Before we begin, it is necessary to make a small digression. No one can deny the fact that the fuel pump in a car’s design is one of the most important elements. Without which the car will not function, and malfunctions will lead to unstable engine operation.

It is worth noting that gasoline pumps can be divided into mechanical and electric. However, this article will not discuss mechanical fuel pumps due to the fact that they were used on older cars and cannot be found in modern cars.

How does an electric fuel pump work?

In the Photo: submersible fuel pump with a disassembled glass

Operating a car fuel pump

As we have already found out, a gas pump is a simple and unpretentious device. However, due to its compact size and high load, the pump requires special conditions for its operation. Firstly, its durability depends on the quality of the fuel, or more precisely on its cleanliness and the performance of the filtering system. Therefore, refueling with dirty, poor quality or contaminated fuel should not be allowed. Any specks of dust or particles can affect the integrity of the mechanisms.

To do this, it is necessary to regularly inspect fuel filters and screens that do not allow foreign elements to pass through. In addition, modern cars use submersible pumps, which are located directly inside the tank and are cooled by the fuel itself. Therefore, it is unacceptable to operate the car on an empty tank; overheating will certainly cause pump failure.

Symptoms of malfunction

Firstly, failure to comply with the rules for cleanliness, quality and availability of fuel in the tank will lead to pump failure, but other malfunctions associated with the fuel pump may also occur. But first, you need to understand the symptoms that will indicate a fuel pump failure.

First of all, you should pay attention to the unstable operation of the motor. The reason for this may be insufficient pressure in the fuel system due to the pump. At the same time, the car may gradually lose power or drive sharply, either normally or not at all.

Another sign of a malfunction or imminent breakdown of the fuel pump is the appearance of noise in the rear of the car. Strong buzzing sound from the fuel pump. Especially when you turn on the ignition, this is the first signal to replace it. Moreover, if you didn’t even pay attention to his work before.

In the Photo: The process of replacing a submersible fuel pump

Another sign of unstable operation is problems starting the engine. However, in such a situation there can be many reasons. From problems with the wiring of the entire car, to a malfunction of the motor itself or the electronic part of the control unit.

And the main sign of a malfunction is the complete inability to start the car, and complete silence in the fuel tank area when the ignition is turned on and attempts to start the engine.

How to find a breakdown

To start troubleshooting, you will have to know the entire structure of the fuel system. After all, a breakdown can occur not only in the fuel pump, but also in other elements of the fuel system. The entire fuel supply circuit consists of: a fuel tank with a fuel pump, fuel carrying pipes and hose, a fuel filter, injectors or other injection system and a return circuit of the fuel system.

If there is a suspicion of a drop in pressure in the fuel system, then the malfunction could occur in one of these elements. Next we will briefly go through each of them.

Fuel tank

In most modern cars, the fuel tank is a sealed container with a pressure release valve. However, the pressure in the tank is maintained and helps the entire system operate. But there are cases when the valve in the tank cap stops functioning normally and pressure disappears in the fuel tank or excess pressure accumulates. In this case, the entire system may not work correctly.

In addition, the tank may leak due to damage or corrosion. In this case, in addition to increased consumption and loss of pressure in the tank, there is a high probability of fire.

Fuel pump malfunction

The device itself can fail for a number of reasons:

• The gasoline pump has already exhausted its service life and the membrane with all its elements is not capable of pumping the required amount of fuel and maintaining the nominal pressure in the system.

• The valve responsible for maintaining constant pressure in the fuel system has failed and is constantly leaking fuel. Because of this, the engine does not receive enough gasoline and power decreases.

• The clogged mesh at the inlet to the fuel pump has become very dirty and has stopped passing a sufficient amount of fuel. In this case, in addition to reducing engine power, the fuel pump itself begins to work with increased load, which leads to rapid breakdown.

In the Photo: Filter mesh clogged with various dirt

• Also, the electrical wiring to the fuel pump may be damaged, or the contacts on the terminals of the device itself may be oxidized. But first of all, you should check the fuse in the cabin unit. If you successfully replaced the fuse with a new one, and it burned out again, you will have to carefully check the electrical wiring.

Signs of a faulty fuel pump

The very fact of a malfunction or failure of the fuel pump is determined by a number of external signs. As a rule, this is the inability to start the car or interruptions in engine operation while driving. In addition, symptoms of a breakdown may include an uncharacteristic hum and loss of power during acceleration.

The fuel system of a modern car consists of the following elements:

fuel inlet pipe;

fuel outlet pipe;

The reason for stopping the fuel supply to the engine may be a malfunction of any of these components.

Checking the serviceability of the pump on the injector

If you hear a slight noise when turning the ignition key, then this is how the fuel pump functions. By pushing up the fuel, it creates pressure in the structure. If, when trying to start, there are no similar symptoms of the fuel pump, then we can assume a breakdown of the electrics, the fuel pump or its separate elements.

Reasons for fuel pump failure

The pump can fail for various reasons:

- For carburetor engines, the main source of the problem is usually the fuel pump rod. During operation, it becomes shorter and the pump stops supplying the required amount of fuel to the engine.

- The device may stop functioning due to wear on the inlet valve or its O-ring.

- Injection engines are equipped with electric fuel pumps. In this case, the most common cause of device failure is poor quality fuel. The inlet strainer becomes clogged with dirt and restricts the flow of fuel.

- Electric pumps may become inoperable due to faulty wiring, relays, fuses, or terminal oxidation.

Some of these problems can be prevented by refueling with high-quality fuel at well-established gas stations. In addition, it is recommended to occasionally clean the gas tank and replace this and other elements of the fuel system when their service life has expired.

Checking the functionality of the relay

The fuel pump relay is a device that supplies or stops electrical power to the fuel pump. If it fails, the operation of the fuel system will stop.

Electrical power to the fuel pump is supplied through a relay

Checking the functionality of the relay and the corresponding one is carried out according to the following scheme:

Open the hood and remove the cover from the fuse and relay box.

Using your hands or special pliers, remove the relay and fuse that control the pump.

Inspect the relay and fuse and, if faulty, install new ones.

Check if current is flowing to the relay. This can be done with a wire with a 12 V lamp, connecting it to the connection point.

Often the relay stops working after installing an alarm system on the car. In this case, you should reset all settings from the alarm key fob.

Video: checking relay functionality

The mechanism works, but does not pump fuel

Sometimes the device makes a characteristic hum, but gasoline is not supplied to the engine. The fact is that the pressure in the fuel system should not exceed 3 atm. It can be measured by connecting a pressure gauge to the fuel rail. If there is no pressure or it is very low, the element has failed.

It may happen that the device simply does not receive voltage. To check this, turn on the ignition and determine by ear whether the pump is working. It should make a slight buzzing sound. If nothing is heard, power is not supplied to the pump. Relays, fuses and wiring should be checked.

Video: what to do if the pump does not pump fuel

Pressure in the fuel supply system is not maintained

The pressure in the fuel system is maintained not by the pump itself, but by its check valve. Fuel enters through the inlet valve, which supplies it under pressure through hoses to the engine, and the check valve does not allow gasoline to return.

Due to severe wear, the check valve may not operate. As a result, the mechanism loses its ability to maintain the required pressure.

Depending on the make of the car, the check valve can be located either inside or outside the device body. Replacing a valve is a rather complicated procedure. Therefore, it is more convenient to replace the pump as a set.

The car jerks at low speed

If the engine begins to make unusual noises and jerk while driving at low speeds, the filter screen is most likely clogged. The pump simply does not have enough fuel to operate properly. The problem will go away after cleaning the mesh.

Similar symptoms may also be caused by incorrect operation of the device valves. Due to wear, they cannot pass gasoline in both directions. In this case, it is necessary to replace the mechanism.

BOSCH fuel pump VAZ 2110 – pros and cons

Among manufacturers of automotive electrical equipment, the most reputable is BOSCH. The combination of affordable prices and good quality allowed this brand to conquer the shelves in every auto goods store. However, counterfeit manufacturers do not sleep and have flooded the market with their products of worse quality.

How to choose a Bosch fuel pump of original quality for a VAZ 2110

Despite the high-tech equipment of factories with counterfeit activities, it is possible for the buyer to identify original products from counterfeits. This guarantees the car owner that the service life declared by the manufacturer for the Bosch fuel pump for the VAZ 2110 will be observed.

A fake is identified by the following criteria:

- the corners on the packaging stickers are sharp, not oval like on the original;

- typos and errors in the text of the accompanying documentation;

- the pump is packed in a vacuum plastic bag without oil;

- the date of manufacture and shift number may be poorly printed on the case or missing.

Bosch fuel pump performance and characteristics

The manufacturer BOSCH produces a pump for each fuel system with certain pressure parameters. It is not necessary that the pressure strictly correspond to the performance characteristics. The main thing is that it should not be less, otherwise it will not be enough for the normal operation of the fuel system. As for the excessive pressure, in this case the return line helps out by returning the fuel to the tank.

If you are going to repair a VAZ 2110 fuel pump (injector) yourself, then you should purchase an electric motor with number 0580453453. In addition to the Togliatti family, a part with this code is installed on some RENAULT models.

Table 1. Characteristics of the fuel pump for VAZ 2010-12

| Options | Indicators |

| Manufacturer code | 0580453453(BOSCH) |

| Type | submersible |

| Productivity (hp) | 60 |

| Revolutions per minute | 5600 |

| Pressure maximum (kPA) | 650 |

| Minimum pressure (kPA) | 450 |

| System pressure max. (kPA) | 350 |

| System pressure min. (kPA) | 100 |

| Current consumption (A) | 5 |

| Voltage (V) | 6-13 |

| Diameter (mm) | 38 |

| Length (mm) | 111,4 |

| Cost, rub) | 2 800 |

Many car owners of the “tenth” family do not have the desire to immediately purchase a Bosch fuel pump for their VAZ 2110 (8-valve injector), since its cost of over 2,500 rubles significantly impacts the personal budget. However, having experienced failure after installing a fake, you can hear an objective assessment from the first person, which has its pros and cons.

Table 2. Advantages and disadvantages of the BOSCH 0580453453 fuel pump

| Advantages | Flaws |

| Durability | High price |

| High quality | |

| Easy to install | |

| Adds dynamism to the car | |

| Stable pressure | |

| Warranty at point of sale | |

| Suitable for all VAZ models |

Adjusting the pressure in the fuel system

A simple way to regulate the operation of a worn-out fuel pump is to install a fuel pressure regulator. It connects to the fuel rail and shows the pressure, allowing you to change it either up or down.

The device allows you to adjust the fuel pressure in the system depending on the situation

To measure the fuel pressure in the system, you can also use a pressure gauge by connecting it to the fuel rail.

Car won't start after replacing fuel pump

Sometimes, after installing a new pump, the car cannot be started. There may be several reasons for this problem.

A defective product has been installed. It needs to be replaced.

The fuel inlet and outlet pipes are not connected correctly.

The power plug is not connected correctly.

The terminal contacts have oxidized. They need to be cleaned.

Proper connection of wires and fuel supply pipes guarantees proper operation of the fuel pump

The fuel pump is the main element of the fuel supply system. Any malfunction leads to the impossibility of further operation of the vehicle. You should pay attention to all symptoms of decreased performance of the mechanism, immediately identify them and take appropriate measures. Good luck on the roads!

A car fuel pump is a device designed to provide an uninterrupted supply of fuel to the installation in which the fuel mixture is formed. Even the slightest malfunction leads to interruptions in the operation of the engine, and in the event of more serious problems, you simply will not start it.

In this article we will look at situations where the gas pump does not pump fuel at all, or pumps it, but not in the amount required by the power unit for normal operation. We will also try to understand the possible causes of this or that malfunction of the fuel supply device and discuss methods for eliminating them independently using the example of domestically produced cars carburetor VAZ-2109 and injection VAZ-2114.

Replacement process

Before proceeding with the replacement, it is necessary to prepare the tool and the place for disassembling the glass itself. To do this, you need a clean cloth to spread it on a workbench or table and work on it. This is necessary to prevent excess debris from getting into the fuel pump.

Required tool:

- Ratchet or crank;

- Head on “10” or “8”;

- Key to "17";

- Pliers;

- Screwdriver;

Step by step process

The first step is to relieve the residual pressure in the fuel line. To do this, remove the fuel pump fuse (F3-15A). The fuel pump fuse is located under the center console on the passenger side behind the plastic footwell vent cover.

We start the car and let it idle until the car stalls.

Next we proceed to removing the rear seat. On sedan cars, you must press the seat latches on both sides.

On station wagon and hatchback cars, you need to pull the tongue and lift the seat up.

Unscrew the two self-tapping screws of the fuel pump glass cover.

We clean out all the debris and dirt under the lid of the glass. You can use a brush, vacuum cleaner or compressor. This is necessary so that after the fuel pump glass is removed, excess dirt does not get into the tank.

Remove the fuel pump connector.

We unscrew the fuel pipe fittings on cars older than 2003. On cars manufactured after 2003. plastic fitting clamps were installed. In order to remove the plastic clamp, you need to press the buttons as shown in the picture and pull the fitting towards you.

Next, using a “10” or “8” head (also depends on the year of manufacture of the car), carefully unscrew the 8 nuts securing the fuel pump cup ring.

We remove the glass, without carefully bending the fuel level sensor, from the tank.

Next, we proceed directly to disassembling the fuel pump glass on a clean rag.

We pull out the glass stopper and remove the sump.

We remove the old fuel pump mesh by prying it up with a screwdriver.

We install a new mesh and reassemble in the reverse order.

When tightening the fuel pump cup ring, do not apply excessive force, otherwise the pins on the gas tank may come off.

We hope the article was useful to you, then you can watch a video on replacing the fuel pump mesh on a Priora.

What types of fuel pumps are there?

Cars with gasoline engines, depending on the make, model and modification, can be equipped with gasoline pumps of different designs. But they all fall into two main categories: mechanical and electrical. Most carburetor engines are equipped with mechanical fuel delivery devices. If we take the VAZ 2109 (carburetor), then from the factory it was equipped with a diaphragm pump manufactured by DAAZ. The main difference of this device is its simplicity of design, which is easy to understand even for a beginner. In the carburetor "nine" the fuel pump is located in the engine compartment of the car. It is easy to recognize by its characteristic hemispherical cap and fuel line hoses.

VAZ 2114 injection engines are equipped with electric fuel pumps. Their design is also based on a membrane, but unlike “mechanics”, the fuel supply devices in cars with automatic fuel injection are not under the hood, but directly in the tank.

Choosing motor oil for manual transmission

Transmission oil is designed to lubricate mechanical parts. High-quality oils with high performance during the operation of the gearbox pass through all parts, creating a special film on them. Thanks to this, the wear resistance of spare parts increases and they become stronger. In view of this, oil for a manual transmission is considered a significant consumable.

According to the manufacturers' recommendations, it is possible to pour motor lubricant into a manual transmission if the car has front-wheel drive. Engine and gearbox oils differ in viscosity index. Engine lubricant is thinner. You can verify this by shaking bottles of engine and transmission oil.

When choosing which oil to pour into the unit, be sure to take into account the viscosity index and operating indicators. Transmission oils are divided into the following categories:

- GL-1 – mineral water without additives;

- GL-2 – contains fatty foods;

- GL-3 – resists scuffing well;

- GL-4 – is resistant to scuffing and wear;

- GL-5 – resistant to corrosion, wear, and scuffing.

Oils included in the first three categories are used in the mechanics of machines produced a long time ago. Lubricants of the 4th and 5th categories are used in transmissions of passenger cars of various models. GL-4 is only available in cars with front-wheel drive. GL-5 is suitable for gearboxes of rear-wheel drive vehicles and drive axles.

Today, the most common are universal petroleum products, that is, those that can be used at any time of the year. Seasonal replacement of consumables is not very profitable for the motorist; it takes money and time.

https://youtube.com/watch?v=jpzO7iyGtpk%3F

Design of a carburetor fuel pump VAZ 2109

To understand why the VAZ 2109 fuel pump (carburetor) does not pump, let’s briefly look at its design. So, the “nine” fuel supply device consists of:

- housings;

- pusher with mechanical pumping lever;

- diaphragm assemblies;

- covers with valves and fittings for attaching hoses;

- mesh filter;

- manual pumping lever.

Repair

Mechanical fuel pump repair

Repairing a mechanical fuel pump consists of installing a new repair kit (diaphragm and valves) and, if necessary, a worn pusher with a spring. A deeper repair of this device is impractical, since the costs of purchasing and repairing worn parts are close to the cost of a new product. If the pump housing is deformed or damaged, it must be completely replaced.

Electric fuel pump repair

The electric fuel pump is equipped with a non-separable housing, and if it breaks down, the product is replaced with a new one. Without special skills, equipment and spare parts, opening and repairing it is impossible. But some workshops undertake similar work, the price of which is lower than buying a new pump. The main failures of the device are as follows:

- Damage to brushes and motor commutator. Repair involves replacing them with new ones.

- Breakage of the plastic coupling connecting the rotor and the motor armature shaft. The clutch is replaced with a new one.

- Anchor failure. The repair involves rewinding this part.

The described actions allow us to eliminate the gas pump malfunction on all models of the VAZ: 2101, 2102, 2103, 2104, 2105, 2106, 2107, 2108, 2109, 21099, 2110, 2111, 2112, 2113, 2114, Niva, Priora, Kalina, Grant, Vesta and most foreign cars.

Operating principle of a mechanical fuel pump

The fuel pump is driven by the camshaft cam, which moves the pusher in a horizontal direction, causing it to perform reciprocating movements. The pusher, in turn, acts on the mechanical pumping lever, and it already raises and lowers the membrane rod.

Thus, a certain pressure is created inside the fuel pump, which is maintained by the valves of the device cover. One of them lets fuel in without letting it back in, and the second pushes it into the fuel line going to the carburetor.

As you can see, the design is very simple, therefore, to determine the reason that the fuel pump does not pump, it is enough to disassemble it and check the condition of the main elements.

Location

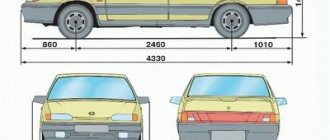

The fuel pump on the VAZ 2110 is located in the fuel tank and is inserted into a special glass, which is attached to the tank with several screws. There are pins sticking out on the tank that press the washer through the O-ring that secures the fuel station cup.

You can find it by removing the back seat of the car, unscrew the rectangular hatch, it is attached to two screws, after which access to the location of the fuel pump will open.

Pump filter and manual pumping lever

The first thing you will see when you disassemble the fuel supply device is the strainer. It is made of thin perforated plastic. The reason why the fuel pump does not pump can also be if it is deformed or severely contaminated.

In the first case, the filter must be replaced, in the second, it must be washed with carburetor cleaning fluid.

The manual pumping lever has nothing to do with the fact that the fuel pump does not pump fuel when the camshaft rotates. The only thing that can break in it is the spring that tilts it back to its original position.

The fuel pump does not pump: injector

As already mentioned, pumps in carburetor and injection engines have different designs. In cars with forced fuel injection, all processes associated with its supply to the combustion chambers are controlled by an electronic control unit, so breakdowns of various types of electronic devices can occur here.

The main reasons why the fuel pump of an injection engine does not pump include:

- malfunction of the device's electric drive;

- pump filter clogged;

- relay failure;

- fuse blown.

How to understand that the cause of engine interruptions is the fuel pump

Diagnosing problems with the fuel pump in a car with an injection engine is much easier than in a car with a carburetor engine. The fact is that when you turn on the ignition, you can clearly hear the sound of the electric motor of the fuel module. It lasts for several seconds. This sound indicates that the fuel pump is turning and pumping fuel.

If this happens when you turn the key, then there is nothing wrong with the device itself, and the cause needs to be looked for elsewhere. Well, if when you turn on the ignition you do not hear the characteristic sound of the pump, you can be sure that the problem is in it, or in the elements of its energy supply.

Video on the topic

The fuel pump is one of the main components of a car. Without it, it is simply impossible to start the engine, much less operate it. Therefore, if you have any problems starting or operating the engine, you first need to check the fuel pump. To find out how to check a gas pump, you must first determine the basic principles of operation of this unit and possible breakdowns. As a rule, the fuel pump is not repaired and is replaced by a working one. However, it is necessary to identify that this is where the problem lies.

Start with the relay and fuse

Considering that the fuel supply module is located in the car tank, and it is not so easy to get to it, it is better to start diagnostics with the relay and fuse:

- Unscrew the screws securing the cover of the mounting block located to the left of the steering column.

- Underneath it, find fuse F3 (15 A) and relay R2. These are the elements that we need to check.

- As for the fuse, it needs to be “ringed” with a tester. If unusable, replace it.

Checking the relay in a garage is quite difficult. But you can take a similar one (from an adjacent socket), a known good relay, and install it instead of the one being diagnosed. Now turn on the ignition. Is the fuel pump pumping? The reason has been found! Well, if nothing has changed, move on.

Common mistakes

You can use our instructions in one case: when the fuel pump does not work, but other systems are working properly.

Sometimes the engine does not start for several reasons at once. And then you need to reduce the pressure like this: wait 5-6 hours, and do not turn on the ignition. Be careful! Actually, the ramp is under pressure

You can find out about the presence of pressure in the standard way:

Open the hood; There is a fitting on the fuel rail, closed with a plastic cap. It is turned away (photo 1); Using the nipple cap (photo 2) you can unscrew the fitting plug

This action is performed carefully: the residual pressure has not disappeared anywhere.

Even if gasoline starts to gush out, do not try to tighten the fitting right away. Let the pressure drop a little.

Diagnostic connection and plug

Trying to fix a fuel pump is commendable. It will be possible to change its mesh. But the cause of the problem may also be a clogged fine filter.

The replacement filter (“can” 2112-1117010) gradually fails. On all fuel-injected cars, including the VAZ-2112, the fuel pump will not stop working even if the filter is completely clogged. Fuel is not pumped, but the engine does not burn out.

Electric drive and filter

The fuel pump in the injection VAZ 2114 is an element of the fuel module, which is located in the car’s tank. It also includes:

- coarse filter;

- fuel level sensor;

- pipes for connection to the fuel line.

To get to the module, you need to remove the lower part of the rear seat, disconnect the wiring harness and unscrew the 8 screws securing its cover. Remove the entire device assembly. First of all, inspect the coarse filter. If it is clogged, replace it.

To test the electric motor, you will need to connect it directly to the battery terminals. If it is operating normally, “ring” the wiring and check the contact of the ground wire on the module cover. If the electric motor shows no signs of life, the question “why the fuel pump doesn’t pump” has finally found its solution.

It is not advisable to try to repair it yourself. Just buy a new motor and install it in place of the old one. And yet, you shouldn’t spend money on buying the entire module, which now costs about 3 thousand rubles. Buy the electric motor and a new filter separately. All this will cost you three times less.

One of the most important elements of the fuel injection system of a gasoline engine is the electric fuel pump, which is located in the fuel tank of the car. The fuel pump pumps fuel into the system from the gas tank, creating a certain pressure.

Auto repair experts identify the following common fuel system problems that are related to the fuel pump:

- The fuel pump pumps poorly and does not create the required pressure;

- the fuel pump does not pump when the ignition is turned on;

Considering that the fuel pump is an electromechanical device, the most common fuel pump malfunctions are related to both the mechanical and electrical parts. Next, we will look at what signs indicate a breakdown of the fuel pump and why the fuel pump stops pumping partially or completely.

Read in this article

CORRECT DISASSEMBLY AND REPLACEMENT PROCEDURE

In order to properly remove the fuel pump, you must perform the following sequence of actions:

- Buy a repair kit right away.

- Remove the air filter and its housing.

- Disconnect the gasoline supply and return hoses from the fuel pump fittings.

- Unscrew the nuts that secure it.

- Remove it carefully so as not to damage the gaskets.

- After this, inspect each part for cracks, check all its valves for leaks.

- Make sure that the discharge and suction fittings remain motionless in their sockets.

- The diaphragms must be free of peeling and ruptures.

- The filter must be absolutely clean and undamaged.

- Wash all filter parts with gasoline and then rinse with a compressor.

- Replace all damaged parts, it is also recommended to install a new pump gasket.

- When installing the gasket, apply Litol-24 type lubricant to its surface.

- If the housing is damaged or there is other irreparable damage to important parts, the pump will have to be completely replaced.

- Then you need to move on to installing the pump in place.

- In this case, you should immediately adjust its supply using spacers.

- To do this, you need to measure the protrusions of the pusher.

- If the protrusion is too strong, the gasoline pressure will be increased, which will easily break the carburetor shut-off valve.

- If the distance is lower than required, when the load increases and the vehicle speed increases, insufficient gasoline will flow into the carburetor.

- Install the gasoline pump in reverse order.

- Make sure that the arrow located on the body points towards the carburetor.

- When installing the diaphragm unit, the holes in its gasket should be located away from the muffler pipe.

Thus, you have outlined detailed instructions for removing and disassembling the fuel pump, which will help you carry out this operation yourself. You can finish here, you shouldn’t have any difficulties.

Signs of fuel pump malfunctions

The main symptoms of fuel pump failure, as well as malfunctions in its operation, are:

- the car starts with difficulty, the engine runs unstable, there are dips, jerking when pressing the gas pedal, etc.;

- the pump does not pump after turning on the ignition, does not turn the starter and does not pump the fuel pump, the engine does not start;

There have also been cases when the fuel pump stops pumping while driving. In such a situation, the engine begins to malfunction and stalls immediately after the remaining gasoline in the fuel line is used up. The problem can occur either regularly or periodically.

Extraneous sounds

If suddenly there is an extraneous sound when the fuel pump operates, you will need to completely remove it. It is worth noting that the VAZ 2110 fuel pump consists of several parts; the base is an electric motor. It drives an impeller, which pumps gasoline from the tank into the fuel line. As a rule, extraneous sounds appear when the engine itself wears out or when the mesh is excessively contaminated, as well as when a non-original one is installed. If you suddenly have such a symptom, it is necessary to either replace or repair this mechanism, since there is a very high risk that in the near future this unit will simply fail.

The fuel pump does not pump: causes and diagnostics

Let's start with the fact that if the gas tank is full, the battery is charged, the spark plugs are dry and there is a spark, the starter turns the engine normally, but the engine does not seize, then you should pay attention to the gas pump. A common problem is that there is no power to the fuel pump after the ignition is turned on. In a similar way, the malfunction manifests itself in motion, when the power to the fuel pump is lost and the engine suddenly stalls.

An equally important point is how much the fuel pump pumps. In other words, the pump may hum and buzz (power is being supplied), but not create the required pressure in the fuel line. The pressure in the fuel system with a working fuel pump must be more than 3 bar (which depends on the specific car model). The indicated pressure is accumulated in the fuel rail and has an indicator of 300 kPa and above.

To check, you need to measure the pressure in the fuel rail with a pressure gauge, taking into account the indicators that are the norm for a specific car model. Using the example of injection VAZs, the pressure when the ignition is turned on is 3 atmospheres, at idle the figure is 2.5 atmospheres, when you press the gas 2.5-3 atmospheres. This method will help you accurately determine:

- malfunction of the fuel pressure regulator in the rail;

- breakdown of the fuel pump or a noticeable decrease in its performance due to wear;

- severe contamination of filters (fuel filter and/or fuel pump mesh);

Electric fuel pump for VAZ 2107

Increasingly, owners of “classics”, including the VAZ 2107, are installing modern devices on their cars. So, the mechanical fuel pump is replaced with an electric one. The main goal of introducing an electric fuel pump is to get rid of the problems that arise with standard pumps. However, you need to understand that if on injection “sevens” such a mechanism is installed directly in the gas tank, then on carburetor cars it is placed under the hood.

Which one can be installed

As an electric fuel pump, you can install any device designed to work on fuel-injected cars on the “classic”. Based on reviews from Zhiguli car owners, Chinese-made pumps, as well as Magneti Marelli and Bosch, are often used. It is important to know that the product must provide low pressure . A standard mechanical pump produces about 0.05 atm. If the indicator is higher, then the needle valve in the carburetor will simply let fuel through, which will lead to it leaking out.

Installation of an electric fuel pump

To install an electric fuel supply pump on a carburetor “seven”, you will need a certain list of materials:

- tee 8x6x8 mm;

- fuel line for VAZ 2107;

- check valve from the "eight";

- 8 mm threaded fitting;

- clamps, blocks from Kalina for a four-pin relay (3 pcs.) with a fuse holder;

- the four-pin relay itself (3 pcs.);

- fuel jet (150);

- fuel return hose from the V8;

- wires;

- non-latching button.

We carry out the work in the following sequence:

- We lay the fuel pipe (return) parallel to the standard fuel line, securing it in the factory locations.

Video: installing an electric fuel pump on a VAZ 2107

Once the installation of the mechanism is complete, it will function according to the following algorithm:

- after turning on the ignition and pressing the pumping button, the pump is activated and pumps up gasoline;

- when the starter starts, the fuel pump turns on;

- while the engine is running, the pump is powered by a generator;

- after the engine stops, the operation of the unit stops.

Installation benefits

Owners of Zhiguli cars who have installed an electric fuel pump on their cars note the following advantages:

- an engine with such a device operates more stable at idle speed;

- when accelerating sharply, the car responds well to the pedal, there are no dips, which is not the case with a mechanical pump;

- when switching gears there is a smooth ride, and when the gas is abruptly released there is no twitching;

- at high speeds the engine spins better;

- there are no jerks at low speeds when starting the car after a long trip.

The VAZ 2107 fuel pump sometimes has to be repaired or replaced. Doing this is not as difficult as it might first seem. Repair and adjustment work is carried out with a minimum set of tools in accordance with step-by-step instructions.

Regardless of the type of fuel for which the car is designed, it must be supplied to the engine uninterruptedly. Its reliability and stable operation directly depend on this. The quality of domestic gasoline traditionally leaves much to be desired - most engine mechanisms and systems suffer from this, primarily the fuel pump. To prevent it from breaking down at the most unexpected moment, you need to know the signs and causes of the malfunction, and also adhere to preventive measures to maximize the life of the gas pump.

Other causes of fuel pump malfunctions

Quite often, unprofessional installation of additional electrical equipment or security anti-theft systems leads to the fact that the power to the fuel pump is lost due to mixed up contacts or other connection errors.

Finally, let’s add that the gas pump in the gas tank is immersed in gasoline, in which it is actively cooled. The habit of driving with an empty tank can quickly damage the electric motor of the fuel pump, as it burns out.

What functions does the fuel pump relay perform, signs of breakdown. Where is the fuel pump relay installed, how to properly check the fuel pump relay.

Why does the starter turn normally, but the engine does not catch and does not start? Main causes of malfunction, checking fuel supply and ignition systems. Adviсe.

Diagnose faults that may indicate problems with the fuel pump. Self-check of the device, measuring the pressure in the fuel rail.

The causes of whistling and increased noise during operation of the fuel pump are overheating of the pump. How to diagnose and fix the problem yourself. Tips and tricks.

How to change a fuel pump. Location of the fuel pump, releasing pressure in the system, unscrewing the fuel lines, removing the pump, reassembling.

What to do if the car accelerates worse, does not pick up speed, or has failures during acceleration. Why the engine does not pull, how to find the reason for the decrease in power.

Difficulties with fuel supply - common symptoms

Failures of the fuel supply system are conventionally divided into 2 groups:

- The combustible composition does not enter the cylinders at all.

- Fuel flows intermittently or under low pressure.

In the first case, the engine cannot start and does not engage the starter during rotation, i.e. it does not work. In such a situation, it is much easier to determine the cause of the malfunction.

If little gasoline enters the cylinders, the following symptoms occur:

- turning on the power device “when cold” is too difficult, the engine seizes, “sneezes”, and starts after 3–10 attempts;

- The idle speed is unstable, the engine “troubles”;

- active acceleration becomes unrealistic - sudden opening of the throttle causes a prolonged dip, as well as deceleration;

- if the driver releases the accelerator pedal, the engine usually quiets down;

- The car has difficulty climbing hills and also accelerates slowly when fully loaded.

The cause of the above phenomena may be a breakdown of the fuel pump or other system components. In addition, the main features are almost the same. To perform a clear diagnosis, you need to know how the power supply structure of the machine works.