02/04/2022 28 224 VAZ Kalina

Author: Ivan Baranov

As you know, not only the movement of the car, but also its functioning as a whole depends on the operation of the gearbox (gearbox). Transmission malfunctions entail not only the inability to change gears, but also expensive vehicle repairs. Therefore, if you are the owner of a Lada Kalina car, then you will be interested to know why first gear on Kalina is difficult to engage or does not engage at all. We will also tell you about repairing faults at home.

Remember that transmission problems in any vehicle should not be neglected. Otherwise, a series of breakdowns may occur, which will require you to spend not only a lot of time and effort, but also money.

VAZ Kalina car [Hide]

Why first gear is difficult to engage in Lada Kalina: reasons and solution

Lada Kalina 2. Gears are difficult to engage

Reasons for difficult gear engagement

| Possible causes of malfunction | Troubleshooting |

| Clutch faulty | Carry out diagnostics |

| The selection cable or gear shift cable is faulty (broken, torn, stuck in the sheath) | Replace the faulty cable |

| The gearbox control mechanism is worn or damaged | Replace mechanism |

| Worn or damaged gear shift mechanism | Repair or replace transmission |

| Worn gear synchronizers | Repair or replace transmission |

- Clutch malfunction. In this situation, the gears will engage either poorly or not completely.

- Problems in the drive of the switching mechanism. Broken traction leads to difficult engagement of 1st and reverse gears. -Jet thrust is faulty. -Wear of plastic parts in the box control drive. -The slide is set incorrectly. A weighty element, incorrect adjustment leads to malfunctions.

- Wear of bearings. This is a fairly rare occurrence; anyone can experience this, especially when you have a manual transmission. In such a situation, it is usually difficult to engage first gear. -The box shaft is faulty. By itself, it is not subject to heavy loads, which could lead to wear. A factory defect may cause the entire unit to be replaced.

-Failure of clutches. Often found among owners of cars with an automatic transmission. The malfunction is eliminated by replacing the clutches. -Failure of synchronizers - the problem most often occurs among gearbox breakdowns. They are made of brass, and this metal itself is quite soft. During use, it wears out and wears out. —-

-The breakdown is usually accompanied by a grinding noise when switching to another speed.

Manual transmission (gears are difficult to engage)

There are also several clutch malfunctions that cause manual transmission gears to shift poorly:

- Airing of the clutch release hydraulic drive or leakage of fluid from it. The malfunction is eliminated by replacing failed components of the hydraulic system and pumping it. - Worn or broken clutch release fork. The part requires replacement or repair. - Warping (runout more than 0.5 mm) or the thickness of the new driven disk is too large.

-Failure of the basket (temperature deformation of the pressure plate or its distortion). -Loss of mobility of the support bearing of the gearbox input shaft (at the end of the crankshaft to which the flywheel is attached). - Jamming of the clutch driven disc hub on the splines of the gearbox input shaft. To eliminate the defect, clean the splines of the gearbox hub and input shaft.

It wouldn’t hurt to lubricate them a little with lithol. -Too much free play of the clutch release fork. Its value needs to be clarified with the manufacturer, since it is slightly different for different cars. Until you find out the value of this parameter for your car, set it from 5 to 8 mm. Too little free play of the fork is also undesirable, as it leads to clutch slipping and increased wear of the release bearing.

-Excessive wear of synchronizers mainly occurs in those gears that are engaged more often: these are usually first, second and third. The rear one is not included in this list because it does not have a synchronizer. When your gear shifts poorly, and you assume that the reason for this is wear of the synchronizers, firstly, you should only have difficulties with this while driving. Secondly, in this case it switches better if you use double squeeze.

(What is a double squeeze. To shift into an upshift: squeeze the clutch, put it in neutral, release and squeeze the clutch again, shift into gear)

To switch to a lower gear: double squeezing must be combined with re-engaging, that is, when the clutch pedal is released and the gearbox is in neutral, you need to press and release the accelerator pedal. This is how gears are changed in cars that do not have synchronizers. If the gearbox shifts easier using double squeezing, then the culprit for poor gear shifting is most likely worn synchronizers.

A malfunction in the vehicle's clutch mechanism can also cause poor gear engagement:

- the tightness of the hydraulic clutch circuit is broken. As a result, when you press the clutch pedal, the required pressure is not created in the hydraulic circuit. Accordingly, the clutch disc is not released completely, which does not allow the required gear to be engaged. Leakage points are eliminated by replacing the rubber seals or by additional tightening the connecting nuts of the hydraulic circuit. - fracture or wear of the clutch release fork.

The problem is solved by replacing the plug. If it is not possible to replace the part with a new one, the old fork is restored. - runout of the clutch driven disc (more than 0.5mm) as a result of overheating or manufacturing defects. - breakage of the clutch basket spring petals or their deformation as a result of overheating (manual transmission gears are difficult to engage); - failure of the manual transmission input shaft bearing.

Another reason for unclear gear shifting may be a malfunction of parts and mechanisms in the gearbox:

- wear of synchronizers. Excessive wear of synchronizers occurs in those gears that are engaged more often, namely in the urban cycle these are first, second and third gears.

- manual transmission shaft bearings. The breakdown occurs mainly on cars with very high mileage or on cars that, by the nature of their activity, transport heavy loads. In both cases, manual transmission bearings are subject to increased wear. At the initial stage, bearing wear is manifested by the appearance of a monotonous howling sound from the box.

-destruction of gearbox gear teeth due to physical wear or manufacturing defects. When operating a vehicle with a manual transmission, the teeth of one of the gearbox gears may “fall out” with subsequent possible destruction of the gearbox.

Automatic transmission (gears are difficult to engage)

An automatic transmission is much more demanding in terms of accuracy in maintaining the oil level in it than a manual transmission. Both too low and too high oil levels are very harmful to her. Both of these can lead to serious damage. In both cases, oil foaming occurs. When there is a lack of oil due to the fact that the oil pump begins to capture air along with the oil.

When there is excess oil, it foams on the rotating parts, which in this case are immersed in it. Foamed oil compresses better and has low thermal conductivity. Therefore, if you operate a machine with such oil, the pressure in its control systems will be low. Which will lead to slipping of the clutches and their intensive wear.

Why might there be interruptions when engaging first gear?

The reasons for the breakdown of this unit worry many Kalina owners, since the failure of certain gearbox elements, due to which the gears are poorly engaged, can already be called a “disease”. And this disease, one way or another, is associated with a certain defect in the production and assembly of serial models of this car at the plant, which, unfortunately, was never eliminated by AvtoVAZ engineers.

In fact, there may be quite a few direct reasons why the first speed does not engage well, as a result of which even experienced specialists will not be able to immediately calculate the breakdown. What can we say about ordinary car enthusiasts?

Gear shift lever in Kalina

So what makes first gear difficult to engage?

- failure of the cardan or rocker - these faults often cause the inability to engage first gear;

- breakdown of the Kalina gearbox lever itself is also a common problem;

- loosening the clamp;

- the slots of the box have served their service life - they have worn out;

- A malfunction in the release bearing is a fairly rare breakdown encountered by car owners of this Lada model. Usually, when the release bearing breaks down, all gears without exception are switched on with an unpleasant sound, one might say a crunch, and additional effort must be made to shift;

- incomplete disengagement of the clutch - the solution is to replace it;

- failure of the gear drive control rod;

- in the gearbox, the screws securing the hinge or the speed selector rod lever have become loose, so they need to be tightened;

- oil seal failure;

- incorrect regulation of the gear shift drive;

- failure or expiration of the service life of plastic elements in the gearbox control drive;

Kalina gearbox disassembled

The first gear on the viburnum takes off when starting off

Chuciundrik, unlikely. Many people do. And the oil was changed. I drove almost 30 thousand km with the factory clutch. And there were no problems with engaging 1st gear. Then we rebuilt the gearbox and at the same time changed the clutch. Now I’ve been suffering for 3 thousand km. with switching on 1st on a warm engine. So my IMHO is the clutch.

But changing the oil is of course cheaper, so try it, it might help.

Guy on Kanaplin, fill the box with good oil.

This will greatly alleviate the problem, but unfortunately it will not completely remove it. I have a synthetic Shell 75-90 in my gearbox, but after standing in a good traffic jam, when the engine and gearbox are warming up well, the gears still start to “shut up” periodically :pardon: I don’t even know what the root cause here is - the clutch or the synchronizers: nea:

Added after 1 minute 25 seconds

most likely both :spiteful:

Viktor1111, what's the point of adjusting? No matter how you adjust it, the automatic will still return everything as it was. I could also understand the effect of adjusting the gear selection rod. When I overhauled the gearbox, only the main pair was changed. Then I adjusted the clutch cable and traction in every way. But nothing helped. Hence my opinion that the reason is in the clutch. It is in the clutch itself, and not in the cable.

Using this topic I would like to ask. No one will share a link where you could buy it either online or in person, but then only the Krasnodar Territory or Rostov-on-Don is a new type of checkpoint with GP 3.9 and reinforced shafts?

Check what kind of oil is in the box

Oil Lukoil TM-4 80W-85. Is this normal oil or is it better to change to another? I drove it for 4 thousand, filled it with a little more than the maximum.

check the clutch cable adjustment. The cable itself was adjusted two weeks ago. It turns out that they forgot to tighten the nut from the factory: spiteful: They save on everything. But the adjustment did not give anything in terms of changing the gear engagement: sorry:

Causes of reverse gear failure on Lada Kalina and ways to fix the problem

If all of the above manipulations did not lead to the expected result, and the reverse gear disappeared, then it remains to perform a few more testing techniques, namely:

- It is possible that a malfunction has occurred in the fastening mechanism of the gear selection unit. We check and fix it.

- The fixing bolt has received irreparable damage and does not perform its function. We change.

- The spring in the gearbox broke and the reverse gear disappeared.

Checking the condition of the push-button contacts of the blocker is quite simple: lift the cover of the gearshift lever and disconnect the plug. If the guess turned out to be correct, it will be impossible to turn on the ZH.

So, if the Kalina does not start, you need to remove the side wall from the left side in the passenger seat and visually check the ECU. The block must be dry. If it is wet, then it is filled with coolant - in this case, it will not be possible to restore the ECU, only replacement will help.

These faults are truly complex. Such problems must be solved by car service specialists, since they will need to remove the gearbox, disassemble it, find the cause of the breakdown, and then fix the problem. All this takes more than one hour and requires the use of special tools. It is irrational to carry out such repairs at home.

The first gear on the viburnum takes off when starting off

Lada Kalina. Jerking when starting off

| Possible causes of malfunction | Troubleshooting |

| Oiling of the working surfaces of the friction linings of the driven disk | Remove the driven and driving disks, wash the parts with white spirit or gasoline, and wipe the working surfaces of the disks and flywheel. Eliminate the cause of the oiling (replace the gearbox or engine oil seal) |

| The friction linings of the driven disc are heavily worn | Replace the driven disk |

| Settlement or breakage of torsional vibration damper springs, wear of the driven disk | Replace the driven disk |

| Driven disk deformation | Replace the driven disk |

| Loss of elasticity of driven disk springs | Replace the driven disk |

| Seizing of the driven disk on the splines of the input shaft of the gearbox, severe wear of the disk hub splines | If the hub splines are heavily worn, replace the driven disk. Apply CV joint-4 lubricant to the splines of the gearbox input shaft |

| Broken clutch diaphragm spring | Replace drive disc assembly |

| The power unit supports are faulty | Inspect the supports, replace faulty ones |

Causes of jerking and vibration when starting off

In most cases, the cause of the breakdown is a malfunctioning clutch.

Correct diagnostics saves time and money, so do not rush to immediately begin repairing the clutch and replacing failed parts. First, use simple tips to eliminate malfunctions that may be associated with the fact that the car jerks when starting to move.

First, warm up the engine to operating temperature. Secondly, make sure there are no problems with the power and ignition system.

If after the work done the jerking when starting does not go away, then use the list of clutch malfunctions and methods for eliminating them below.

Deformation of the driven disk.

Replace the driven disk.

Jamming of the driven disk hub on the splines of the input shaft of the gearbox.

Clean the splines from dirt, remove minor damage with a file. If the splines are significantly worn or damaged, replace the transmission disc and/or input shaft. Before assembly, apply CV joint grease to the splines.

Significant settlement or breakage of torsional vibration damper springs, wear of windows for springs.

Replace the driven disk.

Seizures on the working surfaces of the flywheel or pressure plate.

Replace the flywheel or clutch housing and pressure plate assembly (clutch basket).

Loose fastening of the friction linings of the driven disc, severe wear or cracks on the linings.

Replace the driven disk.

Loss of elasticity of the spring plates of the driven disk.

Replace the driven disk.

Driving style

You need to start with the obvious things. If you are an experienced driver, then you yourself understand perfectly well that the car can jerk when starting from a stop if the clutch grabs suddenly. That is, if you release the clutch pedal sharply, then it is quite obvious that the car should move jerkily. In this case there is no malfunction, and this situation is quite normal. All you need to do is change your riding style. At a minimum, you need to release the clutch smoothly and add more gas. It will come with time. In order for the clutch discs to engage on time, you need to “feel” for the moment of engagement in your car. To do this, you need to engage first gear and try to move away without pressing the gas pedal. This way you can easily feel the moment the clutch discs engage.

This cannot happen in cars with automatic transmissions, because there is no clutch pedal. In such cars, you just need to smoothly press the gas pedal and not “rip” the car from its place.

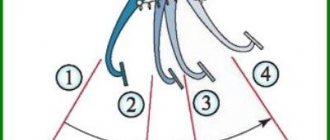

External and internal CV joints

The next reason why the car jerks when starting off may be the inner and outer CV joints. Internal CV joints transmit forces from the box to the car's axle shafts, and then to the wheels, which makes them quite important elements in the suspension system. Considering that these parts are systematically subjected to heavy loads, they may fail. The presence of a malfunction can be determined by the following signs: The CV joint turns when starting to move, there is play. Because of this, the car may jerk when starting from a stop. On the road, the CV joint may knock. Moreover, the road can be perfectly smooth. When turning, you can hear the crunch of the outer CV joints; when they wear out, they can also turn and create jerks when the car starts moving. Outer CV joints most often fail due to driving on bad and uneven roads. It follows that the first malfunction, due to which the car jerks when starting off, can be the CV joints. They are the first to be checked at a service station when a driver contacts a mechanic with a similar problem. Replacing these elements is quick, easy and most often does not cost a lot of money if we are talking about a domestic car and not a rare foreign car. Moreover, some car owners can replace the CV joints themselves; for this you will need a pit in the garage, a small set of tools and new CV joints, which are sold in almost any car store.

Removal and installation of gearbox Lada Kalina 1117 2004 - 2021

Tools:

Parts and consumables:

Note:

We carry out the work with an assistant on an inspection ditch or overpass.

1. Drain the oil from the gearbox as described here. Disconnect the wire terminal from the negative terminal of the battery. Remove the air filter as described here. Remove the starter as described here. We remove the clutch cable lead from the groove of the clutch release fork lever, following the instructions described here.

2. Disconnect the wiring block from the reverse light switch.

3. Disconnect the wire block from the speed sensor.

4. Using a 10mm wrench, unscrew the three bolts securing the lower clutch housing cover.

5. Remove the clutch housing cover.

6. Remove the right and left front wheel drives, as described here. Using a 13mm spanner, loosen the tightening of the nut of the coupling bolt of the clamp securing the control rod to the shank of the gear selector rod hinge. Then disconnect the transmission control rod.

7. Using a 19mm wrench, unscrew the nuts of the two bolts securing the clutch housing to the gearbox housing (which also secure the torque rod bracket), holding the bolts from turning with a head of the same size.

8. We remove the reaction rod with the bracket from the gearbox.

9. Disconnect the plastic throttle cable holder from the gearbox bracket.

10. Using a 13mm socket, unscrew the bolt securing the ignition coil bracket to the clutch housing.

11. Using a 19mm socket, unscrew the two upper bolts securing the gearbox to the cylinder block, which simultaneously secure the bracket with the holders of the throttle cable and wiring harness. The front bolt (in the direction of vehicle travel) is shorter than the rear bolt. We remove the bracket with the cable and wiring harness from the gearbox.

12. Remove the left front suspension brace as described here. We install adjustable stops through wooden blocks under the engine oil pan and gearbox housing.

13. Using a 19mm spanner, unscrew the nut of the lower rear mounting of the gearbox to the cylinder block.

14. Using a 19mm socket, unscrew the bolt of the lower front fastening of the gearbox to the cylinder block.

15. Using the “E-14” head, unscrew the two screws securing the front left support bracket of the power unit to the support.

16. Using a 15mm socket, unscrew the three nuts securing the bracket for the front left support of the power unit to the gearbox.

17. Remove the bracket.

18. Using a 19mm socket, unscrew the two outer bolts 1 securing the rear support bracket of the power unit to the gearbox, and using a 17mm socket, unscrew the middle bolt 2.

19. We move the gearbox away from the engine, removing the input shaft from the hub of the driven clutch disc.

20. When removing and installing the gearbox, do not rest the gearbox input shaft on the clutch diaphragm spring petals so as not to damage them. Before installing the gearbox, apply a thin layer of CV joint-4 lubricant to the splined end of the input shaft.

New Lada: New Lada Vesta engine intake system - what has changed? » Lada.Online

21. We insert the input shaft of the gearbox into the splines of the driven clutch disk and, orienting the gearbox so that the two guide pins fit into the corresponding holes in the clutch housing, and the standard pin of the clutch housing into the hole in the cylinder block, push the gearbox all the way into the engine cylinder block .

22. Fill the gearbox with oil as described here.

The article is missing:

Transmissions are not included. Appears when the engine is running - the main problems

As you already understand, we will talk specifically about a manual “box” and about shifting gears (or rather, not shifting) on it. I have quite a lot of experience in this area; I personally repaired cars such as VAZ 2114, VAZ 2110 (and the 10th family in general). To say that there are global differences between foreign cars, there really aren’t any! So if your speed is not cut off, then the reasons may be similar. In general, the article will be useful, at the end, as usual, there is a video...

A fairly large number of such questions come to me, especially from novice drivers of our VAZs! Especially with front-wheel drive, because in rear-wheel drive cars the lever was installed in the manual transmission itself. I want to answer everyone right away - the problem of non-inclusion may not always be cardinal! Often it’s a small matter, something just got loose or unscrewed from time to time, as a rule, this happens in 50% of cases.

Therefore, I will try to break the material into two large components - simple and complex faults.

I suggest starting with simple faults.

Gearbox linkages and rods

I remember I was “infuriated” on the VAZ 2114 by the fact that the gearbox lever was swinging from side to side like a “spoon in a glass”; I always wanted to make it stiffer, in some way. But there was only one way, to climb down the car and play with the scenes and rods. In principle, they can be released, tightened, the lever can be adjusted for tilt, etc. In general, I played around, but I noticed that if I press the lever too hard to the left, the ability to engage gear (first and reverse) disappears. This manifests itself when the car is not running, I’m already silent about the running engine.

Often the slides break, or they fly out of the fastenings, or the wear is simply enormous and they need to be replaced (this happens with high mileage). The very first thing we do is climb under the car and look at them.

Reasons for unstable engagement of first gear on Kalina and solution

If there is no voltage at the solenoid output, and the fuse is intact, there is a high probability that the solenoid itself has burned out.

Before engaging reverse gear, you should depress the clutch and wait 3-5 seconds, and only then can you shift.

Before you start drastic actions and disassemble “anything and everything”, check the gear shift lever itself, this may be the reason. The linkage and cardan are quite often the cause of this breakdown. The splines could also be worn out or the clamp loosened. This element is very reliable. But do not rule out its breakdown. How to determine what exactly has failed. To do this, you need to squeeze the clutch with the engine running and listen to the operation of the box. If, when you release the pedal, the characteristic sound (rustling) intensifies and the reverse gear on the Kalina does not engage, the reasons are in the bearing.

The clarity of gear engagement and the operation of the entire shift mechanism often worries owners of cars with a manual transmission. A common problem is that after starting the engine, one or more gears are engaged with great effort or not completely, it is not possible to change gears, at the moment of switching on, extraneous noise is heard, unnecessary vibrations appear, etc.

As you know, not only the movement of the car, but also its functioning as a whole depends on the operation of the gearbox (gearbox). Transmission malfunctions entail not only the inability to change gears, but also expensive vehicle repairs.

Using wire cutters, we pinch off the remains of the damaged wiring and install new wires, which we select with a similar cross-section. We recommend soldering the connecting node itself. Now let's isolate. Alternatively, you can use a new corrugation.

Through fuse F21, +12 Volts are supplied to solenoid L1, using switch S1 on the handle, the circuit is closed to ground, after which the solenoid coil is activated.

One of the most common problems is a burnt out lamp. To check this, remove the light bulb from the holder and connect it to the battery terminals with a short wire. If the light comes on, then the fault must be looked for at another point in the electrical circuit. During the operation of a car, various malfunctions can occur; there are breakdowns that are most typical for each car model. On the Lada Kalina, car owners quite often encounter a problem - the reverse gear of the manual transmission does not engage, and when such a defect appears, many car owners are prepared for serious repairs.

Drive and clutch cables

For rear-wheel drive models (VAZ 2101 - 2107), the gears are engaged hydraulically. That is, when you press the clutch, the fluid pushes the piston, which in turn pushes the clutch fork, which retracts the disc. For front-wheel drive models (VAZ 2108 - 2115), there is no hydraulic connection; everything is done here by mechanics, or rather by the clutch cable, which is connected to the pedals. If your slave cylinder leaks on a rear-wheel drive car or the cable breaks on a front-wheel drive car, the car will not engage in gear. The “fork” simply won’t work. We just check and replace damaged parts.

Common causes of problems with first gear on popular cars

Some car models, due to their design features, are more susceptible than others to problems with engaging first gear. In order not to cause a problem and avoid serious damage, they need to monitor potentially vulnerable components and have them serviced in a timely manner. Such cars are collected in the table below.

| Brand, model | Design flaws, weak points | How to prevent the problem |

| VAZ 2108-2115 | The gearbox supports (side and rear) often wear out, causing gears to fly out. Due to the large difference in gear ratios of 1st and 2nd gears, their synchronizers wear out more. Difficulty engaging first at speed is not yet a breakdown, but a characteristic drawback of VAZ front-wheel drive gearboxes, caused by an almost 2-fold difference in the gear ratios of 1st and 2nd gears. But it can develop into problems if you regularly engage the gear with force. A loose cardan of the rocker leads to unclear movement of the lever. |

|

| VAZ 2110-2112, Priora, Kalina | On a car with a rocker drive, the problems are the same as for Samara (weak synchronizers, wear of the cushions, the rocker). Added to these are problems with the gearbox torque rod, damage to which deprives the box and the rocker of a rigid connection. On a car with a cable-driven gearbox, there may be a problem with their tension. | |

| VAZ Classic (06,07,01) | Due to a fluid leak or incorrect stroke adjustment, the hydraulic shift drive does not completely disconnect the engine from the gearbox when the clutch is depressed. | Check the fluid level in the clutch circuit and the adjustment of the release mechanism, add brake fluid and bleed the clutch if necessary. |

| Lada Vesta | On modifications with a VAZ gearbox, the problems are the same as on earlier models: load on the 1st and 2nd synchronizers, unstable gear shift drive. | Gently shift into 1st and 2nd gears, use high-quality gear oil. |

| Volkswagen Passat (from b3 to b8) | The Volkswagen Passat uses a cable shift mechanism, which is sensitive to wear and requires maintenance. | Periodically (at least once every 10 thousand km) inspect the gear selection mechanism and its movement. Adjust cables and replace worn parts. |

| Chevrolet Aveo T250, Lacetti, Daewoo Lanos, Sens, Nexia | On the Chevrolet Aveo and a number of other models developed by GM, the weak point is the shift mechanism (“helicopter”) at the gearbox, which becomes loose. Because of this, it becomes difficult to catch the desired speed. | Monitor the “helicopter”, clean it periodically, and if noticeable play appears, change the switch parts. |

| Hyundai Solaris | The weak point is the clutch circuit. If there is a lack of fluid or air, the clutch is not fully depressed, which is why the first one is difficult to engage. The adjustment of the rocker cables may also go wrong. | Check the fluid level in the clutch circuit and the tension of the gear shift cables. Adjust the clutch drive and cables if necessary. |

| Mitsubishi Pajero | The selector switch on the automatic transmission (inhibitor) often turns sour. | Avoid heavy contamination of the gearbox, monitor its condition and clean it if it is heavily soiled. |

| Gazelle | On the Gazelle, first gear is difficult to engage due to wear on the clutch or problems with its drive. | Periodically (at least once every 10 thousand km) inspect the clutch drive for leaks. If necessary, adjust the drive and bleed it. |

| Opel Astra G (including automatic transmission and robot with 1 clutch) | The weak points on the mechanics are the lever linkage (there are plastic parts there), the “fingers” and the “helicopter” of the gear selection mechanism at the gearbox. Sometimes its settings simply go wrong and production appears. | Monitor the adjustment of the switching mechanism, adjust it in a timely manner or repair it if unclear movement or play appears. |

| Automatic transmission is sensitive to oil level and quality. | Monitor the oil level and change it regularly every 40–50 thousand km. |

Engine mounts

I personally have never had this happen, but many people write that this is a fairly common problem. Actually, the problem is this: the engine hangs on cushions, the gearbox is connected to it (manual transmissions, by the way, have their own cushions). It happens that the fastening breaks, or it unscrews. The engine or “box” may sag, the scenes may break, or they will hit something.

THEN there is another not very serious problem - these are pillows! If the programs don’t turn on, then we watch them.

These malfunctions, AS I THINK, ARE NOT PROBLEMS AT ALL! Anyone can identify them on pits or lifts, and this is done quite quickly. Personally, I came across rockers and cables, using the example of a VAZ, a clutch cable.

However, if you have checked everything, and the gears do not engage with the engine running. Then it’s worth looking at the box itself and the accompanying attachments. Let's move on to complex faults.

Release bearing

The clutch fork is connected to the release bearing; it is this bearing (under the influence of the fork and your foot) that presses the clutch petals and disconnects the disc from the flywheel and basket. If the bearing is “covered”, then this process becomes very difficult. To be fair, it is worth noting that the gears will still be switched on, but it will be very difficult! With crunching, whistling and other jokes. It's worth changing it. However, again you will need to remove the transmission

Clutch basket

Over time, the clutch basket fails on all cars with a manual transmission. Sometimes it’s due to wear and tear, sometimes the petals or the so-called “spider” break. Let me start, perhaps, with the “spider”, this is a mechanically fixed release bearing on several extensions (done like this on some VAZs), if the extension breaks, then it cannot be effectively fixed to the basket - the gears do not engage.

Next, the petals of the box break, or they become weakened. This leads to the fact that it is very difficult, almost impossible, to release the clutch disc. Therefore, the “speeds” do not switch – we just change the basket.

Well, the last wear and tear is the basket disk. It has a metal disk inside, and over time, especially from high mileage, wear forms there. When starting, the car will shake, and if the wear is very large, the gears may not shift.

In any case, we need to change the clutch basket.

What is a reverse gear locking mechanism?

If you decide to repair your gearbox yourself, we suggest you use our instructions. You must be prepared for the fact that any repair involves dismantling and disassembling the gearbox. Remember that if during disassembly of the gearbox you replaced at least one part, then you need to select an adjusting ring for the differential bearings.

Also ask a friend for help, because for removal you will need an assistant and, of course, a garage with a pit or an overpass.

If the fuse is intact, then you need to inspect the switch, which is located under the protective cover of the gearshift knob itself, at the bottom. Two wires must be removed and shorted together. If the speed starts to turn on, then the reason is in the switch.

Disconnect the connector from the stop switch and remove the entire harness. Remove the electrical tape from the corrugation and remove the wires. If the wire is broken or broken, you will notice characteristic signs.

We have already told you how to replace the wires leading to the solenoid. Now let's look at the rules for repairing the Kalina locking mechanism. Its malfunction makes it impossible to turn on the rear. To perform this type of repair, you need to look at the solenoid control circuit. It is given below.

Clutch disc and flywheel

In fact, wear occurs both at the clutch disc and at the flywheel itself. However, here, most likely, the gears will shift, but slip! You release the clutch pedal, but slippage occurs, that is, the car does not move, and it may jerk.

We look at the disk, maybe change it. We also look at the wear on the flywheel! If it is large, then we change it completely.

From experience I can say that our working VAZ 2111 was used mainly intercity, after 2 - 3 years the mileage was very high. The following symptoms began to appear: the gears turned on very poorly when the engine was running! We removed the manual transmission, looked at the basket - clutch disc - flywheel. And everything went for replacement, there was a lot of wear, and one petal on the basket was cracked. They even changed the release lever and the fork.

If the reason is not eliminated even now, then the problem is in the gearbox itself! It's worth taking it apart and looking at it

Synchronizers

If, when the engine is running, you do not engage gears, or shifts occur with VERY great effort and CRUNCHING! Then there may be a problem with the manual transmission synchronizers. Without going too deep, these are soft gears (usually brass or copper) that synchronize the shafts for soft and fast shifting. If they wear out, then shifting may disappear altogether! In general, we are definitely changing.

Manual transmission bearings

And the last thing that could be the bearings - although they are very strong in the box, sometimes they also “stick”. The box will work like a tractor, especially when warm.

In any case, if you have problems in the gearbox itself, then this is an expensive repair. It is also better to entrust it to professionals, because the gearbox is a very complex mechanism.

As you can see, there are quite a few reasons, but in fairness it is worth noting that mechanical transmissions are a fairly reliable unit; they themselves break down quite rarely, especially if you change the transmission fluid on time and pour a branded one of very good quality.

If the gears do not engage, then these are most likely “attached” problems, starting from the rockers and cables, ending with the basket, clutch disc and flywheel.

Now let’s take a look at a short video version of my article.

And that's ALL for me! I think the information will definitely be useful, read our AUTOBLOG.

( 17 votes, average: 4.47 out of 5)

Similar news

Automatic transmission (automatic) 4 or 6 gears? Old or new! I'M TELLING KA.

How to change the oil in an automatic transmission (automatic transmission) or variator (CVT). .

How much does it cost to change the oil in an automatic transmission? Detailed material.

Lada Kalina does not engage reverse gear: reasons, repairs

Let's look at repairing the main breakdowns found in Kalina cars. These breakdowns can be fixed at home if you have basic knowledge of gearbox repair.

In this case, if the Kalina does not start, only a spare or training key, or replacing the remote control will help. I would recommend trying to make adjustments, as well as checking the condition and level of the oil in the box, and if it has not been changed for more than 45,000 km, replace it.

If the check shows that there is current, then the starter will have to be replaced. If the latter makes clicks but does not rotate, then the starter motor has failed. If everything is the other way around, then the problem is with the retractor coil.

Why does the Lada Kalina jerk at low speeds and when starting off?

Many car enthusiasts have come across the concept of Lada Kalina twitching at low speeds. This malfunction can be associated with different car systems, but not every car owner is able to find this malfunction and fix it.

The video shows an example when an 8-valve engine operates “jerkily”, and what to do about it:

Causes of malfunction

General view of the engine

As in any car, in the Lada Kalina, jerking at low speeds is the first sign of a malfunction in one of the systems. Let's look at where the main problems arise:

- The fuel system and its components can cause the problem.

- The ignition system is associated with the fact that the car jerks at low speeds.

- Another reason could be the gearbox.

To more accurately determine the causes of the malfunction, it is worth considering each system and component separately.

Fuel system

The car jerks at low speeds - this may be due to the fact that the engine does not receive enough fuel mixture.

The problem may lie in the fuel system. In this case, you will have to examine several elements that are part of it.

Fuel rail and fuel injectors

Let's look at finding the problem step by step:

- The first place to look for a problem is the fuel rail and injectors . It is the poor condition of this unit that can cause the car to jerk when accelerating.

- The fuel pump, filter and lines can cause the driver to feel slight jolts at low speeds. For diagnostics, you will need to remove the fuel pump from the gas tank housing.

The mesh (strainer) in the fuel pump on a Lada Kalina is clogged

You can diagnose these components and parts yourself or contact a car service center.

Ignition

The ignition system can cause the car to jerk at low speeds. Particular attention should be paid to the ignition switch, in which the contact connections may fail.

A red glow plug removed from the engine

The second reason could be the spark plugs. Their serviceability and contamination can lead to the fact that the car will not only twitch at low speeds, but also work unstably in other ranges. To prevent this from happening, it is necessary to choose spark plugs with the required gap and recommended by the manufacturer.

Transmission

The most unpleasant consequence of the effect may be the gearbox. In this case, you will have to remove the gearbox, change the oil in it and add new oil to the level. And also carry out a complete disassembly of it for diagnostics. Thus, the reasons may be failed synchronizers of 1st and 2nd gears, wear of gears or shafts. Another problem can be bearings that are worn out.

Gearbox disassembled

Of course, you should trust the diagnosis of this unit to professionals at a car service center, but if possible, you can try to fix the malfunction on your own. Ultimately, when all else fails, they will always be happy to see you at the car service center.

Main causes of poor gear shifting

Next, we check the switch itself. For this purpose, we lift the handle cover and find the connector. It is connected directly to the switch. If a fault appears, it means that everything is fine with the switch itself and the manual transmission, it’s all a matter of electrical wiring or poor contact of the plug. After such a diagnosis, the paperclip will need to be removed; driving constantly with the contacts closed on the connector is highly not recommended.

If the Kalina does not start, the starter does not turn, the best way out of this situation is to charge the battery. But if the headlights are bright in high beam mode and are not going to dim, then you will have to look for the reason elsewhere.

On Lada Kalina cars there is an insidious reason that leads to the inability to engage reverse gear. It is interesting that this reason is purely electrical and has nothing to do with mechanics.

It is installed in the main mounting block. If the fuse is intact, then move on to the gear lever. If the fuse jumper is broken, replace it with a new one and see what happens. We try to engage reverse gear.

Lada Kalina, mileage 30 tons. I changed the oil a year ago to semi-synthetic. Previously, when it was cold, as soon as you start it, warm it up a little, turn it on 1st, it doesn’t turn on (the car pulls forward). It's gone now.

After mechanically closing the wiring, we try to turn on the reverse gear. If the problem is solved, leave everything as is. We're going about our business. And at the first opportunity we go to a car service and completely change the reed switch. It is impossible to operate a car with the wiring connected according to the specified diagram for a long time.

As for problematic switching when the internal combustion engine is running, then the list of the most common faults includes:

- lack of gear oil in the gearbox;

- problems with the clutch mechanism;