Replacing the intake manifold gasket on a VAZ-2114 car, as well as replacing the exhaust manifold gasket, is a very complex procedure and requires certain knowledge and experience. Of course, you will have to do a colossal amount of work and spend a lot of time, but this will save 4-5 thousand rubles on replacement at a car service center.

The video below will tell you about replacing the receiver and manifold. During the replacement process, the intake manifold gasket is also changed:

The video will tell you how to properly replace the intake manifold gasket, and also tell you about some of the subtleties and nuances of the process.

What kind of gasket to buy to replace a burnt one?

The new part should be:

- sufficiently elastic so as not to deform during installation and use;

- impermeable to gases;

- resistant to prolonged exposure to chemicals and aggressive substances.

The manufacturer recommends installing only the original cylinder head gasket, its article number is 21083-1003020. The dimensions of this part are calculated for the VAZ-2114 cylinder head. The original spare part is produced at AvtoVAZ, but you can buy a part with the same parameters from Trialli, Patron, and Reinz. But please note that some analogues often cost 2-3 times more than stock components.

Also check out

- When disassembling the valve mechanism, it is necessary to place a wooden block under the valve plate.

- Dry the valve. Remove it from the cylinder head guide bushing.

- Using a key “13”, unscrew the 2 nuts securing the inlet pipe.

- Remove the gasket and pipe.

Assemble and install the cylinder head in the reverse order.

Recommendations :

- Valve stems with engine oil. The same applies to guide bushings.

- Before installation, remove dirt, oil, and remnants of the old gasket from the surface of the cylinder block.

- The cylinder head gasket should be replaced using two special centering bushings.

- Install the mounting screws; the diagram below shows 4 steps on how to tighten them.

- The first tightening torque of the screws is 20 N.m (2 kgf.m);

- The second - with a moment of 69.4–85.7 N.m (7.1–8.7 kgf.m);

- The third - with an extension of 90°;

- The fourth is to turn the screws 90°.

When is cylinder head repair required?

The seal for the VAZ cylinder block cover has a complex structure: sheets of steel, cardboard, and fiber pressed together. They are coated with a layer of sealant, which improves the connection of the parts to each other. Replacement must be carried out if this gasket burns out during engine repairs. The following symptoms indicate a problem with this component:

- Air bubbles in the antifreeze appeared in the expansion tank of the cooling system. This is the first sign that the seal has been broken.

- Exhaust gases begin to escape through the seal. In this case, the gasket may be damaged after repair if you overtightened the mounting bolts.

- White smoke appeared from the muffler, a bit like steam. This happens when coolant enters the cylinders through a breakdown in the gasket.

- White foam has appeared on the oil level dipstick. This is another sign that coolant is present in the engine - it is mixed with the engine oil.

- Increased fuel consumption with insufficient engine power, the car takes more time to gain speed. If the gasket wears out significantly, the vehicle may stall when driving uphill, and when pressing the gas pedal, the driver will feel a dip in the power of the power unit. In the most difficult cases, the car will stall when moving the gear lever to neutral or when stopping at a traffic light.

- Oil stains on the surface of the antifreeze in the expansion tank. This is another sign that the cylinder head is leaking.

- The spark plugs are filled with antifreeze. This malfunction can be detected if you remove the high-voltage wires from the spark plugs and then unscrew them.

In all these cases, you will need to purchase a new spare part to replace it with the failed one.

The main signs and causes of failure of the VAZ 2114 intake manifold

- The main symptom of a failed intake manifold is a sudden loss of car engine power.

- at the same time, there is an increase in fuel consumption , with a deterioration in traction and a drop in engine performance.

- Often a problem is indicated by a missing stud in one of the manifold flanges. It simply comes off when the collector goes “screw”, that is, due to temperature changes, for example in winter, or over time (average service life is 7 years), the collector begins to bend along the plane, and the pin simply “spits out”, pulls out .

- Due to the fact that the manifold has “leaded”, a crack may form and, as a result, exhaust gases from the engine escape, and the manifold must be replaced.

How to change the gasket correctly

To work, you need to place the car in a garage with a pit or drive it onto an overpass. Then make the replacement according to the instructions:

- Remove the negative terminal from the battery so that the voltage in the network disappears.

- Place the transmission lever in neutral until the first cylinder is locked at top dead center. Secure the wheels with bricks or shoes to prevent the machine from rolling during the repair process. Remove the right front wheel after placing a jack under the car.

- Remove the fasteners from the engine compartment splash guard to remove it. Find the cover covering the front camshaft drive; it also needs to be removed.

- Using the generator set fixing screw, turn the crankshaft so that the marks on its pulley coincide with those on the rear cover. The matching marks must also be checked in the clutch housing. To do this, remove the cover from the technological hole.

- Drain the refrigerant from the system, first placing a container under the plug to collect it.

- Relieve pressure in the fuel system.

- Disconnect the intake line of the gas exhaust system from the exhaust manifold.

- Disconnect the intake and exhaust manifolds, throttle body and receiver to remove the cylinder head cover. Loosen the clamp of the pipes supplying air to the throttle. After this, you can remove the throttle assembly with the air intake pipe and the cleaner housing.

- There are several wires to the right of the cylinder head. Disconnect them and remove the fuel rail assembly with other system components.

- Remove the fasteners from the front of the unit cover. Secure the crankshaft from turning, then remove the timing belt.

- Loosen the tension roller and remove it, then remove the spacer washer and remove the camshaft gear.

- Remove the screws from the back of the cover. Disconnect all conductors from the cylinder head exhaust hose by loosening the clamps with a screwdriver.

- Using a hex key, you need to unscrew 10 cylinder head fixing bolts. Do this one by one, unscrewing the outer fasteners halfway first and then the middle fasteners. After this, you can unscrew them all the way.

- Remove the cylinder head along with the gasket, and then carefully clean it and the seat from dirt and engine oil residues. After this, this component is replaced.

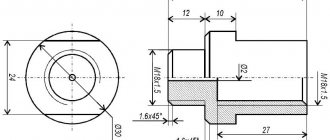

VAZ-2114 engine structure diagram

In order to understand the process and principle of replacing engine gaskets, you need to know the structure and sequence of parts in the main power unit.

So, let's look at the design of the VAZ-2114 engine:

Replacement process

So, when the basic structure of the engine is clear, you can proceed directly to the process of replacing the gasket. But first you need to decide on the tools. So, what do you need to complete the procedure: a torque wrench, a set of open-end and socket wrenches, a set of sockets and a ratchet, bits from a Torx set, screwdrivers, coolant for topping up, a new gasket, rags, containers for draining liquids.

Now that you have everything, you can proceed directly to the replacement procedure:

- We remove the “minus terminal”.

- We dismantle the timing belt protective cover.

- We set the VTM labels.

- Drain the coolant completely from the car.

- Relieve pressure in the fuel system.

- Disconnect the intake pipe from the exhaust manifold.

- Remove the block head cover.

- Disconnect the throttle assembly.

- Remove the air filter.

- We dismantle the fuel rail assembly with injectors.

- We fix the camshaft and crankshaft.

- Remove the timing belt.

- We dismantle the tension roller.

- After unscrewing the fastenings of the camshaft gear, remove it.

- Unscrew the fastener and remove the back cover.

- We dismantle the cylinder head exhaust pipe.

- Turn off and remove the thermostat.

- Disconnect the fuel supply and drain pipes.

- Unscrew the block head fastening.

- We dismantle the cylinder head along with the gasket.

- We clean the surface of the block head from the old gasket, as well as other dirt and dust.

Note! Along the way, you can inspect the condition of the pistons and combustion chambers for the presence of soot and soot. If necessary, “throw in” the oil scraper rings.

- Install a new gasket.

- Before installing the head, check whether the valves on cylinder 1 are closed.

- We tighten the cylinder head mounting bolts according to the diagram. At the first stage, the screws should be tightened with a torque of 20 N.m, at the second - 69.4–85.7 N.m, at the third stage the screws should be tightened by 90 degrees, at the fourth stage the screws should be finally turned by 90 degrees.

- We carry out further assembly in reverse order.

Don’t forget that the timing belt must be tensioned with a certain force; this is discussed in detail in the material: “we correctly tighten the timing belt on a VAZ-2114 with our own hands.”

Gasket selection

In addition to the original spare part, there is a set of analogues that can be installed on the VAZ-2114. Some of them are of high quality and have a service life much longer than the original. So, let's look at what gasket options exist for the 14th series of Lada cars.

Original

21083-1003020 — catalog number of the original head gasket. It fits perfectly into the seats and is recommended for installation by the manufacturer. It is produced at the AvtoVAZ plant and the retail price is 600 rubles.

Analogs

In addition to the original part, there are a sufficient number of analogues that are certified and, as practice shows, are installed on cars. So, let's look at which cylinder head gaskets can be installed instead of the original:

Gasket requirements

When changing and choosing a cylinder head gasket, you must always look at the quality of the product. But not everyone knows what properties it should have. Let's consider the basic requirements for this spare part:

- Long service life.

- Elastic deformation.

- Resistant to hot gases.

- Water and oil resistant.

- Resistance to chemical reactions and influences.

If the selected head gasket meets all standards, then it can be installed on the car.

Symptoms of a problem

So, when all the points have been considered, it remains to list the signs of cylinder head gasket failure:

- A large amount of white smoke comes out of the muffler.

- Sufficient amount of emulsion on the filler cap.

- Antifreeze has an oil effect.

- The oil level in the pan has increased.

- The smell of antifreeze or exhaust gases can be traced in gasoline.

Burnt cylinder head gasket

Read more about the main signs of a broken cylinder head gasket in this material.

How to replace the cylinder head gasket of a VAZ-2114 8 valve

The cylinder head (cylinder head) gasket is a disposable part and therefore cannot be repaired. If for some reason it is damaged, it is necessary to replace the cylinder head gasket in a VAZ-2114 8-valve car. You can understand that this part needs to be replaced by the following signs:

- Coolant is constantly bubbling in the radiator.

- Exhaust gases escape through the gasket.

- The exhaust pipe smokes.

- The oil on the dipstick is covered with a white emulsion that looks like foam.

- The coolant is oily.

Often a sign of such a problem is thick white smoke from the exhaust pipe. This occurrence indicates that the gasket has developed a blowout between one cylinder and the coolant leak hole. If the liquid is oily, this indicates the presence of a breakdown, as a result of which oil began to enter the channel with the coolant. If a sharp whistle is heard when the engine is running, and traces of oil are visible on the cylinder block, this indicates a gasket breakdown.

Also, a sign of gasket failure may be an increase in fuel consumption and a decrease in engine power. However, it is worth considering that some of these signs also occur with other damage to the car’s mechanism. For example, a white emulsion on the surface of the oil also indicates that the block has a crack. In any case, you must first make sure that the cause is a faulty cylinder head gasket.

If in doubt, it is better to entrust the diagnosis to a specialist.

Video “How the gasket replacement process occurs”

The PADuCT channel published a video in which the procedure for replacing the cylinder head seal in a VAZ 2114 car is shown in accelerated mode.

Do you have any questions? Specialists and readers of the AUTODVIG website will help you ask a question

Was this article helpful?

Thank you for your opinion!

The article was useful. Please share the information with your friends.

Yes (80.00%)

No (20.00%)

X

Please write what is wrong and leave recommendations on the article

Cancel reply

Rate this article: ( 5 votes, average: 4.80 out of 5)

Discuss the article:

Instructions

Replacing the cylinder head gasket is a procedure consisting of several stages.

By following the step-by-step guide, you will be able to complete this job quickly and without any problems. To perform this work, prepare sets of open-end and socket wrenches, a set of heads of different sizes, screwdrivers, rags, and a container for draining coolant and fuel.

First, turn off the power to the car. Remove the negative terminal from the battery. Then set the 1st cylinder (its piston) to the TDC position. Drain the coolant.

After this, you need to make sure that the pressure level in the power system is low enough. To do this, unscrew the cap, which is located at the rear end of the fuel rail, press the spool and drain the fuel, then screw the cap back on. It is very important to consider that these actions can only be carried out a couple of hours after using the car. If you do this immediately after stopping the car, it is possible that you will get burned both from contact with the spool and from the fuel that will be sprayed under pressure. In this case, it will not be possible to safely drain it.

Replacing the exhaust manifold and gasket on a VAZ 2114

The exhaust manifold is a unit that is responsible for ride quality, without which comfort is impossible. This is silence and the absence of exhaust smell under the hood, which can be drawn into the cabin through the hole in the cabin filter. Fixing a leak in the exhaust manifold of a VAZ 2114 is a necessary repair. Fortunately, it is not urgent; you can prepare in advance and choose a convenient moment.

Exhaust manifold for VAZ 2114

conclusions

Replacing the head gasket on a VAZ-2114 is quite difficult, since you need to know the design features of this engine, as well as have experience in performing such operations on similar engines.

The choice of gasket should be approached seriously and carefully, since the normal operation of many components depends on its condition. If the process described in the article seems quite complicated and the motorist is not able to carry out the operation on his own, then it is recommended to contact a car service center, where they will help and do everything quickly and efficiently.

Causes of malfunctions

The key factor that causes 90% of exhaust manifold malfunctions on VAZ 2114 cars is high temperature and poor quality materials from which the parts are made. During operation, the steel repeatedly heats up and cools down, which leads to the appearance of cracks in the body. This is a common occurrence for VAZ cars older than 7-8 years.

Auto repair shops offer crack welding services using argon welding. However, for a number of reasons, this activity is useless for cars older than 7 years.

1) Just removing and installing the exhaust manifold will cost about 2.5 thousand rubles. Taking into account the work of the welder and other actions, the cost of repairs can be 4-5 thousand rubles. If you do the work yourself, buying a new part will cost less.

2) Welding, even argon welding, disrupts the structure of “tired” metal. A boiled part rarely lasts longer than a year, after which new holes appear. The older the car, the faster the problem returns, and the collector has to be removed again.

If the car is older than 8 years and there are problems with cracks in the manifold, it is better to remove the part and replace it with a new one.

Signs of trouble

Exhaust manifold gasket

One of the main signs of a leak in the system is a “sporty” growling sound when the engine speed increases. This may be a symptom of various exhaust system problems. To check, it is better to take an assistant and go to a garage with a pit or to an overpass. Most often, you can determine by eye whether the problem lies in the muffler, resonator or exhaust.

Gasket wear may become apparent during planting. Open the hood and start the car - white or grayish smoke rising from the manifold during warm-up indicates a leak for this reason. VAZ car owners usually encounter this problem once every 3-4 years. When using low-quality spare parts and before. The solution may be to manufacture a custom-made steel gasket. It can last as long as the entire collector.

Service specialists, when attracting clients, like to tell scary stories about the explosion of the exhaust manifold on VAZ 2114 cars due to cracks. In reality this is nothing more than a myth. But the real problems are no less serious, so there is no point in putting off repairs.

A cracked exhaust manifold or worn gasket can cause your engine to run rough.

1) A lambda probe is installed in the exhaust manifold, which affects the operation of the injection system. Strong air suction disrupts the oxygen mass content in the exhaust; the lambda incorrectly adjusts the quality of the mixture, causing tripping, uneven idling, loss of power, and “black” spark plugs.

2) Another function is crankcase ventilation. Impaired air circulation causes disturbances in the operation of the gas distribution mechanism, increased wear of valves, the formation of carbon deposits on the pistons and other “joys”.

If increased noise and unpleasant odors during engine operation are combined with dirty work, the car needs urgent repairs.

Assembly Features

Before assembly, you should check the bolts securing the head to the hood; their length should not be more than 13.5 cm; if they are longer, they can no longer be used.

You should also check the flatness of the head. If it was overheated, it is possible that it was warped and will require repair in the form of trimming the plane.

During assembly, the head bolts are tightened in a certain sequence and with a strictly defined tightening torque. Next, everything is assembled in the reverse order of disassembly.

Disassembly is also carried out in the same sequence if the power plant is being modified.

Tools and necessary parts

To remove the exhaust manifold on a VAZ 2114 in order to replace the gasket or entire part, you will need the following tool:

- open-end and ring wrenches for 8, 10, 13, 17;

- wrench with heads 17, 19;

- screwdrivers, pliers.

It is also a good idea to have tools such as a Dremel, nut saw or nut pick on hand. As a rule, the fasteners on the exhaust system parts stick tightly.

A few days before your planned repair, begin treating accessible nuts with WD-40 or another penetrating lubricant. Repeat the operation 2-3 times. This will make the task of removing the manifold a little easier .

The question often arises: is it worth using a sealant after removing and replacing the gasket? Experts believe that if you apply sealant to the gasket, it should only be high-quality silicone. A bad sealant can bring a lot of trouble to a VAZ 2114 engine: when it burns out, it turns into “pellets” that are pulled into the crankcase. And this is unnecessary contamination of the piston system.

Required tool for replacement

Before you begin the process itself, you need to decide on the necessary tools. So, what will you need: a ratchet and sockets for 17, 19; screwdrivers with flat and Phillips tips; a set of keys and the gasket itself.

Now that everything is prepared, you can start working directly. In order for the manifold to be removed without any problems and rusted bolts not to create trouble, everything must be lubricated with WD-40 before performing the operation. It is advisable to do this several times. Before performing the operation, you need to think again, weigh everything and calculate your strength.

Step-by-step instructions (algorithm with photo)

If, nevertheless, the car enthusiast makes up his mind, then we will consider step-by-step instructions for replacing the gasket:

Remove the fuel pipes shown in the photo

Unscrew the pipes shown in the photo

Dismantling the exhaust pipe

Removing the intake manifold

Unscrew the fastening nuts and remove the exhaust manifold

We are replacing the gasket

As you can see, the replacement of the intake and exhaust manifold gaskets takes place simultaneously and, by and large, is the same gasket material.

Part selection

21083-1008081 – original catalog number of the gasket for the intake and exhaust manifold. It consists of two parts or, on newer models, one. This part is produced at the AvtoVAZ plant. The average cost is 250 rubles per piece (if there are two of them) or 450 rubles (for a whole one).

In addition to the fact that there is an original part, you can also find a number of analogues that are recommended for installation. Let's consider which gaskets can be installed under the VAZ-2114 manifolds:

- Trialli GZ 102 0013 is a well-known Russian manufacturer that produces a wide range of analog parts for domestically produced cars. The cost of the gasket is 200 rubles per piece.

- AJUSA 13065200 is another domestic manufacturer that has won consumers over the quality of its products. The cost of the product is 450 rubles.

- Ukrainian also produces and supplies this gasket. But, if you look at it, the quality of the product leaves much to be desired, since the resource is designed for only 20,000 km.

Exhaust manifold removal procedure

Before removing the exhaust manifold yourself, think 7 times. Having this work done by a service center is not cheap, but the inaccessibility and difficulty of unscrewing some nuts can be a serious problem.

Unscrew the bolt securing the intake pipe

It is important to drain the coolant before removal, as antifreeze may enter the cylinders during the process. The sequence of actions for cars with an injector is as follows:

- Disconnect the battery, release the throttle cable from the throttle valve.

- Disconnect the fuel line pipes.

- Disconnect the wires from the TPS and idle speed control.

- Release the crankcase ventilation, vacuum, and brake booster hoses.

- Remove the receiver, remove the injector block wires and remove the injector fuel rail.

- Remove the bracket and thermal shield.

- After this, you can disconnect the exhaust pipe, exhaust and intake manifolds from the manifold.

After disassembly, all gaskets are replaced with new ones. Please note when purchasing that the exhaust manifold gaskets for 8-valve and 16-valve VAZ 2114 are different. Select the parts carefully and you can avoid wasting time and money.

Lada 2114 › Logbook › Replacing the receiver and pipes

I noticed a long time ago that the car started to start worse when cold. Recently, it generally started the second time, after cranking the starter the engine tried to rattle for a second and stalled, on the second attempt it started from half a turn, and when it was hot, everything was fine too. I decided to change the gaskets of the receiver, because I was guilty of leaking air from under them. But removing the receiver turned out to be not so easy. The fastening pins for the throttle cable bracket in the receiver have turned, but you can buy this bracket separately:

I was able to secure one stud from turning with a screwdriver and unscrewed the nut with the help of such-and-such a mother, but the second did not work at all. Then I noticed that there was a crack near the throttle mounting stud:

In the end, I decided not to suffer and bought a new receiver

The receiver came with white seals, like silicone. But still, I bought additional CS 20 seals and kept the standard ones as spares.

While the weather allows, I set up a repair area in the fresh air:

I used a grinder to cut off a screw that had spun

The receiver itself is attached to the intake manifold with five studs, there were no problems with them

Before installing the new receiver, I cleaned the mating surface on the manifold

At the same time, I changed the crankcase ventilation pipes and the intake pipe, they didn’t feel well:

I slightly modified the fastening of the large crankcase ventilation pipe: I recently saw a photo of the latest modification of the 8kL engine 11189 in Largus, there are normal spring clamps on this pipe from the factory. I found the sizes of these clamps in the catalog: 38 mm large and 32 mm small

I didn’t look for the original, I bought Norma self-clamping clamps and pliers for them in Zhelezyaka

Now the pipe is well fixed, the clamp does not squeeze it, and there is no need to tighten anything. Before this I installed self-clamping clamps on the heater pipes, in the future I plan to replace most of the clamps with these.

For the small crankcase ventilation pipe I used ordinary Norma screw clamps; they are expensive, but their internal part is smooth and does not cut the pipe.

There were no large Norma clamps for the inlet pipe, I took ABA companies, also expensive and supposedly Swedish, the quality is not bad

Then I decided to try adjusting the valves

I measured the gaps, figured out how the device worked, but then it was a fiasco: most of the washers did not have dimensions. In the end, I decided to postpone this matter, then I’ll go to a friend’s garage, we’ll either measure it with a micrometer, or put washers with a known size and measure the gap.

READ How to install mods for shadow fight 2

After all the manipulations, I reset the ECU with initialization. When starting in cold weather, now it doesn’t seem to stall, but I still don’t like it, it takes a long time and somehow doesn’t grab hold of it confidently.