar, remove the hinge end from the gearbox. To do this, we insert the flat part of the tool between the outer frame and the box, and then move it like a lever.

Further, the procedure for replacing the unit will be similar to the actions when repairing the external hinge. The inner CV joint must be correctly inserted into the transmission. It is recommended to insert the part into the hub, with the help of which the unit is brought into place by pushing movements. But it is also possible to drive the already assembled shaft with a mallet or a wooden pointer and a hammer. The hinge must be secured with a locking ring.

At the final stage, all removed parts are installed back. At this point, the replacement of CV joints is considered completed.

Didn't find the information you are looking for? on our forum.

We recommend reading:

The dimensions of the VAZ 2114 have disappeared

VAZ 2107 carburetor troits at idle

The injector throws antifreeze out of the expansion tank of a VAZ 2114, reasons for how to prevent breakdown

VAZ 2107 carburetor, eats a lot of gasoline

The tachometer does not work on the VAZ 2110 injector reasons

Dismantling and assembling the gearbox of a VAZ 2101 car. Video

How to make a signal on a VAZ 2107

DIY EUR for VAZ 2114

Similar articles

How to replace a heating radiator Lada Kalina

Adjusting VAZ 2106 valves - adjustment and configuration procedure

How to change the radiator of a VAZ 2114 (2115) stove with your own hands

How to clean the injector nozzle on a VAZ 2107 yourself

Do-it-yourself CV joint replacement on VAZ cars Link to main publication

Tuning 8-valve VAZ engine

The 8 valve engine from the VAZ 2108 has relatively good characteristics; it is not for nothing that it has been produced since 1984, until now. Quite economical, absolutely repairable with a long service life. After installing distributed injection on this engine, previously hidden opportunities for tuning the mechanical part of the unit were revealed.

You can install a lightweight crankshaft, connecting rods, pistons with an increased diameter, an enlarged intake receiver and many other developments on it, with which you can increase the engine power to 130 hp. But since this is a very long process and requires high qualifications (higher than that of an ordinary mechanic at a service station), you should not engage in complete tuning of the unit without undergoing certain training. But partial replacement of parts, such as timing camshafts, special split gears, and so on, to achieve a certain effect, is quite reasonable.

Selection of parts for tuning an 8 valve engine

Before tampering with the engine, it is necessary to accurately determine:

There are about a dozen different types of camshafts, with significant differences in characteristics. Eg:

In other words, we can say that there are three main types of camshaft designs:

- “low-level” (increased power at the “lower” levels from 1200 rpm)

- “civilian” (average version)

- “main” (sport mode, increase at the “top”)

According to the laws of physics, it is impossible to achieve the same increase in all modes, so you should immediately decide on the type of camshaft.

Practice shows that for quiet driving around the city, with the possibility of saving fuel, a “low-level” camshaft is most suitable. For city-highway traffic, it is better to choose the middle option; for highway drivers, the “highway” option is more suitable.

To achieve maximum effect, you should immediately install a split timing camshaft drive gear.

Camshaft replacement

To replace, you need to remove the old camshaft by removing the belt and gear. To do this, you need:

- remove the air filter;

- disconnect the throttle cable and ventilation pipes;

- remove the valve cover;

- Having torn off the central bolt of the camshaft, set the marks and remove the belt;

- remove the distributor (or the housing that mounts the camshaft sensor on the injector)

- unscrew and pull out the camshaft, removing the gear and unscrewing the protective boot;

It is necessary to install the new camshaft in the reverse order, replacing the oil seal 2, the valve cover gasket and paying special attention to the installation of marks, phases and ignition

Valve timing

It should be noted right away that the easiest way to set the valve timing as necessary is to remove the cylinder head by adjusting the split gear so that each phase has an equal and uniform opening of the intake and exhaust valves.

It can also be adjusted on an installed cylinder head by assembling and using the selection method to set the camshaft mark in the range of ± 1 tooth of the belt (-1 tooth is the advantage of the “tops”, +1 tooth of the “bottoms”).

But the most correct adjustment is considered to be the regulation of the valve timing using the vacuum piezoelectric sensor of the oscilloscope. This device most accurately shows the moment of phase overlap and the possibility and need for further adjustment. You should ask about this device from master diagnosticians or specialists involved in “chip tuning”, especially since on an injection machine there will be a need to replace the firmware of the electronic control unit with a more suitable one for detonation of injection time, etc. This will make it possible to further increase power and will make idling more stable on a tuned camshaft.

At the very end, we suggest watching a video on installing tuning on an 8-valve VAZ engine.

avtooverview.ru

On a VAZ, a grenade flies out of the box, reasons, repairs, photos

Repair manual for VAZ 2108, 2109, 2114, 2115 Wires and fuses It is necessary to change the constant velocity joint (CV joint, or popularly a grenade) on a VAZ-2112 when a peculiar knocking (crackling) noise appears in this part. If such repairs are not carried out on time, the grenade may fly out of its place while moving. Then you will have to call a tow truck to transport the car to the service station, since it will no longer be able to drive on its own.

Why are grenades flying?

The grenade flew out and the boot broke

The fact that the grenade is out of order is indicated by a knocking sound in the area of the front wheel when turning, as well as when the clutch pedal is released while the car is standing still. A crash will be heard in the area of the front wheel where the grenade was fired.

In this case, you should check with the speed turned on (the car must be placed on a lift); if the drive spins, but the wheel does not, then the external grenade has failed. If the drive is stationary at switched on speed, then the internal grenade has broken.

The internal grenade just “flies” out of the gearbox. Or rather, it crumbles, one part remains in the gearbox, the other on the wheel drive. Sometimes a situation arises when the retaining ring falls apart, in this case the grenade will also fly out. The breakdown is not associated with incorrectly selected oil in the gearbox.

Grenade replacement

Trialli external grenade - seems to be praised.

When you hear a cracking sound in the grenade, you can fix this breakdown yourself, without resorting to the services of a specialist. To do this, follow simple steps that will be described below.

Process

Don’t forget to check whether the CV joint kit includes a separate boot and clamps. If not, then you will have to buy it all.

Separate boot and clamps

- The car should be raised from the side where the grenade failed. In this case, wheel chocks should be placed under the rear wheels.

- Remove the protective cap from the wheel and unscrew it.

- Remove the hub nut. This may require a strong tool, since the nut may become welded to the axle during operation. You can also use a special wrench for this (weld the head at “30” to the chisel and use a long wrench).

- Unscrew the ball joint (lower) bolts from the steering knuckle.

- Turn the wheel to its extreme position.

- Pull the steering knuckle together with the strut and pull out the CV joint spline from the hub. We took the CV joint out of the hub

- Using a pry bar, you need to pull out the drive splines from the gearbox. If you need to change two grenades at once, then after removing the drive from one side, you need to fix the box with a technological lock. You can use an old CV joint for this. If this procedure is not done initially, the gears on the differential will shift, and then during assembly it will be impossible to insert the CV joints themselves.

- After removing the drive shaft, it must be clamped in a vice.

- Remove protection from grenades. If the anthers are torn, you can simply cut them off and then install new ones. If they are whole, then you should simply wrap them, being careful not to damage them.

- Using a hammer, knock the CV joints off the drive shaft.

- Next, a new spare part is installed. The CV joint must first be lubricated. You also need to put fresh lubricant in the boot. It is recommended to use MoS2. It will last for the entire service life of the hinge. We check the condition of the separator on the grenade and fill it with lubricant

- The boot is attached to the grenade using clamps. We put on the “fashionable” transparent ACVA boot. Reviews are mostly positive

- If the inner CV joint is being assembled, then do not forget about the plastic plug that is placed on the end of the shaft. The old grenade is on the right, and the new one is on the left, they differ in height

- A retaining ring is also installed on the inner CV joint.

- Then the assembled part is placed in the box drive. It should be seated on the slots to the base. To do this, you can lightly hit it with a hammer, placing a block of wood on it. The inner CV joint is already in the gearbox

- Further assembly is carried out in the reverse order of disassembly.

It is also worth replacing the nut that holds the hub with a new one. It must also be tightened in accordance with the requirements of the car manufacturer.

Stabilizer link failure and grenade flying out

As a result of the stabilizer bar breaking, the wheel went to the side, and grenades flew out with it. The anthers also came to an “end.”

Knowing these points and adhering to the given rules, you can replace CV joints on your own and without resorting to the help of a specialist.

Using grenades in a VAZ 2112 car

They began to use grenades when converting cars to front-wheel drive. If in such a design you use crosspieces in the cardan transmission, as in rear-wheel drive cars that have four needle bearings that work in pairs, then equality of angular velocities on the drive and driven shafts will not be ensured. So:

- The use of such a device will lead to an increase in the dimensions of the unit, the price becomes significantly higher, and strong pulsation occurs during the transmission of torque, which increases as the angle between the shafts increases.

- The design of the grenades initially included the same service life as the entire car, but after using the car, it was clear that its outer part would wear out more. The use of flexible, moisture- and frost-resistant material for manufacturing protects the surface of the grenade, but over time, external factors destroy the element and it cannot be used for a long time.

- Rapid wear is explained by the action of constant deformations, abrasive particles and moisture in large quantities. During operation or during repairs, the boot (see) may be damaged. Cracks appearing on the protective rubber lead to failure of the element. The shaft leading to the grenade must not be damaged, which can be seen during a visual inspection of the part.

Replacing the external grenade of a VAZ 2112 car

The instructions for replacing a grenade on a VAZ 2112 indicate that the work is carried out with the part of the car raised and the wheel removed. So:

- First you need to unscrew the hub nut.

- Remove crankcase protection.

- Release the ball joint from the connection with the lower suspension arm. If the support in the lever is pressed in, unscrew them at the same time.

- The ball joint is removed.

- You need to move the stand to the side, it will be in a bent position, and the splined shaft entering through the bearing into the hub will be located at an angle to the drive shaft. The latter connects the inner and outer grenades.

- The splined shaft of the grenade is knocked out of the bearing using a metal spacer from the outside of the wheel.

- Removed from the grenade drive shaft.

- The boot is removed.

- All old grease is wiped off. To make the work easier, you can use WD-40 or another similar aerosol.

Tip: Replacing a grenade on a VAZ 2112 is carried out simultaneously with replacing the thrust and locking rings. There is a locking ring inside the grenade. The assembly must be well lubricated with a large layer of lubricant.

- After installing the grenade on the drive shaft, before its final pressing, you need to center the assembly so that the fork enters without jamming.

- Installing a grenade on the seat.

- Crimping the boot with clamps.

- Assembling the unit yourself is done in the reverse order.

How to replace an internal grenade

Replacing the internal grenade of a VAZ 2112 differs from the external one in that it needs to be done when all the oil has been drained.

Tip: You need to drain the oil from the gearbox with the car raised. If its quality is low, it is better to replace the liquid so that in the near future you do not have to repeat all the operations again.

So:

- The wheel is removed.

- The ball joint is unscrewed, which frees the strut from the lower arm.

- For the external grenade to move freely, the wheel must be moved to the side.

- You need to knock out the outer grenade from the wheel.

- Both the external and internal elements are removed from the gearbox.

Tip: The hole must be covered to prevent dirt from getting into the gearbox.

- The drive shaft is clamped in a vice carefully so as not to damage it.

- Use a screwdriver to release the clamp securing the boot to the body of the internal grenade.

- The boot is removed. An element that has become unusable can be cut.

- Replacing a VAZ 2112 grenade is done by knocking the old one off the drive shaft.

- A new boot and grenade are put on the shaft.

Tip: A plastic plug is installed at the end of the shaft. The space inside the grenade must be generously lubricated with grease.

- During installation, you need to ensure that the seat coincides with the direction of the drive.

- New rings are replaced and installed - retaining and thrust rings.

- Graphite lubricant must be applied to the spline surfaces of the hinge.

- The assembly is inserted into the gearbox as shown in the photo.

Required spare parts

Each car is equipped with two grenades: internal and external. The first joint transmits rotation to the shaft from the gearbox, the second – to the hub from the shaft. Depending on the scope of the repair, you may need:

- internal hinge (article 302315, 2108-2215056);

- external CV joint (article 3107K, 2110-2215012);

- front wheel drive shaft (article 2110-2215070, 21100221507000);

- cover (article 2110-2215068, 21100221506800, 2108-2215068);

- buffer (article 2108-2215073-01);

- hinge clamp (article 2108-2215086);

- internal hinge retaining ring (article 2108-2215104, 21080221510400, 2121-2215084);

- thrust ring (article 2121-2215082);

- clamp (article 2108-2215034Ч, T-00040, 2108-2215036, 2108-2215034-31, 2108-2215034);

- protective ring (article 2108-3103060, 21080310306000).

Attention! It is better to purchase a new hinge using an old grenade, so the risks of purchasing the wrong part will be reduced to zero. It is better to go to a trusted store for a CV joint.

Tools required for repairs.

To remove and install the VAZ 2110, 2111, 2112 CV joint, you will need the following tools:

- jack;

- keys for 17 and 19;

- pliers

- heads for 13, 14, 15, 16, 17 and 30;

- mount;

- knob;

- wheel wrench;

- lubricant;

- rags.

Do-it-yourself repairs are well justified by saving time and money. Since the price of work on replacing the CV joint of a VAZ 2110 and other models in a car service is: for an external one - 1100 rubles, for an internal one - 1300 rubles. Tariffs are valid as of 02/15/2019. And this is comparable to the cost of the parts themselves.

– , , .

| Lada, Lynxauto CO-4600, | + 11:06, 18 1336 |

| () | 09:08, 18 5956 – |

| FJ-218 2108-2110 Finwhale FJ218 | 01:01, STODETALEY |

| | / | Ruville 77201S | 12:23, 22 “-… |

| 22x50x22 : 2108-09, 2110,2111,2112 1.1-2.0i 88> Patron PCV1081 | 14:44, 22 “-… |

| | / | Lada 110,111,112/Samara Ruville 77201S | 22:48, 24 |

| LADA 2110/ 2109 SKF VKJA5708 | 21:16, 24 |

| : 2108-09, 2110,2111,2112 1.1-2.0i 88> Patron PCV1081 | 03:41, 24 |

| LADA 110>112/08>099 1.1>1.5 86> . 828001 GSP | 10:46, 13 Zakaz28rus |

| | / | Ruville 77201S | 08:05, 20 |

| | / | Ruville 77201S | 09:25, 15 Gabarit |

| | / | Ruville 77201S 77201S | 15:44, |

| INKO 415016 415016 | 15:43, |

| INKO 415001 415001 | 15:43, |

| INKO 315007 315007 | 15:42, |

| LADA 110>112/08>099 1.1>1.5 86> . 828001 GSP | 10:53, 22 |

| | / | Ruville 77201S | 07:07, 20 |

| LADA 110>112/08>099 1.1>1.5 86> . 828001 828001 | 07:12, 1 Gabarit |

| LADA: 110 1.5/1.5 16V/2.0 i 95-, 111 1.5/1.5 16V 95-, 112 1.5/1.5 16V 95-, Samara 1100/1300/1500 86-, Samara Forma 1100/1300/1500 87- Ruville 77201 S | 08:03, |

| 22x50x22 : 2108-09, 2110,2111,2112 1.1-2.0i 88> Patron PCV1081 | 08:00, |

| | / | Ruville 77201S | 03:59, |

| LADA: 110 1.5/1.5 16V/2.0 i 95-, 111 1.5/1.5 16V 95-, 112 1.5/1.5 16V 95-, Samara 1100/1300/1500 86-, Samara Forma 1100/1300/1500 87-: Ruville 772 01S | 04:13, 16 |

| 22x50x22 : 2108-09, 2110,2111,2112 1.1-2.0i 88> : Patron PCV1081 | 04:09, 16 |

| , / , | 07:05, 22 |

| | / | Ruville 77201S | 11:35, 7 AutoSup |

| Ruville, (+) 77201S | 15:27, 21 Boost24 |

| 22x50x22 : 2108-09, 2110,2111,2112 1.1-2.0i 88>PCV1081 | 11:34, 21 |

| LADA: 110 1.5/1.5 16V/2.0 i 95-, 111 1.5/1.5 16V 95-, 112 1.5/1.5 16V 95-, Samara 1100/1300/1500 86-, Samara Forma 1100/1300/1500 87- 77201S | 11:05, 21 |

| LADA: 110 1.5/1.5 16V/2.0 i 95-, 111 1.5/1.5 16V 95-, 112 1.5/1.5 16V 95-, Samara 1100/1300/1500 86-, Samara Forma 1100/1300/1500 87- Ruville 77201 S | 09:01, 18 … |

| : 2108-09, 2110,2111,2112 1.1-2.0i 88> | 19:23, 17 Autoclub02 |

| . / 2108-2215010;2108-2215011;2108-2215012;L-302040; | 12:28, 15 24 |

| | / | Ruville 77201S | 10:56, 15 24 |

| INKO 415016 | 09:14, 15 24 |

| INKO 415001 | 09:14, 15 24 |

| INKO 315007 | 09:13, 15 24 |

| lada 2108 2109 2110 LD-001 | 07:16, 15 24 |

| lada 110 95-, samara 86-, samara forma 89-, Skf. VKJA8972 | 00:21, –… |

| . 22*22*50 lada 110 95- 2108 2109 86- 21099 89- Zekkert .gs-3263 | 00:02, – |

| . 22*22*50 lada 110 95- 2108 2109 86- 21099 89- Zekkert. GS3263 | 06:56, –… |

| LADA 2108-09/99/2110-12 86- Ruville 77201S | 23:59, – … |

| 22x50x22: 2108-09, 2110,2111,2112 1.1-2.0i 88 Patron. PCV1081 | 23:24, –… |

| : 2108-09, 2110,2111,2112 1.1-2.0i 88 Patron. PCV1081 | 23:13, –… |

| | / | Ruville 77201S | 10:11, CARakoom |

| LADA: 110 1.5/1.5 16V/2.0 I 95-, 111 1.5/1.5 16V 95-, 112 1.5/1.5 16V 95-, Samara 1100/1300/1500 86-, Samara Forma 1100/1300/1500 87- Ruville. 77201S | 08:08, –… |

| lada: 110 1.5/1.5 16v/2.0 i 95-, 111 1.5/1.5 Ruville .77201S | 06:41, –… |

| : 2108-09, 2110,2111,2112 1.1-2.0i Patron. PCV1081 | 05:25, –… |

| LADA 110>112/08>099 1.1>1.5 86> . 828001 GSP 828001 | 03:34, – … |

| . 22*22*50 Lada 110 95- 2108 2109 86- 21099 89- Zekkert GS3263 | 13:12, 21 Jc-Market |

| . 22*22*50 Lada 110 95- 2108 2109 86- 21099 89- Zekkert GS3263 2110, 2108, 21099 … , 1 | 13:12, 21 Jc-Market |

| 22x50x22 : 2108-09, 2110,2111,2112 1.1-2.0i 88> | 15:58, 13 AutoPart02 |

Causes and symptoms of CV joint failure on a VAZ 2115

How to replace the idle speed control on a VAZ 2108, 2109, 2114

The most common reasons:

- low quality CV joints, installation of fakes or defective spare parts;

- lack or poor quality of lubricants;

- damage to the boot and entry of abrasive debris or water into the mechanism;

- aggressive driving style and disgusting condition of the road surface.

One of the signs of replacing a VAZ 2114 CV joint is the appearance of a characteristic “crunch”. This sound can only be produced by balls that roll along grooves, because... have too much output. Working in close contact under constant load inevitably leads to changes in the properties of rubbing parts, their sizes, and the formation of wear.

Where there is no close contact of these elements and extraneous noise appears. The sound can appear at any time, but usually it occurs when turning, sharp acceleration, or overcoming obstacles. There are other signs indicating a hinge failure:

- slight jerks when starting the car or changing dynamics;

- play of the shaft located between the CV joints when trying to move it in different planes.

Troubleshooting grenades

Causes

Without exception, all specialized literature states that in the manufacture of CV joints only super-strong alloys are used, the wear of which is minimal and practically unnoticeable. But as practice shows, and especially the sales statistics of any car dealership, nothing lasts forever, including CV joints. The reason for this is:

- Counterfeits, defective components and frankly low quality;

- Poor quality and sometimes lack of lubricants;

- Damage to the boot (and this is a separate topic) and, as a result, “undesirable elements” getting into the hinge.

Before replacing the CV joint on a VAZ 2110, it is necessary to troubleshoot it, preferably with your own hands.

Checking the outer CV joint

Smart people call changes in the properties of a part, its dimensions and the presence of wear on its rubbing surfaces wear, which we will look for in constant velocity joints. The main sign of extreme wear of the “grenade” is its “crunch”, which appears when the ball rolls in a groove that has wear, as a rule, the “crunch” appears when the car moves in turns, sharp accelerations and when overcoming obstacles. The following will help you to finally verify the malfunction of this unit actions that will cause a characteristic sound:

- When starting the car, create slight jerks;

- When the load changes (accelerate sharply and release the gas).

You can also try to move the shaft between the “grenades” in the transverse direction to feel the characteristic sound of wear - backlash.

Checking the inner CV joint

Although both hinges are links of the same chain, it must be said that due to the nature of its operation (significant loads and operating angles), the external hinge fails much faster, although it is smaller in size than the internal one. The above-described symptoms relate to a greater extent to external hinges, which raises a reasonable question - how to check the internal “grenade” since in its working position it is almost impossible to achieve a large operating angle? The fact is that, unlike the external one, the internal “grenade” can signal with sounds that it is malfunctioning when the car is moving in a forward direction, especially when overcoming all kinds of obstacles (bumps, snowdrifts, holes). Checking the shaft by hand for play will also help you verify that there is a malfunction. The following experiment will help you finally convince yourself of the need to replace the device:

- We suspend the driving wheels of the car, which will bring the internal grenade to the maximum operating angle;

- We start the engine;

- We engage first gear.

If the inner hinge has extreme wear, that peculiar crunching sound will appear, which suggests immediate repair.

Order of Operations

If there is no inspection hole or overpass, you need to prepare a place for repairs. Raise the car with a jack, put on the handbrake, provide the work area with good lighting, and support the wheels with clamps.

On a note! To replace a broken joint with a new grenade, you will need to perform many operations: removing the VAZ 2110 internal CV joint and wheel, disconnecting the ball joint, and many others.

Replacing the inner CV joint of the VAZ 2110 and other models is carried out in the same way as the outer joint. They are both located on the shaft drive, which you need to get to first:

- On the crankcase protection, two nuts are unscrewed at the front and rear.

- You need to drain the oil from the box - 40 percent of the total volume.

- When replacing the right CV joint on a VAZ 2110, the wheel bolts come off on the right; if the left one is changed, the wheel bolts come off on the left.

- The outer hinge fasteners are completely unscrewed.

- Now you still need to jack up the car and remove the wheel.

- At this stage, two hub bolts securing the grenade become accessible; they need to be removed.

- The hub needs to be separated from the rods, this is done with a pry bar.

- The stand is pulled forward and the CV joint pin is removed from the hub.

- The shaft drive is removed and set aside.

- Now you need to remove the inner grenade from the box. With the hood open, you need to insert a pry bar between these elements. Then the tool jerks the hinge towards the box. The grenade should move. If this does not happen, the operation is repeated again. If the CV joint moves, then both hinges and the shaft can be removed from the wheel arch area.

- You need to remove the covers from the grenades; to do this, use pliers or special pliers to open the small and large clamps.

- The boot must be inspected for integrity. If the cover is damaged, it must be replaced. If the boot is in good condition, you can simply move it away.

- Use a hammer to remove the inner hinge. They need to hit the clip hard. The grenade should fly off. The same action must be performed on the other side.

- The rings are removed from the shaft drive, new ones are installed in their place and the boot is put on.

- The new grenade is also installed using a hammer. It and the boot need to be lubricated.

- The covers are secured to the hinge and shaft with clamps.

- A nut is screwed onto the grenade, then the hinge is driven into the box.

- Further operations are similar to the first, but are performed in reverse order.

See this video for the sequence of replacing the outer and inner CV joints of VAZ 2110 2111 2112:

Fault diagnosis

The VAZ 2114 has 2 external and 2 internal CV joints. First you need to determine which one is knocking. The optimal test would be on a suspension diagnostic stand. If this is not possible, diagnosis by ear is possible.

Two signs indicate a grenade malfunction in a VAZ 2114:

- the sound resembles a crunch;

- It usually appears when turning.

The simplest and most accurate way to do a garage check is as follows:

- Place the car on a flat surface;

- Turn the wheels to one side (to the middle position or a little further);

- Drive off with medium speed. It is worth remembering that starting too smoothly may not reveal a crunch due to insufficient load on the CV joint, and starting too abruptly may lead to the drive flying out of the wheel.

- Repeat the operation by turning the steering wheel in the other direction. The appearance of a crunch indicates a malfunction of the outer CV joint on the side in which the steering wheel is turned.

Visual detection of ruptured anthers will also be a sign of a CV joint failure. If you discover a damaged protection for any grenade, it must be immediately removed, disassembled and cleaned. If there is enough grease and there is no significant wear on the hinges yet, it is enough to replace the boot and fill it with new grease. If the wear of the balls is obvious, it is better to change the grenade.

It is more difficult to diagnose a malfunction of the internal grenade on a VAZ 2114. If it malfunctions, it crunches when starting off in a straight direction, and not when turning. But the same symptoms, for example, include play in the steering rack or wear on the engine mounts.

Sometimes the problem can be diagnosed from the pit by tugging on the drive from the gearbox side: strong play or the appearance of extraneous sounds indicate that the internal CV joint should be replaced.

Replacement

After all the preparations, you can begin the process of replacing grenades with a VAZ 2112.

Removing the axle shaft

So:

- Perhaps this is the most interesting thing in the process.

- Place the car on a level platform, inspection hole. Install wheel chocks.

- First, remove the hubcap from the wheel, if you have one installed.

- Now you need the help of a partner. He should take a driving position and press the brake pedal hard.

- In this case, you should take a 30 socket (in some cases 27 or 32) and a large wrench. The head is put on the hub nut, which secures the grenade to the hub (located in the middle of the wheel) and unscrew it with a large wrench.

Advice! It will take quite a lot of effort to complete the last step described. Therefore, the longer the driver you take, the easier it will be to unscrew the nut.

- Then you can unscrew the wheel bolts and remove the wheel.

- Spray the splined surface of the hinge with rust remover. Most often, an additional remedy is needed - you can’t just knock it out.

- When the wheel is removed, it is necessary to free the hub from. To do this, take a suitable head and unscrew the two bolts securing the ball joint to the wheel hub.

- When the hub is freed from the ball joint, you can try to remove the splined surface of the grenade from the hub. Remove the entire hub nut and metal washer.

- Now you need to take a copper (bronze) adapter and a hammer, and with their help we knock the splines out of engagement. If necessary, add more WD.

- When the splines are disengaged, move the strut to the side and remove the axle shaft from the hub.

Advice! During operation, make sure that the internal grenade does not jump out of the gearbox housing - this is an unnecessary loss of oil.

Grenade replacement

Two methods will be considered:

- Remove the boot from the grenade. To do this, use pliers to cut through the fastening clamp and, using a screwdriver, remove the boot from one side. Turn it out so that it does not interfere with further work.

- Now again you will need the help of a partner. He needs to hold the axle shaft tightly so that it does not jump out of the gearbox. It is recommended to rest the axle shaft against something (usually a lever or anti-roll bar).

- The outer grenade must be turned with the slots up. This gives access to the grenade's internal bearing.

- It is necessary to place a copper adapter on the inner bearing and knock down the grenade with a hammer. When knocking down, the axle shaft must be rotated so that the bearing moves evenly and does not jam.

- After the outer CV joint has been removed, you can begin installing a new one.

Note! Above is the IDEAL option for removing the CV joint. And then we will talk about how it happens MOST OFTEN.

- After removing the grenade from the hub, the axle shaft is removed and pulled out of the gearbox housing. Place a container under the flow of oil from the box so that you do not have to drain the oil. Ideally, a special plastic plug is inserted into the gearbox hole.

- The axle shaft is clamped in a vice for ease of further work.

- The boot is removed from the grenade, but remains attached to the axle shaft. It turns inside out so it doesn't get in the way. If you plan to replace the boot, then it is either cut off immediately or removed after removing the grenade.

- We remove the grenade in the same way as above. We hit the bearing with a pointer and a hammer, and it comes off the axle shaft.

- If we change a grenade, then we change it. If, for example, we are only replacing a torn boot, then we do the following.

- The boot is removed and a new one is put on the axle shaft.

- The grenade is thoroughly washed with a brush in gasoline and then wiped. Then you need to fill it with special lubricant for CV joints.

- If you install a new grenade, then do not forget to fill it with enough grease and distribute it evenly there by turning the bearing.

Advice! Before installing the grenade on the axle shaft, pay attention to the condition of the retaining rings. Replace them if necessary.

- A new or repaired grenade is installed on the axle shaft much easier than it is removed. One sharp blow with a hammer through the attachment and the grenade is in place. Experienced mechanics can even put a grenade on by hand.

- Next, you need to put the boot on the seat in the grenade and secure it with clamps. There are special clamps for grenades (do not use plastic ones). Metal clamps are installed using pliers and a screwdriver.

Advice! Clean the spline joint, both on the grenade and in the hub, with a metal brush and lubricate.

Now the VAZ 2112 axle shaft with a changed external constant velocity joint is ready for installation on the car!

Installing the axle shaft on the car

So:

- The axle shaft is inserted into the crankcase. Its other end is inserted into the hub until it stops.

- Next you need to reattach the ball joint.

- Don't forget to put the metal washer back on and tighten the nut that secures the grenade to the hub.

- Reinstall the car wheel and lower the car from the jack onto the wheels.

- Again, the partner must press the brakes as hard as possible. You take the wrench and socket and tighten the nut with good force!

- Next you need to tighten the nut. This is done with a hammer and a blunt chisel type attachment. This is done to prevent the nut from unscrewing.

That's basically the whole replacement. If something is not clear in the text, remember that you can always watch a visual video that will show it all live.

Nissan X-Trail › Logbook › Inner left front grenade - damn it)))

I don’t even know where to start)) How much time I wasted: - searching for useful information on the Internet; - toured all the investigations in the city; - called investigations in cities that are closer; - how many people I troubled with my problem))). etc. Finally I made up my mind and ordered a low-quality substitute for Febest (0211-T30LH). By the way, it’s cheaper at www.repart.ru/.

Internal CV joint, gearbox side (0211-T30LH)

When purchasing the car, I immediately noticed the torn boot of the inner left grenade. Well, okay, I thought))).then I’ll put on the boot and that’s it)))...it wasn’t there

I called some stores in the city (I was looking for a boot), everywhere from 1500 rubles. and higher. I decided to wait and order through existential for 750 rubles. Febest (0215-071T)

Internal CV joint boot (0215-071T)

While I was waiting for the boot, I wrapped a bag))) with lubricant))

I noticed a slight vibration especially during acceleration. Well, it’s a small thing)))… I waited for the boot. I changed it, it took about 2 hours to replace it… Then I went for a ride)) only then I read on the Internet about vibration during acceleration

Everyone who wrote about vibration mentioned the torn left boot! In existential terms, the cheap Febest substitute at that time cost 4,700 rubles, a couple of months later it began to cost 3,200 rubles.)) Having already driven 6-7t.km. The vibration has increased and it’s not bad))) (by the way, the boot is still intact) I was thinking about a used drive unit, but if X-trails have this problem, then it makes sense to take a used one. I read on the Internet that the left front drive fits from Nissan Cefiro (A33), from Nissan Primera (P12) and, with minor modifications. I was more inclined towards the drive from the Nissan Cefiro (A33), because... The internal grenade will be stronger)).

But nowhere in Kurgan was there a used drive (((in other cities a used one from 5-7 t.r. immediately disappears. To order through the website www.japancar.ru/ it also costs about 5 t.r. and so on will come... unknown ((In the end I made up my mind and ordered Febest (0211-T30LH) 2860 rubles, I couldn’t continue to worry myself and those around me)) I just couldn’t find any reviews about those who installed Febest ((about the fact that Febest is complete shit..., this okay)) let’s see how long it lasts and if the vibration goes away))

As soon as it arrives, I’ll change it right away))