Solex carburetors of the 2108 family have been produced at the Dimitrovgrad Automotive Unit Plant since the mid-1980s. Their development and production were organized specifically for the first series of front-wheel drive “eights”. Thanks to their unique design, reliability and maintainability, these devices even today allow old cars to feel quite cheerful, and their owners can easily and easily assemble or clean the carburetor, reduce fuel consumption, adjust the system and much more.

How does Solex differ from Ozone and Weber?

The main difference between Solex carburetors and devices of previous families is the possibility of installing it on transversely located power units with the float chamber forward. This installation option made it possible to eliminate the leanness of the fuel mixture when the car enters a turn, climbs, or during sudden acceleration.

In addition, Solex has a completely different float chamber design. It has a two-section design, which allows the device to be used both on front-wheel drive cars and on classic cars.

Solex carburetors are reliable and maintainable

New or used?

You can buy a new Solex for a classic, but it is also possible to purchase a used carburetor. In the second case, it is necessary to carry out an inspection - thoroughly clean the channels, polish the diffusers. In addition, it is better to purchase and replace jets.

But at the same time, you should not buy modern products - it is better to ask your friends and acquaintances for those that were made in the USSR. Modern jets found in repair kits often do not correspond to the calibration dimensions.

In order for the diffuser to work effectively, burrs and protrusions are removed from its elements using a file. Such defects create air turbulence, and this does not have the best effect on filling the cylinders.

What brands and models of cars were installed on?

C were installed not only on VAZs. Other automakers also actively used them for their cars.

Table: modifications and applicability of Solex carburetors

| Modification | Applicability | Engine volume, cm3 | Notes |

| DAAZ-2108–1107010 | VAZ 2108, 2109 | 1,3 | |

| DAAZ-21081–1107010 | VAZ 21081, 21091, ZAZ 1102 | 1,1 | |

| DAAZ-21083–1107010 | VAZ 21083, 21093, 21099 | 1,5 | |

| DAAZ-21083–1107010–31 | VAZ 2108, 2109, 2110, 2111 | 1,5 | Has a semi-automatic starting device |

| DAAZ-21083–1107010–35 | VAZ 2108, 2109, 2110, 2111 | 1,5 | Has a two-level semi-automatic starting device (winter/summer) |

| DAAZ-21083–1107010–62 | VAZ 2109, 2115 | 1,5 | Has an electronic device for controlling the composition of the combustible mixture |

| DAAZ-21083–1107010–05 | VAZ 2109 | 1,5 | |

| DAAZ-21412–1107010, DAAZ-21412–1107010–30 | AZLK 2141, 2141–23 | 1,5/1,8 | |

| DAAZ-1111–1107010 | VAZ 1111, 11113 "Oka" | 0,65/0,75 | |

| DAAZ-21051–1107010 | VAZ 2103, 2105 | 1,5 | |

| DAAZ-21053–1107010 | VAZ 21074, 21061 | 1,6 | |

| DAAZ-21051–1107010–30 | VAZ 2104, 2105 | 1,3 | |

| DAAZ-21053–1107010–62 | VAZ 2107, 21072, 21074 | 1,3/1,5/1,6 | |

| DAAZ-21073–1107010 | VAZ 2121, 21213 "Niva" | 1,6/1,7 |

Setting up the launcher

- open-end wrench 7;

- open-end wrench 8;

- flat screwdriver;

- electronic tachometer or multimeter with its function.

1. Remove the air filter from the carburetor. Pull the “suction” towards you as far as it will go. Next, you will need an assistant to start the engine. At this time, you are watching the starter flap, which should open slightly after starting.

2. If this does not happen, it means that the starter is not adjusted.

3. We begin the adjustment. Warm up the engine, turn it off and connect the tachometer as follows.

4. Pull out the choke and start the engine. The suction valve must be completely closed.

5. Next, use a screwdriver to press on the edge of the damper, opening it 30 0 .

8. In this position, holding the bolt with a screwdriver, tighten the locknut.

The adjustment process can be seen in this video

What is the difference between modifications 21081 and 21083

If you compare the two main modifications of Solex carburetors (21081 and 21083), used on front-wheel drive Sputniks and Samaras, then visually you will not find any differences between them. The difference exists only in the operating parameters of some of their elements.

Table: comparison of basic calibration data for Solex carburetors 21081 and 21083

| 21081 | 21083 | |||

| For 1st camera | For 2nd camera | For 1st camera | For 2nd camera | |

| Mixing chamber diameter, mm | 32 | 32 | ||

| Diffuser diameter, mm | 21 | 23 | 21 | 23 |

| Air jet of the main dosing system | 165 | 135 | 155 | 125 |

| Fuel jet of the main metering system | 95 | 97,5 | 95 | 97,5 |

| Idle air jet | 170 | 170 | ||

| Idle fuel jet | 39–44 | 39–44 | ||

| Air jet of the second chamber transition system | 120 | 120 | ||

| Fuel nozzle of the second chamber transition system | 50 | 50 | ||

| Economizer fuel jet | 40 | 40 | ||

| Accelerator pump cam number (size) | 4 | 7 | ||

| Throttle valve starting gap, mm | 1,0 | 1,1 | ||

| Air damper starting gap, mm | 2,7±0,2 | 2,5±0,2 | ||

| Needle valve hole diameter, mm | 1,8 | 1,8 | ||

| Vacuum regulator hole diameter, mm | 1,2 | 1,2 | ||

Installation process

Now you can start installation:

- To protect the collector from dirt, the engine compartment must be thoroughly washed.

- Then the drives and cables, as well as hoses, are disconnected from the standard carburetor.

- To remove the choke cable casing, remove the bracket from the choke panel.

- The surface of the collector is carefully cleaned and sealant is applied.

- After these operations, you need to install gaskets in the form of a sandwich. First the thin one is placed, then the thick one, then the thin one again. The purpose of a thick gasket is to provide thermal insulation. And to make the installation process more convenient, the carburetor is installed on the manifold without a cover. The damper drive must be at the front of the car.

- They mount the throttle valve linkage - on the VAZ-2104 it will be more convenient if it is on the cylinder head side. The slide or “helicopter” is sometimes sawed through the center so that it fits evenly on the carburetor. And so that in normal operation the damper does not jam on the spring, plastic tips are installed on the rods.

Solex design

The Solex carburetor serves for precise dosage of fuel during the formation of the fuel-air mixture, as well as timely supply of this mixture to the combustion chambers of the engine. Its design provides two channels for air passage. Throttle valves are installed at the bottom of these channels. Their drive is designed in such a way that when you press the accelerator pedal, the dampers open alternately: first the first, followed by the second.

Each of the chambers at the bottom has a narrowing into a cone - a diffuser, in which a vacuum is created during engine operation. Under its influence, fuel from the float chamber is sucked into the chamber. The required level of gasoline in the float chamber is maintained thanks to a special mechanism consisting of two floats and a locking needle.

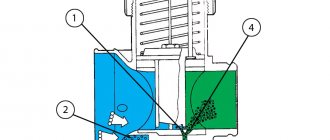

The Solex carburetor consists of two main parts: the cover and the body. The cover contains fittings for fuel hoses, a flange and studs for attaching the air filter. The housing design includes:

- float chamber;

- primary and secondary mixing chambers with diffusers;

- air and fuel channels;

- accelerator pump;

- emulsion wells;

- economizer;

- econostat;

- throttle valves and their drive mechanism.

The parts are connected to each other with five screws.

The Solex carburetor consists of two parts: the cover and the body

Basic systems, mechanisms and devices of the Solex carburetor

The Solex carburetor includes the following systems, mechanisms and devices:

- idle system;

- dosing systems of the primary and secondary chambers;

- transition systems of the primary and secondary chambers;

- float mechanism;

- econostat;

- power mode economizer;

- forced idle economizer (EFH);

- starting device;

- accelerator pump;

- throttle valve drive mechanisms.

Why are there wires on the carburetor?

The Solex carburetor is not a purely mechanical device. One of its parts has an electromechanical design. This is a solenoid valve. It serves to stop the fuel supply to the carburetor when the engine is braking, as well as turning off the ignition. This solution allows you to save from 300 ml to 1 liter of fuel per 100 km.

The valve is connected by wire to the EPHH control unit

The solenoid valve is actuated by the EPHH unit. It is connected to terminal “K” of the ignition coil, as well as to a special contact of the quantity screw, which closes to ground when the gas pedal is released. This allows it to read the crankshaft speed and send a corresponding signal to the valve.

The EPHH unit is located in the engine compartment

Both the valve and the quantity screw contact are connected to the EPHH unit using wires. There are no other electrical devices in the carburetor.

The quantity screw contact is connected to the EPHH control unit

Setting up the float chamber

This type of work allows you to adjust the optimal amount of gasoline in the float chamber. An incorrect level causes a decrease in power, uneven engine operation, and excessive fuel consumption.

- set of wrenches;

- thin probe (diameter 1 mm);

- pliers.

1. Remove the air filter and unscrew the carburetor cover.

2. Carefully remove the float chamber cover.

3. Check the condition and position of the floats. They should be parallel to the imprints of the side walls of the float bath on the gasket.

4. If they are displaced, we align them by bringing them together or spreading them apart.

5. Next, lay the lid horizontally with the floats up and use a feeler gauge to measure the distance from the bottom of the float to the gasket. It should be equal to 1 mm. If it is higher or lower, we continue further adjustment after installing the carburetor on the engine.

6. When fuel is pumped into the float chamber, its level should coincide with the red lines, as shown in the photo.

7. If the floats are set incorrectly, this level will be lower or higher. Simple adjustment is carried out by bending or bending the tongue of the floats, then closing the carburetor cover and pumping fuel.

For details on setting up the float chamber, see here

Signs of carburetor malfunction

Signs of a malfunctioning Solex carburetor are:

- inability to start the power unit;

- complicated starting of a cold or hot engine;

- unstable idle;

- idle speed is too high or too low;

- increased gasoline consumption;

- reduction in engine power characteristics;

- jerks and dips when pressing the accelerator pedal sharply.

Let's take a closer look at each of the symptoms in the context of possible malfunctions.

The engine does not start at all or starts but immediately stalls

If a vehicle's engine does not start (with a known-good ignition system), it is possible that fuel is not getting into the cylinders. To check whether it enters the intake manifold, you need to remove the air filter housing and turn the throttle valve drive sector 2-3 times, observing the “spouts” of the sprayer. The fuel from them should spray out in thin but continuous streams. If this does not happen, it is worth checking the operation of the fuel pump, as well as the condition of the carburetor strainer.

It is also possible that the fuel valve needle may jam in the closed position, blocking the flow of gasoline into the float chamber. In order to return the needle to its normal position, it is enough to gently hit the carburetor body with something (for example, a key). In the future, the needle valve will need to be replaced.

If the engine starts and immediately stalls, this may be the result of a lean fuel mixture or a faulty solenoid valve. In the first case, it is necessary to check the intake pipe for leakage of foreign air, and also adjust the quality of the mixture.

To check the solenoid valve in this situation, disconnect the power wire from it, turn on the ignition and touch its contact with the tip of the wire several times. When touched, a characteristic click should be heard, indicating that the electromagnet is triggered. It would not be superfluous to unscrew the valve, inspect and clean its nozzle with a stream of air, and also check the condition of the rubber gasket.

Difficulty starting a cold engine

Typically, problems with starting a cold power unit occur due to incorrect adjustment or malfunction of the starting device. If during start-up the air damper does not completely close the channel, this leads to an excessively lean fuel mixture. At the same time, the engine “grabs” in places, but still stalls. Incomplete opening of the damper, on the contrary, leads to over-enrichment of the combustible mixture, which increases gasoline consumption and may also cause detonation.

This problem is eliminated by adjusting the starting device.

Difficulty starting a warm engine

The main reason for the difficulty of starting the engine “hot” is also the over-enrichment of the mixture. It can be caused by incorrect adjustment of the starting device, as well as an excessively high level of gasoline in the float chamber. In the latter case, fuel is overfilled, which, again, leads to an increase in its consumption.

“Overfilling” is a fairly common phenomenon for Solex. If, looking at the gasket between the carburetor and the cover, you find that it is wet, and there is a persistent smell of gasoline in the engine compartment, there is an “overflow”. It may occur due to:

- incorrect setting of the float mechanism;

- problems with the fuel valve needle (needle sticking in the open position);

- float damage;

- the float hitting the chamber wall.

To eliminate this problem, it is necessary to disassemble the carburetor, check the valve and adjust the float mechanism.

Unstable idle

Normal idle speed of the power unit is one of the main criteria for assessing the performance of the carburetor. Its violation may be caused by:

- contamination of jets and XX channels;

- breakdown of the solenoid valve;

- malfunction of the EPHH control unit;

- damage to the rubber seal (ring) of the fuel quality screw.

Clogged nozzles can be eliminated by washing and purging them. The faulty valve, EPHH block and seal must be replaced.

Idle speed too high or too low

Engine speeds that are too high or too low when idling may result from:

- contamination of the air or fuel nozzle channels;

- suction of excess air;

- improper adjustment of idle speed (quality-quantity);

- too high or low level of gasoline in the float chamber;

- incomplete opening or closing of the air damper.

This malfunction can be eliminated by adjusting the carburetor after cleaning and flushing it.

Increased fuel consumption

The following carburetor malfunctions can lead to excessive fuel consumption:

- malfunction of the storage economizer system;

- incorrect adjustment of the composition of the combustible mixture;

- clogging of air jet channels;

- incomplete opening of the air damper;

- The fuel level in the float chamber is too high.

The problem of increased fuel consumption is solved by diagnosing and adjusting the carburetor.

Reduced engine power

A decrease in the power performance of the power unit is caused by a lean fuel mixture. At the same time, the car takes a long time to accelerate, and when you sharply press the accelerator pedal, the engine “chokes” and short-term dips appear.

The reasons for this phenomenon may be:

- incorrect adjustment of the mixture composition;

- air leak;

- low level of fuel mixture in the float chamber.

Dips, jerks

The occurrence of jerks and dips under engine load occurs due to:

- clogged strainer on the carburetor inlet fitting;

- clogging of the fuel nozzle;

- air leak;

- low fuel level in the float chamber;

- accelerator pump malfunction.

Let's sum it up

The steps described above for setting up and adjusting a Solex carburetor are basic. In other words, if you wish, you can adjust the carburetor yourself, based on this information. Note that the accuracy of the settings can be further checked on a gas analyzer, after which you can make the necessary adjustments yourself instead of constantly contacting specialists. Finally, we add that a dosing device of this type lends itself to various types of tuning, all kinds of modifications and improvements. For this reason, when choosing a carburetor for a VAZ, it is not for nothing that many car enthusiasts prefer Solex.

How to reduce fuel consumption on a Solex

If you notice that the engine begins to consume more fuel than it should, do not be lazy to check it. The rated fuel consumption for any vehicle can be found in its operating manual. It should be borne in mind that the amount of fuel consumed can be influenced by many factors, from the quality of the gasoline itself to the tire pressure, so before checking, take the trouble to diagnose the ignition system and also adjust the valves.

Flow check

Required tools:

- clean empty plastic bottle (2 l);

- a piece of gas-resistant hose (50–80 cm) with a clamp of the appropriate diameter;

- gasoline (1–2 l);

- marker;

- crosshead screwdriver.

Check procedure:

- We are looking for a flat section of the road (3 km) with good surface and low traffic intensity.

- Warm up the engine to operating temperature and turn it off.

- Using a screwdriver, loosen the clamp screw on the suction fitting of the fuel pump.

- We put one end of the prepared piece of hose onto the fitting. We fix the connection with a clamp.

- We pour a certain amount of gasoline into the bottle, measuring it out into 50 or 100 ml portions and making the appropriate marks on the bottle with a marker. We will use them to determine consumption.

- We lower the other end of the hose from the gas pump into the bottle.

- We start the engine and move along the road section at a speed of 60–70 km/h in fourth gear.

- After driving 3 km, we stop, look at the bottle, estimate the consumption and compare it with the passport data.

Idle setting

- flat screwdriver;

- electronic tachometer.

1. Start the engine, warm it up to operating temperature, and then turn it off. We press the “choke” all the way, opening the flap of the starter device as much as possible. We connect the tachometer using the same principle.

2. Start the engine, turn on all the lights and the heater fan at full power.

4. If in this way it was not possible to achieve the required speed, unscrew the quality screw to the maximum number of revolutions. Next, turn the quantity screw, setting the motor to 900 rpm. After this, use the quality screw to reduce the speed to 800 rpm.

Details in the video

Problems with the accelerator pump

The accelerator pump serves to consistently and timely supply a fuel stream through an uncovered carburetor valve. A weak flow or dripping is not considered normal. Spreading fuel along the walls of the diffuser is also taken as a deviation.

The acceleration pump nozzles are inserted into different chamber compartments. However, for speed, they can only be installed in the primary, which in exceptional cases will result in excessive overflow.

Introduction

Any car makes its owner happy until any troubles begin to happen to it. Naturally, such circumstances upset every driver. If the car is not new, then the repair costs may be too high, and it is very difficult to resolve the issue on your own. However, real VAZ connoisseurs are trying to study their iron horse inside and out and carry out repair work themselves. This primarily concerns the repair of important components; many are interested in installing a Solex 21083 carburetor on a VAZ-2107.

The most popular carburetor for the VAZ-2107 is Solex

Since the release of VAZ cars with carburetor engines, parts from the following manufacturers have been installed on them: Ozone, Solex, Weber. But Solex carburetors were and continue to be the most popular. Let's look at the adjustment and tuning of the carburetor of this brand in a little more detail.