02/04/2022 80 568 117 120 Sensors

Author: Ivan Baranov

The main signs of a malfunction of the mass air flow sensor are loss of engine power, difficult starting, “floating” engine speed. To find out the exact cause of the flow meter failure, you need to visually inspect the device and then test it with a scanner (via Openidag), a voltmeter or a motor tester.

[Hide]

Where is the VAZ MAF sensor located?

If you do not know where your mass air flow sensor is located, then read the text carefully. On any car, be it a VAZ series 2110, 2111, 2112 or any other

brand, the installation location of the mass air flow sensor DMRV is the same.

The manufacturer installs this sensor after the air filter. Having found the wires going to the sensor installed after the air filter, in 99% it will be a mass air flow sensor

. We look at the photo below of the owner of AvtoVAZ.

Where is the mass air flow sensor installed VAZ 2110, 2111, 2112 DMRV

Replacing the air flow sensor

To replace the sensor with your own hands, you need to prepare a shaped screwdriver and a “10” key.

The replacement procedure consists of the following steps:

- First you need to turn off the ignition and open the hood.

- Then you need to disconnect the negative terminal on the battery.

- At the next stage, you need to loosen the clamp with which the corrugation is attached to the mass air flow sensor.

- Next, remove the corrugation from the pipe.

- Then you need to bend the comb and disconnect the sensor connector.

Disconnecting the sensor connector - Then, using a key set to “10”, you need to unscrew the sensor mounting bolts to the air filter housing.

- Now you can remove the mass air flow sensor.

- Installing the sensor yourself is carried out in the reverse order.

Thus, if the car stalls and has all the signs of a breakdown of the mass air flow sensor, then before you start repairing it, you should check the level of its signal, it should not be low, perform a full diagnosis of the car and repair all faulty components and parts.

It is important to undergo regular vehicle inspections and perform timely maintenance, then the parts and components will last longer.

How to check the MAF sensor of a VAZ?

Before you start checking the sensor with the same multimeter

You should perform a visual inspection not only of the sensor itself and its installation location, but also of the adjacent pipes and air duct for the presence of foreign debris.

Checking the sensor visual inspection of the air flow sensor

Where to start a visual inspection? It is enough to loosen the hose clamp on the air filter and remove it, after which you will have the opportunity to look inside and assess the condition of the sensor.

Inspection of the mass air flow sensor

In my case, both the sensor itself and the plastic air intake pipe are in good condition; there is a very thin layer of dust, but this is not critical. If your situation is different and there is dirt, oil and other debris, then it is better to remove both the sensor itself and the plastic air intake to rinse and clean it. By the way, special products are sold for cleaning the mass air flow sensor. Since the mass air flow sensor is a very sensitive sensor

then even small foreign objects can distort and change its readings.

Where to buy car accessories

Spare parts and other products for the car are easily available for purchase at auto stores in your city. But there is another option that has recently received significant improvements. You no longer need to wait a long time for a parcel from China: the AliExpress online store now offers the opportunity to ship from transshipment warehouses located in various countries. For example, when ordering, you can specify the “Delivery from the Russian Federation” option.

Follow the links and choose:

| DVR, Dual, 1080P, 4G, Android 8.1, 10-inch | Charger with two USB ports, 5 V | AUTOOL X95 car compass, horizontal inclinometer, speedometer |

| 12V car heater | HD night vision camera with 360 degree viewing angle | Karadar G820STR radar detector with GPS |

How to check the mass air flow sensor with a multimeter?

To check the mass air flow sensor DMRV with a multimeter

you need to know exactly which wires are responsible for what, if you have another car other than the VAZ 2110, 2111, 2112 family, then look for a power supply diagram for the sensor.

Well, if you are the owner of AvtoVAZ, then look at the photo below. Wires for the mass air flow sensor

And so we need the green wire is the ground and the yellow wire is the signal output from the sensor. To test the sensor, connect the multimeter to the green and yellow wires. It is not necessary to strip the wires in any way; you can simply insert probes into the terminal and measure the voltage.

Mass air flow sensor Fully working: 0.996 – 1.01 Volts;

The mass air flow sensor is working, but it was already working: 1.01 - 1.02 Volts;

MAF old: 1.02 - 1.03 Volts;

The mass air flow sensor is reaching its end and will soon need to be changed: 1-03 - 1.04 Volts;

The mass air flow sensor is almost dead: 1.04 - 1.05 Volts;

Mass air flow sensor needs to be replaced: 1.05 Volts and above.

Readings from the mass air flow sensor indicate that the sensor is working

What values does a working device show?

When the engine is not running, the voltage should be 0.996 V. If the readings are 1.016 or 1.025 V, then this wave is acceptable.

But when the values reach above 1.035 V, this may indicate that the sensitive element is clogged. To fix it, you can do without repairing the mass air flow sensor, just clean it.

You can determine exactly how much the numbers deviate from the norm as follows: to do this, you will need to evaluate how the engine operates at different speeds.

For a working 1.5 liter VAZ 2111 model engine at idle speed (from 860 to 920 rpm), the correct readings are from 9.5 to 10 kg/hour. When the flow meter at 2000 rpm shows approximately 17 kg, the car will drive stable.

If the indicator is about 23 kg/hour, then it will drive steadily. In this case, gasoline consumption per 100 km will be about 10 liters. Moreover, the car starts worse in frosty weather. Reason: fuel overflow when warming up.

What does a DMRV failure lead to?

Faulty mass air flow sensor

may lead to the following manifestations of vehicle operation.

- The engine does not start (this is very rare and on VAZ cars the mass air flow sensor is not capable of affecting the engine’s operation so much; moreover, if you turn it off completely, the on-board computer will set the default value)

- Changes in idle speed - they may increase or, on the contrary, decrease

- Increased fuel consumption with decreased acceleration dynamics. (incorrect readings from the mass air flow sensor interfere with the correct preparation of the fuel-air mixture).

- The most obvious sign of trouble is the Check Engine light on the dashboard.

In general, monitor the technical condition of your car and carry out all possible scheduled work on time to prevent engine breakdowns, including timely oil and filter changes.

Principle of operation

The piston stroke occurs when fuel is burned with air in a ratio of 1:14, maintaining which ensures optimal operation of the power plant. When the proportion decreases or increases, the engine does not stop working, but there is excessive fuel consumption or a decrease in engine operating power. We need a mass air flow sensor so that air flows in portions. The operation of the unit proceeds as follows: the VAZ 2110 air flow sensor calculates the portion of fresh air, and then sends the data to the main computer, which, based on this information, calculates the portion of fuel.

The harder you push the gas, the more filtered air the powerplant requires. The mass flow sensor detects the increase and commands the electronics to increase the amount of fuel. When moving at the same speed, each portion should be equal to the previous one. The mass air flow sensor receives data on the load of the power unit, and then calculates the required portion of air. When the driver presses the pedal, the throttle valve opens, thereby increasing the volume of intake air - the load increases. When the pedal is released, the load drops.

Damaged sensor due to dust

Information about the operation and design of the mass air flow sensor

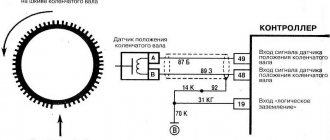

Again, we will not consider the historically outdated mechanical options with a weather vane and the General Motors frequency flow meter, which was used in conjunction with the January 4-series ECU. Modern flow meters for the VAZ 10 series operate on the principle of a hot-wire anemometer.

It is based on the properties of some metals to significantly change resistance depending on heat (the MAF sensor uses an alloy of iridium with platinum, which causes the high cost of the device). There are two resistors in the air flow: one is precision, the second can change the resistance using heat. Voltage is applied to it, the thread is heated until it matches the standard. Depending on the strength of the air flow, the thread cools and the resistance changes. By increasing the voltage across the resistor, the temperature and, accordingly, the resistance are restored. This happens in real time, that is, the control of the air mass is constant. At the output, the mass air flow sensor displays the signal voltage with an accuracy of hundredths of a volt. The received information is processed by the ECU to accurately dose gasoline into the fuel-air mixture.

What happens if the flow meter breaks down? The engine will continue to operate, but in emergency mode. At idle speed without load, the speed will be set to 1500, power will be lost, and fuel consumption will increase. In some modes the motor may stall.

All elements are arranged into a single electronic model, which is placed in the measuring channel (air duct).

Sensor device

The sensor itself is a combination of two sensors - control and working, as well as a heating resistor.

View of the flow meter from the grid side.

The sensor is disassembled.

The platinum thread is visible in this photo.

As a result, air flow and temperature are converted into electrical impulses understandable to the ECU. This is a very gentle and accurate device; it allows you to calculate the cyclic filling of the cylinders with air and updates the parameters every 0.1 s.

Mass air flow sensor diagram.

The working body of the sensor is a heated platinum thread. It heats up to operating temperature (from 100 to 1000 degrees), and when air enters, it cools down. The amount by which the filament temperature drops is converted into an electrical signal and, based on this value, the ECU calculates the mass and temperature of the air entering the combustion chamber. And based on this data, it prepares the required portion of fuel. In short - yes.

Visual inspection

As for visual diagnostics, first of all it is necessary to check the condition of the corrugation in which the flow meter is installed, as well as the device itself. If, as a result of the check, you see traces of motor fluid or condensation, then it is possible that the device does not work for this reason. In some cases, cleaning the device from contaminants allows the flowmeter to resume operation and prevent possible replacement. It should be taken into account that contaminants usually accumulate as a result of infrequent replacement of the air filter element (the author of the video about the regulator malfunction is the channel In Sandro’s Garage).

If you notice traces of engine fluid, then there is a possibility that the reason lies in a clogged oil seal, or the problem may lie in exceeding the permissible level of lubricant in the crankcase. When cleaning is complete, you will need to make a visual inspection of the regulator - on the front of it you can see the rubber seal that is used for sealing. The seal is necessary to prevent uncleaned air flow and it may be that the rubber band moves a little - this will lead to the accumulation of dust on the flowmeter grid.

In what situations is it necessary to check the control device?

The following signs indicate that the controller has failed:

- Check is on, errors appear during system self-test;

- fuel consumption increased;

- the car began to slowly pick up speed;

- problems with hot starting of the engine;

- reduction in engine power.

Most often, the breakdown of the mass air flow sensor occurs after mechanical damage to the sensor or due to the negligence of the owner of the VAZ-2110. In particular, you need to check the condition of the rubber seal. If it is worn out, air mixed with foreign particles will enter the sensor. As a result, the wire will become dirty and the readings of the device will be distorted. The easiest way to test this device is to use a multimeter.

Troubleshooting methods

Among the simplest are the following:

- the sensor is turned off;

- the car is started;

- when the computer does not detect the mass air flow sensor in its control system, the engine is switched to safe mode.

In this situation, air and fuel are supplied taking into account the position of the throttle valve. In this condition, you need to drive 200-300 meters. A malfunction is indicated by the vehicle accelerating too quickly.

It is important to know that the sensor should always be dry and as clean as possible. If oily deposits or moisture are detected on it, an urgent replacement of the air filter is required. Contamination of the device requires:

- checking the oil level;

- cleaning the oil separator installed in the vent hole of the crater;

- replacing the rubber seal.

How the air flow sensor works and is designed

The abbreviation MAF hides the mass air flow controller. It measures the amount of air entering the VAZ-2110 engine. Unlike other sensors, it is not a classic resistance sensor, but is a hot-wire anemometer flowmeter. Inside it is a thin platinum wire.

Depending on the volume of air masses passing through the controller, the temperature of the wire changes. The more air enters the engine, the colder it becomes. Also, voltage is applied to the wire, which helps to avoid fluctuations in its temperature. High voltage costs indicate that a large amount of air is entering the engine.

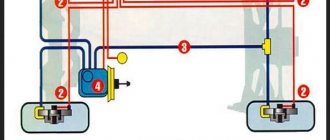

If the sensor fails or starts sending incorrect signals to the control unit, the engine will not work correctly, the fuel-air mixture in it will not be enriched enough or vice versa. In order to obtain accurate data, the sensor is placed on the air filter, and a tube extends from it to the throttle valve.

How to remove the mass air flow sensor on a Priora for cleaning: instructions for removing contaminants from the sensor and repairing the mass air flow sensor

If you decide to clean the mass air flow sensor on a Priora, then the first step is to remove the device from the car. Afterwards, you need to directly remove the sensor itself, which is built into a cylindrical body and is secured with two self-tapping screws. It would seem that it could be difficult to unscrew the screws and remove the air flow sensor itself. However, not everything is so simple, because the device is attached using self-tapping screws with a specific shape of the edges of the cap, so difficulties arise with unscrewing them. The photo below shows what the screw head on the Priora mass air flow sensor looks like.

This is interesting! The special shape of the screw head is made in order to eliminate the possibility of access to the working part of the sensor. Any interference with the design of the mass air flow sensor is unacceptable, as stated by the manufacturer.

It will not be possible to select a bat from a standard set, so there are three ways to solve the problem:

- find and order a special bit or screwdriver with the appropriate tip shape;

- Unscrew the screws using pliers;

- make cuts or notches on the cap in order to unscrew the screws with a screwdriver (it is recommended to do this only with a metal file, but not with a grinder).

Naturally, you should choose the second or third option. To do this, select the optimal version of the pliers (by size) and unscrew the fasteners. The photo below shows how this should be done correctly.

You need to unscrew the screws carefully and slowly, eliminating the possibility of strong vibrations of the sensor. After unscrewing the screws, you can begin to remove the device. After removal, it is important not to drop it, since the slightest impacts can lead to deformation of the working elements. Next, we proceed to the actual part of cleaning, which can be done using a can with an extension tube or a syringe with a thin needle.

To perform cleaning, there is no need to disassemble the unit, since during these manipulations the device can be damaged, and in addition, during reassembly, the seal may be broken. That is why, using a special liquid, it is necessary to treat the crystal and the thermistor with it (the TVB sensor if there are signs of contamination). Moreover, you only need to spray or pour liquids on them, but do not try to climb inside the channel (labyrinth) with a cloth or other objects in order to additionally wipe them. After treating with substances, you need to leave the part for 30 minutes so that it dries thoroughly, and then assemble and install in place. Test it in action in a car.

In order for the cleaning liquid to get onto the crystal, you need to spray it into the hole shown in the photo below.

Do not forget to wash the mesh of the cylindrical body, in which a lot of dust and debris may have accumulated. It can be placed in a bath of alcohol for a while to clean off any existing dirt.

If the DTVV, the location of which is shown in the photo below, fails, it can be replaced if the resistance value is known.

The malfunction of this semiconductor element can be determined by measuring its resistance. Below are the resistance limits depending on the air temperature.

If the multimeter shows a value above 100 kOhm, it means there is an open circuit. Do not forget that the presence of contamination on the thermistor leads to the fact that it begins to incorrectly determine the temperature. If the thermistor is faulty, it can be replaced using a soldering iron. The thermistor must be selected according to its resistance depending on the temperature, based on the table above.

You need to solder the thermistor with a short touch so as not to overheat the mass air flow sensor board. After such repairs, assemble the part and install the sensor in place.

How to check a sensor with a multimeter

The easiest way to check the mass air flow sensor is to disconnect it from the power supply and then try to start the car. If it accelerates quickly, then the controller is not working properly. In this case, it is worth checking it with an electronic multimeter. The testing device is switched to voltage detection mode up to 2 V. Then you need to take measurements. Be guided by the location of the wires, as their color may vary depending on the year of manufacture of the car. You need to find wires to measure:

- yellow – incoming signal;

- gray-white – power supply;

- green with black ground;

- black and pink, going to the main relay.

The conductors are located in the same order as in the list, if you move from the windshield. You need to connect the red (positive) probe of the device to the input signal wire, and the black (negative) to ground. After this, pay attention to the instrument readings. They can be:

- up to 1.02 – the sensor is absolutely working;

- up to 1.03 – mass air flow sensor is functioning, but contamination is possible;

- up to 1.04 – the device is operating at the limit;

- up to 1.05 – breakdown is possible in the near future;

- over 1.05 – the controller has failed.

In the latter case, it is worth replacing it or trying to restore it. Since the sensor is expensive (up to 3,500 rubles), it can be additionally checked by a motor test. This can only be done at a service station that has the appropriate equipment.

Testing and diagnostic methods

Shutdown

This method involves starting the motor with the sensor removed - we need to disconnect its connector. When turned off, the controller starts emergency mode, and new portions of the mixture are calculated based on the position of the damper. We need to drive a little, the speed should be above 1500 rpm. If the car behaves more dynamically without a mass air flow sensor, then the diagnosis is complete - it’s time to change the consumable.

Checking with a multimeter

This test requires that you have skills in using a multimeter (tester). The method is suitable for almost all VAZ models, including 2110. We need to take a multimeter and set it to a mode that measures constant voltage, which is usually designated DCV or only V. To work with the mass air flow sensor, you need to understand its pinout, it is as follows:

- Yellow, closest to the windshield, supplies current to the signal input;

- Green indicates ground;

- The pink or red-black wire comes from the main relay;

- The white-gray wire is responsible for the voltage output.

Depending on the model, the colors may be different, but the location does not change. Here you will have to deal with a specific model. But once you find the input signal wiring (closer to the windshield) and grounding, you can do it without instructions. The wiring is clear, now you need to turn on the ignition without starting the engine. The tester sets a limit of 2 Volts. The black probe of the tester is connected to the green ground wire of the air flow sensor, and the red one is connected to the yellow one. The measurement takes place between two terminals. The probes must be inserted carefully; an additional needle is not required, since the probes can be freely inserted along the wires without damaging the insulation.

We look at the tester display. If the consumable is new, then there we will see a voltage indicator of 1.01. Over time, the indicator increases as the resistors wear out (the resistance drops). The larger the number, the greater the wear of the sensitive element:

- In good condition, the indicator will be 1.01… 1.02;

- With “normal” - 1.02... 1.03;

- The sensor will soon stop working – 1.03… 1.04;

- The dying state of the flow meter is accompanied by an indicator of 1.04… 1.05;

- Replacement of the unit is required when the reading is 1.05 or higher.

Diagnostics can also be carried out without a multimeter. Instead, you can use the on-board computer. To do this, you need to go to the “voltage from the mass flow sensor” section; we are interested in the “U MAF” indicator.

see also

Visual inspection

Here we need to carefully examine the surface of the corrugation and consumables. To check the condition, we need to loosen the air intake clamp at the outlet of the mass air flow sensor, and then pull it off. If you see traces of grease or condensation on the surface, then most likely they have damaged the unit. Sometimes the sensor can be “reanimated” by removing all the dirt. It ends up in the consumables due to rare changes of the air filter. If liquid appears on the sensitive element, this is a 90% failure. Lubricating oil enters due to a clogged oil separator or due to an increased level in the crankcase.

What to do if the device fails

If tests show that the sensor is faulty, then you should first try to restore it. To do this you need to follow the instructions:

- Remove the negative terminal from the battery.

- Get to the air filter and remove the sensor from it.

- Disassemble the controller, being careful not to touch the platinum wire. It is forbidden to touch it, as this will disrupt the operation of the sensor.

- Wipe the remaining parts of the mass air flow sensor with battery cleaning fluid.

- Reassemble the sensor and reinstall it.

Even if you fail to restore the device, you will not lose anything. Test the restored device using a multimeter. If it shows a normal value, then you can do without replacement. When installing the sensor, inspect the air filter and seal. If the rubber gasket is worn out, you need to install a new one in its place. The need to install a new air filter is indicated by contamination of the old one.

Is the air flow sensor covered? Don't rush to buy a new one

A new sensor costs from 2 to 3.2 thousand rubles. But before we run to the nearest store or car market, let’s try to bring the old one back to life. This method of resuscitation does not provide a 100% guarantee of restoration of functionality. But it's worth a try.

First, disconnect the negative terminal on the battery. Remove the sensor from the vehicle. Remove it from the air filter housing. Disassemble the device using a Phillips screwdriver. Be careful with platinum threads, do not touch them with your hands or other objects. Clean with carburetor cleaner. Spray the liquid 3-4 times onto the areas indicated by arrows in the photo. Assemble the mass air flow sensor and install it on the car.

Recommendations for extending the service life of the mass air flow sensor

The service life of the device is affected by the purity of the air flow that passes through it. Therefore, when using a flowmeter, it is necessary to prevent the formation of deposits on its working surface. To do this, it is recommended to periodically check the functioning of the air filter device. If necessary, the sensor must be changed regularly. If the car is operated in a large and polluted city, then the part must be replaced more often than indicated in the car maintenance regulations.

Sensor restoration

Before starting work on the car, it is necessary to deactivate the ignition and disconnect the plug with wires from the regulator.

What will you need?

To carry out the procedure you will need:

- rags;

- set of wrenches;

- cleanser;

- a screwdriver if its use requires dismantling the flow meter.

Selecting a cleaner

Products that can be purchased at the store to clean the controller:

- WD-40. A universal product that can also be used for cleaning.

- Liqui Moly. The use of such a composition is relevant for working sensors. The product is universal and can be used on both diesel and gasoline engines.

- Alcohol.

- Cleaning agent for carburetor engines.

- Liquid key. This product is sold as a spray.

- Air Senso Clean.

Good to know

Do not use cotton swabs or compressed air to clean the device. It is important that the cleaning agent does not contain acetone or ether.

Algorithm of actions

| Image | Step |

| The user must remove the hose connected to the sensor; to do this, use a wrench to unscrew the screws securing the device to the air filter housing. The dismantling algorithm may differ depending on the design features of the car. | |

| |

|

Video “Diagnostics and malfunctions of mass air flow sensor”

The 24 Hours channel spoke in detail about the signs of malfunction of flow meters and how to diagnose them yourself.

Do you have any questions? Specialists and readers of the AUTODVIG website will help you ask a question

Was this article helpful?

Thank you for your opinion!

The article was useful. Please share the information with your friends.

Yes (100.00%)

No

X

Please write what is wrong and leave recommendations on the article

Cancel reply

Rate this article: ( 2 votes, average: 5.00 out of 5)

Discuss the article:

Spare part selection

There are sensors on the market in three price categories:

- Inexpensive. Typically these are Chinese-made sensors priced up to 1,200 rubles.

- Average. This category includes sensors from AvtoVAZ and foreign analogues of approximately the same quality. Their price ranges from 1400 to 2600 rudders.

- Expensive. High-quality and reliable mass air flow sensors from manufacturers Bosch or Siemens. Their price can reach 5,000 rubles.

We recommend giving preference to original sensors from AvtoVAZ or foreign analogues in this price category.

Also, when choosing a sensor, pay attention to its catalog number. The number can be found on the case. We strongly recommend buying a sensor with the same number or selecting analogues based on it.

Peculiarities

We conclude that the sensor is selected not by the number of valves or engine size, but solely by the firmware version and ECU model.

Bosch sensor (21083-1130010-01) for controller January version 5.1.

For example, for the Bosch M7.9.7 ECU it is necessary to use the Bosch mass air flow sensor 0 280 212 116, and for the January controller version 5.1 - only Bosch 21083-1130010-01. That is, even if a sensor is installed from the factory that does not correspond to the ECU firmware, you cannot expect correct engine operation and normal fuel consumption. By the way, there are often cases when sensors were installed from the factory that do not correspond to the firmware version. Therefore, the first check is for compatibility. And then we take a multimeter and go into battle.