When the cold season sets in, the car owner often discovers that the air temperature control system in the cabin of the VAZ 2110-12 does not function normally. The stove either blows cold air or operates at maximum heat output. Both options do not allow you to create a comfortable environment inside the car; in addition, at low air temperatures, the windows may fog up, which makes driving unsafe. You can solve the problem yourself if you know how to do it.

Functions and main malfunctions of the interior temperature sensor

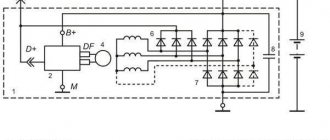

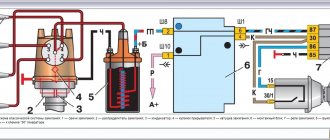

The heating system in cars of this brand is controlled by a signal method. The impulses come from the electrical control unit. Temperature is a factor affecting every system controlled by the unit. The essence of its work is to compare the indicators on the sensor (16-30°C) with the real heat intensity, which is measured by it.

When a temperature difference is detected, the motor turns on. Its function is to change the flow of warm air using dampers and fan speed. The cabin air temperature sensor is a thermistor or semiconductor resistor, which has a close relationship between thermal state and resistance. From the control electrical unit, voltage is supplied to this device through a resistor located inside.

One of the most traditional defects of this device, which operates on the basis of a semiconductor thermistor, is the discrepancy between the temperature of the external part and the resistance. To correct this discrepancy, you need to know the main features of its work. Typically, this defect manifests itself in a rapid increase in resistivity with small fluctuations in the degree of heating of the outer part.

In addition, there may be a break in the electrical circuit of the sensitive element of the converter itself, which is why you will have to buy a new interior temperature sensor. Periodically, a situation arises in which the thermal state of the device shell varies over a certain small range, and the resistance increases disproportionately with voltage. As a result, the heat calculated by the block turns out to be less than in reality.

In the event that the difference in temperature becomes significant, the command unit evaluates this as the arrival of cold air flow and reduces its amount, while simultaneously adding fuel.

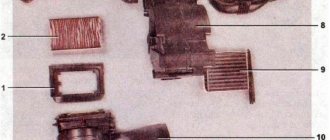

Checking the resistance resistor

The resistor of this car model has 2 spirals. The first has a resistance of 0.23 Ohm, and the second - 0.82. If both spirals are used at once, the heater electric motor is used at the first speed, and the second is turned on at the first spiral. The third does not need resistance, so it works without a resistor and is considered the most powerful. A lack of antifreeze can cause a malfunction, and a malfunctioning thermostat or pump will make the situation much worse. If the cause of the breakdown is a burnt out resistor, replace it with a whole one. You can purchase it at any car market or service center.

The fuse can also cause a breakdown. Despite the fact that it is as simple as possible to find, the problem is much more difficult to identify. We need a 25 ampere fuse F18. It is located in the main mounting block and is also partially responsible for the cigarette lighter and heated rear window. Check all circuits, perhaps the problem lies in a short circuit.

The cooling system of the VAZ 2110 is very capricious and unreliable, so it is strongly recommended to regularly check it for serviceability. This will contribute to a comfortable ride and allow you to be calm about your safety, because inappropriate conditions can cause an accident.

Replacing the interior temperature sensor

The VAZ 2110 interior temperature sensor is installed near the ceiling lamp. If this device malfunctions, it may need to be replaced. To do this, you must have access to the working mechanism. You can replace it yourself, or use the service at a car service center. Although there is no need to rush into a clear solution to this issue.

If a system malfunction is detected, the first thing you need to do is double-check how correctly it is configured. To do this, with the windows and doors closed, you need to set the temperature a couple of degrees higher than the current one. Then place the thermometer directly next to the converter. After a quarter of an hour, you should look at the readings again.

If there is a discrepancy between the thermometer readings and the set temperature, you can adjust the device using the adjustment screw on the controller. Turning clockwise increases its readings and vice versa.

But if you fail to fix the system, you should look for another reason. This could be a failure of the command unit, damper control micrometer, or temperature sensor. Of all the listed devices, the last one, although it is considered unreliable, is still the most accessible for dismantling, checking and possible replacement.

Since it is located close to the lighting shade and is attached to the drapery with four latches, removing it with a screwdriver is not difficult. Then you need to disconnect a couple of connection pads. Only after these manipulations will the device be dismantled. If you have a new device, install it in reverse order.

Although it is not at all difficult to recheck the old meter. Using the simplest multimeter at room temperature, you should measure the resistance between contacts 1 and 2. Then put the sensor in the refrigerator for a couple of minutes and measure again. If the converter is in good condition, the resistance on the ohmmeter should show a significant increase.

If there are no indicators, you can remove the cover and inspect the print board. There is a real chance of restoring the mechanism when checking the contacts.

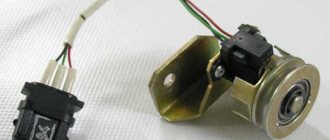

During operation of this device, minor breakdowns sometimes occur. For example, the interior temperature sensor “buzzes.” To eliminate this problem, you should know that this device is equipped with a fan, which helps to quickly and reliably determine the temperature level in the car showroom. A peculiar annoying sound appears if the lubricant dries out on the axis of the ventilated device. To eliminate the defect, it is enough to apply 2-3 drops of oil.

If you turn off the fan while keeping the sensor connected, the climate control will be quite rough. The stove will work even without a temperature meter. The sensor itself controls the air damper through the climate control unit.

In opposite positions of the temperature regulator of the control unit, the fan and sensor are off. Moving to the left gives cold, right - heating mode. In such cases, the damper will be either completely open or closed. The fan will not emit an unpleasant “buzzing” sound.

Basic climate control capabilities of the VAZ-2110

The purpose of a car air conditioning system is to automatically control the air conditioning system (the ventilation system in the absence of an air conditioner) and the heater inside the car. Let's look at the operation of the air conditioning system using the example of the Breeze control unit, which can be installed on all modifications of the VAZ-2110 family, regardless of the injection system and type of power unit.

The control unit (controller) for the climate control of the VAZ-2110 “Breeze” car is able to maintain a user-specified temperature in the cabin, referring to single-zone climate control systems. Controls the operating modes of the standard heater and air conditioner, guided by the readings of a temperature sensor installed near the car's backlight. To ensure objectivity of temperature monitoring inside the cabin, the sensor is equipped with a blower fan. The unit has the function of interpreting readings taken from both temperature sensors (interior and external), the ability to display (indicate) fault codes for climate control, ECM, power unit temperature and on-board electrical voltage on the display.

There are dozens of air conditioning operating modes:

- automatic maintenance of the interior temperature specified in the settings;

- semi-automatic mode of operation of the climate system;

- switching to manual mode for controlling the internal microclimate;

- control of the operation of the car air conditioner and furnace fan.

Messages 5

1 Topic from mars.rus 2015-01-04 20:04:53

- mars.rus

- New member

- Inactive

- Registration: 2013-12-12

- Messages: 25 Thanks : 3

- Car: VAZ 21102

Topic: How to check the interior temperature sensor?

Hello. The heater in my car was not working properly. Car 2001 8kl. In general, from the max position, when switching back to the direction of decreasing temperature, the damper began to rotate only when the handle reached the 20-degree position. And the damper immediately lowered to the end. And the same in the opposite direction. And before that, in general, the damper only moved either all the way down or up when switching from max or min. Between these intervals, when switching, it did not react at all. As a result, by disconnecting the contacts from the ceiling sensor, everything began to be regulated. I blame the ceiling sensor. Although it works, it buzzes in all positions of the handle except min or max. Maybe someone else can confirm my guesses or give a different opinion, maybe there’s something else I need to look at? Thank you.

What to do if the stove does not turn on in any speed mode

If the VAZ 2110 stove unit does not work, the problem lies in the operation of the electrical network, since its electric motor is quite reliable and rarely fails. Before work you need to prepare a set of tools:

- Tweezers for removing fuses.

- Screwdriver Set.

- Chain tester.

- Jumper with contacts.

- 12 V indicator lamp (control).

- Wooden stand.

When working with wires, you may need pliers, wire cutters and other standard tools from an auto electrician's kit.

Stove fan

Structurally, the fan consists of a DC electric motor with a commutator-brush assembly and an impeller mounted on the electric rotor. motor. The electric motor is powered from the vehicle’s on-board network. There are several modes of fan operation, the difference between which comes down only to the rotor rotation speed, and this is realized by inserting a resistor into the power supply circuit of the electric motor.

The fan operating mode is set using a handle located in the heater control unit on the center console. Initially, on the VAZ-2110, this handle was part of the design of the SAUO controller, but functioned separately from the controller itself. Later, the ACS added an automatic fan control function (position “A” on the handle), using which the controller regulates the rotation speed of the electric motor in order to maintain the set temperature.

The electric motor used in the design of the VAZ-2110 fan is simple, but it has “weak points” - the commutator-brush assembly and bearings. Wear of these elements causes incorrect operation and complete inoperability of the fan. Short circuits and winding breaks in the stove drive are rare, but don’t forget about these breakdowns either.

Symptoms of failure. Heater components that affect fan operation

Signs of a malfunctioning stove fan are quite obvious and impossible not to notice. Common symptoms of failure:

- Increased noise, grinding noise during operation.

- Significant reduction in air injection efficiency.

- The fan does not turn on.

- Spontaneous change in the rotation speed of the electric motor.

- It can be determined by ear that the electric motor is operating under heavy load.

In some cases, such consequences result from malfunctions in the power supply and fan control circuits, so you should check them first. This applies to:

- fuse (blowout is the cause of complete failure of the electric motor);

- resistor (if it is faulty, some speed modes of the electric motor stop working);

- controller (the knob for switching fan modes is part of its design, so malfunctions of the automatic control system affect the functioning of the electric motor);

- wiring terminals of the power and control circuits (oxidation, damage to wires is one of the reasons for a malfunctioning electric fan).

If diagnostics of these elements shows that they are in good working order, it is necessary to dismantle and repair the fan itself. But it can be diagnosed first.

Fan check

A check is done by directly powering the electric motor from the battery (we lay wires from the battery terminals and connect them to the power terminals of the motor) - operation under load, difficulty in gaining rotation speed, squeals and squeaks indicate wear of the drive components and the need to replace them. But if, even with direct voltage supply, the electric motor does not start, it is most likely that it has burned out or the windings have broken. Such faults are difficult to fix and it is easier to replace the entire unit.

Typical breakdowns

It happens that the stove on a VAZ 2110 does not heat well, does not allow you to fully control it, and so on. Let's look at the most typical breakdowns for this unit.

- The ability to control is lost, that is, the temperature of the stove on the VAZ 2110 is not regulated;

- The ceiling sensor refuses to work;

- The device does not work for heating, the stove blows cold air into your VAZ 2110;

- The flow of hot air to the feet or to the side windows is poor;

- The coolant level drops;

- The heater fan on the VAZ 2110 does not work properly;

- The stove turns on and heats up, but this is accompanied by a lot of noise.

How to check the heater damper micro-reducer?

To check the damper drive, you will need an ohmmeter for measurement. In old SAUO controllers, the resistance at the minimum position of the blue dot should be from 800 to 1200 Ohms, and in new controllers - 3.5-5 kOhms. To check, you will first need to set the degrees to minimum and wait 15 seconds. Disconnect the controller connector and, with the engine running, measure the resistance between contacts X1.4 and X1.1.

At maximum temperature (red dot of the left handle), the multimeter should show 3.2-5 kOhm if the controllers are old and 1.2-1.6 kOhm if there is a new controller (1323.3854). If there is no resistance or if it does not change, it reports that the micro-gearbox shaft position sensor is faulty ( the tracks are erased ) or the ACS itself has simply failed and no voltage is supplied to the micro-gearbox.

To replace the microdetector, check the fan or repair the heater radiator, you will have to disassemble the stove.