The role of a car's suspension is not the main one, but it is far from secondary. This part of the car is directly responsible for the driving experience of the driver and passengers. With its help, we do not feel vibrations when hitting bumps, and the parts do not hit each other. Without this part of the chassis, operating a car would be like riding a carriage.

Both the rear and front suspension of the VAZ 2109 are well made for their time. If you squeeze the maximum out of it, you get a car that is above average in ride comfort, even compared to modern cars. In order for the suspension to serve for a long time, its elements, as well as the accompanying components of the VAZ, not to break, care and supervision of it is important. To identify faults, you need to have at least basic knowledge of the design and operating principle. Let's figure out what the front and rear suspension of the VAZ consists of, and what are the main malfunctions that occur while driving.

Payment via PayPal

After selecting payment via PayPal, the PayPal payment system will launch, where you need to select the payment method: bank card or PayPal account.

If you already have a PayPal account, then you need to log into it and make a payment.

If you do not have a PayPal account and you want to pay using a bank card via PayPal, you need to click on the “Create an Account” button - shown with an arrow in the picture.

PayPal will then prompt you to select your country and provide your credit card information.

After specifying the information required to make the payment, you must click on the “Pay Now” button.

Front suspension

McPherson independent suspension

The weakest point of the front suspension is the shock absorber struts. The main task falls on them, and therefore the load is corresponding.

Disassembly and replacement

Many VAZ 2114 owners dream of installing air suspension. These are completely feasible fantasies, which, however, will require serious financial investments from you.

Therefore, if you have not yet saved up enough money for pneumatics, and the knocking in the front suspension of the VAZ 2114 haunts you, you will have to disassemble it, determine the causes of the malfunctions and put the entire structure back together. How to do it? Now we'll tell you.

- The car can be lifted using a lift, or simply placed on a viewing hole. It all depends on what resources you have. Be sure to apply the handbrake, remove the wheel caps, loosen the bolts and remove the hub nuts. The front must be effectively locked in order to remove the wheels.

- Now remove the ball joint pin. It is located in the swing arm on the A-pillar. After this, the front stabilizer strut is removed. It will have to be disconnected from the front suspension arm. Only now can you remove the stretch marks from the body. The next step will be to remove the ball joint. In case you forgot, it is located and attached to the steering knuckle.

- Now we proceed to remove the front suspension arm. To do the job as competently as possible, unscrew the bracket attached to the body. Now remove the lever along with the extension and bracket. Don't forget to remove the bolts securing the pads to the steering knuckle.

- Well, now in front of you is a fully assembled caliper. It is not recommended to completely remove it, since reassembling it can lead to unpleasant consequences and unnecessary financial costs. It is better to take a hook and hang it so that there is no load on the main hose. Next, you can press the splined shank out of the hub.

- Go to the engine compartment and from there remove the protective cam. For such an operation, you will need to unscrew the nuts on the telescopic strut, and then remove the strut from the suspension of the front of the car. It comes immediately with the hub and steering knuckles. The second strut of the front suspension is dismantled in the same way, and then the struts are removed from the bar.

- When removing the ball joint and steering knuckle bolts, be sure to use only socket wrenches. If you neglect this rule, you risk severely damaging the protective cover of the hinge. By doing this, you will incur unnecessary financial expenses on yourself.

- As you dismantle, inspect the condition of certain suspension elements and replace them if necessary.

- The assembly process is carried out almost entirely by analogy with disassembly. But there are a couple of nuances. The first is when installing the fastening bracket to the body, try not to damage the threads, so work carefully. Second, when installing the anti-roll bar, try not to cause longitudinal displacement of the cushion on the bar.

If your own experience is not enough, it is not worth adding to it, starting with similar work. It is better to immediately contact the specialists of a trusted service station. It will cost extra money, but the result of the repair will be completely worth it. Driving a faulty car is definitely not the solution to the problem.

Symptoms of a problem

There are several main signs of failure of the rear beam silent blocks, including:

- Unstable behavior of the car on the roads;

- Tires wear unevenly, which is not difficult to notice from the tread pattern;

- When driving on a bad road (that is, 95% of all our roads), unpleasant squeaks and impacts on the car body are observed.

These signs are indirect, since they may be associated with other failures of the vehicle’s chassis. For example, dull knocks are also a sign of a faulty rear pillar. Therefore, in order to make sure that there is a particular problem, you will need to fully diagnose the chassis.

Malfunctions

Often, replacing the rear beam bushings is due to the fact that defects arise in the design of the element. They are like this:

- The elasticity of the rubber element deteriorates;

- The rubber breaks;

- The central bushing is displaced;

- Rotations occur in the seat.

If problems are detected with the silent block of the rear beam, you will need to drive the car into the garage in the near future and replace the damaged components. Unlike foreign cars, changing the silent seal on a VAZ 2109 is quite simple and without outside help. Plus it costs almost pennies.

Before you start replacing the silent blocks of the rear beam, you need to decide what exactly you will replace the old, worn bushings with.

We figured out the markings and realized that for the VAZ 2109 you need to take only those that are suitable in size and diameter for the rear beam of the nine.

Today, for the VAZ 2109 they offer two types of silents, differing in the material of manufacture.

The choice should be made based on the available budget. Rubber elements cost several hundred rubles cheaper

As for manufacturers, we recommend paying attention to the companies SEVI, BelMag, Boge and SS20

To replace you will need:

- New rear silent blocks;

- A small wooden beam;

- A device for pressing in a silent block (you can do the job without it);

- Open-end wrenches;

- Socket wrenches;

- Spanners;

- Hammer.

When everything is ready, you can start working.

- Place the car on a level surface in the garage above a pit or overpass. Be sure to place wheel chocks and shoes under the wheels. All for your safety.

- It is better to remove the rear wheel to make it easier to work.

- But it is not at all necessary to remove the rear beam. Just complicate your work with unnecessary dismantling processes.

- On the left side of the driver is the pressure regulator rod for the rear brakes. It will disturb you while you work, so we advise you to remove it. This is done by removing the locking bracket of the rod and the handbrake cable. You will remove the latter from the right side from the mount.

- Unscrew the nut from the bolt with a 12mm wrench that holds the rear beam to the bracket. This may cause problems. Place a socket wrench on the driver to increase leverage on the fastener. Remove the bolt, lift the car with a jack and move the beam down. It will come out of the eyelet this way. Do not overdo it to avoid damaging the nearby brake hose. If you press too hard on the pry bar while moving the eye, you risk breaking the hose.

- Take a pre-prepared wooden block and insert it between the body and the beam. This must be done so that the beam is below the eye.

- Using a hammer and a drift (regular metal tubing will do), knock out the old worn bushings. By the way, if you come across such a concept as “fungi”, don’t worry. This is what car enthusiasts often call these bushings because of their external similarity.

- Clean the seat from accumulated dirt and rust. Be sure to lubricate the areas with soapy water. Without it, it will be difficult to press in new silent blocks. Or use a simple dish detergent. Under no circumstances should you lubricate the seats with grease or oil, as these substances will soon begin to corrode the element.

- Now it presses in new elements. Ideally, you should have a special pressing tool. If you don't have one, use a regular hammer.

- Take out a wooden block.

- Armed with a second jack, lift the beam and insert the mounting bolt into place and tighten it with a nut.

- Reinstall the rear wheel and lower the car to the ground.

Only upon completion of all these stages can the bolts of the new silent blocks be tightened until they stop.

Such an operation should not cause any special problems, so it is not at all necessary to go to a service station and spend extra money.

Front suspension

Rear suspension

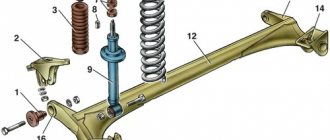

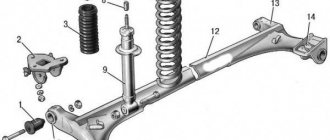

In fact, the front suspension design of the VAZ 2114 is much more complex than the rear one. Judge for yourself, because its design includes a total of 41 elements. The main one is the shock absorber strut. It is mounted on the steering knuckle using two bolts. The bolt passing through the holes of the rack bracket is equipped with an eccentric washer and a similar belt. When the steering gear is turned, the top bolt also turns. This causes the entire car to turn.

Front design

The weakest point of the front suspension is the shock absorber struts. The main task falls on them, and therefore the load is corresponding.

Disassembly and replacement

Many VAZ 2114 owners dream of installing air suspension. These are completely feasible fantasies, which, however, will require serious financial investments from you.

Clamp

Therefore, if you have not yet saved up enough money for pneumatics, and the knocking in the front suspension of the VAZ 2114 haunts you, you will have to disassemble it, determine the causes of the malfunctions and put the entire structure back together. How to do it? Now we'll tell you.

- The car can be lifted using a lift, or simply placed on a viewing hole. It all depends on what resources you have. Be sure to apply the handbrake, remove the wheel caps, loosen the bolts and remove the hub nuts. The front must be effectively locked in order to remove the wheels.

- Now remove the ball joint pin. It is located in the swing arm on the A-pillar. After this, the front stabilizer strut is removed. It will have to be disconnected from the front suspension arm. Only now can you remove the stretch marks from the body. The next step will be to remove the ball joint. In case you forgot, it is located and attached to the steering knuckle.

- Now we proceed to remove the front suspension arm. To do the job as competently as possible, unscrew the bracket attached to the body. Now remove the lever along with the extension and bracket. Don't forget to remove the bolts securing the pads to the steering knuckle.

- Well, now in front of you is a fully assembled caliper. It is not recommended to completely remove it, since reassembling it can lead to unpleasant consequences and unnecessary financial costs. It is better to take a hook and hang it so that there is no load on the main hose. Next, you can press the splined shank out of the hub.

- Go to the engine compartment and from there remove the protective cam. For such an operation, you will need to unscrew the nuts on the telescopic strut, and then remove the strut from the suspension of the front of the car. It comes immediately with the hub and steering knuckles. The second strut of the front suspension is dismantled in the same way, and then the struts are removed from the bar.

- When removing the ball joint and steering knuckle bolts, be sure to use only socket wrenches. If you neglect this rule, you risk severely damaging the protective cover of the hinge. By doing this, you will incur unnecessary financial expenses on yourself.

- As you dismantle, inspect the condition of certain suspension elements and replace them if necessary.

- The assembly process is carried out almost entirely by analogy with disassembly. But there are a couple of nuances. The first is when installing the fastening bracket to the body, try not to damage the threads, so work carefully. Second, when installing the anti-roll bar, try not to cause longitudinal displacement of the cushion on the bar.

Working with the front and rear suspension of a VAZ 2114 requires increased concentration and knowledge of the structure of this unit. Therefore, before starting repairs, be sure to familiarize yourself with the suspension diagram and study the recommendations from the operation and repair manual. You can even watch several video tutorials that clearly explain the replacement and repair of front and rear suspension elements.

If your own experience is not enough, it is not worth adding to it, starting with similar work. It is better to immediately contact the specialists of a trusted service station. It will cost extra money, but the result of the repair will be completely worth it. Driving a faulty car is definitely not the solution to the problem.

The front suspension of the VAZ-2114 receives the full load of the body, as well as not only the weight of the engine itself, but also the load force of the transported cargo. Therefore, this element must be very durable. Not many motorists know how the front suspension works, its elements, as well as the nuances of its operation.

Diagnostics

It would be wisest if you do not wait for a breakdown and diagnose the chassis. There is no consensus on its timing - each specialist has his own opinion on this matter. The mileage recommended for vehicle maintenance varies from ten to thirty thousand kilometers. First of all, you need to focus on operating conditions - if you drive on broken country roads, this figure will be minimal. So:

- The diagnostic procedure includes checking the degree of wear of the shock absorbers. In car services, it is done with a special device that checks the elasticity of the spring. It is impossible to determine the degree of wear visually. Springs that have lost their elasticity may break.

- Be sure to inspect the spring cups, which may also have defects and damage. They check the play in the VAZ CV joint - a torn boot can create problems. Inspection of ball joints and tie rod ends is also necessary.

- Silent blocks are connecting elements between the frame and suspension; due to this worn-out part, the smoothness of the car is lost. Both brake pads and wheel bearings are subject to inspection, and the tightness of the hoses is checked.

- Computer diagnostics makes it possible to identify and promptly eliminate even minor faults, which will protect parts from more significant damage.

- When you fall into a hole or hit a curb, the rims are the first to suffer. The rim of the disc may bend, which will certainly be felt when moving. An iron or cast disk can be rolled, but a forged one cannot be repaired. It will simply burst upon impact.

- The wheels of any car need periodic balancing and checking tire pressure. It should be as prescribed by the operating instructions. When changing wheels seasonally, you need to alternate their installation from the front to the rear axle, which will balance out the abrasion of the tires.

Wheel balancing

If these simple rules are not followed, not only the tires will wear out, but also the steering, braking system and transmission elements. Timely maintenance of the chassis is the key to your safety on the road.

Types of independent suspensions

McPherson

Ford Focus 2: rear suspension and problems

McPherson suspension is the most common front axle suspension on modern cars. The lower arm is connected to the hub via a ball joint. Depending on its configuration, longitudinal jet thrust can be used. A shock absorber strut with a spring is attached to the hub assembly, its upper support is fixed to the body.

Double wishbone front suspension

The transverse rod, attached to the body and connecting both levers, is a stabilizer that counteracts the roll of the car. The lower ball joint and shock absorber cup bearing allow the wheel to turn.

The rear suspension parts are made according to the same principle, the only difference is that the wheels cannot be turned. The lower arm has been replaced with longitudinal and transverse rods that secure the hub.

Pros:

- simplicity of design;

- compactness;

- reliability;

- inexpensive to manufacture and repair.

Minuses:

average handling.

Double wishbone front suspension

More efficient and complex design. The upper mounting point of the hub is the second wishbone. A spring or torsion bar can be used as an elastic element. The rear suspension has a similar structure. This type of suspension design ensures better vehicle handling.

Air suspension

Air suspension

The role of springs in this suspension is performed by pneumatic cylinders with compressed air. With air suspension, it is possible to adjust the body height. It also improves ride quality. Used on luxury cars.

Hydraulic suspension

Adjusting the height and stiffness of Lexus hydraulic suspension

The shock absorbers are connected to a single closed circuit with hydraulic fluid. The hydraulic suspension makes it possible to adjust the rigidity and ride height. If the car has control electronics, as well as adaptive suspension functions, it independently adapts to road and driving conditions.

Chassis SS20

These spare parts for domestic and foreign cars are produced under the “System Technologies” brand. These racks have become so popular due to their high quality. For Priora, the manufacturer offers 4 product options that differ in hardness. Which stands are better? They need to be selected according to your driving style. The softest ones are the “Standard” series racks. Rear shock absorbers from the same series are also offered.

A reinforced version is offered to increase the load capacity. Next are the “Comfort” racks. According to reviews from many car owners, this is the best option. They are stiffer than the Standard, but the suspension works equally well on bad and good roads.

The “Highway” kit is suitable for those who like stiff suspension and high speed. With these racks you can drive on bad roads, but it will be uncomfortable. “Sport” is the toughest option from this manufacturer for Priora cars. A front suspension of this type is not very suitable for the city, but for sports competitions it is just right.

Front suspension

In fact, the front suspension design of the VAZ 2114 is much more complex than the rear one. Judge for yourself, because its design includes a total of 41 elements. The main one is the shock absorber strut. It is mounted on the steering knuckle using two bolts. The bolt passing through the holes of the rack bracket is equipped with an eccentric washer and a similar belt. When the steering gear is turned, the top bolt also turns. This causes the entire car to turn.

The weakest point of the front suspension is the shock absorber struts. The main task falls on them, and therefore the load is corresponding.

Disassembly and replacement

Many VAZ 2114 owners dream of installing air suspension. These are completely feasible fantasies, which, however, will require serious financial investments from you.

Therefore, if you have not yet saved up enough money for pneumatics, and the knocking in the front suspension of the VAZ 2114 haunts you, you will have to disassemble it, determine the causes of the malfunctions and put the entire structure back together. How to do it? Now we'll tell you.

- The car can be lifted using a lift, or simply placed on a viewing hole. It all depends on what resources you have. Be sure to apply the handbrake, remove the wheel caps, loosen the bolts and remove the hub nuts. The front must be effectively locked in order to remove the wheels.

- Now remove the ball joint pin. It is located in the swing arm on the A-pillar. After this, the front stabilizer strut is removed. It will have to be disconnected from the front suspension arm. Only now can you remove the stretch marks from the body. The next step will be to remove the ball joint. In case you forgot, it is located and attached to the steering knuckle.

- Now we proceed to remove the front suspension arm. To do the job as competently as possible, unscrew the bracket attached to the body. Now remove the lever along with the extension and bracket. Don't forget to remove the bolts securing the pads to the steering knuckle.

- Well, now in front of you is a fully assembled caliper. It is not recommended to completely remove it, since reassembling it can lead to unpleasant consequences and unnecessary financial costs. It is better to take a hook and hang it so that there is no load on the main hose. Next, you can press the splined shank out of the hub.

- Go to the engine compartment and from there remove the protective cam. For such an operation, you will need to unscrew the nuts on the telescopic strut, and then remove the strut from the suspension of the front of the car. It comes immediately with the hub and steering knuckles. The second strut of the front suspension is dismantled in the same way, and then the struts are removed from the bar.

- When removing the ball joint and steering knuckle bolts, be sure to use only socket wrenches. If you neglect this rule, you risk severely damaging the protective cover of the hinge. By doing this, you will incur unnecessary financial expenses on yourself.

- As you dismantle, inspect the condition of certain suspension elements and replace them if necessary.

- The assembly process is carried out almost entirely by analogy with disassembly. But there are a couple of nuances. The first is when installing the fastening bracket to the body, try not to damage the threads, so work carefully. Second, when installing the anti-roll bar, try not to cause longitudinal displacement of the cushion on the bar.

Working with the front and rear suspension of a VAZ 2114 requires increased concentration and knowledge of the structure of this unit. Therefore, before starting repairs, be sure to familiarize yourself with the suspension diagram and study the recommendations from the operation and repair manual. You can even watch several video tutorials that clearly explain the replacement and repair of front and rear suspension elements.

If your own experience is not enough, it is not worth adding to it, starting with similar work. It is better to immediately contact the specialists of a trusted service station. It will cost extra money, but the result of the repair will be completely worth it. Driving a faulty car is definitely not the solution to the problem.

Ways to increase the rigidity of engine fixation on the body of a VAZ 2109

To prevent the VAZ 2109 cushion from being replaced frequently, and to increase the rigidity of the power unit, instead of the standard support, a more advanced part is installed, which has a rigid body and a rubber part inside.

Minimize the movement of the motor when braking, hitting bumps on the roads, or abruptly starting the car. With its help, you can avoid self-switching off the transmission. Increase the resource in the exhaust system and drive the drive wheels. Improve the design of the engine compartment. You can increase the rigidity of the motor by installing an additional fourth support . Its purpose is to connect the clutch housing to the cross member of the front suspension of the VAZ 2109. When installing the device, it is necessary to install a new bracket and find a place for the ignition module. The work procedure includes: Dismantling the VP for spark plugs. Disconnecting the wire connectors from the ignition module of the car. Disconnecting the clutch housing of this module from the cylinder block. The remaining three nuts securing the module are unscrewed, which is then removed. The ignition module takes a different place and new fasteners are installed. A bracket for mounting the fourth support is attached to the cross member of the front suspension. A bolt is installed in the hole on the terminal clamp, the nut is placed and screwed initially by two turns. The lower head of the rod is inserted into the support fixing eye. The bolt is installed in the eye and support, the nut is tightened. The size of the rod is adjusted until the holes in the clutch housing and on the upper head coincide. Another bolt is installed.

For a car to move, it needs an engine. This unit is installed in the front part of the body (in most cases). It is mounted on a subframe or on side members. However, the vibrations that the engine gives off during operation are strongly reflected on the body. To smooth them out, it is installed using rubber pads. They are a kind of buffer. Over time, all rubber products become unusable. Engine supports are no exception. What are engine mounts, signs of malfunction and methods of elimination are further in our article.

Front suspension assembly for VAZ 2109

Hello everyone, in this part we will assemble the front suspension, here is the finished result

I started with the steering rack; in the last posts you could see how I installed the steering rack. I decided to replace the tips, they were dead, the brake discs were also tired, you can see in the photo

Here are the new spare parts for assembling the front chassis

We also bought a right grenade, the old one became unusable, and the rest of the grenades are in excellent condition

New metal brake disc protectors were purchased, the old ones rotted

The stand is assembled, with a -70 spring, and with new supports

The chipper was cut, leaving 1 bagel

At the moment the front chassis looks like this)

Everything looks like new, I also replaced the old bolts that were rusty, thanks to everyone)

"Bogdan"

The coexistence of the previous model and the new one in the same market is a worldwide practice. As soon as the new version finally puts the previous one to shame, production of the old model is stopped or transferred to other countries. So the painfully dear sedans and station wagons of the tenth family, having left the assembly line in Togliatti, appeared in the model range of the Ukrainian corporation Bogdan.

The new VIN code did not scare off fans: in Russia alone in 2010, more than 5 thousand Extogliatti small cars were sold, and in the first half of 2011 - more than 3 thousand. Since we have a dime a dozen sedans in this class, we decided to understand why aliens from the past captivate buyers using the example of the Bogdan-2111 station wagon and its direct relative, the Lada-Priora.

In Russia, the tenth family left the main conveyor in stages. In 2007, the sedan left the scene. The hatchback and station wagon lasted two years longer, then the family finally gave way to the Priora. Although the factory stubbornly insists that this is not a restyling, but a radically redesigned car, the buyer is skeptical about such statements.

Features of the Duster rear suspension

On machines of the 2WD series, the position of the hubs is fixed, there is no mechanism for adjusting the angles, the manufacturer recommends periodic checking of the parameter (if the value is outside the tolerance range, the beam or levers must be replaced). The transverse beam is connected to the longitudinal arms by contact welding with additional gussets that increase the strength of the structure. When driving over uneven surfaces, the transverse part of the suspension twists, softening the shock.

On vehicles with all-wheel drive, the rear suspension has a bolt with an eccentric head that changes the length of the wishbone and corrects the toe angle. In this case, camber adjustment is not provided; the parameter is set by the geometric dimensions of the rods and subframe. Before starting the adjustment, foreign loads are removed from the machine, and the tank is filled to 50% of its volume. The shock absorbers are pumped by 2-3 successive clicks on the rear and then on the front bumpers (force within 40-50 kg).

Troubleshooting

Ford Focus 2: rear suspension and problems

If the issue is physical impact or wear and tear, then the parts are completely replaced. Moreover, the entire assembly or mechanism will have to be replaced. If the fasteners become loose, they are tightened. Such repairs are carried out even in a garage.

It is not uncommon to encounter leaking shock absorbers. Their seals wear out and scuff marks appear. The solution to this problem is only a complete replacement of the part.

If there is poor resistance at the moment of recoil on the strut, then the reason for this may be the lack of a sufficient amount of fluid in the shock absorber. However, it is better not to repair shock absorbers at all, because new spare parts are relatively inexpensive, and it is better to replace them.

Product added to bookmarks!

- Description

- Reviews

Rear independent suspension "AUTOPRODUCT" for VAZ 2108, 2109, 21099, VAZ 2110, 2111, 2112, VAZ 2113, 2114, 2115, VAZ 2170, 2171, 2172 (Lada-Priora).

– loss of contact of the rear inner wheel with the road on turns is eliminated;

– stable contact with different road surfaces and clear control of the vehicle during maneuvers;

– low unsprung mass;

– increased driving comfort.

Original silent blocks "LEMFORDER"

.

Installed on cars with suspension lowered up to -50 mm or with suspension raised up to +15 mm.

Installation is possible only with modification of the muffler bend or with the AUTOPRODUCT direct-flow muffler.

For installation you will need:

– brake pipe, length from 350 mm – 2 pcs.

– corrugated tube with a slit, internal diameter 12 mm or 14 mm, length 210 mm – 2 pcs.

– nylon clamp 5 x 350 mm – 2 pcs.

How the front suspension of the VAZ-2109 works

It is very important to do timely maintenance of the vehicle’s chassis, since the main load during operation falls on it. Moreover, the load occurs even at rest.

The chassis includes the following elements: frame, wheels, rear and front suspension. Early diagnosis will help avoid many problems.

What is the front suspension? This element of the car is independent, which allows the car to be more maneuverable, since the front wheels work independently of each other. If one of them hits a pothole, the other avoids this impulse. Such design features allow you to adjust the wheel alignment of the car; you can also correct the “behavior” of the car on the road using a small negative value for the rolling radius.

The main part of the front suspension is the shock absorber struts, the springs are attached to them. There are 3 bolts and a bearing attached to the top of the rack. All this as a whole provides the ability to rotate the stand with the wheels of the machine.

The next main part is the rotary cam. Its lower part is attached to the ball joint, and its upper part is connected to the bottom of the rack. The connection is provided by bolts. The upper one adjusts the camber. The lateral stability of the car is ensured by a rod, which is secured by silent blocks to the base of the car using brackets.

Thus, we see that the front suspension includes a lot of parts, but the most basic of them are:

- spring;

- lever arm;

- shock absorber;

- ball joints;

- tension joint;

- brackets.

The main advantages of installing air suspension

Installing an air suspension on a Lada Priora car instead of the standard factory hydraulic suspension represents a change in the factory design of the car, i.e. suspension tuning. Installing this car suspension design allows the Lada Priora suspension to ensure excellent absorption of unevenness and potholes on the road while the car is moving. A car equipped with air suspension becomes more stable on the highway.

At the same time, installing air suspension on the car allows you to improve the dynamic qualities of the car. The rear independent suspension installed on the car, along with the installed front independent suspension, allows you to obtain a huge number of advantages, which are expressed in the following:

- The mounted independent suspension on the Priora reduces the lateral roll of the vehicle when the interior is unevenly loaded.

- Installing an air suspension on a Priora allows you to reduce the load on the suspension elements, thereby significantly increasing its service life.

- Driving a Lada Priora with installed independent air suspension allows you to achieve more comfortable driving on roads with varying road surface qualities.

- The independent suspension on the Priora allows you to increase the degree of stability of the vehicle when making turns on the road while driving.

- Installing air suspension on the Priora allows you to reduce the negative consequences on the car if it is overloaded.

- The mounted independent suspension on the Priora eliminates the possibility of vehicle roll while driving on the road.

Installing an air suspension on a Priora allows the driver to independently control and change, if necessary, the car’s ground clearance, taking into account the quality of the road surface and the load on the vehicle’s suspension.

Air suspension on Lada Priora

Feedback from motorists who have decided to make changes to the design of the car and replace the standard suspension on it with an air suspension, as a rule, turns out to be positive, since the use of an air suspension allows you to obtain a number of advantages during the operation of the vehicle.

Design and purpose of the VAZ 2110 front suspension

Let's look at how the front suspension of the VAZ 2110 is designed, how well it complies with modern standards, what functions it provides, and what attention it requires.

Purpose

First of all, it is intended for fastening the wheels, and is also designed to provide shock absorption for the entire front of the car, its stability on the road while driving, the possibility of a number of wheel adjustments, namely along the axis of rotation (the angle of its longitudinal inclination), toe, camber.

VAZ 2110 front suspension assembly diagram

Main nodes

Let's talk about its device.

The most important element of the front suspension is its strut (hydraulic telescopic) - indispensable in the matter of shock absorption, that is, ensuring a comfortable ride, without much shaking (as far as possible) over bumps and potholes on our roads. It is thanks to the rack, or rather its steering knuckle with an upper bolt equipped with an eccentric washer and a belt, that makes it possible to change the camber of the wheel.

Telescopic strut of the front suspension of VAZ 2110

The following are installed on the rack:

- Special spring;

- Buffer limiting the compression stroke, made of polyurethane;

- Upper support. Its structure is as follows: it is attached to a stand, to which the mudguard is attached with self-locking nuts. Therefore, if you make repairs yourself, do not miss this moment - you cannot use ordinary nuts;

- A bearing that makes it possible to rotate the stand together with the wheels;

- A shock absorber in which a spring and a plunger are installed for better performance.

The ball joint combines the lower parts: the steering knuckle and the lever. The longitudinal braces, lower arms, and supports that the crossbar has are connected to each other by rubber-metal hinges. With the help of special washers, it becomes possible to adjust the longitudinal inclination of the turning axis. An angular contact, non-adjustable bearing secures the wheel hubs.

Ball joint VAZ 2110

The cross member is the rod to which the lower arms are connected. It is attached to the body in the middle, helped by rubber cushions. This, in a nutshell, is the front suspension design. Now let’s look at possible malfunctions, which in some cases can be fixed with your own hands, in others it is better to contact specialists.

Cross member VAZ 2110

Knock

If you hear a knock in the front suspension while driving, the main reasons may be:

- Faults in the rack;

- The bolts have become loose, the stretch marks or cushions with which the cross member is equipped may have worn out;

- The attachment to the body has become loose;

- The rubber parts have collapsed, and the knocking has a distinct “metallic” sound;

- A “limp” or even a broken spring knocks;

- Wear of hinges;

- Knocking due to wheel imbalance.

In principle, in any of the listed cases, repairing the VAZ 2110 front suspension, done by yourself, can help, during which you need to replace a worn part or (in the latter case, the reasons why a knock is heard) - balance the wheel.

Vehicle pull to the side

The car pulls to the side when driving straight. The reasons for this malfunction may include:

- Each spring has its own compression ratio. In this case, the spring that has lost its elasticity must be replaced;

- Tires have different pressures. We check and correct;

- The rubber element near one of the strut supports was destroyed. At the same time, a characteristic knocking sound is also heard while driving. The problem is solved by replacing this element;

- The wheel alignment angles are incorrect. Increased tire wear may be associated with this malfunction. If you can’t handle it yourself, it’s better to entrust this task to specialists.

Tire wear

This may be due to improper driving (rash acceleration, braking, exceeding the permissible load of the vehicle), or other reasons:

- violations of wheel alignment angles;

- high wear of the hinges;

- wheel imbalance.

Suspension check

Knowing the meaning and design of the suspension, you will be able to check its condition every time you inspect the machine on a pit (overpass) and perform maintenance.

Pay special attention to the condition of the protective covers on the ball joints. Check to see if any deformations, cracks or dents have appeared on the suspension due to shaking and bumps.

Be sure to check the condition of all rubber and rubber-to-metal parts, as well as the ball joint of each wheel. Remember: a malfunction noticed and corrected in time is much less evil than repairs when everything is already falling apart.

Suspension modifications

Many owners of the VAZ 2110 do not consider the factory suspension to be ideal, and tune it to improve stability and handling on the road.

- Benjamin

Noise or knocking

A knock in the front suspension (Priora station wagon also suffers from this), as well as a characteristic noise, is one of the signs of a malfunction.

All owners of domestic cars of this family have repeatedly encountered this. Chassis maintenance specialists claim that in this case, strut malfunctions are possible. Also, during operation, the bolts that secure the stabilizer bar to the car body loosen. Another noise may be associated with wear of the bar itself or the cushions. In the case of struts, to get rid of the nasty knocking, you only need to replace the worn shock absorbers. If the fastener is loose, it should be tightened. If the cushions fail, they should be replaced. It is not expensive. Now there are any spare parts for Priora on sale.

The knocking noise can also be caused by a loose fastening on which the upper support is installed to the body. Experts recommend tightening the support nuts. Another cause of noise is a worn rubber element in the strut support. You need to purchase a new part and install it. Then the characteristic noise will disappear.

If the silent blocks on the levers, braces or struts wear out, the suspension will also knock. These parts need to be replaced. Other faults include worn ball joints, broken or deformed springs, worn compression buffers, and unbalanced wheels.

Selection of parts and necessary tools

Before you start directly replacing silent blocks, it is important to properly prepare for it. There are few recommendations specifically for choosing new parts.

The auto parts market is simply filled with silent blocks from different manufacturers, mostly they are all quite good. The only thing you can do to make a better choice of new parts is to consult with auto mechanics in your area. The main thing is that the new vibration isolators fit completely.

For repair work you will need the following things:

Set of new silent blocks

Replacing suspension silent blocks with your own hands

The suspension silent blocks on the VAZ-2112 are located in the arms of both the rear beam and the front one. It is advisable to replace them comprehensively. The replacement process is approximately the same on both the rear and front parts of the suspension. Below are instructions for both cases.

Front control arms

Replacing front control arm silent blocks on a VAZ-2112 is the following process:

- First of all, the car must be placed above the inspection hole or use a lift. Then remove the engine compartment protection represented by the casing.

Removing the engine protection

Unscrew the nut of the stabilizer bar mounting bolt.

Unscrew the nut on the extension

Unscrew the nut of the bolt securing the lever to the body

A long bolt, a couple of washers and a nut are all sold in hardware stores and can be used to make a puller

“Let’s spritz”, it’s better to heat it up some more. Next, we use our puller to press out the silent block.

We clean the socket from rust and dirt, lubricate

We press new silent blocks into the mounting groove

New silent block installed

Video

- Again, the car must be driven into a viewing hole or raised on a lift.

- Then, taking a 19mm wrench, you need to disconnect the rear beam from the bracket by unscrewing the nuts securing it.

How to benefit from increased ground clearance?

Rear suspension of Lada Vesta / VAZ Vesta since 2015

Obviously, neither the double nor triple ground clearance of the Priora can be compared with the ground clearance of any jeep. But we should not forget that, in tandem with the improvement of certain other features of the car, the Priora’s ground clearance can give good results. Let's be clear for now.

The distance from the ground to the bottom is 165 mm. But knowing this fact alone is not enough to draw any conclusions. The motorist must certainly take into account the properties indicated below, such as:

- Full length of the machine.

- Distance from front overhang to rear.

- Wheel base.

- Vehicle track width.

- The presence of some parts protruding from the bottom of the car.

- The way the ground clearance changes when the car is 100% loaded.

Only working on the joint improvement of all these features can lead to benefit from the increase in ground clearance of the Priora.

Installing rear independent suspension on a car

The rear independent suspension is installed on the VAZ 2170 instead of the standard system installed by the manufacturer. The rear independent suspension, made on the basis of triangular levers, is ideally suited for installation on the Lada Priora. The rear independent suspension provides increased comfort when operating the car.

When operating a vehicle on which a standard rear suspension is installed, the vehicle beam shifts towards the arch when cornering by approximately 1 cm. If the vehicle is equipped with a rear independent suspension, then such a beam displacement is not observed under similar operating conditions. The rear independent suspension is attached rigidly to the body, without using silent blocks in mounting the rear suspension on the Priora, which avoids lateral displacement of the beam.

In the design of both the front and rear suspension of the Priora, rubber-metal structural elements such as silent blocks are used. These structural elements consist of a rubber body and a bushing made of metal, which is vulcanized with the base material of the silent block. In this case, the connection between the sleeve and the base is inseparable.

Silent blocks, which are part of the design of the rear and front suspensions, perform the function of damping all torques and bending moments that may occur during movement, thereby ensuring a stable position of the vehicle on uneven road surfaces and when turning.

It is the rubber-metal design of silent blocks that is capable of providing the maximum possible damping of emerging vibrations and absorption of emerging deformations. Silent blocks are structural elements that do not require additional maintenance and lubrication during operation. These structural elements cannot be repaired; after a certain period of operation, silent blocks are replaced.

Silent blocks are mounted on a car as an element of the chassis and suspension, since this structural element is one of the most reliable and economical ways to prevent the influence of various types of deformations and loads that can occur during the operation of the car on the car body. Installation and replacement of silent blocks on Priora is provided for in some vehicle suspension components:

- front and lower arms, by installing silent blocks the arm is attached to the car body; in addition, by installing silent blocks, the rod was attached to the lever;

- on the stabilizer, using silent blocks, it is attached to the lever through the strut;

- on the front linkage mount, called the crab;

- on the rear beam, on fastenings to the car body;

- on the rear pillars, in the upper and lower mounting points.

Main characteristics of the air suspension on the Lada Priora

Suspension clearance has the property of changing its value in a range equal to the stroke of the installed shock absorbers. To carry out pneumatization of shock absorbers, the hose method is used. Installation of air suspension parts on Priora is carried out by replacing standard spring elements. The assembly of the vehicle air suspension structure is carried out using lines with a diameter of 6 mm.

To operate the suspension, a compressor and a receiver with a volume of 8 liters are installed on the car. In some models, the independent suspension on the Priora is equipped with a compressor with a 10-liter receiver. This Lada suspension has a reaction time of about 4 seconds. The control principle is manual, and control is carried out using pressure gauges. The control is four-circuit (separate for the front and rear axles, as well as for the right and left sides of the car).

As a rule, the air suspension on the Priora is equipped with options such as wheel inflation, air signal and intermediate shaft. Additionally, the independent suspension on the Priora can be equipped with a remote control and a control controller.