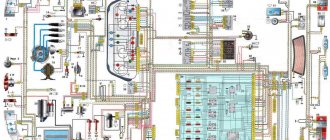

Instrument panel diagram Kalina 2

Steering shaft for Lada Kalina since 2004

1,2 – blocks of the instrument panel wiring harness to the blocks of the front wiring harness; 3, 4 – blocks of the instrument panel wiring harness to the blocks of the rear wiring harness; 5 – lighting control module; 6 – ignition switch; 7 – on-board computer mode switch; 8 – windshield wiper switch; 9 – instrument cluster; 10 – light signaling switch; 11 – trunk lock drive switch; 12 – diagnostic block; 13 – block of the instrument panel wiring harness to the block of the wiring harness of the air supply box; 14 – rear window heating switch; 15 – alarm switch; 16 – brake signal switch; 17 – multimedia system; 19 – rotating device; 20 – driver airbag module; 21 – sound signal switch; 22 – mounting block: K1 – relay for the electric fan of the engine cooling system; K2 – door lock relay; K3 – additional starter relay; K4 – additional relay; K6 – windshield wiper relay; K7 – headlight high beam relay; K8 – sound signal relay; K9 – relay for low beam headlights; K10 – relay for turning on the heated rear window; K11 – main relay; K12 – fuel pump relay; 23 – electric power steering; 24 – cigarette lighter; 25 – lampshade lighting of the glove box; 26 – glove box lighting switch; 27 – block of the instrument panel wiring harness to the block of the ignition system wiring harness; 28 – engine control system controller; 29 – block of the instrument panel wiring harness to the block of the rear wiring harness 4; 30 – electronic accelerator pedal; 31 – additional resistor; 32 – heater electric motor; 33 – solar radiation sensor; 34 – ESC switch; 35 – relay (K13) of the electric fan of the engine cooling system 3; 36 – compressor relay (K16); 37 – relay (K14) for heating the windshield; 38 – relay (K15) for heating the windshield 2; 39 – headlight range control regulator; 40 – clutch pedal position signal switch; 41 – passenger airbag module; 42 – evaporator temperature sensor; 43 – steering angle sensor; 44 – windshield heating element; 46 – windshield heating switch; 47 – central unit of body electronics; 48 – micromotor reducer of the air flow distributor damper; 50 – controller of the automatic climate control system; 51 – micromotor gearbox for mixing air flows; 52 – micromotor gearbox for recirculation damper drive.

The design and principle of operation of the torque converter

Review of the standard radio (mms) of the Lada Granta, Kalina 2 and Priora (luxury)

The first such mechanism appeared in 1902 and 5 years later it was installed in the design of a high-speed vessel. Later, namely in 1928, the fluid coupling was successfully built into the transmission of a bus, and then into a car. General Motors and Chrysler companies, from 1945 to 1980, qualitatively improved the design of the fluid coupling, which provoked the emergence of a unit with a new name - the torque converter. It was this mechanism that began to be equipped with all automatic transmissions produced, and engineers worked only to improve it.

The torque converter of an automatic transmission is an analogue of the clutch of a manual transmission, which operates in automatic mode. Today, this hydromechanical device performs three main functions:

- The first one transmits rotation from the engine shaft to the automatic transmission mechanism;

- The second one softens the transmission of rotation to the level in which the gearbox is able to accept it without problems (that is, the torque converter protects the machine during sharp decreases and increases in the speed of the running engine);

- And the third - normalizes the supply of rotational motion to the box during acceleration (this is necessary in order to “dampen” the double increase in rotation transmitted from the motor to subsequent shafts).

Modern automatic transmission torque converters may be considered separate units from the planetary gearset (box), but they will not be able to work independently without it. This is due to the fact that this mechanism and the automatic transmission valve body (hydraulic plate) are inextricably linked. Their connection, by the way, is very simple - the second transmits the required amount of transmission fluid to the first, without which the operation of the torque converter is simply impossible.

The design of the device is also not particularly complicated and is a mill, some of the blades of which rotate due to the connection with the engine, and the others regulate the rotation using the hydraulic oil pressure available in the mechanism. The operation of the torque converter is important for the box only at vehicle speeds of up to 60-80 km/h, therefore, when this speed is reached, all the blades of the mechanism are locked into a single unit, after which rotation is transmitted directly to the box. Note that it is in locking the torque converter that the automatic transmission valve body plays an important role, therefore the functioning of these elements of the machine cannot be separated.

Wiring diagrams Lada Kalina 2 hatchback (luxury)

| This section contains electrical diagrams for the new Kalina (VAZ 2192) luxury version. |

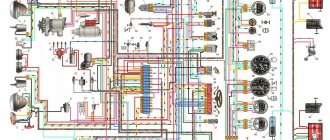

Front wiring diagram Kalina 2

Popular reviews from owners of Lada Kalina 2013 - 2015, automatic with photo

1 – right headlight; 2 – electric motor for washers; 3 – left headlight; 4 – starter; 5 – rechargeable battery; 6 – main fuse block; 7 – generator; 8 – sound signal; 9, 10, 11 – front wiring harness blocks to the instrument panel wiring harness blocks; 12 – air conditioning fan electric motor; 13 – electric fan of the engine cooling system; 14 – ABS hydraulic unit; 15 – right front speed sensor; 16 – left front speed sensor; 17 – front wiring harness block to rear wiring harness block; 18 – right fog lamp; 19 – left fog lamp; 20 – ambient temperature sensor; 21 – reverse lamp switch; 22 – air conditioning compressor; 23 – audible alarm signal; 24 – rear window washer electric motor.

Instrument panel diagram Kalina 2

1,2 – blocks of the instrument panel wiring harness to the blocks of the front wiring harness; 3, 4 — blocks of the instrument panel wiring harness to the blocks of the rear wiring harness; 5 – lighting control module; 6 – ignition switch; 7 – on-board computer mode switch; 8 – windshield wiper switch; 9 – instrument cluster; 10 – light signaling switch; 11 – trunk lock drive switch; 12 – diagnostic block; 13 – block of the instrument panel wiring harness to the block of the wiring harness of the air supply box; 14 – rear window heating switch; 15 – alarm switch; 16 – brake signal switch; 17 – multimedia system; 19 – rotating device; 20 – driver airbag module; 21 – sound signal switch; 22 – mounting block: K1 – relay for the electric fan of the engine cooling system; K2 – door lock relay; K3 – additional starter relay; K4 – additional relay; K6 – windshield wiper relay; K7 – headlight high beam relay; K8 – sound signal relay; K9 – relay for low beam headlights; K10 – relay for turning on the heated rear window; K11 – main relay; K12 – fuel pump relay; 23 – electric power steering; 24 – cigarette lighter; 25 – lampshade lighting of the glove box; 26 – glove box lighting switch; 27 – block of the instrument panel wiring harness to the block of the ignition system wiring harness; 28 – engine control system controller; 29 – block of the instrument panel wiring harness to the block of the rear wiring harness 4; 30 – electronic accelerator pedal; 31 – additional resistor; 32 – heater electric motor; 33 – solar radiation sensor; 35 – relay (K13) of the electric fan of the engine cooling system 3; 36 – compressor relay (K16); 37 – relay (K14) for heating the windshield; 38 – relay (K15) for heating the windshield 2; 39 – headlight range control regulator; 40 – clutch pedal position signal switch; 41 – passenger airbag module; 42 – evaporator temperature sensor; 44 – windshield heating element; 46 – windshield heating switch; 47 – central unit of body electronics; 48 – micromotor reducer of the air flow distributor damper; 50 – controller of the automatic climate control system; 51 – micromotor gearbox for mixing air flows; 52 – micromotor gearbox for recirculation damper drive.

All other schemes are suitable for the “norm” and “standard” configurations.

Connecting Kalina fog lights

In addition to fog lights and mounts, the kit should include wiring, which is often missing. We recommend that you purchase several meters of wire with a cross-section of at least 0.75 sq. mm. We pull the wires from the engine compartment into the passenger compartment using a piece of wire on the starboard side through the hole above the clutch pedal. To gain access you will need to remove the front left wheel and fender liner.

The most practical places to install the PTF button are in the tunnel, or on the panel instead of the air conditioner button.

A less popular method is to connect the PTF to the light control module (LCM). We fix the relay with a hinged mount in the mounting block.

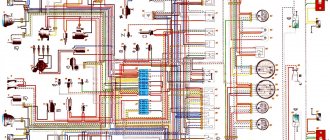

Ignition system diagram Lada Kalina Lux

"Kalina", cooling system: malfunctions and improvements. Radiator cooling fan Lada Kalina Kalina engine fan does not work

1 — oil pressure warning lamp sensor; 2 — coolant temperature indicator sensor; 3 — additional fuse block; 4 — fuses for the electric fan of the engine cooling system; 5 — electric fuel pump relay; 6 — relay for the electric fan of the engine cooling system; 7 - ignition relay; 8 — relay 2 of the electric fan of the engine cooling system; 9 — relay 3 of the electric fan of the engine cooling system; 10 — electric fan of the engine cooling system; 11 — throttle position sensor; 12 — idle speed regulator; 13 — coolant temperature sensor; 14 — diagnostic block; 15 — ignition system harness block to the instrument panel harness block; 16 — solenoid valve for purge of the adsorber; 17 — speed sensor; 18 — ignition system harness block to instrument panel harness block 2; 19 — mass air flow sensor; 20 — crankshaft position sensor; 21 — oxygen sensor; 22 - controller; 23 — rough road sensor; 24 — diagnostic oxygen sensor; 25 — ignition coil harness block to the ignition system harness block; 26 — ignition coils: 27 — ignition system harness block to the ignition coil harness block; 28 — spark plugs; 29 — nozzles; 30 - resistor; 31 — air conditioning system pressure sensor; 32 — blocks of the ignition system harness and injector wiring harness; 33 - phase sensor; 34 - knock sensor.

Ignition system wiring harness -11184-3724026-10. Ignition coil wiring harness -1118-3724148-00. Injector wiring harness -11184-3724036. A - to the “plus” terminal of the battery.

Basic data for monitoring, adjusting and maintaining the cooling system

| Temperature at which the main thermostat valve begins to open, °C | 85-89 |

| Full opening temperature of the main thermostat valve, °C | 102 |

| Opening pressure of the outlet valve of the expansion tank plug, kPa (bar) | 110-150 (1,1-1,5) |

| Opening pressure of the inlet valve of the expansion tank plug, kPa (bar) | 3-13 (0,1) |

| Coolant temperature in a warm engine at an ambient temperature of 20–30 °C and a fully loaded vehicle moving at a constant speed of 80 km/h, no more, °C | 95 |

| Resistance of additional resistor, Ohm | 0,23 |

| Volume of liquid in the engine cooling system, l | 7,8 |

| Coolant (mixing liquids of different brands is not allowed) | OZhK-KHT; OZh-40-ХТ; OZh-65-ХТ; OZH-K Antifreeze; OZh-40 Antifreeze; OZh-65 Antifreeze; OZh-40; OZh-65; OJK-KSK; OZh-40SK; OZh-65SK; Lada-A40; OZH-K Tosol-TS; OZh-40 Tosol-TS; OZh-65 Tosol-TS; Antifreeze G-48; AGIP Antifreeze Extra; GlysantinG03; GlysantinG913 |

pinout of Kalina switches – Snobdenie

Light control module 118 help with pinout - Connector for power window switch block Kalina 2. Kalina 11183 Repair Electrical diagrams! Please help with pinout. I downloaded electrical diagrams for viburnum on the internet. Repair of VAZ Kalina 9 - power window switch. Connector for power window switches Kalina (2 buttons) 10 terminals assembled. And they additionally need a GPS antenna and a switch. I searched for a long time on the Internet and electrical circuits for pinouts. 11 — on-board computer mode switch; 12. To the door lock switch in the switch block: 3. Lighting control module Lada - Kalina VAZ - 1117, 1118 External switch. Lada 2114 owner story – electrical and electronics. Good evening I’ll add here the pinout of the steering column contacts. Windshield wiper and washer switch; 25 - switch. In general, I bought an outdoor lighting switch with illumination from the nine. Electrical diagrams for the new Kalina 2 Hatchback. Home Lada Kalina Instrument panel pinout. Pinout of ECU connection block January 7, bosch m7. The Lada Kalina car uses a headlight unit. Then the current flows to switch 4 Electrical diagram of the instrument panel Kalina 2. Electrical equipment GAZ (21, 2410, 3102, 31029, 3110) and pinout when changing the tidy (combination. Diagram, pinout of the electrical package controller 2170 - 3763040 - 00 VAZ 2170 Priora Sound switch. Need pinout of instruments for Lada Priora and Kalina. Steering column switch on VAZ2104 from tens of Kalina. And buy Kalina steering column switches. Ignition switch 2170 pinout Detailed Pinout El. Squeezing the spring clamps of the right switch, remove it from the connector together. Some owners of Lada Kalina 2nd generation. Door lock; 4 - switch block; 5. Kalina control unit - sent to Lada Kalina: Electrics: Greetings Kalinovodov. All about the mounting fuse block on the Lada Kalina, where it is located, diagram and explanation. Kalina glass lift buttons hold more pleasantly. On cars Lada Kalina VAZ 1118 is equipped with a standard electronic alarm.Coils On VAZ 1118 Kalina cars. An electromechanical one was installed on the Lada Kalina. Pinout of fuse box Kalina Lux Relay and fuse box Lada Kalina, not. All files in the category ECU firmware for Lada Kalina - optimization of vehicle performance. They claim that 2 switches with 2 positions can only have 4 options. Hi all! I decided to upgrade the instrument cluster. Wiring diagram for LADA KALINA and other units. Electrical diagrams for Kalina 2 Universal. On-board computer mode switch. Location and purpose of fuses in the fuse box of the Lada Kalina car. The pinout is useful in any case. Replacing the oil pressure sensor on Lada Kalina; Corolla 1999 fuse pinout. Lada Kalina pinout of alarm unit aps 6. Lada Kalina: all information about VAZ cars of the Lada Kalina family: VAZ 1117 station wagon. ELECTRICAL CONNECTION DIAGRAMS FOR CARS OF THE lada kalina FAMILY V. Dashboard on the second generation Kalina. Purpose, principle of operation and design of steering column switches VAZ 2108 2109 21099.

Replacement features

Electrical diagrams for Lada Kalina (2004-2013)

Briefly about the procedure for replacing the control module on Kalina 2:

First, the instruments are dismantled from the center console; there is nothing difficult about it. Then the lower part of the center console trim is unscrewed, the trim is removed, and you gain access to the fuse and relay box. The mounting block with safety devices can be unscrewed, but it cannot be removed because it is connected by wires. You can rotate it a little so that it takes a horizontal position. You can stick your hand into the gap formed as a result of turning. Having done this, you will be able to feel the shelf on which the TsBKE is installed. A little to the left there is a bolt with which this module is fixed - you need to unscrew it. After this, through the top, through the instrument panel, you will need to disconnect the two connected connectors

After completing these steps, you can carefully dismantle the CBKE and remove it by slightly moving the fuse box. Please note that you should not pull the device too hard, since on the other side there are two more connectors that will need to be disconnected

When the wires are disconnected, the CBKE can be completely dismantled and repaired or replaced.

Basket

Double-glazed window control unit “Norma” 1118 – 6512010 for VAZ 11183 “Kalina”

Aktuator On cars of the Kalina family, 2 types of non-interchangeable (by wiring) glass unit control controller 1118 - 6512010 and 11180 - 3763040 can be installed. 1118 – 6512010 has one 25-pin connection connector, 1118 – 3763040 (1118 – 3763040 – 10) – two connectors.

Remote control system for double-glazed windows “norm” on a VAZ 11183, Kalina. Controls power windows and central door locking. When the connector is removed, the engine does not start; the device performs some of the anti-theft functions.

Connection

| № | Wire color | Purpose, addressing |

| 1 |

* A regular shock sensor from any alarm system (Alligator, Saturn, Clifford, APS) is suitable.

+ 12 V connect to pin 12; body – on the 6th; We connect the signal wire (a ground appears on it at the moment of activity) to the 1st contact.

During normal arming, Kalina now reacts to an impact on the body (it sounds a horn and blinks turn signals). Similarly, instead of a shock sensor, you can connect a volume sensor (for example, single-level MMS‑1).

You can also connect a pager: + 12 V of the pager transmitter on pin 12, minus on pin 21.

Double-glazed window control unit 1118 – 3763040 (- 10 ) for VAZ 11183 “Kalina”

| External shock or volume sensor input (Not used)* | ||

| 2 | Pink/Black | To the door lock switch in the switch block |

| 3 | Brown/Green | K-Line. To Kl. 71 ECM, Cl. 18 APS‑6 |

| 4 | Brown | Connects to ground when the driver's door is closed |

| 5 | Grey | To rear window heating element |

| 6 | Black | Weight |

| 7 | Pink/White | To the door lock switch in the switch block |

| 8 | Yellow/Blue | In the instrument cluster, to the APS-6 indicator |

| 9 | Black/White | Connects to ground when opening the hood. C VK engine compartment lamp |

| 10 | Two White/Red | Connects to ground when opening the rear doors |

| 11 | Brown/Red | Connects to ground when opening the right front door |

| 12 | Output 12 V power supply for external sensor (Not used)* | |

| 13 | Not used | |

| 14 | Yellow | Pulse + 12 V, closing all doors and trunk |

| 15 | Red/Blue | To class 14 APS‑6 |

| 16 | Blue with Black | To the left direction indicator |

| 17 | Red/Blue | Impulse + 12 V, opening passenger doors |

| 18 | Red/Black | Pulse + 12 V, driver's door opening |

| 19 | Pink/Red | Impulse + 12 V, opening the trunk lock |

| 20 | Yellow/Blue | To terminal “15”, through fuse F 9, in the mounting block |

| 21 | Grey/Black | "-" Horn relay |

| 22 | White/Blue | Connects to ground when the driver's door is opened |

| 23 | Red | To permanent plus through fuse F 5, in the mounting block |

| 24 | Blue | To the right turn signal |

| 25 | White black | Connects to ground when opening the trunk |

| Controller board |

| Controller board |

Sign

| Possible reasons | Elimination method |

| The key code is not readable |

1 . 1 Malfunction in the VZ communication coil circuit

1 . 2 Malfunction in the circuit from the block to the communication coil to the APS ECU

1 . 3 Transponder missing in OK

1 . 4 The transponder in OK is faulty (detected during pre-production preparation)

1 . 5 The transponder in the Republic of Kazakhstan is faulty (detected during pre-production preparation)

1 . 6 Malfunction of the input transponder circuit in the APS ECU

1 . 8 The communication coil came off from the VZ pad on the inside

Abbreviations: IS – status indicator; VZ – ignition switch; OK – training key; RK – working key; RC – remote control; KSUD – engine control system controller; ECU - electronic control unit

The Kalina electrical package control unit is used to automatically raise and lower windows and control doors. Additionally, it makes it possible to control alarm activation and trunk opening.

If we are talking about the luxury configuration of Kalina 2, then the electrical package control unit is responsible for blocking the ignition switch. That is why any malfunctions in its operation negatively affect the driving performance of the vehicle.

Prevention measures

All configurations of Kalina hatchback

What preventative measures should be taken to prevent problems in the operation of the electrical circuit:

- Use only original instruments and devices - the use of cheap Chinese analogues can lead to voltage surges or short circuits. For example, a splitter in a cigarette lighter. As you know, the cigarette lighter socket is designed for a certain power. By connecting two or more devices instead of one (using a splitter), the load on the node increases significantly. This can cause a short circuit and even a fire.

- Solve problems that arise in the operation of electrical appliances as quickly as possible. If the faults continue to accumulate, it can lead to more serious problems later.

- At least twice a year, it is necessary to carry out scheduled maintenance for the battery. It is recommended to do this before the onset of cold weather and with the arrival of spring. Check the electrolyte level in the banks, charge the battery to replenish the lost charge, and also regularly conduct visual diagnostics of the device body.

- Use only original fuses; using homemade fuses can lead to serious problems.

Have you encountered problems with wiring in your car?

Survey

- Yes

- No

- I don’t know (I don’t repair my car)

Loading …

CBKE errors

- * there is no fault code in TsBKE 21900-3840080-10;

- If an “active” fault code is detected, perform the checks outlined in the “diagnostics” column;

- After troubleshooting, clear fault codes using a diagnostic tool.

Deciphering fault codes

:

- B1002 Open in driver lock control circuit

- B1004 Open in the front left window control circuit

- B1006 * Open in the rear left window control circuit

- B1008 Open in the alarm sound control circuit

- B1010 Open in the trunk gear motor control circuit

- B1012 Open in the passenger lock control circuit

- B1014 Open in the front right power window control circuit

- B1016 * Open in the rear right window control circuit

- B1017 ROM checksum error of the central unit of body electronics

- B1018 Short circuit in the rear window heating relay coil circuit

- B1019 Short circuit in the windshield heating relay coil circuit

- B1020 Short circuit in the seat heater relay coil circuit

- B1021 Wiper malfunction

- B1023 Short to ground or overheating in the control circuit of the common board bus

- B1027 Malfunction of the power window control keys in the passenger doors

- B1028 * Short to ground in the rain sensor sensitivity regulator circuit

- B1030 Open circuit (lamp burnout) of daytime running lights

- B1031 * Open circuit in the rain sensor sensitivity regulator circuit

- B1033 Open (lamp burnout) in the left turn signal circuit

- B1034 Open (lamp burnout) in the right turn signal circuit

- B1040 Open or short to ground in the low beam headlight relay coil circuit

- B1041 * Short circuit in the automatic lighting control relay coil circuit

- B1042 Short circuit in the high beam relay coil circuit

- B1043 Short circuit in the low beam relay coil circuit

- U1044 Lack of communication with MDV

- U1045 Communication error with MDV

- U1046 * Communication error with rain and light sensor

- U1047 * No communication with rain and light sensor

- U1048 CAN bus fault

- B1049 High voltage on-board network

- B1050 Low voltage on-board network

- B1051 * Short to ground in the right mirror control circuit

- B1052 * Left Mirror Control Circuit Malfunction

- B1057 Internal malfunction of the MDV

Also using this program you can configure the central unit of the body electronics.

Set the delay for turning on the wipers after the washer is activated (from 0 to 2.56 sec).

Activate or deactivate the function of turning on the interior lamp when the ignition is turned off

Set the delay for turning off the interior lamp when closing the door (from 0 to 60 sec)

Set the delay of the energy saving mode (power loss on the interior lamp, trunk, control wire of the radio (Kalina 2) (from 0 to 10 min)

Activate or deactivate the stepwise door unlocking mode, as well as the automatic door unlocking mode when the ignition is turned off

Activate or deactivate the automatic mode of raising/lowering the driver's window

More details about the TsBKE block are described in Technological Instructions (TI) 3100.25100.12051, which you can download here.

All reference information on models

:

- Lada Granta

- Lada Kalina

- Lada Priora

Keywords: Lada Priora windshield wipers | windshield wipers for Lada Granta | windshield wipers Lada Kalina | heating for Lada Granta | heating Lada Kalina | heating for Lada Priora | external lighting for Lada Granta | external lighting for Lada Priora | external lighting for Lada Kalina | interior lighting for Lada Granta | interior lighting for Lada Kalina | interior lighting for Lada Priora | window lift for Lada Kalina | window regulator for Lada Granta | Lada Priora window regulator

5

Found an error? Select it and press Ctrl+Enter..

Personalize existing features

Recommended tire and wheel sizes for Lada Kalina 2 (hatchback and station wagon)

The manufacturer has provided for the timing of regular technical inspections, which are mandatory. For non-compliance, the company reserves the opportunity to deprive the car owner of the right to free service.

The most vulnerable is the comfort block, which includes many logical circuits. Its purpose boils down to the following functions:

- activation of interior lighting;

- adjusting the operation of car alarms;

- turning on the heated rear window;

- automatic mirror adjustment;

- control of electric windows;

- remote control of locks.

The manufacturer has provided the ability to personalize each element. To do this, the electrical package control unit must be recoded at an authorized automotive center. Using official software, the wizard will add or remove certain features. If everything is done correctly, 20 minutes after requesting the appropriate service, you can safely use the “iron horse”.

According to reviews from car enthusiasts, the Lada Kalina car is distinguished by electronic filling with increased sensitivity to operating conditions. Aggressive driving style and minor damage lead to malfunctions.

As a result, you need to visit a service station to replace the device. To do this, remove the control unit, which must be done as follows:

- turn off the battery;

- unscrew the screws from the driver's seat;

- Use a ratchet wrench to remove the nut;

- the plastic plug is squeezed out completely;

- carefully pull out the seat;

- remove the seat by dismantling the terminals;

- remove the cover plate.

Lada Kalina Hatchback 2010, 80 l. With. — tuning

Lada Kalina, 2012

Comments 54

Hello, can you tell me if the front fog lights are on, what needs to be switched off so as not to burn anything? There is no MUS, I need to check!

I actually threw out this block, installed 2 4-pin relays and a switch for the turn signal from a foreign car and everything worked. and thank you so much for the pinout diagram)

The dimensions are supplied with a black and white cable (58) from pin #9, which in the MUS is connected from pin #11 - pink cable (30). For the low beam there is a green cable (56) from contact #12, which in the MUS is connected from contact #10 - a blue-black cable (Xz). IMHO: only contacts #10 with #12 can be shorted with jumpers without consequences. Contacts #10 and #9 are never bridged in the ICC, respectively, when they are bridged and the knob is turned to the “dimensions” or “low beam” position, contacts #10 and #11 (pink and blue-black cables) are bridged. Hence your phenomenon of the engine running without a key since 12 volts are sent to the ignition in the opposite direction through the blue-black cable. How unsafe this is for electrical and electronics is doubtful for me personally...

Safe, I tried it. When installing a jumper between contacts 10 and 9 and turning on the ICU in the “dimensions” position, contacts 9, 10 and 11 are connected, and in the “low beam” position 12 is added to them, that is, ALL four are connected (as if both jumpers). But it’s also a plus in Africa, it can’t go in the “that” or “reverse” direction, plus 12V plus 12V can’t be burned out, at least in this case. Yes, the ignition is kept on if you set the MUS to “dimensions” (it also turns on without a key, as if the key was inserted and turned to the ignition: the instrument lights up, the heater fan turns on, etc.). This also seemed convenient to me, the previous car had autostart, but this one does not have it YET, but thanks to MurZone, now we know an intermediate solution on how not to freeze next to the car while it is warming up. It’s a pity that when the ignition is on, the doors do not close with the key (although they OPEN), but if necessary, they can be closed manually mechanically. I decided to go a little further and not just threw a jumper, but soldered taps to all four wires (9,10, 11 and 12) and brought them out into two relay blocks - maybe someday I’ll implement more complex on-off algorithms (then You will also need a minus from pin 8). In the meantime, instead of a relay, I stuck a jumper between 10 and 9 and am very pleased. By the way, if for some reason you don’t want the ignition support effect when the lights are on, just put a diode in the jumper.

conclusions

The installation and repair of the Lada Kalina headlight is quite simple and dismantling and installing the element will not take much time. Of course, if the housing is destroyed, the entire element will need to be replaced. As experience shows, if the fastening elements, the so-called “ears”, break, the headlight does not change, and the damaged part is simply “soldered”. It's much cheaper than replacing an entire element.

I assembled it according to the “American” scheme using a 5-pin relay to start the link from where I got information and inspiration. www.drive2.ru/l/5263282/ Dimensions for turn signals on one lamp. (American dimensions).

This guy has some useful info, but the diagram is for 2109 www.drive2.ru/l/10359022/ American women via relay, tinting the forehead - 35% Kalina www.drive2.ru/b/2652080/ American women via relay 2109 www.drive2. ru/l/7213413/ Correct light bulbs for American women Here you can find out how to install two-pin light bulbs on a clearance with additional.

+. I’ll say right away that I don’t recommend installing an additional dimension

, so I won’t even give an example! And I also don’t want to talk about 2-pin light bulbs for a long time.

Straight to the point. What do Americans need via relay?

1. FIVE-contact relay. (Any) - 2 pcs. 2. Capacitor 4700uF*25V - 2 pcs. (according to the second scheme) 3. 5819 silicon diode 2A (more powerful if possible) - 2 pcs. (according to the second scheme) 4. Block for the relay. - 2 pcs. 5. Connectors for connecting wires (10-15 pcs) 6. Bulbs in size, preferably also orange L12805Y LYNX or simple yellow L12805 LYNX 7. Bulbs for the turn signal single-pin L14421Y LYNX or 7507 Osram If you do it with a button, you will need more Wire - 2x1.5 - 2 meters Button - 1 pc. Fuse 10A - 1 pc.

The connection diagram is simple, but the only drawback was the failure of the front turn signals without dimensions

. During use, this has never become a problem for me, but the desire to finish it to perfection can motivate me to assemble a relay with conductors and diodes. In any case, everything works without any problems.

Preparation for replacement and necessary equipment

To replace the old switch you will need a Phillips screwdriver, a dry, clean cloth or thick napkins. And, of course, a new detail. Before changing the Kalina steering column switch, you have to carefully get to it, since such procedures are usually carried out rarely. Don't forget to disconnect the negative battery terminal.

The first stage of preparation is removing the steering wheel. First, move it to the lowest position. Using a Phillips screwdriver, carefully unscrew the 7 fasteners of the plastic casing. We remove first the lower and then the upper part.

Recommendations for both cases

First of all, we note that when connecting the relay to the power wiring, you cannot make the control pulse too long. Setting the value for more than a second can burn out the actuators. Here we were talking about programming, and now let's talk about the electrical part. As you know, before installation you need to open the hood and disconnect the negative terminal.

This advice should not be ignored in any case.

As for installation, it will be better if the power wire taps are carried out by an auto electrician. With signal wiring, everything is simpler, but the rules will be the same in each case:

- Do not let the cord touch the insulation to metal parts. If contact occurs, additional protection is used. For example, a heat-resistant tube placed over electrical tape is suitable;

- It is better to connect any power cables using twisting. Each twisting point is carefully isolated.

- The cross-section of wires carrying significant current must be sufficient so that the conductor does not heat up. This is how you can protect yourself from unforeseen consequences.

The last tip concerns power wiring. And the ability to twist is a whole art.

You cannot learn this art in one day.

When connecting any equipment, you should strive to make as few changes as possible to the standard wiring.

There must be an opportunity to do the following: return everything as it was. Sometimes it happens that one or more signaling parameters do not take a value that is suitable for the car. And then, the alarm system is changed or they refuse to use it altogether. This needs to be taken into account.

Ignition circuit Kalina 2

1 – oil pressure warning lamp sensor; 2 – generator; 3 – throttle pipe with electric drive; 4 – coolant temperature sensor; 5 – ignition system wiring harness block to the instrument panel wiring harness block; 6 – solenoid valve for purge of the adsorber; 7 – air conditioning system pressure sensor; 8 – mass air flow sensor; 9 – crankshaft position sensor; 10 – oxygen concentration sensor; 11 – controller; 12 – diagnostic oxygen concentration sensor; 13 – blocks of the wiring harness of the ignition system and the wiring harness of the ignition coils; 15 – ignition coils; 16 – spark plugs; 17 – nozzles; 18 – blocks of the wiring harness of the ignition system and the wiring harness of the injectors; 19 – phase sensor; 20 – knock sensor.

Which wire goes where?

First, let's look at the back of the instrument panel. At the top there are:

- fuel level indicator;

- dashboard lighting lamps;

- control of right and left turns (separately);

- tachometer;

- block with many plugs;

- coolant temperature gauge.

As you can see, there is really nothing particularly complicated here. At the bottom of the instrument panel on the back side there are controllers:

- high beam;

- "emergency lights";

- CHECK ENGINE;

- battery charge;

- parking brake;

- oil pressure;

- air damper (for models with a carburetor);

- outdoor lighting work.

In addition, there is also a speedometer and a brake fluid level indicator lamp.

Now let's take a closer look at the pads. There are two of them - white and red. In the first, the connectors and wires look like this (in order):

- Ground wire black.

- Red-brown – low-voltage supply from the ECU to the tachometer.

- Yellow – high-voltage supply to the tachometer from the coil.

- Red-blue - comes from the battery through the 6th fuse Const with a voltage of 12 volts.

- Green-white - leads to the coolant temperature sensor.

- Green-yellow – fuse F1, responsible for the side lights.

- This connector has no color, it goes to the throttle valve.

- Red and white – leading to the CHECK ENGINE indicator light.

- 2 orange wires leading to two F19 + 12 volt power fuses.

- Same as the previous connector.

- 2 blue-brown wires leading to the “VK” terminal of the handbrake.

- The output to terminal D of the generator is a brown-white wire.

- Gray and blue - wire going to the oil pressure sensor.

Lighting control modules (LCM) 344.3769, 345.3769. Pinout.

Lighting control modules (LCM) 344.3769, 345.3769. Pinout.

Connection: block 1118-3724500. Applicability: Lada Kalina (1117, 1118, 1119). Lighting control module Lada Kalina.

Lighting control modules 344.3769, 345.3769 are designed for switching electrical control circuits for external lighting, front and rear fog lights, adjusting the level of illumination of controls and instruments, and controlling the angle of the light beam of automobile headlights.

Numbering and assignment of contacts. Contact

| Purpose | |

| G | to the gearmotor of the headlight range control |

| 56b | to the gearmotor of the headlight range control |

| 58b | to backlight sources |

| 31 | "Weight" |

| Xz | + 12 V (from terminal “15” of the ignition switch) |

| 56 | to the low/high beam headlight switch |

| 1 | from rear fog lights |

| 2 | to the rear fog lamp relay |

| 3 | from the front fog lights (only for MUS 345.3769) |

| 4 | to the front fog lamp relay (only for MUS 345.3769) |

| 58 | to side lamps |

| 30 | + 12 V (from terminal “30” of the ignition switch) |

Main characteristics.

Rated voltage, V: 12.

Rated load:

- Active: 2 mA pin G, 0.001-0.1 A pin 2 (load is switched to pin 31).

- Inductive, at 100 mH: 0.15 A pin 4.

- Tube: 35 W (3.3 A) pin 58b, 10 A pin 56 and pin 58.

Viewing surface color: black.

Character color: white.

Symbol backlight color: light green.

Indicator illumination color: rear fog lights - yellow, front fog lights - light green.

Album of schemes for "VAZ 1118"

Lada Kalina hatchback (lada kalina hatchback)

This album is available in the Lada Kalina technical manual. The general scheme includes 59 components, among which you can find:

- sources and consumers;

- protective and control elements;

- ECU;

- sensors

A separate printed block displays the electrical circuit for connecting the electronic motor control module with other system components. We are talking about spark plugs, injectors, sensors, and the ignition unit of the Lada Kalina car.

There is also a separate electrical diagram that highlights the front and rear cable harnesses. A detailed display of all connections of the electrical components of the front panel in the cabin is provided. In addition, the diagram contains clear connections for the wiring harnesses of the door panels and the interior ventilation unit.

In order for the cable connections to ensure reliable contact, they are connected to special blocks with terminals. All terminals are compatible with cable harnesses, the wires of which have their own characteristic sheath color. Each electrical diagram in the album is designed in such a way that the color shade of the sheath of a particular cable actually matches the color shown in the documentation.

Numbers are written next to the drawn lines, allowing you to use the symbols to determine the connector to which a particular wire fits. For example, the marking on the “9/14” diagram “tells” us that this cable is connected to the 9th block via connector No. 14.

Kalina 2 front wiring diagram

1 – right headlight; 2 – electric motor for washers; 3 – left headlight; 4 – starter; 5 – rechargeable battery; 6 – main fuse block; 7 – generator; 8 – sound signal; 9, 10, 11 – front wiring harness blocks to the instrument panel wiring harness blocks; 12 – air conditioning fan electric motor; 13 – electric fan of the engine cooling system; 14 – ABS hydraulic unit; 15 – right front speed sensor; 16 – left front speed sensor; 17 – front wiring harness block to rear wiring harness block; 18 – right fog lamp; 19 – left fog lamp; 20 – ambient temperature sensor; 21 – reverse lamp switch; 22 – air conditioning compressor; 23 – audible alarm signal; 24 – rear window washer electric motor.

Power supplies Lada Kalina

The on-board network of the Lada is characterized by direct current, the nominal voltage of which is 12 V. The electrical circuit of the VAZ 1118 is single-wire. The main elements of the Kalina network can be divided into 4 groups.

- Sources.

- Consumers.

- Protective elements.

- Sensors

Sources and consumers of electrical energy are connected by negative terminals to a metal body (“ground”), which acts as a second wire. Power for all electrical devices of the Lada Kalina car is supplied from two main energy sources: a generator and a battery. While the engine is running, power is supplied to consumers from the alternator. When the engine is turned off, the devices are powered by a battery. While the generator is running, the battery is charged.

A generator is an alternating current synchronous eclectic machine. The rotating crankshaft of the car rotates the moving element of the generator - the rotor. In this way, the mechanical energy of the crankshaft rotation is converted into electricity. The rotor shaft rotates in bearings located in the covers. The bearings are lubricated at the factory with a material that does not require replacement until the end of the generator's service life. The stationary element of the generator - the stator - is tightened with four bolts to the generator cover.

The generator is the main source of electrical energy in Kalina. It supplies power to consumers when the engine is running. The generator is equipped with a built-in rectifier and voltage regulator. The Kalina stator includes a three-phase winding. The permissible voltage range of the generator is 14.4–15.1 V. The gear ratio of the engine to the generator is 1:2.4. The maximum generated current is 85 A.

The leads of the field winding located on the rotor are attached by soldering to copper slip rings on the rotor shaft. The generator voltage regulator is a non-separable part; if it breaks, it requires replacement. In order to protect the Lada's on-board network from voltage surges during ignition, a capacitor is connected between ground and the positive valve.

When the engine is turned off, all electrical appliances in the Lada Kalina are powered by the battery. In addition to the fact that the battery is an auxiliary source of energy for consumers, it helps to start the engine. In the electrical circuit of the Lada Kalina, a parallel connection is used for the generator and battery.

The negative contact of the battery is connected strictly to the body of the Lada, and the positive contact is connected only to the “B+” terminal on the generator. Do not remove the battery while the engine is running. This can lead to voltage surges in the network, resulting in damage to circuit elements.

Which headlights to choose

Factory technology provides for the installation of headlights in a luxury configuration. Indeed, today such products are produced by many manufacturers, large and small.

The following types of products can be found in the retail chain:

- Products under the Bosch brand are always sold as a set (2 pieces) and are distinguished by fairly durable glass and good quality luminous flux. We can say that this is the most reliable option, but its price is noticeably higher than all other analogues.

- Production PTFs are in many ways similar to those described above, but in fact their quality is noticeably inferior to the first option. The only advantage is lower cost.

- Kirzhach fog lights on Kalina have lens-shaped convex glass, which allows you to concentrate the light flux and direct it exactly where it is required. Quite a good and reliable solution.

- Products under the ProSport brand and other similar brands are produced by Chinese factories. It is difficult to judge their reliability and quality, since one option can be excellent, while the second one will fail in a very short time.

Bosch products play leading roles here too

The question of which fog lights are better for Kalina raises a number of disputes, so the decision is yours. As practice shows, the most popular options are Bosch and Kirzhach.

Common faults

An electrical wiring system includes many different devices and components. Therefore, there can be quite a lot of malfunctions in its operation. In Lada Kalina cars, electrical circuit elements are repaired if any malfunctions in the operation of the equipment are detected. All these breakdowns can be determined using a multimeter.

What groups can faults be divided into:

- Device failure. If the lighting stops working, the light bulbs may have burned out. If the audio system does not function, then the problem may lie in the performance of the car radio itself.

- The fuse or relay has failed. Again, if the near and does not work, then the reason may lie not in the burnout of the light bulb, but in the failure of the corresponding fuse or relay. In this case, the failed element can be found in the block, guided by the diagram. Typically, fuses blow out as a result of power surges, so before replacing burned-out parts, it is necessary to find and eliminate the cause.

- There is a break in the wiring or a wire has come loose from the device. Wire breaks and chafing usually occur where there are rubbing or moving parts. Therefore, after replacement, the wire must be laid in such a way that it does not come into contact with moving elements.

- Lack of contact. If there is no contact, but the wire is intact, then the problem lies either in the fact that the contact has come loose, or that it has oxidized. If it comes loose, then you just need to connect it back; if it has oxidized, then you need to clean it (the author of the video is Vladimir Semyashkin).

As practice shows, one of the most common malfunctions is battery discharge or breakdown.

For what reasons may a battery be inoperative:

- the terminals of the device are oxidized;

- there are signs of damage or cracks on the battery case, because of this electrolyte may leak out of the battery;

- inside the battery there are special plates that can be destroyed due to improper operation and maintenance of the battery, or constant vibrations;

- short circuit between electrodes.

In any case, if problems arise in the operation of electrical equipment, and you have never encountered circuit diagnostics before, we would recommend contacting an electrician. You may have to pay for this service, but you will be sure that everything was done correctly (the author of the video is the randomnameres channel).

Light control module diagram (LCM) Kalina 2

| A1 - external lighting switch; A2 — rear fog lamp switch; A3 — control device for rear fog lights; A4 - front fog lamp switch; A5 - control device for front fog lights; A6 - device for turning on side lights; HL1, HL2 - LEDs for illuminating the pointer and outdoor lighting symbol; HL3 ... HLn - LEDs for illuminating symbols (symbols). | 1 + 12V. (Taken from the central unit, the signal for turning on the dimensions). 2 To the rear fog lights. 3 To the front fog lights. 4 To daytime running lights. 30 + 12V to generator terminal (30) 31 Housing. 56 To low beam headlight lamps. 58 To the side lights and the circuit of illumination sources. Xz To the ignition switch (+ 12V, terminal 15). |

Windshield cleaner and washer

The Lada Kalina windshield cleaning system includes:

- Electric motor with gearbox;

- Set of levers and brushes.

Standard electrical wiring Kalina windshield cleaning system

The diagram below shows:

- Electric washer fluid reservoir pump;

- Standard ignition switch;

- Control unit for electric motor operating modes;

- The windshield wiper motor itself;

- Fuse and relay block;

- Terminal “A” from the power supply.

Washer kit includes:

- Polyethylene tank with pump;

- Injectors located on the hood of the car;

- Set of flexible connecting hoses.