Among car enthusiasts and specialists, discussions often arise on the topic of optimal fuel consumption in the form of gasoline or gas. As practice shows, gas-cylinder equipment is more economical during operation. However, its installation requires capital investment. In the Russian Federation, Digitronic equipment is in demand. It is the Digitronic HBO that will be discussed in our article today.

About the Digitronic brand

In 2004, the engineering and management staff of GAZPART 95 began developing the foundation for a new brand. The idea was to use a wide range of high-quality components from various manufacturers. According to the technical specifications of Digitronic specialists, work is being carried out to manufacture equipment at the Italian plant AEB (Alternative Fuel Electronics). However, there are components from other countries. For example, from the Polish company STAG. And this is one of the Digitronic policy lines, in which there are no restrictions in the selection of a high-quality assortment.

In many respects, gas cylinder equipment of this brand can be considered universal, because it can be installed on different car models. It is important that these products are applicable to trucks and passenger vehicles.

BRC

One of the most famous Italian brands of HBO manufacturers. All components are produced at the same factory and adjusted to each other. HBO BRC is a high-quality product that will last a long time. But like all high-quality equipment, equipment from this manufacturer cannot be cheap.

The advantages include:

- High quality products;

- Rate of fire of injectors;

- Balance of all equipment and stable operation under any conditions.

The disadvantages are:

- High price;

- Non-separable design of the injectors, which does not make it possible to repair them using repair kits;

- Inappropriate for use on commercial vehicles.

Thus, BRC gas equipment is a reliable, but expensive equipment that is advisable to install in the middle or premium class of new cars.

Products

The company supplies items such as:

- HBO cylinders are cylindrical and toroidal of various capacities;

- Nozzle (Injection) rails;

- Additional components and parts (multi-valves, filters, dispensers, mixers, clamps, tubes, rubber hoses and other consumables);

- Gearboxes;

- Various electronics (injection and traditional gas equipment, CVTs, emulators, sensors and indicators);

- Kits (for four, six and eight cylinders, as well as FSI with direct injection).

In addition, tuning systems, adapters, programming interfaces and much more are provided.

Advantages and disadvantages

Digitronic 3d power has a lot of advantages over analogues:

- can be adjusted manually, taking into account gas temperature and engine speed;

- gas injector heating function;

- convenient self-adjusting system;

- cars with Digitronic 3d-s Power comply with Euro 5 emissions standards;

- the presence of a sound signal informing about the start of the internal combustion engine in the event of a malfunction;

- digitronic 3D power adjusts the gas pressure in the reducer at the moment of shutdown;

- installation on turbo systems is possible;

- recognizes engines that operate on the rotary piston principle;

- saving fuel thanks to accurate calculations;

- automatic switching to gas supply;

- The ECU pinout diagram is not complicated;

- sealed waterproof housing;

- wide selection of compatible gas injectors;

- Digitronic 3ds Power minimizes the occurrence of errors in the operation of the piston group.

Among the disadvantages, car owners name only one: it is difficult to find a technician who would do a flashing if necessary.

Read further:

Powerful Digitronic Maxi 2: saves money and time

HBO Zenit: reliable equipment at an adequate price

OMVL Saver and its settings

HBO Digitronic: versatility and affordable price

HBO Polytron: taking into account the realities of machine operation

Features of HBO 4th generation Digitronic

The most popular systems are the fourth generation of gas equipment associated with changes in engine production. The Digitronic company has well established itself as a manufacturer with well-thought-out components for 4th generation HBO. The advantages of brand development are:

- Stable and reliable, trouble-free operation;

- Ergonomic installation;

- Easy to set up.

The equipment is designed in such a way that it will function successfully, regardless of the qualifications of the installer. And the ease of installation allows you to set an adequate cost for the work or carry out the installation yourself.

Another plus for Digitronic gas equipment is that the system is designed in such a way that exhausts as a result of fuel combustion practically do not enter the environment. You can also note some operational characteristics that increase the demand for these systems:

- Increases vehicle range

- Design features reduce maintenance costs

- Engine oil service life increases to forty to fifty percent

- The engine starts quickly

- Engine parts are not exposed to tar deposits, soot or carbon deposits

- Spark plug and engine depreciation is slower

However, with all the advantages, there are also standard disadvantages that cannot yet be improved: cost, cylinder dimensions and an increase in the total weight of the car.

Converting kilowatts to horsepower

Follow us on social networks

Please note that this website is for informational purposes only and under no circumstances constitutes a public offer as defined by the provisions of Article 437 of the Civil Code of the Russian Federation. Prices on the website are provided as a guide only and are subject to change at any time without notice. The manufacturer may change the configuration, characteristics and appearance of the product without prior notice. Images may differ from actual product. For detailed information about the cost, configuration, terms and conditions of equipment delivery, please contact the company's managers.

Multivalve

Gas systems of any type must be equipped with shut-off valves. For cars, a multivalve is used, which combines up to ten functions, in addition to shut-off. The device includes several elements: actuator, shut-off, control and safety. Multivalves can also be divided into two types: without a safety valve with a volume limitation for equipped cylinders and with a valve.

Device functions:

- Possibility of manually shutting off the fuel supply;

- Availability of gas supply speed control;

- Blocking the loss of the gas mixture in the event of a disconnection from the filling column;

- Emergency gas release in case of cylinder depressurization;

- Fuel level sensor.

Other elements

The Digitronic company supplies gearboxes, injection racks, pressure gauges, filters and peripherals to the Russian market.

There are seven types of gas reducers in the product catalog. This is the main element in the car's gas system. It serves to reduce the pressure of the gas mixture to a level at which it can be supplied to the engine. They differ in the type of gas mixture used (propane or methane) and the power of the engine for which they are designed. Methane gearboxes AT-12 and AT-12HP are designed for engines with power up to 250 and up to 400 horsepower, respectively.

Methane reducer

Maximum power for propane gearboxes is up to 300 horsepower DIGITRONIC PALLADIO. At the same time, their selection is extensive and allows you to choose a model for the most popular engines with low power. Thus, the DIGITRONIC ALASKA gas reducer is designed for cars with an engine up to 120 horsepower. All samples have a built-in liquid phase filter. This eliminates the need to install an additional valve. An advantage of the DIGITRONIC ANTARTIC SUPER gearbox is that it can be completely disassembled, making it easier to repair in the event of a malfunction. In addition, its gaskets are made of material that is resistant to aggressive environments. This gearbox is designed for engines up to 240 horsepower.

Gas filters are presented in four modifications with similar characteristics. Their connection diagram is the same. They can operate at temperatures from -20 to +120 at a pressure of 450 kPa. This element is installed between the pressure sensor and the reducer and serves to purify the gas mixture from foreign impurities. It is important due to the varying quality of gas sold on the Russian market, which can cause problems.

Digital connection diagram

A gas filter reduces the possibility of their occurrence to a minimum.

An extensive selection allows you to choose a part for almost any car.

Twelve types of hoses are produced under this brand. They are intended for both gas mixtures and other vehicle systems (gasoline, antifreeze, vacuum). Their diameter is from 5 to 16 mm, operating temperature is from -25 to +125. The equipment is certified according to international standards.

Digitronic kits

The company supplies both individual components and kits for engines with different numbers of cylinders.

A comprehensive solution involves the selection of each element, which affects the efficiency and stability of the entire system as a whole. The set of gas equipment includes:

- Switch between gas mixture and gasoline (Gas-gasoline button);

- Cylindrical or toroidal gas cylinder with a volume of forty liters or more;

- An electromagnetic valve with a filter, designed to remove impurities from the fuel mixture and performing a shut-off function;

- A ventilation box, which includes shut-off valves and valves, the purpose of which is to reduce the risk of an emergency in the event of a gas leak;

- Reducer - an evaporator through which liquefied gas passes into the gaseous phase;

- Valves for gasoline and gas are electromagnetic type to stop the supply of fuel to the combustion chamber.

Mounted injector rails, gearbox temperature sensors and an electronics kit can also be supplied.

Controller Features and Functionality

The production of an electronic control unit for gas systems is established in Polsky, whose products have long proven themselves in the gas equipment market.

The device was developed on a 32-bit high-performance processor, has a compact design, assembled in a sealed plastic case, convenient for installation.

Main features of Digitronic Maxi 2/Titan:

- compatible with methane/propane gas equipment

- designed for engines up to 4 cylinders, with distributed fuel supply (paired, phased, asynchronous)

- building a 2D map based on injection time

- work in conjunction with a parameter recorder and an oscilloscope

- Suitable for turbocharged internal combustion engines, also with Valvatronic system

- there is an adjustment for t° and gas pressure

- work with heating of gas injectors

- adjusting the number of emergency starts with sound alarm

- a start-stop system is available (compatible with hybrid power plants, a warmed-up engine starts immediately on gas)

- automatic adjustment of fuel level sensor

- tests components (gas valve, buzzer, injectors, LED alarm), reads and records system errors

- automatic calibration

- reading engine speed from gasoline injector signals

- setup via bluetooth connection

- adaptation to work with the main types of gas injectors

- possibility of setting a lock with a PIN code (after the programmed time has elapsed, the machine will stop switching to gas)

- records the parameters of the machine and gas equipment with subsequent information about the maintenance of gas equipment

According to the manufacturer's plant, the electronic control unit for gas equipment of the 4th generation digitronic maxi two, compared to its predecessor (maxi-1 (also discontinued digitronic four maxi)), has increased quality and reliability, proven by numerous tests. In addition, for a moderate cost, the average price for the original Maxi-2 electronics kit, which includes a map sensor, a gas/gasoline button, and a wiring harness, is 7,150 rubles.

Also, based on reviews from car owners, we can conclude that no global problems arise during the operation of a gas system with a maxi-2 controller.

The causes of malfunctions are usually:

- poor installation

- non-compliance with the service interval (TO)

- The supplied controller is not the original one.

Digitronic control unit MAXI 2

For four cylinder engines, Digitronic has developed the MAXI 2 control unit. This line is designed to reduce installation and calibration time.

The basis of the unit is a thirty-two-bit processor with the possibility of upgrading. Such a unit can be quickly installed thanks to a small number of wires and a sealed compact housing. Calibration is carried out through functions located on two panels, which eliminates the problem of switching between tabs. There is a separate button with a buzzer, which is connected using three wires.

The software capabilities of the unit include displaying engine operating parameters on an oscilloscope, a gasoline injection time map in 2D format, functions for correcting gas pressure and temperature with corresponding maps, heating gas injectors, setting the maximum load on the gas mixture, changing the time for opening and closing injectors, as well as the flow through them, and much more.

The MAXI 2 unit is compatible with almost forty manufacturers of gas injectors, including AEB, Hana, Valtek, Rail, Matrix. Functional and software characteristics have made Digitronic MAXI 2 one of the most popular on the Russian market.

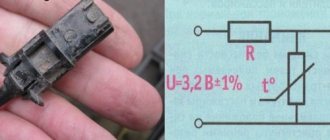

Reasons for malfunction of the gas temperature sensor

Any, even very good equipment can break. HBO temperature sensors are considered durable devices. They break extremely rarely. The gas ECU that controls the operation of the injectors gives a signal that is adjusted by several main factors:

- pressure arising in the nozzle rail itself;

- heating antifreeze;

- gas temperature.

If any of the listed components fails, the LPG ceases to function normally. The coordinated operation of all equipment components is disrupted. The probable causes of a malfunction of the gas temperature sensor are:

- If there is voltage on the device, but its signal does not reach the ECU. Consequently, contact between these devices has disappeared. To find the location of the breakdown, it is necessary to diagnose the connecting wires.

- There is no tension at all. There may be no power supply. If, after applying current, the sensor is still silent, it means that it is completely broken. To determine the unavailability of power, a “ring” is made of all suitable cables, the pressure sensor, as well as the temperature sensor itself.

After eliminating the malfunction, the functionality of the device is fully restored. If, after eliminating breaks in the electrical system, the device still does not function, replace it.

If an electronic component receives incorrect information from a temperature sensor, this is rarely due to a breakdown of the device. Most often, the cause of such a breakdown is caused by incorrect adjustment of the product.

To correct the situation, you will need to first diagnose the system. For this operation you will need:

- connecting wires;

- software;

- computer.

When setting up the system, it is necessary to take into account the modification of the gas equipment and the model of the car on which it is mounted. Such an operation cannot be performed without experience and special knowledge.

Source

Digitronic control unit IQ series

This line is intended for engines with a number of cylinders other than four. Each IQ block model is installed for its own number of cylinders. The functions of the IQ block include:

- Automatic closing of the solenoid valve if the temperature at the gearbox drops below 10ºC;

- Correction of the volume of injected gas;

- Indication of target OBD corrections depending on engine speed with a map;

- Fuel level emulator (for cars whose gasoline indicator drops when switching to gas fuel);

- Correction of the volume of injected gasoline along with gas;

- An oscilloscope showing the operation of gas and gasoline injectors, as well as engine speed;

- Flow calibration on gas injectors;

- Open Loop adaptation for closed and open loop.

Depending on the specific interface version and block model, the set of functions may differ. The electronic control unit system has been carefully designed down to the smallest detail, minimizing the adjustment of gas equipment after installation.

Step-by-step instructions for setting up gas equipment

The vehicle must first be warmed up to operating level. Then remove the load (heating, air conditioning, air conditioning, etc.) from the engine so that the car remains idling. Before entering the parameters menu, you need to connect to the gas equipment using a special cord. If necessary, the software must be updated to the latest firmware version. Algorithm for setting up Digitronic gas equipment using special software:

- Set the basic parameters of the car (number of cylinders, engine type, etc.), and in the “GAS Controller Settings” tab select the type of injectors, temperature sensors, etc.

- In the calibration section it is required to indicate the operating and emergency gas pressure. Calibration setup is done automatically using the ISA-2 adaptation tool. It must be carried out on a warm internal combustion engine (internal combustion engine).

- When the procedure is completed, the system prompts you to take a ride to set up the gas map. While driving, a map consisting of multi-colored cells will be displayed on the laptop monitor. It is necessary that the maximum number of them turn black.

- After receiving sufficient information on the use of gasoline fuel, you should switch to gas and continue driving.

Filling out each card usually requires driving several kilometers. The curve of the petrol and gas maps should be as close as possible. If they do not match, you need to adjust the coefficient:

- Place a mark on the orange curved line at the point where the two graphs diverge.

- Place a point on the orange curve at the convergence of the blue and green lines.

- Select the area of greatest deviation of the gas and gasoline curves. This point must be clamped and moved so as to minimize misalignment.

- Make another trip by car to generate new maps. If they do not match again, you need to try the whole procedure again.

The coincidence of the map graphs is not a 100% guarantee of the correct fuel mixture. After the initial setup, you need to drive the car for some time to observe the “behavior” of the curve. If necessary, additional steps must be taken to obtain the best result.

Selecting the right gas mixture

To determine the optimal fuel characteristics, it is necessary:

- Start the car and warm up the gas fuel and gearbox to operating condition.

- Switch the vehicle to gasoline and let the engine run for about 10 minutes. Observe in the program how the injection time changes. It is recommended to additionally monitor the fuel trim and lambda.

- Switch the car to gas and check how the fuel injection timing changes. An increase indicates a poor gas mixture, so the electronic control unit tries to enrich it. It is necessary to ensure that the injection does not change when switching from gasoline to gas. To do this, you need to move the orange curve up or down until the desired result is achieved.

A deviation of 10% is allowed. The software allows you to adjust other parameters in order to more accurately configure the operation of gas equipment. It is not easy to set the correct characteristics on your own, so it is better to contact a specialist who will optimize the operation of a car on a gas fuel system.

specializes in installation and maintenance of gas equipment in St. Petersburg. Experienced craftsmen will quickly and accurately adjust gas equipment to obtain optimal performance.

If necessary, company managers will answer your questions and fill out a preliminary application. If you require installation or adjustment of 4th generation HBO, call +7 (812) 777-0-180.

Source

Digitronic gearboxes

For a gas cylinder system, the gearbox is one of the most important parts. Digitronic works with TOMASETTO gearboxes, which are designed for carburetor and injection engines and are part of the gas equipment starting from the second generation. Different models from this manufacturer differ in power and some variations in functions, such as preheating at the inlet or without an additional heating stage.

Equipment installation

Digitronic brand gas equipment for the 4th generation is well suited for the Russian market. It is designed for local conditions with variations in ambient temperature and various driving conditions. The company provides a good guarantee in case of malfunction of one or another element of the system.

The company categorically does not recommend installing 4th generation gas equipment with your own hands. This is a safety issue; in addition, independent installation and configuration can cause malfunctions of various equipment components.

At the same time, due to its popularity, installation and configuration can be carried out in many car services. The company has developed a training course that can be used by any interested auto mechanic.

The connection diagram is supplied with the equipment kit. The instructions cover the initial setup, which is recommended to be done at a specialized car service center. Configuration during operation can be done independently.

maxi2 functionality

The Digitronic maxi 2 gas control unit is equipped with a 32-bit processor, designed for efficient modernization and firmware updates in the future. Placed in a durable, sealed plastic box.

The device is equipped with a fuel level sensor. The fuel switches accompanied by sound. The maxi2 kit includes universal electrical wiring, fittings, terminals, pressure and temperature sensors.

The function of additional injection of gasoline fuel is provided at a certain number of engine speeds, the period of gasoline injection and gas fuel pressure.

The connection diagram and pinout of the Digitronic dgi for maxi 2 multi-connector is simple due to the small number of cables and connectors. It will not take much time to install the device and connect to the equipment. The pinout of multi-connectors is simple. Many craftsmen make the adapter cord for tuning themselves, but you can also buy an inexpensive ready-made one.

The calibration program is easy to understand. There is no need to switch between bookmarks. There are detailed instructions for connecting the Digitronic maxi 2.

The 32-bit Digitronic maxi 2 process of the 4-cylinder engine offers unlimited prospects for updates and additions of functions. Digitronic Maxi is suitable for two types of fuel - propane-butane mixture and methane. The software can be run in Demo version.