January 26, 2016 Lada.Online 112 755 2

The standard location of the Lada 4×4 generator is at the bottom, which cannot be called a good solution. During off-road driving, water and dirt easily get on it, or antifreeze drips, which significantly reduces its service life. To protect an important part from moisture, owners resort to modifications. Let's look at how to move the generator up to a Lada 4×4.

Alternator bracket diagram for VAZ 21213 (carburetor)

The author of the drawing made a bracket from a piece of metal 80x80 mm, 4 mm thick.

The upper adjustment bar for the generator is borrowed from the Volga. It was cut in place and a new 8.5 mm mounting hole was drilled. VAZ 2110 crankshaft pulley, GAZ 3110 pump pulley, 6RK1290 belt. A standard cooling fan is installed on the pump pulley. The location of the generator is top left. The lower mounting point of the fuel pump, at the front we attach it to a standard stud and bolt, and at the top there is an M8 cylinder head bolt. The lower long generator mounting bolt with an engraver and an additional locknut.

Another bracket drawing provides for a belt measuring 1375 mm. You will need to modify the plane on the head in the area of the M8 bolt with an angle grinder, and also change the studs and bolts securing the front cover.

Features of installing the bracket in the video:

Mounting drawings for injection Lada 4×4 with power steering (VAZ 21214)

The author of the design proposes to move the generator to the place of the power steering, having previously installed the following bracket in its place:

Belt 1220 mm profile “A” (ZIL157), wedge angle 40 degrees. High pressure pressure hoses have a length at the centers of the fitting holes of 1450 mm. Return sleeve - 1115 mm. You will have to cut a hole for the hoses in the right protective casing. The belt is 710 mm long, other dimensions are the same. The photo on the left shows the hydraulic pump bracket, on the right - the power steering in the new place.

Turn the power steering pump upside down. Result of moving the generator to the top:

There are ready-made kits for moving the Lada 4×4 generator upwards on sale, but the price for a piece of iron can be greatly inflated. Thus, by making such a bracket ourselves, we extend the service life of the generator and save money.

Have you ever encountered such a modification? How did you solve a similar problem? Let us remind you that in another article we determine whether the Lada 4×4 needs a more powerful generator.

Keywords: 4x4 generator

Fastening drawing

The drawing suggests moving the generator to the place of the hydraulic booster. To do this, you need to make a bracket and install it next to the power steering. You need to select washers for the bracket ears in advance.

This option uses a belt with a size of 1220 mm. It is important that the angle of its wedge must be exactly 40 degrees. An excellent solution would be to buy a belt with ZIL 157. The return hose has a center length of 1115 millimeters, and the high-pressure pressure hoses are 1450 mm.

Check all dimensions carefully, remember the saying: measure 7 times, cut once, there is no need for mistakes here. There is no standard hole for these hoses in the right casing, so you will have to take it and cut it yourself.

The bracket itself for moving the device upstairs is made according to this drawing:

The pump must be turned upside down so that the generator is completely seated. The result of the transfer looks like this:

If you don’t have much experience in carrying out such upgrades, then you can buy a ready-made kit. It will include a new bracket for the Niva and the necessary fastenings. Reviews from motorists indicate that the cost of this simple part is too high.

Generator NIVA

Bracket for transferring generator VAZ-2121 for NIVA

It took me a long time to decide to do this kind of work. I really didn’t want to deal with the change in the recently put order in the engine compartment: the electrical wiring was neatly laid in its place, the cross-section of the wires was chosen with reserve and satisfied my “today’s” needs, and to all that was said, you can also add the embarrassment of using a non-standard V-belt , which can only be obtained upon order. I became the proud owner of a VAZ-2121 generator transfer bracket

Generator transfer bracket from Z-IQ

The generator belt was not included in the kit and its size was not known to me, but a simple empirical method was used to determine, in my opinion, the most optimal belt size - 1350mm

V-belt, purchased to order

To install the bracket, you must: — unscrew and replace two studs and two M6×20 bolts of the camshaft drive cover with four M6×25 bolts; — use a file to modify the bead around the cylinder head bolt and the bead on the cylinder block (shown in the figure below) under the bracket mount. Carry out the work locally; the approximate work time, if you have suitable and working tools, is 1/2 hour.

The design of the bracket consists of three parts and implies the possibility of installing generators from different manufacturers. In my case, the KZATE VAZ-21214 80A generator is installed in the middle vertical position. Before finally assembling and pulling the bracket, you must first check the alignment of the belt on the pump, generator and crankshaft pulleys.

Finally, we move on to the final part: disassemble, break and assemble. There are also positive aspects, for example, I used a large cross-section wire for the generator from the battery, in connection with its transfer, and reduced the length of the wires to the ignition switch from the generator.

Transferring the KZATE 80A generator (step-by-step instructions for a carburetor internal combustion engine) for NIVA

What you need: - Generator 21214 or similar - Generator mounting bracket 21214-3701650 with two nuts and bolts with a thin head for fastening to the KIT kit - KIT generator transfer kit - generator belt 1350 mm long - mounting bolt for generator 2110 assembly - two M8x20 bolts and M8x30 with nuts

1) Remove the spare wheel from under the hood, unscrew the extension on which it rested 2) Unscrew the two studs and two bolts above the crankshaft pulley. We replace them with four longer bolts. If there are no problems with unscrewing the bolts, then there may be an ambush with the pins. It’s not difficult to solve; you can either weld it to the stud, or sharpen the stud with a file on both sides and turn it out with pliers. Everything turned out for us without any problems!

3) Now we take a grinder or a file and sharpen the engine block for the upper mounting of the bracket (the bolt to the left of the distributor, if you stand at the driver’s fender). On the block the tide has a round shape, but we reduce it to a rectangular shape!

4) We attach the generator mounting bracket 21214-3701650 to our massive structure

This is where the first difficulties appear. The generator bracket 214 should not rest against the outlet fitting of the fuel pump. On the KIT bracket there are three positions for installing the bracket from the 214 generator. We chose the middle one, there are also possible options: -upper (a 1375mm belt is required) -lower (replacement of the fuel pump with a 2108 is required) 5) Attach the bracket to the engine block 6) Disconnect the “-” from the battery, remove the belt from the generator, disconnect the wires from the old generator . We unravel the braid of wiring from the lower generator to the level of the battery itself and the electrics. wiper motor (this length was enough for me to reach the upper generator) We pack the wiring in corrugated paper.

7) Install the generator on the upper bracket, put on the belt. We check the alignment of the pulleys. If necessary, adjust the position of the bracket from the 214 generator. Install the tension bar. Let's tighten the generator belt!

We connect the wires, start the engine, check the voltage! (we didn’t succeed the first time due to a defective regulator relay

We secure the wiring with plastic clamps. We attach the coolant hose to the gas hose mounting eyelet, which goes from the fuel pump outlet fitting to the carburetor.

9) We inspect the engine compartment for the presence of jambs, making sure that they are absent, close the hood.

Alternator belt tension VAZ 21214 injector

We check the belt tension by its deflection between the pulleys of the units. 1. With normal belt tension, its deflection under a force of 98N (10 kgf) should be 10–15 mm between the pump pulleys and the generator

2

. . or 12–17 mm between the pump and crankshaft pulleys. We adjust the belt tension by shifting the generator (with its fastening nuts loosened): from the engine to increase the tension or to the engine to decrease the tension.3. To replace the belt, loosen the nut securing the generator to the tension bar with the “17” head on the carburetor engine.4. . or a “13” head - on an injection engine. We move the generator towards the cylinder block to loosen the belt tension.5. We move the generator, acting on it with a screwdriver as a lever in the slot of the tension bar:

on a carburetor engine;

6. on a VAZ-21214 engine.

Install the belt in reverse order. Turn the crankshaft clockwise two turns and check the belt tension. Excessive belt tension causes increased loads on the generator and pump bearings.

The original alternator belt on a VAZ 2121 can serve the driver for about 100 thousand kilometers on domestic roads, such messages came from many owners of the people's favorite. But it is not always possible to find an original alternator belt on the automobile market; the problem is that sellers tend to deceive gullible customers and the service life of the basement belt can be reduced by 2-3 times. Today we will tell you how to replace the alternator belt on a Niva with your own hands in a garage.

When you already have a new alternator belt in your hands, you need to prepare a 17-mm open-end wrench and a convenient place for repairs. As people say, I'll leave this video here.

Video. DIY alternator and drive belt replacement

1. The image shows how to properly loosen the alternator belt tensioner nut.

2. When the nut is slightly loosened, you need to move the car's alternator to the side to have good access to the belt. The arrow in which direction you need to move the generator is shown in the photo.

3. Remove the belt from the pump pulley, see the image for more details.

4. The alternator belt has been completely removed, now you can begin installing a new one.

The cost of a new belt is about 100 rubles. We carry out the installation in the reverse order, also do not forget about tensioning the alternator belt, you can watch the video above about this operation.

Insufficient tension on the alternator belt can also lead to its failure. If the belt slips, its full effectiveness is not used. And as we know, this particular part is the connecting link between the generator and the battery, which transfers energy from one unit to another. In simple words, if the belt is not fully used, the battery charge drops.

If you suddenly hear an incomprehensible whistle coming from under the hood of your vehicle, you should know that water has gotten onto the stretched alternator belt. This means that you need to replace it and tighten it well. To do this, you will need a 17mm ratchet wrench and a 19mm socket wrench.

How to tighten the VAZ 2121 alternator belt

1. Open the hood and unscrew the nut that secures the generator and tensioner plate.

2. Do not loosen the fastening nut too much.

3. Now you can tighten the belt. This is done like this: grab the tensioner nut with your hand and move the generator down. If you move it up, the belt, on the contrary, will loosen.

4. When the correct position is found, tighten the tensioner nut. 5. Tighten the bottom bolt and start the engine. If you hear extraneous noises or see that the belt is slipping, you need to repeat the procedure.

6. Testing must be carried out with the maximum number of electrical appliances turned on. 7. If in this case the battery produces at least 13 Volts, then everything is done correctly.

Many drivers overdo it and tighten the belt too much, forgetting that this can lead to bad consequences. Among them are belt stretching and, as a result, slippage and bearing wear.

Pay close attention to your car and pay attention to extraneous sounds. Let's remember that in the previous article we talked about

Drawings of the generator transfer bracket in the field

After checking the components of the entire car, I noticed that the generator was giving a weak charge. The first thing I decided to do was check the brushes. It turned out that to replace the brushes in the field, I would have to remove the generator - no problem. I took off the genadium and removed the cover, and I saw a diode bridge in a terrible condition (dirt, rust).

I immediately lost the desire to repair the generator, because after repair it would not work for long. It was decided to move it to a drier place. As they say, Google helps. There is a lot of information, but the price for the brackets, in my opinion, is very high. The two pieces of iron are welded together, painted, and for this, on average, 3000 rubles. I found a couple of articles with drawings and set to work. Two drawings were taken as a basis, transferred to paper 1: 1, then to metal. I cut it out and began to adjust it. I re-drilled and re-drilled it many times, but in the end everything worked out. I didn’t extend the wires, I just pulled them out of the factory harness, and later I’ll run them through the corrugation. The module was also moved higher. Now the generator can be repaired. But that’s a completely different story. I will help you with any questions.

07/14/2017 Installation of a secret transfer of the generator to a carburetor field

After purchasing a Niva (for the first time), any sane person will want to check the statement about the (phenomenal) depth of fords subject to the Niva.

And not sparing anyone or anything:

...he will definitely try to force the water obstacles. And he will even succeed! Almost no soaking of the seats, but 146% cleanup of the generator. Which sooner or later will quack like a wild duck and refuse to live in harmony with the rubbish and dirt. Having googled “generator transfer”, thrifty citizens will download the drawing for “cutting out”, the thrifty ones will buy a kit for “welding” or look for something inexpensive, but in reality it is usually quite crooked. Well, beautiful and successful people will relax actively in their free time from their main work, and they will entrust the transfer of the generator in their car to specialists. Despite the fact that version 1.4 is on the shelf in the manufacturer’s store, we receive a “secret” version 1.5 in the warehouse! The bracket is made by bending, is geometrically perfect and has a lifetime guarantee!

Here it is, this installation kit, the generator is not included in it, it was purchased separately))

Let's start betting. In fact and according to the instructions, you can’t do without “finishers” at all. In the area of the M8 cylinder head bolt, you need to remove a couple of mm of aluminum for a tighter fit of the mounting ear. UPD:

*After this installation, information arrived that the product had been upgraded since 11/11/17. A file is no longer required:

Otherwise, almost less time and effort is spent on installation than on disassembling and removing the old generator. It became very convenient to install! Special bolts allow you to adjust the position and alignment without disassembling the entire assembly:

...and thanks to the original adapter bracket, there is no problem with the gas hose breaking (as on other transfer models):

There is no point in describing the entire installation process; everyone has intuition (instructions) Bracket in place:

Don't forget to ground and install a safety plug:

The mechanics part is finished, the mechanic washes his hands, and the electrician approaches the machine with his bookkeeper:

The “excitation” wire was rotten, and more than one. Therefore, it is cut and soldered to the extension:

Frankly rotten power terminals also need to be replaced. The wires are crimped into one terminal:

Regardless of the position of the ignition switch, there is always a “+” on the generator. Therefore, all wiring is retracted into the corrugation:

... and it itself is fixed with an enlarged clip on the return hose bracket:

All is ready. Battery voltage:

Network voltage of a running vehicle:

Voltage with distant and all possible consumers:

The work is finished. Generator transfer version 1.5 kit - 3500 RUR. Generator StartVolt M 135A - 5500 rub. Installation work and dismantling of the old generator - 3500 RUR.

Moving the generator upstairs in Niva VAZ-21213

In order to move the generator upward on the Niva, it is necessary to make a special bracket. It is made of metal, the thickness of which should not be less than 4 millimeters. Its width and length are about 80 millimeters. In order to assemble this device, you will definitely need some other spare parts from domestically produced cars. Namely:

- adjustment bar;

- belt 6РК1290;

- crankshaft pulley suitable for VAZ-2110.

You will also need an upper adjustment bar, which can be borrowed from the good old Volga. To begin with, it should be cut in place, and then drill a new place for future fasteners.

The diameter of this hole should be 8.5 mm.

A fan is mainly installed on the pump pulley from the Volga, and the generator itself is located at the top left. The cylinder head is attached on top of it thanks to an M8 bolt, while standard studs and a bolt are most often used on top. In order for the resulting bracket to hold well, it is best to secure it with another additional nut.

But there is also a second option for moving the generator on the Niva to the top. In this case, you should use a belt whose size is 1375 millimeters. You will have to perform much fewer actions, but you simply cannot do without working with an angle grinder. This tool will be necessary to reduce the plane of the head, which is located near the M8 bolt.

Battery charging lamp VAZ 21214

After replacing the alternator belt, charging stopped

, as a result, the battery died and the controller stopped working. The location where the charging relay is located near the field is determined by the age of the car. Thus, a remote relay can be found on the right fender liner of a car with a classic engine compartment layout; more modern modifications of generators are equipped with a launch vehicle combined with a brush assembly.

The element is not repaired, but replaced completely. To assess the condition, you will need power supplies of 12-14 V, followed by replacement with 16-22 V, and also an incandescent lamp of 1-3 W. According to the diagram drawing, apply current to the voltage regulator in series. If the first test is characterized by the operation of the lamp, and the second - by the absence of glow, then the LV is working.

If there is a break, the lamp will not light up at all; if there is a breakdown, it will glow constantly. In addition, weak charging, as well as its absolute absence, is often explained by abrasion of the brushes (residual height less than 5 mm) and slip rings of the generator. If the first part is changed along with the brush holder, then the second is restored by grinding, grooving or removing the remains of the old rings and pressing in new ones. It is recommended to supplement the disassembly of the unit with a total cleaning.

Read news about the new Niva

- On June 1, the 1st shift of the All-Russian military-historical camp “Country of Heroes” starts

- Niva Chevrolet where is the starter relay located?

- Generator Niva 2121, 21213, 21214: which one is installed, replacement

- Generator Niva 2121, 21213, 21214: which one is installed, replacement

- Generator Niva 2121, 21213, 21214: which one is installed, replacement || Niva generator no charge

- Generator Niva 2121, 21213, 21214: which one is installed, replacement

- Generator Niva 2121, 21213, 21214: which one is installed, replacement

- Generator Niva 2121, 21213, 21214: which one is installed, replacement

Transferring a generator for VAZ 21213 NIVA - Video tutorials

The video was created on the topic of how to move the generator to the top of a fuel-injected VAZ (LADA) 21214M 2012 car with power steering. The bracket used was a “modified” one.

It is installed without any modifications or adjustments (tested on yourself) and is attached to 8 (!) mounting points - 4 on the side of the front cover of the internal combustion engine and 4 on the left side (in the direction of travel) to the standard places of the block. The problem with the radiator pipe was solved by cutting the pipe on the radiator side by 2 cm.

And another important point that was missed in the video is the grounding of genes. The bracket is painted, so you can’t just “hang a lot” on it; you need to choose a place where the wire will be in reliable contact with the body of the genes (otherwise the car will not start)

A brief overview of the bracket for transferring the generator to a carburetor Niva without Gear. What are the options, how to establish what the outcome is.

#vtc #tuning #club #vaz #lada https://vk.com/vaztuningclub - our car club) Using this method, the car became 1.5 -2 cm higher. I did it because I cut the springs more than needed -2.5 turns and the rear was significantly lower than the front end.

After installing these spacers, the car became taller, but taking into account the fact that I cut the springs, the stiffness remained higher than on the standard ones, and the suspension travel was not affected. This is what I wanted to achieve. The result is that the car rolls less. The best solution to the problem of roll and sway in corners would be to install springs and shock absorbers from the field.

And again, the lower the car sits, the lower the center of gravity and, as a result, less roll and better responsiveness to the steering wheel.

The magic of the winemaker from Kanev truly strikes. The man transforms old cars with amazing mechanisms. You have selected a unique collection, which has no analogues in the world.

The design feature of this model allows not only to differentiate the angular speed of the car’s driving wheels during its maneuvers, but also to gently redistribute torque from the engine to the drive wheels, depending on their coefficient of adhesion to the road surface.

A wheel that is on a slippery surface or hanging out will receive a minimum amount of torque. Compared to a classic serial differential, the effect is “the opposite”.

Operating principle of the hydraulic control system

In the video below you can watch how a self-installed power steering works (the author of the video is Vladislav Mantula).

Reg.: 04/07/2005 Topics / Messages: 8 / 439 From: Moscow Age: 20 Car: 21213 2000

What is preferable and why, if you do not pay attention to the difference in price?

Reg.: 02.02.2005 Topics / Messages: 16 / 769 From: Moscow, Chertanovo. Age: 57 Car: 2121395

If I didn’t feel sorry for the money on my old lady, I would definitely install an EUR, as it seems to me more reliable and much easier to install.

Reg.: 07.28.2005 Topics / Messages: 1 / 2646 From: Ivanovo Age: 43 Car: Nivka2121. g.v. worn-out 1.9i and other minor tuning Murzik MV 300TD 1993

Reg.: 12/06/2004 Topics / Messages: 628 / 51730

rdoctor: Power steering, unlike electric power steering, dampens the transmission of impacts from the wheels to the steering wheel - when hitting a pothole at speed, the steering wheel will not be torn out of your hands. Actually, this is the main (and perhaps the only) plus of the power steering. The power steering uses a standard steering gearbox. With a booster, you will be spinning the wheels more often on a stationary car, which will shorten the life of the standard RR. The power steering comes with its own gearbox.

As for the rest, the EUR has only advantages. Price, ease of installation. And the fact that if the power steering malfunctions, you will simply get a standard steering wheel, and not a steering wheel that can barely be turned (although we have never heard of malfunctions in our power steering).

But the question is... Does our Nivsky power steering change the force on the steering wheel depending on the speed, or not? I want the steering wheel to stiffen as the speed increases, and not remain weak. As far as I understand, the power steering monitors the speed (does it really load the steering wheel as it increases?) And the power steering? Is he just unloading? Or does it still track? (how does it track, by the way, if it does track?)

People, let me know who installed the Nivo EUR, how is it in terms of quality? I want to buy it, it’s cheaper than the Priorovsky one and the lock, the steering wheel and steering columns don’t need to be changed, everything is original. The only difference is that the Priorovsky one has height adjustment.

How does power steering work? Its main element is a pump, which, using a belt from the crankshaft, sucks in oil and pumps it into the distributor. The latter, in turn, monitors the force applied to the steering wheel and, using a torsion bar (follower device), helps turn the drive wheels. When moving in a straight line, the torsion bar does not twist, so the distributor channels are blocked and the oil drains back into the reservoir.

Power steering is most often useful when parking and turning, making the work of your hands three times easier. We can also say that the mechanism weakens the transmission of microshocks from the road surface to the steering. The mechanism is also useful in case of a sharp drop in tire pressure. The disadvantages of power steering include the fact that it interferes with “feeling the car”, so designers need to achieve a compromise between informativeness and tightness of the steering wheel.

Foreign manufacturers conduct a lot of research in order to make the hydraulic booster light at low speeds and elastic at high speeds. To do this, German hydraulic boosters from ZF are equipped with pressure modulators, which limit the oil pressure in the operating circuit as speed increases. In addition, circuits with power steering driven by an electric motor are acceptable, which makes it possible to change the pump performance in accordance with the rotation of the electric drive. Sometimes the gear ratio is also changed.

Device Description

On Niva 21214 cars there is a generator of type 9412.3701, on VAZ 21213 - type 371.3701, on Niva Chevrolet there is a generator 2123. All of them are alternating current electric machines with electromagnetic excitation, having a built-in rectifier unit with silicon diodes and an electronic voltage regulator. The maximum current produced by the generator unit type 9412.3701 is 80 A, voltage - 13.2 - 14.7 V, rotation - right.

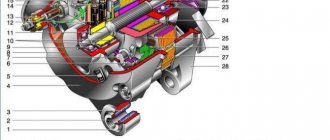

Design of unit 21214

The unit covers are attached to the stator using 4 bolts. The covers have bearings installed. They rotate the rotor shaft. In the front bearing, the inner race is clamped with a nut along with a thrust ring and washer. The 2nd bearing is also pressed into the back cover.

The stator has a 3-phase winding, one of the ends of which is connected to a rectifier unit consisting of 6 diodes. Of these, 3 diodes are negative, 3 are positive. According to the polarity, they are pressed into the plates. The entire structure consists of a rectifier unit, which is located on the back cover of the generator unit covered with a protective casing.

The design of the unit also includes contact rings and brushes. On the back side of the back cover there is a brush holder, which is structurally connected to the voltage regulator. The rectifier contains a capacitor that protects the electrical network from power surges.

The “B” terminal of the generator set must be connected to the positive terminal of the battery, and the negative terminal of the battery to the vehicle ground. If the connection is incorrect, this will lead to breakdown of the diodes.

Characteristics of the standard generator

The main characteristics of the generator installed by the manufacturer in Niva 21214, 21213, 2121 will be considered using the example of generator type 9412.3701:

- current – 80A;

- voltage – 13.2 V,

- rotation is right.

The cost of standard models of electric generators is 5-7 thousand rubles. If the unit breaks down, it is possible to replace its components or completely replace it with the original or analogues. The prices of the most common ones are presented in the table.

| Analogue | vendor code | Cost, in rubles |

| Generator VAZ-2104-21073,21214 | 9412.3701-03 | 5900 |

| Generator VAZ-2104-21073,21214 | 372.3701-03/05 | 3800 |

| Generator VAZ 2121-21213,21214 | 9412.3701 | 5450 |

The table shows that in the process of replacing a generator on a Niva, you can give preference to a cheaper universal analogue.

| Analogue | vendor code | Cost, in rubles |

| Generator VAZ-2104-21073,21214 | 9412.3701-03 | 5900 |

| Generator VAZ-2104-21073,21214 | 372.3701-03/05 | 3800 |

| Generator VAZ 2121-21213,21214 | 9412.3701 | 5450 |

Generator - device, characteristics, operation check

Start the engine, let it run for a few minutes, then, pressing the gas pedal, bring the crankshaft speed to 3000 rpm. Turn on the high beam headlights, heated rear window, and heater fan.

Measure the voltage at the battery terminals, which should be above 13.2 V for generator 9412.3701 and 13.6 V for generator 371.3701.

If this is not the case, the voltage regulator with the brush assembly, the generator windings are faulty (open or shorted) or the contact rings of the field winding are oxidized.

The removed voltage regulator of the generator 9412.3701 can be checked by connecting a lamp (1–5 W, 12 V) between the brushes, and a power source to the “D” and “ground” terminals (DC only, “minus” to ground!) , initially with a voltage of 12 V, and then 15–16 V.

In the first case, the lamp should be on, in the second - not. If the lamp lights up in both cases, there is a breakdown in the regulator; if it doesn’t light up, there is a break or broken contact between the brushes and the regulator terminals. In both cases the regulator should be replaced. To check the generator regulator 371.3701, the current source should be connected to terminals “B” and “C” (“plus”) and “ground” (“minus”).

Also interesting: Where is the Chevrolet Niva fuel pump relay located?

To check the valves of the rectifier unit, disconnect the wires from the battery, generator and from the voltage regulator terminal(s).

Connect the “plus” of the battery through a lamp (1–5 W, 12 V) to terminal “B” of the generator 9412.3701 (to terminal “30” of the generator 371.3701), and the “minus” to its body.

If the lamp is on, then there is a short circuit in both the block of “positive” and the block of “negative” valves.

To check the short circuit in the “positive” valves, connect the “plus” of the battery through a lamp to the “B” terminal of the generator 9412.3701 (with the “30” terminal of the 371.3701 generator), and the “minus” - to the terminal of one of the phase windings of the stator. If the lamp is on, one or more positive valves are broken.

To check the short circuit in the “negative” valves, connect the “plus” of the battery through a lamp to the terminal of one of the phase windings of the stator, and the “minus” to the generator housing. If the lamp is on, one or more negative valves are broken or the stator windings are shorted to the generator housing.

To prevent short-circuiting of the windings, remove the generator from the car and, having disconnected the windings from the voltage regulator and rectifier unit, check their short circuit to ground with a lamp or ohmmeter. The generator valves can also be checked with an ohmmeter without connecting the battery and test lamp.

The short circuit of additional diodes can be checked by connecting the “plus” of the battery through a lamp to terminal “D” of the generator 9412.3701 (to terminal “61” of the generator 371.3701), and the “minus” - to the terminal of one of the phase windings of the stator (to one of the mounting bolts of the rectifier block ). If the lamp is on, one or more additional diodes are broken.

A break in the main valves is determined by a sharp decrease in the output current (voltage drop under load). However, it can also be caused by an open or shorted circuit in the generator windings.

A break in the additional valves can be determined by the low voltage at plug “D” of generator 9412.3701 or plug “61” of generator 371.

3701 (below 14 V) at low and medium generator rotor speeds.

The serviceability of each diode (main or additional) can only be determined with a removed rectifier unit using an ohmmeter or a test lamp. If the rectifier unit fails, it is recommended to replace it as an assembly.

It is possible to replace individual valves, but the main valves will require repressing them in the holder - an operation that requires care and skill.

Read news about the new Niva

- Niva generator transfer bracket drawing

- Niva Chevrolet front hub repair

- Niva Chevrolet where is the starter relay located?

- Do-it-yourself Niva suspension lift. How to lift the front and rear suspension of a Niva car?

- Generator Niva 2121, 21213, 21214: which one is installed, replacement

- Generator Niva 2121, 21213, 21214: which one is installed, replacement

- Generator Niva 2121, 21213, 21214: which one is installed, replacement

- Generator Niva 2121, 21213, 21214: which one is installed, replacement

Generator faults

Checking the health of the unit is done using a multimeter. After the engine is started, the voltage at the battery terminals should be 13.6 V. If the value is higher or lower, this indicates a break or short circuit of the windings, oxidation of the slip rings, a malfunction in the brush assembly, or voltage regulator.

The generator unit may not work well due to weak belt tension or its breakage. In this case, you need to adjust the tension or replace the belt. Faulty voltage regulator, needs to be replaced. If a breakdown, short circuit, or damage to the rotor windings is detected, it should be replaced. If there is a break or short circuit in the stator windings, it requires replacement. If the diodes are damaged, the rectifier unit is replaced.

During the operation of any car, unpleasant situations often arise in the form of failure of one or another element. Niva is no exception, and most often the generator suffers.

If the generator seems to be faulty, it is recommended to check its functionality using a multimeter. To do this, you will need to start the engine and check the voltage at the battery terminals. The standard value that a multimeter should read is 13.6 V.

If the readings during measurement are higher, it means that a break or short circuit in the windings has occurred in the structure. The same can be said about the case when the voltage is below the specified number. This procedure is carried out regardless of the engine: injector or carburetor.

Also, if the breakdown is caused by another reason, you can replace the generator itself. Usually, for replacement, they turn to special service stations, but if necessary, the work can be done with your own hands.

Nuances of moving a generator

The disadvantage of domestic Niva SUVs is the location of the generator unit - at the bottom of the engine compartment. It constantly gets contaminated when driving off-road, and coolant constantly drips. The problem is solved by moving the generator upstairs (the author of the video is SARTANETS).

To transfer, you will need a set of keys, a bracket, mounting bolts, and a V-belt. You can make a generator transfer bracket with your own hands according to the drawing below.

Drawing of a homemade bracket

Sequence of actions during transfer:

- We dismantle the propeller, pump and remove the belt.

- By unscrewing the standard bracket, you can remove the generator.

- We cut off the bead around the side of the cylinder head and on the cylinder block.

- Then you should unscrew the two bolts and two studs.

- Next, the assembly is installed on a new bracket and final assembly is performed.

Thus, moving the generator unit upstairs is not difficult.

Generator transfer kit without power steering

- color - red, yellow material - steel

- Price – 1600 RUR (full set)

- color - red, yellow material - steel

- Price – 1100 RUR (light set)

The generator transfer bracket is designed to install the generator above the standard mounting point, because it, i.e.

The generator, when mounted at the factory (at the bottom of the block, almost at the crankcase), when operating the car starting from moderate off-road conditions, gets all the “goods” flying from under the wheels (water, dirt, snow, etc., etc.

) as a result, even when overcoming a small puddle, the battery charge often disappears, sometimes briefly, and sometimes completely (until you remove it and at least clean it, and it’s not easy to remove it from there, even in a garage, not to mention "conditions" far from civilization).

Guide to removing and connecting the generator

To remove the unit, you need to prepare a set of tools: keys “10” and “19”, ratchets with heads, a hammer and a small extension.

The process consists of the following steps:

- First of all, remove the negative terminal from the battery.

- Next, you need to remove the engine protection and the right mudguard.

- Then, using a hammer, carefully knock out the mounting bolt and remove it.

- At the next stage, you need to disconnect all the wires going to the generator: the plug and the wires secured with a nut.

- Then the fastening on which the belt tensioner is located is unscrewed.

- By removing the belt, the assembly can be dismantled through the hole that was formed after removing the protection.

- After replacement or repair, install the unit in reverse order.

The generator is connected according to the diagram.

Price issue

The VAZ 21214 generator has good repairability, which allows you to significantly save money if worn or broken parts are replaced in a timely manner.

If you change the complete unit, the cost of replacement will be as follows:

- generator 21214 – 3125 rub.;

- lower mount – 133 RUR;

- fastening bolt - 53 rub.;

- tension bar - 55 rub.;

- relay RS-527 – 57 rub.

A) Belt break.

Carefully examine the presence of a belt on the water pump and generator pulleys. To return it to its destination, you will need socket wrenches 17 or 13, depending on the year of manufacture of the car, as well as a strong flat-head screwdriver.

Disconnect the HF position sensor (for example, at 21213,21214).

Loosen the nuts securing the tension bar and slide it to the side towards the cylinder block.

Put a belt on your professionalism landing place.

After installation is complete, adjust the tension, controlling the deflection when pressing with a huge finger on the clearance of the belt between the generator and pump pulleys - 10-15 mm, pump and crankshaft - 12-17 mm. Failure to comply with this requirement may result in the belt slipping with subsequent damage and rupture.

Generator replacement

To repair or replace the generator, the car owner will have to remove the unit completely from the car or turn to professionals for work. If you still want to carry out the replacement yourself, then first you will need to prepare all the necessary tools:

The procedure consists of the following sequence of actions:

- First, you will need to park the car in a place designated for inspection and repair. The car will also need to be secured using special wheel chocks. Finally, in order for the work to be carried out safely, you should disconnect the battery by disconnecting the terminals from it.

- After this, you need to remove the engine protection. It is attached to several bolts, and they must be unscrewed to get to the lowest bolt of the generator.

- After this, you will need to knock out the mounting bolt using a hammer. It is recommended to knock carefully so as not to damage the thread and to prevent the bolt from coming out in the opposite direction. A hammer is necessary, since a wrench or any other tool simply cannot handle a bolt.

- Next, you need to remove the bolt, swinging the generator from side to side. It is necessary to bolt in any case, as this makes it easier to remove the rod.

- The fourth step involves disconnecting the wiring. To do this, the power wires connected to the housing are disconnected from the unit. In this case, you can first disconnect the plug from the wires.

- Wires are also attached to the generator, tightened with a nut or bracket. In this case, the nuts must be unscrewed with a wrench, and then the loose wires must be pulled out.

- Finally, after disconnecting the wires, you can begin to unscrew the upper fastening element with the belt tensioner. For this you will also need a wrench, as well as a small extension cord.

- Disconnecting the fastener will allow you to remove the belt and alternator. Then you can start cleaning the vacated space with a brush and installing a new unit.

The structure is assembled in the reverse order; the entire procedure will take about two hours if you have all the necessary tools.

We recommend: Step-by-step guide to selecting and replacing Lada Granta spark plugs on 8 and 16 cl engines

Additionally, it is worth noting that when everything is assembled, you will need to adjust the position of the generator using the tensioner. To do this, you need to unscrew the tensioner nut and tighten or loosen the belt, while observing the battery charge.

If the indicator returns to normal, then the selected tension is sufficient. There is no need to tighten the structure, as the generator bearing may fail. If the tension is insufficient, the generator will work intermittently, and this can also lead to breakdown.

How to replace power steering fluid in a Chevrolet Niva

The power steering system itself is a Chevrolet Niva hydraulic system, part of the steering mechanism to make it easier to turn the steering wheel and set the trajectory. If the power steering fails, it is possible to drive the car, but the steering wheel will be difficult to turn and will become heavy.

The power steering fluid level in a Chevrolet Niva can be determined by the marks on the plastic power steering expansion tank.

During operation, Chevrolet Niva power steering fluid can leak in various places, most often through hoses. As a result, the power steering oil level will drop.

Driving without fluid in the Chevrolet Niva's power steering puts you at risk of breaking the power steering pump, which costs a lot of money, since it will run dry. As a result, it will suffer serious damage and fail. The power steering pump in the Chevrolet Niva starts working as soon as you start the car. If your Chevrolet Niva is left without oil in the power steering system, then the best solution is to call a tow truck.

Intensive use of the Chevrolet Niva makes the color of the power steering oil darker over time, often with a burning smell.

This is a reason to think about replacing it. Overheating of the oil often occurs when the steering wheel is held in the extreme position for a long time, until it boils; the pressure in this case is maximum. You should also not leave your car parked for a long time with the steering wheel turned all the way.

Quick prevention and inspection of Chevrolet Niva power steering includes:

monitoring the power steering oil level and its quality in the power steering expansion tank, checking the tension of the drive belt on the Chevrolet Niva power steering pump, assessing the condition of the hoses - cracks, leaks, fogging, as well as searching for leaks at the joints of power steering elements.

There are two ways to replace the fluid in the Chevrolet Niva power steering:

- partial replacement of power steering fluid for Chevrolet Niva.

- complete replacement of power steering fluid for Chevrolet Niva.

To partially replace the power steering oil, you will need a syringe (with a tube) and the oil itself, enough so that at the end of the work it will no longer be dark.

Partial replacement of power steering fluid in Chevrolet Niva:

- Unscrew the cap of the Chevrolet Niva power steering expansion tank.

- Using a syringe with a tube, completely pump out the fluid from the power steering reservoir.

- Fill the reservoir with new fluid to the MAX level.

- We start the engine and turn the steering wheel left and right to the extreme position.

- We turn off the engine and repeat step No. 1 again until we get the required result - light oil.

The following method for changing power steering oil in a Chevrolet Niva will allow you to achieve almost 100% replacement.

Complete replacement of power steering fluid in Chevrolet Niva: