Normal operation of a car engine is possible only if all its constituent elements, as well as the main components of the car, are in working condition. One of the main components of the ignition system in domestic “tens” is the starter device. You can learn more about how to repair a VAZ 2110 starter with your own hands and in what cases it needs to be carried out from this material.

How does the starter of the VAZ “Ten” work?

Domestic “tens” are equipped with a starter unit with number 5702.3708, which is essentially a DC electric motor. One of the main components of such a device is a traction relay, as well as a planetary gearbox. The motor is excited by the action of permanent magnets installed inside the unit structure. The body of the mechanism itself is made of steel; it is connected using two pins to the covers of the device.

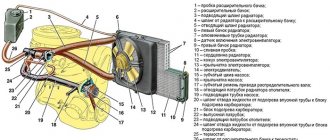

Designation of the component elements of the device

Also, the design of the starter unit implies the presence of an armature and a stator. The armature is designed to carry out rotation in metal-ceramic liners, as a result of which the rotation is transmitted through a gearbox to the device drive. When the driver turns the key in the ignition, voltage from the car's battery is transferred to the relay windings. As a result of the influence of the magnetic field, the armature is first retracted, causing the gearbox gear to mesh with the flywheel. Accordingly, this leads to the closure of the contact bolts inside the structure.

Then the armature itself remains in the same state, it is fixed in this way with the help of a holding winding. When you turn the key in the ignition switch, this winding is de-energized. Ultimately, this contributes to the fact that the armature returns to its original position (the author of the video is Avtoelectrica HF).

Characteristic malfunctions of the mechanism

If the device stops working, the reasons may be:

- Low battery. Before repairing the VAZ 2110 starter, you need to make sure that the battery is fully charged and operational.

- The appearance of oxidation on the wires, as well as the terminals of the mechanism. As a result, the contacts can no longer transmit current, and therefore the operation of the starter device will be impossible. This malfunction also includes poor fastening of the wiring, in particular the lugs. In this case, in order to get rid of the malfunction, you will need to clean each contact, as well as the terminals. If during the diagnostics you notice that there are loose elements or clamps on the mechanism, then they should be secured as much as possible. In addition, the connecting components will need to be treated with Vaseline or grease, this will further prevent oxidation of the contacts.

- Failure of the traction relay. Due to the inoperability of this device, short circuits may occur in the unit, which will lead to a complete stop of the mechanism. A failed element will need to be replaced. The reason may lie in a broken electrical circuit.

- Failure of the traction winding - such a malfunction can also cause short circuits in the system.

- Failure of the contact part of the ignition switch. Such a malfunction, as a rule, cannot be repaired, therefore, when it occurs, the contact group must be replaced.

- Anchor failure. Its malfunction may manifest itself in the fact that this element cannot scroll as a result of complications during rotation. For more accurate diagnostics, this component should be dismantled and the efficiency of its rotation should be diagnosed. If the diagnostics confirm a faulty armature, then the device must be replaced (the author of the video is the stas di channel).

Instructions for repairing and replacing the device

Replacing a VAZ 2110 starter and repairing it looks like this:

- Disconnect the battery and disconnect the wire plug from the relay. Dismantle the wire itself, which o.

- The starter mechanism should be disconnected from the engine; to do this, unscrew the nuts that secure it.

- If you are making a replacement, then at this stage the device can be dismantled and replaced with a new one. If you decide to repair, then move on.

- On the relay itself, unscrew the nut, and then disconnect the traction element from the screw. The relay is removed; to do this, you also need to unscrew the two clamps.

- Then the anchor is dismantled from the seat; to do this, the element should be slightly lifted up.

- Remove the pins, and then remove the starter cover. The cover is dismantled first with the drive and gear element, and then with the brush assembly and their retainer, which is located next to the commutator.

- Next, the gear is removed from the anchor shaft, and the anchor itself is then removed. Having done this, you can remove the gears from the gearbox. If they show signs of damage or defects, the gears should be replaced.

- The gear component is removed from the cover. Check the quality of the seal and replace it if necessary.

- Using a mandrel, it is necessary to dismantle the restrictive ring; it is located directly on the locking ring, after which the drive and other elements, including supports, levers and washers, are dismantled. Each of the elements, if necessary, must be replaced.

- After dismantling the brushes, you need to check them. If signs of wear are visible, the brushes are replaced. All failed components are replaced, and the starter is reassembled in the reverse order.

Causes of frequent problems with the starter

As practice shows, the most common problems with the starter appear in the electrical part.

When your car won't start, the first thing you need to do is check the battery. The starter is powered only from the battery. If the battery is discharged and does not produce the required voltage, then even clicks will not be heard. If your car has a tester, you can check if the battery charge is correct. Simply turning on the headlights will help replace it; an experienced driver can understand the degree of dilution of the battery based on the lighting power. You can also twist the fasteners on the battery terminals if you suspect low voltage.

Solenoid relay

Once behind the wheel, the driver inserts the key and turns it, the fuel pump starts working, the dashboard lights up, but when turning further, the pump and the panel turn off, and the starter does not turn. In such a situation, the solenoid relay is most likely to blame.

First of all, you need to check whether there is voltage going to it. If it does, then it’s worth checking the lock itself or the alarm system, which may close the circuit. If all the elements work separately and do not start together, then the starter does not turn due to the solenoid relay.

Sticking contacts

In the case under consideration, the VAZ 2110 injector does not turn the starter, it starts hard and makes clicking noises. That is, first it clicks inside, and then it starts to turn the engine. The first thing you should do is look at your contacts. It’s better to start with the battery, where the cause is oxidation of the terminals.

If the VAZ 2110 does not start and the starter does not click, then inspect the mass and the device itself, because they also tend to oxidize. There is also a proven method: simultaneously turn the ignition key and knock on the relay with something hard. If the car starts, then the problem is that the contacts or coins are stuck. Then it is better to purchase a new relay.

Starter motor brush wear

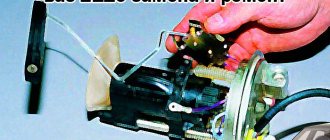

Electric motor brushes play an important role in the operation of the starter. You can inspect the condition by removing the relay, stator, armature, and unscrewing the tie rod nuts. Then you need to remove the gear from the shaft, unscrew the screws on the back cover and remove it.

Carefully analyze the condition of the winding and commutator. No breaks or burns should be noticeable. For performance, it is recommended to clean the commutator and armature shaft journal. If the brushes are worn out, they should be replaced as an assembly.

The overrunning clutch has failed

A cold engine starts without the slightest problem. You are driving quietly, stopping somewhere - to go to the store or for other matters. You return a few minutes later and are faced with a problem: the starter clicks, but refuses to work. And only after the engine has cooled down the car starts.

The first culprit in this situation is the overrunning clutch (popularly called Bendix, from the name of the well-known manufacturer of this part). It is better to replace it with a gearbox.

But you check and there is no malfunction? The next line is the wires going to the battery. Examine them carefully. It is quite possible that replacing the wire will solve all the issues.

There may be another situation: while on the road, the radio starts to turn off spontaneously, despite your attempts to turn it on. Having stopped to look and turned off your VAZ 2110, you soon discover that you cannot get the starter to crank. We checked the battery, everything is fine, but the car, which previously started normally, suddenly struggles.

You start pushing, and it works, everything works again. Almost certainly the problem is in the Bendix.

When the immobilizer is a hindrance

The engine stalled unexpectedly, the starter refuses to turn it, and it also won’t start with a “push.” The battery was checked - charged, serviceable, terminals clean and in place.

However, your immobilizer is working, and most likely the problem is there. The protection is triggered, the engine is silent. It is necessary to tow the VAZ 2110 to a car service center for diagnostics.

Faulty injector

The standard version of the VAZ 2110 is not equipped with injectors, but they can be supplied separately. Drivers choose these devices for many reasons: reduced fuel consumption, no need to warm up the engine in cold weather, increased power characteristics.

If the starter is not working well, then you need to check the injector, which may be acting up due to bad gasoline. This is the only drawback of the injector - it requires high-quality fuel. It is also worth checking whether the connection diagram is followed.

Each of these reasons requires appropriate repairs:

- Checking wire connections;

- Cleaning bolt connections and tightening them;

- Replacing the traction relay eliminates the problem of armature rotation.

In order to repair electrical systems of a car, you must have certain knowledge and skills. It is better to replace the VAZ 2110 starter or partially repair it in an inspection pit or lift.

Starter repair for VAZ 2110, VAZ 2111, VAZ 2112

Welcome! A starter is a very necessary thing in a car; thanks to it, the engine of the car turns on and starts, but recently starters have begun to be counterfeited and made of poor quality, and therefore many car owners, when installing a new starter, after a very short period of time go back to the service center and replace it with a new one , although you don’t have to change it at all, but simply repair it thoroughly yourself and at the same time put lubricant in the gears, which is so little put at the factory where new starters for cars are made.

Note! To repair the starter, you will need to take from the following tools: Keys, namely wrenches, sockets, sockets, in addition, expansion pliers will be required and a screwdriver (It all depends on what exactly you will change in the car, if there is only one solenoid relay, for example, then In this case, you won’t need anything else except wrenches)!

Summary:

When should the starter be repaired? If your car stops starting or starts poorly, then this indicates that the starter may have become unusable, but besides it, the ignition switch can also cause problems and the car will not start or even the same wires, so it’s clear to say that it’s the starter it didn’t break so easily, but still the most common reasons are when something clicks when you turn the key and the car doesn’t start, or when the starter spins but does it very weakly and the engine cannot start due to this (In this case, the battery is also may be discharged), and the last thing is when, when you turn the key, you hear extraneous sounds (grinding of metal and the like) if you hear such sounds, then we do not recommend using the car in the near future, otherwise in the future you will need to change the crown of the flywheel You will have to remove the flywheel itself from the car to do this.

Causes of failure

A starter is a unit that is used to start the engine. Essentially, this is an electric motor that rotates the engine flywheel through a clutch until the flammable liquid ignites and the engine starts.

There can be many reasons for replacing or repairing the starter:

- a grinding noise in the engine compartment when turning the ignition key to start (bendix malfunction or flywheel wear);

- clicks when turning the key (retractor relay);

- The engine is difficult to turn (rotor brushes are worn out).

These are the main reasons; an electrician will tell you in more detail during disassembly and diagnostics. Basically, it can be repaired, but if reasons such as replacing the armature arise, then it is advisable to replace the entire starter assembly, but the problem arises: how to remove the starter on a VAZ 2110?

Many motorists have encountered situations where the starter in a car does not turn. You can read about possible reasons in the following article: https://vazweb.ru/desyatka/elektrooborudovanie/ne-krutit-starter.html

How to repair the starter on a VAZ 2110-VAZ 2112?

Note! First, the starter is removed from the car and then checked for functionality. You can find all this information in the article entitled: “Replacing the starter on a VAZ”, but in addition, check out the video below, which talks in more detail about How can you check the removed starter for functionality?

Disassembly: 1) First, unscrew the nut indicated by the blue arrow and remove the wire behind it indicated by the green arrow, thus after this operation the solenoid relay can already be removed from the car and no wires will interfere with this (But regarding the removal of the relay, a little We’ll explain everything later, since there are still a couple of bolts to unscrew, but if you need to change it, then immediately skip all the points and read carefully point number 3 in which everything is described), now unscrew the two nuts (Indicated by red arrows ) tie rods that hold the stator and then disconnect it from the front cover.

2) Now remove the three planetary gears of the gearbox from the starter (All of them are indicated by arrows), but you can only have three or four of them, if you still find four gears, then first pry off the very central one with a screwdriver and then remove it , then the remaining three and when they are removed, check their condition; the gears should not have chips, scuffs, signs of corrosion or other damage, otherwise they are replaced with new ones.

Note! After removing all the gears, there will be one more single and large one, called the ring gear, it should also not have chips or other defects, it can be removed either separately, for this you just need to pry it off with a screwdriver (see large photo), or together with the drive shaft, drive lever and lever support, for this you need to pry it off with the same screwdriver, but not by the gear itself, but by the support (see small photo), if you suddenly completely removed the entire drive, then first of all inspect it and make sure that the teeth on the drive are not painted in any other color and that there are no nicks or deformations on them; minor defects are eliminated with a diamond file or an abrasive stone; if necessary, replace the entire drive or the entire starter with a new one!

3) Regarding the removal of the solenoid relay, it has two bolts that secure it, they are also indicated by red arrows, so if you want to remove it, then unscrew these bolts and then, carefully pulling the relay (indicated by the blue arrow), remove it from the starter and by the way, about checking it, connect an ohmmeter to the terminals of the traction relay and then press the armature inward all the way, while the ohmmeter readings should be close to zero, if this is the case for you, then the relay is working properly and does not require replacement.

4) Then take a wrench and a hammer and, using them, knock down the travel limiter ring (see photo 1, do not forget to place some kind of piece of wood or a piece of thick rubber under the drive so that it does not deform), as soon as the ring is knocked down, using a screwdriver, remove the other retaining ring from the groove and then remove it and then remove the travel stop ring from the shaft (see photo 2), then remove the drive from the shaft and when it is removed, use expanding pliers to pry up the retaining ring and its remove (see photo 3) and thereby you can disassemble the drive and replace the parts worn out in it, and finally, the remaining part with the shaft can also be disassembled if necessary, to do this, remove exactly the same retaining ring (see photo 4) and remove the thrust washer from the shaft, as well as the shaft support, and so on.

This is interesting: Adjusting the carburetor Java 638

5) Next, using a flat-head screwdriver, pry and thereby remove the front cover (It is indicated by a green arrow) from the stator and by the way, if when removing the stator the same central gear remains seated on the shaft, which is still indicated by the red arrow, then you remove it, Otherwise, you won’t be able to remove the cover, it will rest against this gear (Don’t forget to check the gear, if traces of deformation are found on it, then replace it with a new one).

6) And finally, unscrew the two screws securing the stator cover (see photo 1) and then remove it, as soon as the cover is removed, using a screwdriver, pry up the starter brush assembly (see photo 2), then remove the one located behind it the front shaft support (see photo 3) and the thrust washer as shown in the fourth photo and at the end, grasping the shaft (It is also indicated by an arrow for clarity), overcoming the force of the magnets, remove the armature from the stator and after removing it, inspect its commutator and winding , traces of charring and various kinds of deformations should not be found on the armature windings, otherwise the armature is replaced with a new one, but if everything is in order with the winding, then proceed to cleaning the armature commutator, namely, if it is very dirty, then using sandpaper (Nulyovka), clean it, then rinse the starter armature with water in which the detergent will be diluted and at the very end, when the work has already been done, clean the armature dry with a clean rag from water and dirt and blow it with compressed air (Compressed air can be supplied parts such as compressor, tire pump and so on).

Note! There is something else we wanted to warn you about: when the brush assembly is removed, check its brushes, the height of which must be at least 3.5 mm, and the brushes must not have damage or other types of deformation, except for the brushes of the gearbox part (These include all gears) and the drive with white spirit, in addition to all this, rinse and then you can begin to reassemble the starter and install it on the car!

Assembly: During assembly, apply grease to the gearbox parts, dip the drive in engine oil and wait until it drains from it, lubricate the bushings in which the armature and starter drive shafts rotate and also the screw splines of the drive with engine oil, if you removed the brushes to replace them, then they can be installed in their place using a special mandrel, or if it is not there, then proceed in the following way, namely, secure the brush assembly to the cover with two screws, then lubricate the end of the armature shaft with two drops of engine oil and insert everything (Four ) brushes, into the corresponding brush holders, but do not install the brush springs in their places and then put the brush assembly on the armature commutator, then use pliers to open the outer stops of the springs of all brushes (see photo 1), then insert the springs into these places (see . photo 2) and holding each spring separately (First one, then the second, and so on) there with a screwdriver (To prevent it from flying out), bend the spring stops with pliers, install the other springs in their places in the same way and insert the armature into the stator ( When you insert it, do everything carefully and try to ensure that the armature commutator does not get out of engagement with the brush assembly, otherwise you will have to re-install the brush assembly), while the brush assembly and cover should already be on the anchor, assemble all the remaining parts in the reverse order removal

Additional video: You can clearly see the starter repair procedure in the video below:

Note! The video above does not show the repair of the Bendix, also known as the drive, but only shows partial disassembly of the starter. For more details on how to remove and disassemble this drive, see another video, which is also located below:

Assembly

You can install the brush assembly on the starter armature commutator using a special mandrel or tool head of a suitable size and shape. If they are missing, brushes can be installed without these devices. For this:

1. Using two screws, secure the brush assembly to the rear cover of the starter.

2. Lubricate the end of the starter armature shaft with two drops of engine oil.

3. Insert four brushes into the corresponding brush holders. Without inserting the brush springs into the brush holders, we put the brush assembly on the armature commutator.

Tens starter device

The VAZ 2110 is equipped with a mechanism model 5702.3708, which is a DC motor containing two main components: a traction two-winding relay; planetary reductor. This motor is excited by permanent magnets. They are attached from the inside of the starter housing, which is made of steel. The specified body is connected to the covers (fastening is done using two studs).

The starter design includes an armature and a stator. The armature shaft rotates in cermet liners, and from it the rotation goes through the planetary mechanism to the drive. When the starter starts, the car battery transmits voltage to the relay coils. The armature, experiencing the influence of a magnetic field, is retracted, after which the planetary gear gear engages with the flywheel, which causes the contact bolts in the device to close.

After this, the armature remains retracted, and its fastening is ensured solely by the holding winding. When the driver turns the key in the lock, de-energization of this winding is noted. This causes the anchor to take its initial position.

Checking the functionality of the VAZ 2110 starter - why doesn’t it turn?

Before we begin disassembling the starting system mechanism of interest to us, we should make sure that it does not work precisely because of its malfunction. The check is performed as follows:

- We turn the gear in the direction of rotation of the armature. It should not turn in the opposite direction. If such reverse rotation is present, this indicates a faulty starter.

- We check the ease of movement of the device coupling along the shaft (use a screwdriver). With a normally functioning mechanism, the coupling moves without the slightest difficulty.

Using the “lighter” wires and the battery, we analyze the serviceability of the starter. To do this, we connect the negative terminal (black wire) to the starter housing, and connect the traction relay through its control cable to the positive terminal (red wire).

In cases where the relay operates normally, the drive clutch extends and a characteristic click is heard. If it does not turn on, you will have to disassemble the starter and replace the traction device.

Also, the starter of a VAZ 2110 car does not turn when its anchor does not work. Checking the armature is done as follows: remove the cable from the relay (from its output); connect the specified cable to the contact bolt. If the armature is in good working order, its rotation frequency should be at least five thousand revolutions per minute. If the frequency is lower, the starter does not operate.

How to disassemble and repair the VAZ 2110 starter?

It is impossible to troubleshoot the starter without removing and disassembling it, so it has to be removed. The diagram of this procedure is given below: remove the battery terminals; We disconnect the cable connector from the relay; remove the wire marked “plus”; disconnect the starter from the engine by unscrewing the mounting nuts.

The mechanism has been dismantled, now you can begin disassembling it by performing the following steps:

- Unscrew the nut on the relay and disconnect the traction device from the contact bolt;

- remove the relay by unscrewing the two clamps;

- remove the relay armature from the lever (you need to slightly lift it up);

- remove the starter cover (it is necessary to remove the studs).

After all these operations, it becomes possible to remove the mechanism cover: first, it is removed as an assembly with the drive and gearbox on the drive side, and then with the brushes and their holder on the commutator side. Now you can remove the gear from the anchor shaft and take out the anchor, and then dismantle the gearbox gears. If they have defects, the gears need to be replaced (it is because of them that the starter often does not turn).

Next, with some force, we press on the drive gear and remove the gearbox from the cover. After this, remove the support from the lever (it is equipped with a sealing element) and check it for hardening and deformation. Very often the starter does not turn because of such little things. Just install another gasket, and you will forget about the inoperability of the starting system for a long time.

At the next stage of disassembly, using a mandrel, remove the restrictive ring from the retaining ring, then remove the drive, the lever ring and the lever itself with the washer and driver, as well as the lever spring. Now you can remove the drive shaft support, gear, and seal ring. Replacing the last of these parts is necessary in cases where it has lost its elastic characteristics (or has obvious signs of deformation).

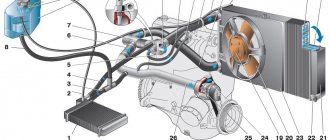

Dismantling

To disassemble, remove and repair or replace the generator, you will need to do the following.

- Drive onto an inspection hole or overpass to have access to the bottom and engine compartment.

- Remove the battery, otherwise it will not allow you to get to the nut that holds the generator you are looking for.

- Next, the same nut and adjustment bar are removed. Here you will need a 17 mm wrench. Use an extension cord. This will make the task easier; you will have to apply less force to unscrew the fastener.

- In the engine compartment, remove the shield that performs dirt protection functions.

- Now the drive belt is removed and the wires are disconnected.

- Be sure to remove the protective cap and use a 10mm wrench to unscrew the nut that holds the tip and positive cable of your battery.

- There is another nut on the fixing bracket, which will also have to be unscrewed.

- That's it, you can remove the generator. Just remember to pull out the long bolt first.

- When removing, keep an eye on the buffer sleeve. It won't be good if you lose it.

Dismantling work

This completes the procedure for removing the generator. You can proceed with partial repairs or complete replacement of the unit.

Belt

Often, the solution to a poorly functioning alternator is simply adjusting the belt.

Belt

- For the device to work effectively, it is necessary to ensure normal deflection of the belt;

- The deflection size should be 6-10 millimeters with a force of 98 N or 10 kgf;

- To adjust or replace the belt, you need to move the generator slightly to the side, towards the cylinder block;

- By rotating the adjusting bolt, you can adjust the belt tension.

If this measure does not help, you will have to pay attention to the voltage regulator and brushes.

Brushes and regulator

It is not recommended to repair the generator brushes, as well as the voltage regulator if they are worn out.

Experienced specialists advise purchasing a complete unit that includes both elements. Replacement is completed in a matter of minutes.

Brushes

But we will definitely tell you how you can change the brushes on your car’s generator with your own hands.

- Disconnect the negative terminal from the battery and remove the battery.

- Remove the generator following the instructions above.

- You can replace the brushes without removing the generator, but this causes certain difficulties. It is much easier to remove the unit.

- Remove the cover, which is the protective casing of the generator.

- The wires and the generator itself are disconnected from the brushes. To do this, simply unscrew a couple of bolts.

- On the right side of the dismantled device there is a nut that can be unscrewed by 13 millimeters with a spanner.

- Now lift the voltage regulator lever, which will allow you to get to the brushes.

- Using new brushes, install them in place of the old ones and reassemble the assembly in reverse order.

Disassembly and repair of brushes, armatures, bushings and starter assembly dozens

The brush holder is removed from the commutator side by removing two screws. The pressure springs and the entire brush assembly should be inspected, paying special attention to its stoppers. All deformed elements are immediately replaced. Installing new brushes is a simple process, so there is no need to describe it in detail.

But you may have to “tinker” with the armature, since it is often the reason that the “ten” starter does not turn (and replacing the bushings can take a lot of time). It is advisable to lightly grind the armature commutator, and also turn it on a lathe if its roughness is high. The armature is replaced when the runout in relation to the axles of its core is more than 0.08 millimeters. It is also recommended to install a new anchor if there are large nicks and burrs on it.

It may be necessary to replace the bushings (the shafts rotate in them), which are located on the drive side in the cover of the trigger mechanism we are describing. Installation of new bushings is recommended if there are holes on them and if they are heavily worn. Reassembling the starter is done in reverse order.

Replacement and repair of VAZ 2110 starter

The VAZ 2110 starter is a powerful DC electric motor. If used incorrectly, the unit may be damaged or burn out. One example is holding the key in the “start” position for a long time.

It is quite easy to determine if the starter is faulty - it does not turn, it clicks when you try to start the engine, or it simply does not work. This article details the process of removing and installing a new component. In some cases, the starter can be repaired - a separate section is devoted to this process.

This is interesting: Design and adjustment of the VAZ 2107 carburetor

Design

The starter is a fairly powerful DC motor operating at 12V. It also includes a retractor relay, which helps the gear on the starter engage with the flywheel ring.

Below in the picture you can see in detail all the details of the VAZ 2110 starter.

Purpose of the starter and its location

The “ten” has a small, but quite powerful 4-band electric motor, which is responsible for the primary rotation of the crankshaft. Without the participation of an electric motor, it is impossible to ensure the required crankshaft rotation speed. We replace this unit, since for a gasoline engine with an average cylinder capacity, 3 kW of energy is enough to start.

The starter supplies energy from the battery; it is a DC motor. Receiving voltage from the battery, the motor power is increased by four brushes. They are the main elements in any car starter. If necessary, the brushes can be replaced. If the starter meters are faulty, they can be purchased separately and replaced. But to do this, in any case, you will first need to remove the starter.

What is a starter

The VAZ-2110 is equipped with a starter with a gearbox, which has one advantage - it consumes less current. It is capable of ensuring rotation of the crankshaft even with a weak battery charge. Thanks to this feature, your car will start even in conditions where other models refuse to work. However, with prolonged use, the electric motor with gearbox may fail for no apparent reason. In this regard, starters without gearboxes are more advanced - they are easy to repair due to the simplicity of their design.

Starter replacement

You can remove the starter yourself, as the procedure is quite simple. You need to start by preparing the tools for work.

Required tools:

- Extension.

- Handle with ratchet.

- Socket head for 15 and 13 mm.

Attention! Removal can begin after disconnecting the negative terminal from the battery. This applies not only to dismantling the starter, but also to any other work related to electricity.

To make the process easier, you need to remove the air filter housing.

- The next step is to disconnect the wiring from the solenoid relay. It is important to ensure that the positive wire is also unscrewed from the terminal. The photo shows the elements that we need to dismantle.

If it is no longer possible to repair the VAZ 2110 starter yourself, then replace it with a new unit yourself in the reverse order.

Brushes

With brushes the situation is much simpler, and getting to them is not difficult.

If necessary, replace the brushes and springs that have burst with new ones; in principle, repairing the starter with your own hands is the easiest here.

Let's move on to the starter rotor.

Pay attention to the rotor commutator, where it contacts the brushes, clean it if necessary.

The rotor may have a special brake ring made of plastic. You can find it in the cover of the brush assembly. If it bursts, replace it.

The starter bushings are also replaced. The bushings are selected to match the rotor shaft.

Next we check the bendex.

In order to check the bendex, its sprocket is clamped into a cleat, but the clamping is done through soft metal so as not to damage the sprocket itself.

By turning the coupling (the steel ring that goes immediately behind the sprocket) first in one direction or the other, we make sure that the bendex is in good working order. The ring should only turn in one direction. If this is not the case, then replace the bendex.

Repair

You should start with the pull-out relay. You should remove it carefully, as you can easily pull out the contacts. They need to be inspected for oxidation. If there is a lot of rust, then clean the copper contacts - this applies not only to the lever, but also to the bolts.

You can check the relay using a tester:

- “Minus” should be applied to the housing, and “plus” to the flat contact coming from the ignition switch.

- There is an alternative method, where the “plus” goes to the flat contact, and the “minus” to the brushes that are installed in the housing. When working properly, you can hear a clicking sound.

If the problem is in the contacts, then you can “throw” tin on the washer. If the condition of the relay is very bad, then it is easier to replace it. The asking price is about 500 rubles. If the starter burned out recently, you may smell a burning smell. By removing the retaining ring, you can verify this. In this case, the unit needs to be replaced. It can be purchased for about 1,500 rubles.

DIY starter repair on a VAZ car

The article describes in great detail with photo accompaniment the process of repairing a starter on a VAZ 2110 car.

In a new car, breakdowns and malfunctions in the starter rarely occur. But if the car has been in service for more than 5 years, then problems may arise. The car owner himself can determine if the starter is faulty - the car will not start, there are uncharacteristic sounds when starting the engine, the starter turns off spontaneously.

But many motorists do not pay attention to such car signals. And they bring the situation to the point where it is no longer possible to “save” the starter. But an experienced motorist who monitors his car will immediately determine the malfunction of this part by the sound of the car running. So how do you repair a starter? Its repair takes place in several dozen stages described below.

Where is

The VAZ 2110 starter is located on the gearbox housing and is mounted on two studs. It is easier to see the starter in detail on 8-valve engines, since there is more free space in the engine compartment with such an engine. In a 16-valve engine, to see the starter, you need to remove the air filter housing.