Tell me the position of the ECU on the Lada Granta.

- Location of diagnostic connector Lada Granta - 2 answers

- Why did the battery charge in the VAZ Grant disappear? — 4 answers

- Spontaneous combustion of a VAZ Granta fan - 2 answers

- The oil pressure warning light stopped lighting when the ignition is turned on in the Lada Granta - 2 answers

- Lada Granta electronics do not work

The Grant ECU is located under the glove box, directly in front of the passenger seat. It is hidden under the upholstery and soundproofing of the floor. To get there, you need to fold the lining and sound insulation.

In short, the ECU serves to control the engine by coordinating its operation based on data received from various sensors. As a result, if the ECU is closed, the engine will not operate properly.

And it covers up quite easily - from moisture. Water penetrates through the ring inserted into the housing. They say that this problem was corrected at the factory (and the cars were recalled), but in order not to bother, it won’t hurt to go through the sealant.

The ECU has become an integral part of a modern car. This device, marked “M74 CAN,” is equipped with the domestic Lada Granta model. The module allows you to automate most processes occurring in nodes and systems. The control function of the ECU is achieved due to the presence in the blocks of various types of sensors that send signals to the “brain center” of the car.

Over the long period of operation of the Lada Grant, one annoying drawback of the ECU has emerged: its insufficient tightness and sometimes pinout of the ECU is required. Penetration of moisture into the unit body causes depletion of the microcircuit, which subsequently results in the need to replace the device.

The ECU is located at the bottom of the dashboard (under the glove box) in front of the front passenger seat and is hidden from view by layers of sound-absorbing material and pads on the inner surface of the bottom. Now you know where the ECU is located, it remains to figure out other details.

Error P1335 Lada Priora, Kalina, 4x4 - ME17.9.7 / M75 EURO-4

Code P1335 Monitoring throttle actuator control, throttle position out of range

Code P1335 is entered if: - the throttle position exceeds the maximum permissible for 0.5 s; — the throttle valve is in the maximum permissible position for 3 s.

The malfunction indicator lights up 5 s after the fault code appears. Description of checks

1 Using a diagnostic tool, check for the presence of codes P0122, P0123, P0222, P0223, P2135, P1545, P1558, P1559, P1602, P1336, P1388, P1389, P0606. Troubleshooting must begin with these codes. 2 If the fault occurs periodically, the controller must be replaced. Diagnostic information From the moment the ignition is turned on until the main relay is turned off, the controller monitors the throttle position. The maximum permissible throttle position is calculated depending on engine speed, accelerator pedal position, engine temperature, etc. If a malfunction is detected, the engine control system will operate in emergency mode until the end of the current trip - de-energizing the electric throttle drive and limiting engine speed (2500 rpm).

The reason for fixing code P1335 may be a malfunction of the processor hardware or software errors that lead to incorrect calculation of the specified throttle position.

throttle valve diagram Lada Priora, Kalina, 4x4 - ME17.9.7 / M75 EURO-4

Source

Dashboard voltmeter readings for a healthy battery.

For some time now I have begun to more closely monitor the condition of the original battery on Grant. There is a built-in voltmeter on the dashboard; unfortunately, it cannot actually measure EMF or NRC, because It only starts showing when the ignition is turned on. With such a load, the condition of the battery can only be judged indirectly.

When the readings dropped to 11.7 Volts, I decided to measure the voltage with a voltmeter with the ignition on and off, but without removing the terminals. I planned to remove the battery for stationary maintenance; a wattmeter and a Vympel-55 charger appeared on the farm. I temporarily installed a replacement, fully charged battery, and at the same time took voltage measurements with it.

Multimeters on the original battery with the terminals not removed without turning on the ignition gave 12.41-12.43 Volts. When the ignition was turned on, the voltmeter on the dashboard showed 11.7 Volts. At the same time, multimeters showed 12.06-12.08 Volts at the battery terminals. More confidence in the new multimeter which showed 12.06 Volts. Thus, the voltmeter on the dashboard is off by about 0.36 volts.

Next, I installed a new battery and made the same measurements on it. With the ignition on, a more accurate multimeter showed 12.21 Volts, while the dashboard showed 11.9 Volts. The difference is 0.31 Volt. The conclusion from all this is that if, when you turn on the ignition, the voltmeter on the dashboard shows 11.9 Volts (heated seats and windows are turned off), everything is in order with the battery - it is charged. If less, it requires recharging or stationary maintenance, which is what I did.

Error P1335 Lada Granta, Kalina 2, throttle valve

Code P1335 Monitoring throttle actuator control, throttle position out of range

Code P1335 is entered if: - the ignition is on; — the throttle position exceeds the maximum permissible for 0.5 s; — the throttle valve is in the maximum permissible position for 3 s.

The malfunction indicator lights up 5 s after the fault code appears. Description of checks

1 Using a diagnostic tool, check for the presence of codes P0122, P0123, P0222, P0223, P2135, P1545, P1558, P1559, P1602, P1336, P1388, P1389, P0606. Troubleshooting must begin with these codes. 2 If the fault occurs periodically, the controller must be replaced. Diagnostic information From the moment the ignition is turned on until the main relay is turned off, the controller monitors the throttle position. The maximum permissible throttle position is calculated depending on engine speed, accelerator pedal position, engine temperature, etc. If a malfunction is detected, the engine management system will operate in emergency mode until the end of the current trip: de-energizing the electric throttle drive and limiting engine speed (2500 rpm). The reason for fixing code P1335 may be a malfunction of the processor hardware or software errors that lead to incorrect calculation of the specified throttle position.

Throttle valve wiring diagram for Lada Granta, Kalina 2

Source

How to check mass on a car

In fact, only a small group of motorists pay enough attention to this issue. Others begin to think about it when, when the cooling fan or headlights are turned on, the engine speed begins to sag, or when the rear window heating is turned on, the engine begins to tremble, transmitting vibration throughout the body.

But even at this stage, many limit themselves to a banal inspection and tightening the ground connection nuts on the engine and body. Everything is screwed down - that means everything is in order.

Then the car begins to jerk for no apparent reason, idle speed freezes, misfires, security system glitches, and so on, until the starter fails at the most inopportune moment. But even here, many will not go check the masses, but will run to the store for a new starter. After all, the wire to the starter is intact and there is voltage, but it, a radish, does not turn.

The speed check (e-gas) lights up, error P1335

Description of the problem: At a speed of about 90 km/h, the “Check Engine” light comes on.

I should note that this is a fairly common situation among e-gas owners. We can say that this is most likely a manufacturing plant defect.

As for AvtoVAZ, it refused to recognize this problem as a “defect”, but published an information letter containing a description of this problem and ways to solve it.

This problem occurs in both Kalin, Prior, and Samar, equipped with 8-valve engines with an electronic gas pedal.

The “check” lights up due to error P1335 - “The damper position is in an unacceptable position.”

Lada Granta liftback 2015, 87 hp – observation

Comments 10

I also have this problem! In real life, for example, the voltage with a voltmeter showed 12.4 and the on-board display showed 11.4. The car didn’t start! Tell me, is it possible because of this?! I put the car on charge and it started as if nothing had happened!

When you turn the key, voltage goes to the computer and other systems, mine shows 11.6 and the key fob shows 12.6

It just all depends on the place of connection and the method, that is, the science of contacts continues to exist. If the BC is connected with twists, this is very possible, as well as connecting through a loose connector. The further the connection is from the battery, accordingly, the greater the circuit resistance, the number of transition contacts and the magnitude of the drop in this total voltage resistance.

when I was seven. that was such a trick. you come to the car, open it up and open the hood. you measure the battery with a voltmeter and the readings are, say, 12.3 or 12.5, as soon as you turn on the ignition the fuel pump is triggered, the lights on the dash come on, the readings on the voltmeter drop to 11.9, there was just a scale on the dash, but I connected the BC to my seven, there the readings also dropped to the same as on the voltmeter.

But if you stand in this state for some time, the fuel pump will pump up the pressure and stop, and the voltage will settle down to around 12.1.

In short, the car will stop starting if the battery output is less than 10.55, the ignition will turn on, the fuel pump will pump, but the starter will not turn, the relay will click, but the car will not start. From the pusher, yes. but she herself doesn’t.

So look, if the readings drop to 11.5 not started with the ignition off, change the battery or charge it. otherwise there is a chance it won't start.

Source

Reason for the error

- Faulty mass air flow sensor (on e-gas it is installed of the frequency type).

- The air-fuel mixture does not meet the standards (bad gasoline, injectors are overfilled/underfilled, high/low pressure, etc.).

- Faulty controller.

If you have checked these elements and the indicator does not go out, then all that remains is to reprogram the ECU using PB-6 (you will need an additional cable for the M74 controller) using the file “I414DE07.hex”.

This file can be found on the Internet.

A similar service should be provided by official AvtoVAZ dealers.

Source

Brake calipers - an exclusive problem

Only in some car models with disc brakes in the rear, the brake calipers become loose or simply play. This is problem number one for all budget cars with rear disc brakes. It is the budget nature of fasteners that often causes parts to fail. It is very interesting that calipers can be an invisible cause of knocking, that is, very difficult to diagnose. You will have to perform the following procedures:

- first, you can try to pull the caliper with your hands while the wheel is installed; perhaps the parts of the mechanism are hitting the disc, everything should be tightly screwed;

- Next, you should remove the wheel and carry out manual diagnostics of all possible fastenings of this unit; you should tug the mechanism with your hands to understand the absence of play;

- the next step should be to disassemble the caliper to determine the loose parts, but doing this without experience is not recommended, as many problems can be found;

- when disassembling, you should pay special attention to the quality of tightening of each module and each bolt, this is what can tell you where the knocking problem lies;

- when reassembling, pay attention to the pads; it is quite possible that they are worn out or deformed, and are simply knocking in the places where they are installed during operation.

These are the types of brake problems that can arise in a modern car. This rarely happens in the absence of unprofessional intervention, but it is quite normal on budget cars. With a drum brake system, everything is much simpler; in this case, not a single mechanism can knock. Unless the entire brake drum fell apart, the pads and other parts flew out. This can only be checked by disassembling the entire mechanism.

Error p1335 Priora 16 valves

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

Today I'm standing at a traffic light turning left. I see the window, I pull away sharply, and I understand that the car is not moving - the check light comes on, the revolutions do not rise above 3 thousand on the tachometer, the car drags along, I try to squeeze the clutch and accelerate - the same thing. Somehow I passed the intersection, I pressed the gas - the revs did not rise above 3,000. Config: 111830, 1.6 8 cells, e-gas, brains of NPP Itelma M74 11183-1411020-55, some kind of non-stock firmware, we reflashed it, there were no complaints before, except for the error 1335 that popped up once. I read the errors via bluetooth: P1335

and

P0830

:

Low voltage or BC is lying?

Greetings my subscribers!

I made some observations on the onboard voltage and here are the results. When starting the engine, I check the voltage, it shows 11.8-11.3, I start it - it starts as always without problems, although when I had 14 at this voltage it no longer started. Today I decided to measure the voltage with a multimeter directly from the battery terminals. With the engine turned off, it showed 12.6, and at that time the BC showed 11.9. I started the engine at terminals 14.4-14.5, according to BC 13.9. So the question is, why does bookmaker lie? Where does he get these values from? So what should I do?

PS I foolishly almost bought a new battery today.

Lada Granta error P1335

Welcome to ChipTuner Forum.

Theme Options

Nik53rus

Tikhorchanin

Vadim26

new car, ECU 11186-1411020-47

The marks were checked, the key was ok. A new damper was installed.

I myself was inclined towards phases because when the gas is transferred to the gas release, pops occur in the outlet

Nik53rus

Under the words, which ECU and year of manufacture, there was clearly something completely different. For example: I464AI10, I484GU17, with P504 and F1. Maybe the plant produced some other masterpiece. Or maybe both ECUs with tuning (including the replacement one). For example, I have all replacement ECUs, with commercial firmware, but tested. I set it up, the client immediately feels the difference in the operation of the machine, and you want something like that for yourself. As an example for VS-5.1, there is an opinion that the hardware of the ECU is to blame, it manifests itself during startup, as if the contact group of the ignition switch is at fault. But it turns out that there is no and there is a software solution. It’s the same with I02, in a city traffic jam it stalled and immediately started, we have rpm over 2000. How can we prove this if we don’t substitute a replacement ECU with tuning.

Or, remember: OCT 29, 2012 No. 20800/5232

1. On cars of the “Lada Samara”, “Lada Priora”, “Lada Kalina” family, equipped with an 8-valve engine and an electronic accelerator pedal, a discrepancy occurs: “When the vehicle speed is above 90 km/h, the “Check Engine” indicator lights up. , error code P1335.”

The causes of error code P1335 “Throttle valve actuator control monitoring, throttle position out of range” may be:

— the mass air flow sensor is faulty; — too rich or too lean air-fuel circuit; - ECM malfunction.

In the absence of the above malfunctions, it is recommended to reprogram the ECM.

Maybe the author of the topic should start with a proven stock?

Source

Where is the mass located: engine - battery - body

On most cars, the engine-body mass has a primitive appearance and is made of two pieces of cable connected together by crimping on the negative terminal of the battery

This crimp connects two wires. One goes to the engine and is secured with the starter mounting nut...

...and the second one on the body in the area of the left wing

It would seem that this is the simplest and most reliable chain that will serve well for years. But this is not at all true and it’s all to blame for the weak points in this design, which do not withstand the test of atmospheric influences.

Diagnostic methods

There are two proven methods for finding problems on this modification of the car. Each has its own advantages and disadvantages.

Self-diagnosis using on-board computer

This method does not require the user to have additional equipment. All the necessary systems are already installed inside the machine. The processing sequence looks like this:

- Find the odometer reset key on the daily mileage;

- While holding the button, turn the ignition key.

If everything is done correctly, all the lamps on the dashboard will light up, the arrow indicators will make a full revolution and drop to the “0” position. In this way, the functionality of all vehicle systems is checked. If there is no response from any indicator, you need to check the circuit following the indicator. To more accurately determine the source of the problem, you can, in the same mode, press the mode scroll key to the “error codes” position, which in 90% of cases provokes the appearance of one of these indicators:

- 2 – short circuit or high voltage flow on the BS;

- 3 – the fuel level sensor in the gas tank is covered;

- 4 – antifreeze temperature sensor has burned out;

- 5 – error of the sea thermometer;

- 6 – severe overheating of the internal combustion engine;

- 7 – you need to check the oil level – the pressure has dropped;

- 8 – failure or jamming of the calipers, the pressure inside the line has dropped;

- 9 – battery “died”;

- E – failure or violation of the integrity of the EEPROM data packet.

Checking weight in a car

Transmissions on some vehicle models are equipped with a chassis or protective shield for modules, sensors, and solenoids (relays). You can also test these grounds using your digital multimeter.

- Check the voltage drop between the transmission and the negative terminal of the battery. The voltage drop should be 0.2V or lower.

- Check individual chassis grounding by checking the voltage drop across each ground terminal on the transmission. The voltage drop should be 0.2V or lower.

Clean, repair or replace the transmission ground as necessary. Remove grease, rust and paint from ground terminals or replace damaged ground straps.

General Voltage Drop Values

Choke cables and other equipment can be damaged when high electrical current cannot find the correct path back to ground.

Decoding error codes Lada Priora

Note! These encodings are also relevant for the Kalina version.

Exhaust (0000)

- 30 – break or damage to the oxygen sensor heater before the catalyst;

- 31 – same as 30 with short circuit to body ground;

- 32 – similar short circuit for on-board wiring;

- 36 – break in the wiring of the oxygen heater after the catalyst;

- 37 – wiring short to ground;

- 38 – open circuit from short circuit to BS.

Air supply failure (0101, etc.)

- 102 – open or damaged air flow sensor circuit;

- 103 – short circuit of the mass air flow sensor network;

- 112/13 – violation of the temperature indicators of the air mixture on the intake manifold;

- 115/16 - failure of antifreeze temperature sensors - the system does not cool, the main fan may not work correctly;

- 117 – open circuit of DTOZH;

- 118 – short circuit of the same sensor;

- 122/23 – violation of the throttle position sensor circuit;

- 130 – error DC 1;

- 131 – break in oxygen sensor 1;

- 132 – short circuit of DPKV 1 circuit;

- 133 – difficulty in response of the oxygen sensor (possible poor contact);

- 134 – break in the oxygen sensor line;

- 135 – failure of the heating device DK2;

- 136 – ground fault DK2;

- 137/138 – weak/high impulse of DC2;

- 140 – break in the DK2 highway;

- 141 – failure of heater DK2;

- 171/172 – excessively lean/rich air-fuel mixture.

Failure to supply fuel mixture (0200)

- 201-204 – break in the control line of injectors 1-4, respectively, characterized by engine tripping;

- 217 – internal combustion engine overheating;

- 230 – open circuit of the fuel pump control relay – the engine does not turn on or does not start;

- 263/266/269/272 – failure of the injector driver for cylinders 1-4, respectively;

- 261/267/270/264 – ground fault of injector lines from 1 to 4, respectively;

- 262/265/268/271 – short circuit at 12 V.

Ignition design violation (0300)

- 300 – no spark on all cylinders (large number of misfires);

- 301/302/303/304 – ignition interruptions in 1-4 boilers, respectively (ICE triples or doubles);

- 325 – DD break or failure;

- 327/328 – violation of knock sensor readings;

- 335/336 – violation of the DPKV operation;

- 337/338 – short circuit to ground or violation of the DPKV signal;

- 340 – DRF failure;

- 342/343 – violation of the phase distribution sensor signal;

- 346 – exceeding the tolerance of DRF indicators;

- 351-354 – the wiring of the ignition coils for cylinders 1-4 is interrupted, respectively;

- 363 – no supply of fuel and air to the cylinders.

In addition to voltage: the density of the electrolyte of a charged battery

Since the era of battery shortages, it has been known that the voltage of a charged car battery directly depends on the density of the electrolytic fluid. Nothing has changed since then. The electrolyte is still a mixture of sulfuric acid and distilled water, and the hydrometer is the No. 1 device in the kit of a young battery worker.

1.26-1.28 g/cm3 at +20…+25°C. This density of the chemical substance in each jar corresponds to a voltage of 12.6-12.7 V. A similar ratio of hydrometer and multimeter readings indicates that the capacity of the power source has been restored to 100%. Scientifically speaking, the sulfate deposited on the plates during the discharge as part of lead sulfate completely left the electrodes and reacted with hydrogen, turning into sulfuric acid.

Troubleshooting

After finding out the reason why the Priora or Kalina does not drive, it is necessary to correct the situation. If the coding indicates a break in the power supply to a structural element, you need to completely check the entire line and the device itself. It is better to do this by replacing parts with known good ones (new ones). It is also taken into account that standard connectors may become loose or fail over time. In such a situation, the computer will show errors even with a 100% working network. To detect such “surprises”, it is necessary to check all terminals and connections for oxidation, broken contacts or loosening - the elements must fit tightly in the sockets, without play.

Note! If you are unsure of your own abilities, the motorist is strongly recommended to seek help from a specialized workshop or a qualified technician.

If you have the necessary equipment, you can determine whether 8 or 16 valves are broken in a Lada Priora car yourself. Due to the simple design of the machine, repairs do not require the user to have in-depth knowledge of mechanics, electronics or other sciences.

Source

Granta 39 7 new size

The suspension springs must not be damaged. Tearing, cracking and severe deformation of rubber bushings, cushions and compression buffers of shock absorbers are unacceptable.

Liquid leakage from shock absorbers is not allowed. A slight “fogging” of the shock absorber in its upper part, while maintaining the characteristics, is not a malfunction.

If the rubber element of the upper support of the front suspension telescopic strut settles or is destroyed, the support must be replaced.

What causes deviations from the norm of 12.6-12.7 V

Deep sulfation of the plates prevents the restoration of voltage without load to normal values. In general, this is not its only sign:

- The density of the electrolytic liquid in the jars decreases.

- The battery discharges quickly and charges quickly.

- The plates are covered with a white layer.

Large sulfates do not dissolve during a normal charging cycle at 10% of the battery capacity. Therefore, the charging time from a standard charger is reduced, and the electrolyte boils quickly.

The progression of sulfation is caused by storage in a discharged state. A special case is use in chronic undercharging mode. Neither calcium nor progressive AGM and EFB batteries are capable of resisting destruction.

What should you know about the on-board voltage of your iron horse?

In order for the vehicle's electrical equipment to operate normally, the vehicle's on-board network must always have the nominally set voltage. Its surges can lead to possible short circuits in the electrical wiring, which will cause the failure of certain electronic devices and equipment. What should be the voltage in the car's on-board network and how to increase it - read below.

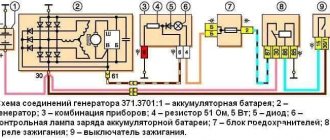

Instructions for removing the generator

Let's start by describing the process of removing the generator from an eight-valve car that is not equipped with air conditioning. You need to start by disconnecting the “ground” from the battery, for which you remove the negative terminal (this manipulation must be carried out when removing this unit from any modification of the Grant, this will help to avoid a short circuit). Further actions are performed in the following order:

- the bolts on which the motor protection is attached are unscrewed, after which it is removed;

- disconnect the block with wires from the generator;

- after removing the protective cap of the nut holding the power drive, the nut itself is unscrewed and the wire is disconnected from the generator;

- then the upper mounting nut of the generator is unscrewed, and the unit is pressed out using a mounting spatula, and the upper mounting bolt is also removed at the same time;

- the lower fastening nut is unscrewed, the generator is carefully moved away from the engine, and the fastening bolt located below is pulled out;

- the generator is shifted to the right mudguard, the belt is removed from its pulley, the generator itself is pulled out;

- The process is completed by removing the belt from the crankshaft pulley.

Now let's look at a similar process carried out on a sixteen-valve Grant without air conditioning. Such machines are equipped with belt tensioners, and therefore the work described has some differences. So:

- First, the mounting bolts are unscrewed and the block is disconnected from terminal “D”;

- then the cap covering terminal “B” is removed;

- then the nut holding the wire tip is unscrewed and the nut holding the tension bar is loosened;

- the adjusting bolt of the tension mechanism is turned counterclockwise, and at the same time the belt tension is loosened with a 10 key;

- the generator is moved towards the motor, and the belt is removed from the pulleys;

- then the tension mechanism adjustment bolt is unscrewed and removed, and the tension bar is dismantled;

- the fastening nut located at the bottom is unscrewed;

- the spacer sleeve is removed, after which the mounting bolt located at the bottom is removed out;

- Finally, remove the tension bar and remove the generator out.

New Lada: Is the body of LADA cars galvanized or not?

Now let's move on to describing the process of removing the generator from a car equipped with air conditioning. Since the air conditioning devices installed on Grants operate from the generator belt, they must be carefully moved to the side, after which you can proceed directly to the removal itself.

To successfully carry out this procedure, you must sequentially perform the following steps:

- to begin with, all the bolts that hold the cushions and bracket are treated with WD-40;

- then the mounting bolts are unscrewed and the protection is dismantled;

- after the WD-40 starts to work, unscrew the bracket nut;

- the jack is installed in front of the car, on the right, while the bolts holding its right front wheel are loosened;

- lift the jack, while hanging the wheel, and then remove it from the car;

- Next, the tension roller is dismantled, then the bolts that secure the pillow are unscrewed;

- the car is carefully lowered, hanging it (thus, the cushion moves towards the motor, opening a direct path to the generator).

At the final stage of work, you will need to remove the generator using one of the methods described above.

What kind of charging should go to the battery from the generator?

It is traditionally believed that 13.5-14.5V should be supplied by the generator to the battery and this is absolutely enough to replenish the battery costs.

It is worth considering that using a battery with a higher power in a car than the manufacturer recommends also requires the installation of a more productive generating device.

It is necessary to take into account the load that the generator must withstand - it is calculated based on the maximum indicators of all electrical appliances and car systems.

Do not forget that the charging current from the energy-generating device will allow you to start the car in the cold season. In order to avoid problems with starting the car, we recommend purchasing generating equipment, the charge current of which will be approximately 10% of the capacity of the power source. That is, a battery of 100 A/h requires a generator that can produce 10A. Please note that for many cars, 100 amp equipment will operate at its maximum capacity, because the power consumption of the automotive system is in the region of 80 amps. Therefore, the choice of a source generating energy must take into account both the battery capacity and network consumption.

In winter: what should be the voltage of a fully restored car battery in cold weather?

12.9 V at -10…-15°C. This potential difference corresponds to 100% battery charge. At sub-zero temperatures, the progress of electrochemical reactions slows down and the facts confirm this:

- At -30°C, the actual battery capacity is approximately 50% of that stated on the label.

- Electrolyte density is 1.28 g/cm3. Voltage at -30°C is 12.4 V, and at +25°C – 12.7 V.

- At temperatures below -25°C the battery stops taking charge from the generator.

In cold regions, it is customary to add sulfuric acid to the electrolyte, thereby increasing its density. At 1.30-1.32 g/cm3, the car battery voltage in the cold should be 12.9 V without load (temperature: -10...-15°C). When increasing the concentration of the sulfuric acid component, you should not exceed 1.35 g/cm3, otherwise it will begin to corrode the plates.

For your information. During discharge, water is released and the density of the electrolytic liquid drops, causing it to freeze at sub-zero temperatures. Ice warps the plates, which damages the battery.